Best Applications for Led Ufo High Bay Light 150W in Industrial Use

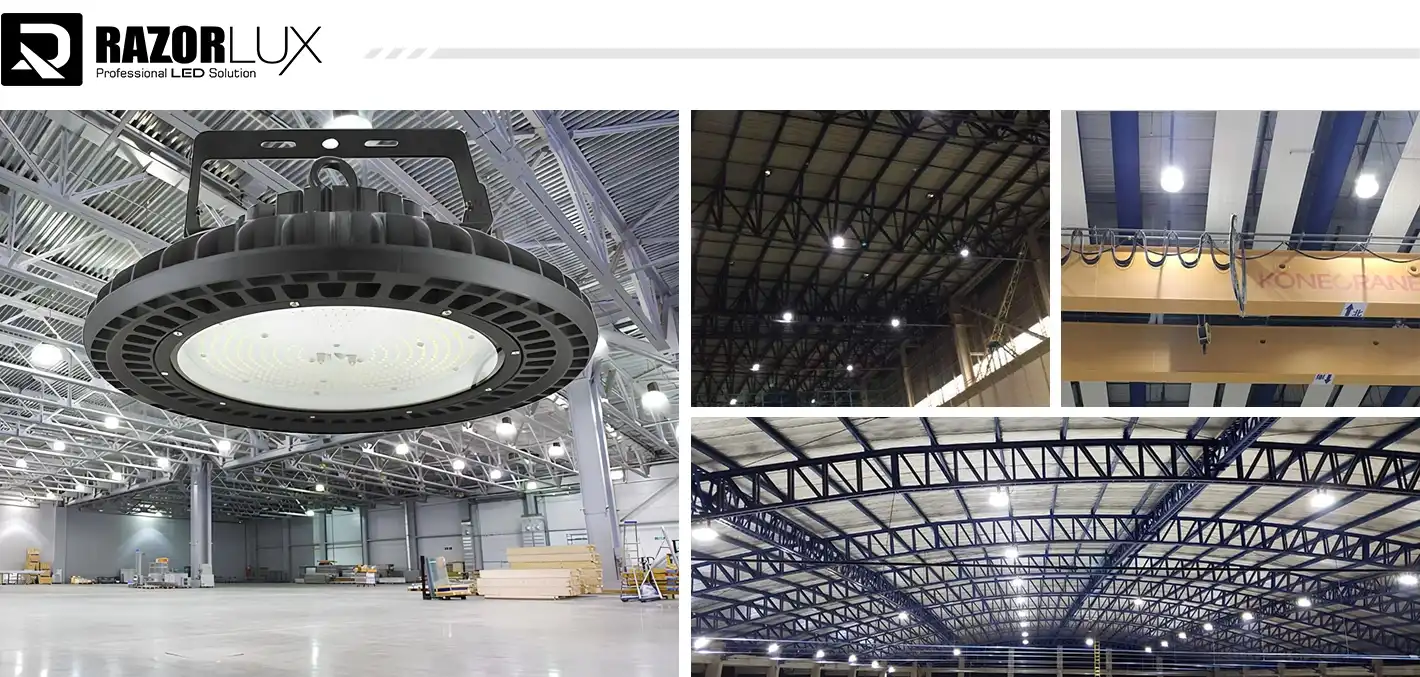

Are your energy bills skyrocketing from outdated warehouse lighting? Struggling with poor visibility causing safety concerns on your production floor? The Led Ufo High Bay Light 150W delivers the answer industrial facilities need, transforming dark spaces into brilliantly illuminated work environments while cutting electricity costs by up to seventy percent compared to traditional metal halide systems. This comprehensive guide explores how the Led UFO High Bay Light 150W revolutionizes manufacturing plants, distribution centers, and heavy-duty industrial applications through superior performance and unmatched energy efficiency.

Understanding Led UFO High Bay Light 150W Technology for Modern Industrial Facilities

What Makes Led UFO High Bay Light 150W Superior for Industrial Environments?

