Light Up Your Boat Deck: Choosing the Right LED Lights

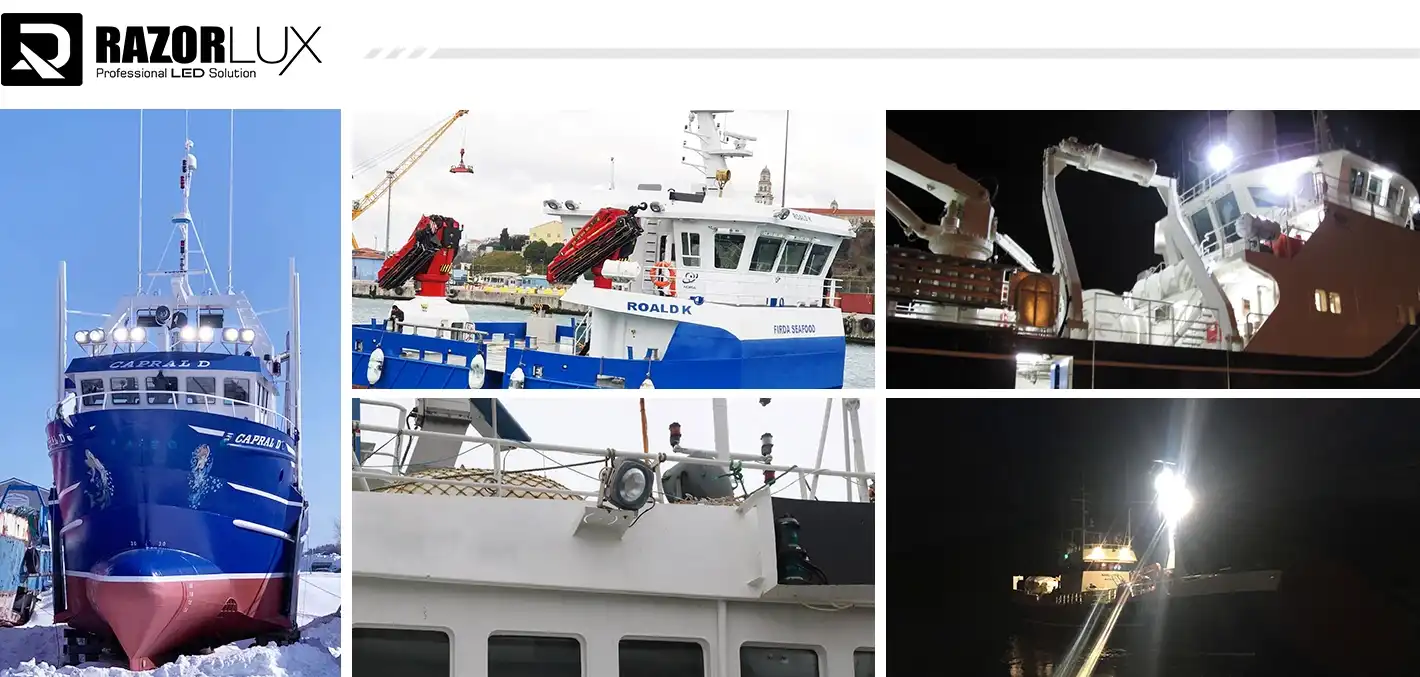

Picture this: you're returning to dock after a perfect day on the water, but darkness falls faster than expected. Without proper LED Boat Deck Light illumination, what should be a simple docking maneuver becomes a dangerous challenge filled with shadows and uncertainty. Marine lighting isn't just about convenience—it's about safety, functionality, and transforming your vessel into a beacon of reliability. This comprehensive guide reveals everything you need to know about selecting the perfect lighting solution for your maritime adventures, ensuring every voyage ends as safely as it began.

Essential Features of Marine LED Boat Deck Light Systems

Waterproof Protection Standards for Sailboat Deck Lights

Marine environments demand exceptional protection standards, making IP67 certification the minimum requirement for any serious LED Boat Deck Light installation. High ingress protection ratings indicate their effectiveness against water and solid intrusion, with corrosion resistance being equally important for long-term durability. Premium marine lighting systems feature sealed housing construction with marine-grade gaskets that prevent moisture infiltration even during the harshest weather conditions. Advanced LED Boat Deck Light models incorporate stainless steel brackets and powder-coated aluminum housings that withstand saltwater corrosion for decades. The emergency power function allows these systems to operate for two hours during power outages, ensuring continuous safety lighting when electrical systems fail unexpectedly.

Power Efficiency and Voltage Compatibility Options

Modern Sailboat Deck Lights operate efficiently across wide voltage ranges, with professional-grade systems accepting AC80-315Vac and DC80-400Vdc input without additional adapters. Energy efficiency ratings of 130 lumens per watt significantly outperform traditional halogen alternatives while reducing battery drain on smaller vessels. Smart LED Boat Deck Light systems feature intelligent drivers that maintain consistent brightness regardless of voltage fluctuations common in marine electrical systems. Power factor ratings exceeding 0.98 ensure minimal electrical interference with navigation equipment and communication systems. Total harmonic distortion below 10% protects sensitive onboard electronics while maximizing the lifespan of both the lighting system and connected equipment throughout the vessel's electrical network.

Color Temperature Selection for Optimal Visibility

Professional marine applications benefit from adjustable color temperature ranges spanning 2700K to 6500K, allowing operators to optimize visibility for specific tasks and conditions. Warm white temperatures around 3000K reduce eye strain during extended nighttime operations while maintaining excellent color recognition for safety equipment. Cool white options at 5000K-6000K provide maximum visibility for detailed work such as navigation chart reading and equipment maintenance. LED Boat Deck Light systems with high color rendering indexes above Ra75 ensure accurate color perception critical for identifying navigation markers and potential hazards. Advanced Sailboat Deck Lights offer programmable color temperature settings that automatically adjust based on ambient light conditions and operational requirements.