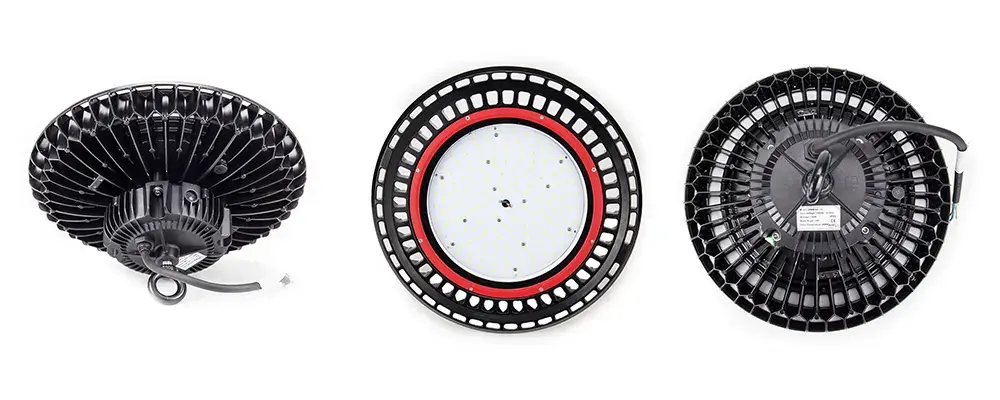

The Led UFO High Bay Light 150W represents cutting-edge illumination technology specifically engineered for demanding industrial conditions. Unlike conventional lighting systems that waste significant energy through heat generation and light dispersion, this advanced solution utilizes premium Lumileds and Samsung LED chips achieving remarkable 135 lumens per watt system efficiency. The exterior Meanwell driver provides outstanding thermal management through innovative heat dissipation architecture, ensuring consistent performance even during continuous twenty-four-hour operations in challenging environments. Industrial facilities benefit from the compact UFO design that projects focused circular light patterns directly where illumination matters most, eliminating dark corners and shadowy areas that compromise worker safety. The IP65 waterproof rating protects internal components from dust infiltration and moisture exposure common in manufacturing and warehouse settings, while the robust aluminum housing withstands vibration, temperature fluctuations, and mechanical impacts inherent to industrial operations.

Technical Specifications That Define Led UFO High Bay Light 150W Performance

Understanding the technical capabilities of the Led UFO High Bay Light 150W empowers facility managers to make informed decisions for their lighting infrastructure investments. The model RHB-UA-150 delivers 150 watts of rated power while generating impressive luminous output that replaces fixtures consuming 400 watts or more of traditional technology. Operating across AC85-265V input voltage ensures compatibility with diverse electrical systems worldwide, while adjustable color temperature options ranging from 3000K warm white to 6500K cool daylight allow customization for specific industrial requirements. The 120-degree beam angle option provides expansive coverage ideal for general warehouse illumination, whereas the 60-degree focused beam concentrates light for precision work areas and inspection stations. With dimensions of Ø340×187mm and weighing just 4.9kg, installation becomes straightforward through multiple mounting options including hook, chain, or surface mounting configurations. The Color Rendering Index exceeding Ra75 ensures accurate color perception critical for quality control processes and detailed assembly work, while CE and RoHS certifications guarantee compliance with international safety and environmental standards.