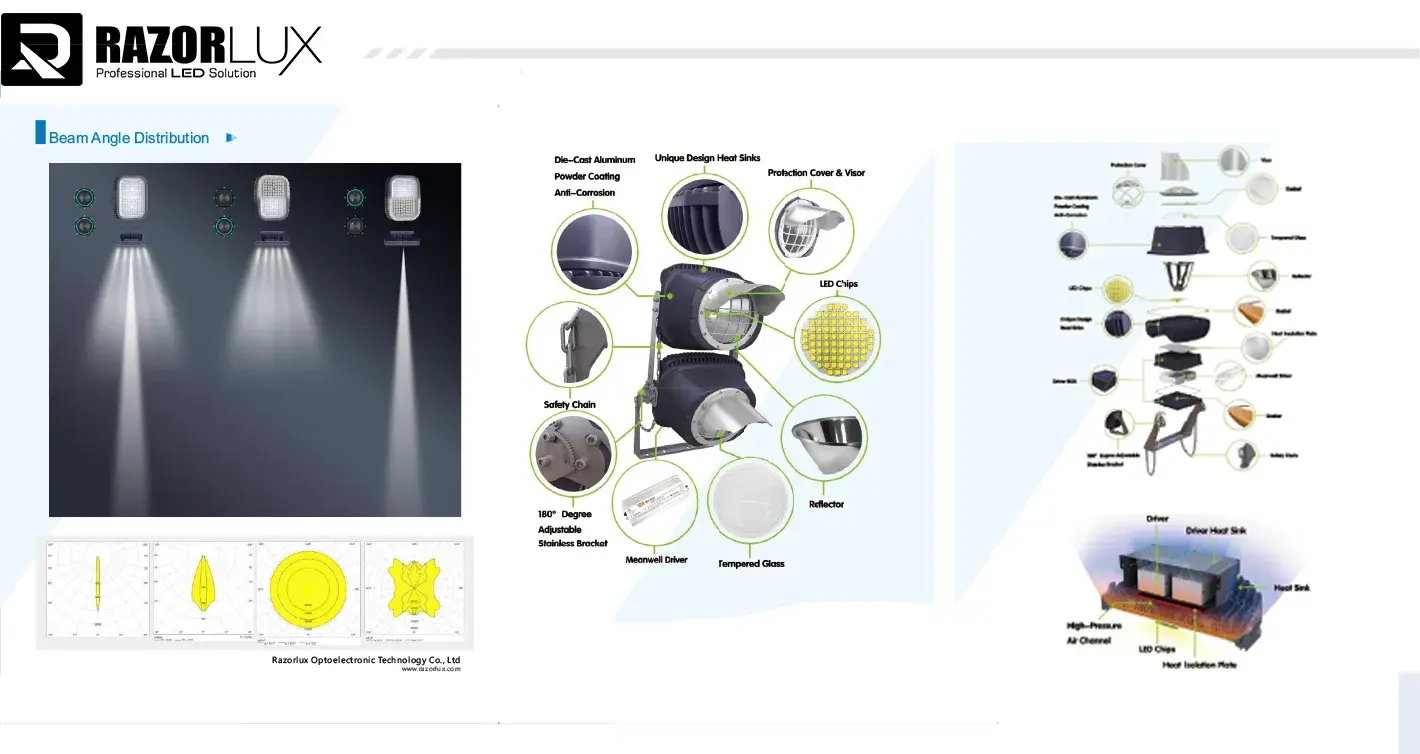

Beam Angle Configuration for Maximum Coverage

| Beam Angle | Application | Coverage Area | Recommended Use |

|---|---|---|---|

| 60° | Focused Work | 10-15 feet | Engine compartments, instrument panels |

| 120° | General Area | 20-30 feet | Main deck, cockpit areas |

| 140°x60° | Wide Coverage | 35+ feet | Large deck areas, work platforms |

Strategic beam angle selection determines lighting effectiveness across different vessel areas and operational requirements. Narrow 60-degree beams concentrate illumination for detailed mechanical work and instrument reading without creating excessive glare. Standard 120-degree configurations provide balanced area coverage suitable for general deck activities and passenger movement. Ultra-wide 140x60-degree asymmetric beam patterns maximize coverage for large working decks while minimizing the number of required fixtures and installation complexity.

Professional Installation Guidelines for LED Boat Deck Light Systems

Mounting Hardware Requirements and Marine Standards

Stainless steel mounting systems resist corrosion while providing secure attachment points that withstand constant vibration and movement inherent in marine environments. Professional-grade LED Boat Deck Light installations require marine-certified fasteners rated for continuous saltwater exposure and extreme temperature variations. Adjustable mounting brackets allow precise beam positioning and easy maintenance access without compromising structural integrity or watertight seals. Compliance with RMRS, CE, RoHS, SAA, C-Tick, UL, DLC, and CB certification standards ensures compatibility with international maritime safety regulations. Installation documentation must include detailed technical drawings and specifications supporting marine surveyor inspections and insurance requirements for commercial vessels.

Electrical Integration with Onboard Systems

Proper electrical integration requires understanding vessel power distribution and load management to prevent overloading existing circuits during LED Boat Deck Light operation. Professional installations incorporate dedicated switching systems with manual overrides and emergency backup capabilities for critical safety lighting applications. Advanced Sailboat Deck Lights feature compatibility with 0-10V and DALI dimming protocols allowing integration with sophisticated vessel management systems. Proper grounding and bonding prevent galvanic corrosion while ensuring electrical safety in the conductive marine environment. Circuit protection must account for starting currents and provide adequate fault protection without nuisance tripping during normal vessel operations and equipment cycling.

Thermal Management in Marine Environments

Effective thermal management extends LED lifespan while maintaining optimal performance during continuous operation in challenging marine conditions. Advanced heat sink designs utilizing aluminum construction with powder coating finishes dissipate heat efficiently while resisting corrosion damage. LED Boat Deck Light systems operating in enclosed spaces require adequate ventilation to prevent thermal buildup that reduces efficiency and component lifespan. Temperature compensation circuits maintain consistent light output across the -40°C to 60°C operating range typical of global marine operations. Proper thermal design prevents condensation formation within fixture housings that could compromise electrical connections and create safety hazards during extended offshore operations.

Maintenance Access and Service Considerations

Strategic fixture placement facilitates routine maintenance while ensuring adequate illumination coverage throughout the vessel's operational areas and safety zones. Modular LED Boat Deck Light designs allow component replacement without complete fixture removal, reducing downtime and maintenance complexity during critical operations. Service access requirements must consider vessel layout constraints while providing adequate working space for technicians during scheduled maintenance intervals. Quick-disconnect electrical connections and tool-free housing access speed routine cleaning and inspection procedures essential for maintaining optimal performance in harsh marine environments.

Comparative Analysis of LED Boat Deck Light Technologies

Traditional vs LED Performance Metrics

| Technology | Lifespan | Power Draw | Heat Output | Maintenance |

|---|---|---|---|---|

| Traditional HID | 2,000-4,000 hrs | 250-300W | High | Frequent bulb replacement |

| LED Technology | 50,000+ hrs | 120W | Minimal | 5-year warranty coverage |

| Halogen Systems | 1,000-2,000 hrs | 200-400W | Excessive | Monthly replacement |

LED technology delivers superior performance across all critical metrics while reducing operational costs and maintenance requirements significantly. Traditional lighting systems generate excessive heat that creates fire hazards and increases air conditioning loads in enclosed spaces. LED Boat Deck Light systems maintain consistent performance throughout their extended operational life without the gradual degradation characteristic of conventional technologies. Energy savings from LED conversion often pay for initial installation costs within the first year of operation through reduced fuel consumption and maintenance expenses.

Advanced Control Systems and Smart Integration

Modern Sailboat Deck Lights incorporate intelligent control systems offering programmable operation schedules and automatic brightness adjustment based on ambient conditions and operational requirements. Wireless control capabilities allow remote operation and monitoring from bridge stations or mobile devices, enhancing operational flexibility and safety oversight. Integration with vessel monitoring systems provides real-time status reporting and predictive maintenance alerts that prevent unexpected failures during critical operations. Advanced LED Boat Deck Light controllers offer zone-based control allowing selective illumination of specific deck areas while conserving power in unused sections.

Cost-Benefit Analysis and Return on Investment

Initial investment in professional-grade LED Boat Deck Light systems typically recovers through operational savings within 12-18 months of installation completion. Reduced maintenance costs, extended replacement intervals, and lower power consumption combine to deliver substantial long-term savings compared to traditional lighting technologies. Insurance premium reductions often available for vessels equipped with certified marine LED lighting systems due to improved safety and reduced fire risk. Increased vessel value and charter appeal from modern lighting systems provide additional financial benefits beyond operational cost savings and enhanced safety performance.

Quality Assurance and Certification Standards

Premium LED Boat Deck Light manufacturers maintain ISO 9001 certified manufacturing processes ensuring consistent quality and reliability across all product lines and production batches. Rigorous testing procedures including photometric analysis, aging tests, and environmental stress screening validate performance specifications and identify potential failure modes before product release. Component traceability and quality documentation support warranty claims and provide verification of compliance with marine certification requirements and international safety standards. Sailboat Deck Lights from established manufacturers include comprehensive technical support and replacement part availability ensuring long-term operational support throughout the product lifecycle.

Conclusion

Selecting the right LED Boat Deck Light system transforms vessel safety, operational efficiency, and maritime enjoyment while delivering substantial long-term cost savings through reduced maintenance and energy consumption.

Ready to illuminate your maritime adventures with professional-grade lighting solutions? Xi'an Razorlux Optoelectronic Technology Co., Ltd. stands as your trusted China LED Boat Deck Light manufacturer, offering comprehensive LED Boat Deck Light for sale with competitive pricing as a leading China LED Boat Deck Light supplier. Our China LED Boat Deck Light wholesale programs support fleet operations while maintaining the highest quality standards. Contact our expert team at sam@razorlux.com for personalized consultation, custom samples, and LED Boat Deck Light price information. With over 200 patents, 5-year warranties, and global shipping capabilities, we're your reliable China LED Boat Deck Light factory partner for superior marine lighting solutions. Don't navigate in darkness—bookmark this guide and illuminate your path to safer, more efficient maritime operations today!

References

1. Maritime Safety Administration Guidelines for Marine Lighting Systems, International Maritime Organization Technical Standards, 2024

2. LED Performance Standards in Marine Environments, Society of Naval Architects and Marine Engineers Technical Report, 2024

3. Energy Efficiency in Marine Electrical Systems, Marine Engineering Society Professional Guidelines, 2023

4. Corrosion Resistance Testing for Marine Equipment, American Society for Testing and Materials Marine Standards, 2024

VIEW MOREMarine Spot Flood Light

VIEW MOREMarine Spot Flood Light VIEW MOREbadminton led light

VIEW MOREbadminton led light VIEW MOREoutdoor basketball court lighting

VIEW MOREoutdoor basketball court lighting VIEW MORE2700K Outdoor Flood Light

VIEW MORE2700K Outdoor Flood Light VIEW MORELed Lights For Outdoor Badminton Court

VIEW MORELed Lights For Outdoor Badminton Court VIEW MOREIp65 Backyard Stadium Lights 600W 5700K Solar Powered Flood Lights

VIEW MOREIp65 Backyard Stadium Lights 600W 5700K Solar Powered Flood Lights VIEW MORE300W Led Flood Light Price

VIEW MORE300W Led Flood Light Price VIEW MORETop Rated Flood Lights

VIEW MORETop Rated Flood Lights

_1750326878398.png)