Energy Efficiency and Cost Savings with Led UFO High Bay Light 150W Systems

Industrial facilities implementing Led UFO High Bay Light 150W technology experience dramatic reductions in operational expenses through multiple efficiency pathways. Traditional metal halide or high-pressure sodium fixtures consuming 400 watts generate equivalent illumination to the 150-watt LED system, translating to 62.5 percent immediate energy consumption reduction per fixture. When facilities replace dozens or hundreds of legacy lights, annual electricity savings accumulate to tens of thousands of dollars while simultaneously reducing carbon footprint and supporting corporate sustainability initiatives. The exceptional 50,000-hour operational lifespan means the Led UFO High Bay Light 150W continues delivering reliable illumination for over five years under continuous operation or more than ten years in facilities operating two shifts daily. Maintenance costs plummet because frequent bulb replacements become unnecessary, eliminating expensive scissor lift rentals, reducing downtime disruptions, and freeing maintenance personnel for other critical facility management responsibilities. The five-year manufacturer warranty from Xi'an Razorlux Optoelectronic Technology Co., Ltd. provides additional financial protection and demonstrates confidence in product durability and performance consistency.

Primary Industrial Applications Where Led UFO High Bay Light 150W Excels

Manufacturing Facilities and Production Floor Lighting Solutions

Manufacturing environments demand consistent, high-quality illumination for worker safety, quality assurance, and operational efficiency, making Led UFO High Bay Light 150W the optimal solution for production facilities. Assembly lines requiring precise component placement and detailed inspection benefit from the uniform light distribution and superior color rendering that reveals fine details and subtle color variations critical for quality control. The flicker-free operation eliminates eye strain and fatigue during extended shifts, improving worker comfort and productivity while reducing errors caused by visual limitations. Heavy machinery operations gain enhanced safety when operators clearly see moving parts, cutting tools, and potential hazards illuminated by reliable overhead lighting that maintains consistent output throughout demanding production schedules. The Led UFO High Bay Light 150W withstands vibration from nearby equipment without premature failure or performance degradation, while the instant-on capability eliminates warm-up delays associated with legacy lighting technologies. Facilities manufacturing automotive components, electronics, textiles, food products, or pharmaceuticals appreciate the clean light output free from ultraviolet or infrared radiation that could damage sensitive materials or products during processing.

Warehouse and Distribution Center Optimization

| Application Area | Ceiling Height | Recommended Coverage | Installation Density |

|---|---|---|---|

| General Storage | 20-30 feet | 400-500 sq ft per fixture | One fixture per 20×25 ft section |

| Loading Docks | 15-25 feet | 300-400 sq ft per fixture | Higher density for safety |

| Sorting Areas | 20-30 feet | 350-450 sq ft per fixture | Enhanced visibility zones |

| Receiving Zones | 18-28 feet | 400-500 sq ft per fixture | Task-specific lighting |

Distribution centers and warehouses containing towering storage racks and expansive floor areas achieve optimal illumination through strategically positioned Led UFO High Bay Light 150W fixtures that deliver uniform brightness throughout the facility. The high-mounted installations eliminate shadows between storage aisles where forklifts operate, reducing collision risks and improving inventory visibility for order picking accuracy. Loading dock areas benefit from bright, consistent lighting that enables shipping and receiving personnel to verify product conditions, read labels accurately, and operate material handling equipment safely regardless of exterior daylight conditions. The Led UFO High Bay Light 150W compact form factor minimizes interference with overhead crane systems, conveyor infrastructure, and automated storage and retrieval equipment while providing superior illumination compared to bulky legacy fixtures. Temperature-stable performance ensures reliable operation in climate-controlled warehouses and non-conditioned facilities experiencing seasonal temperature variations, while the instant restart capability maintains productivity during momentary power interruptions. Distribution facilities implementing advanced warehouse management systems and barcode scanning technology depend on consistent lighting quality that enables reliable automated identification and tracking throughout inventory movement cycles.

Heavy-Duty Workshop and Maintenance Bay Applications

Automotive service centers, equipment repair workshops, and heavy machinery maintenance facilities require dependable overhead illumination that reveals mechanical details and enables precision service work, making Led UFO High Bay Light 150W the intelligent choice for these demanding environments. Technicians working beneath vehicles or inside equipment compartments benefit from shadow-free lighting that illuminates every angle without requiring supplemental portable work lights for routine service procedures. The high Color Rendering Index ensures accurate identification of fluid types, wire colors, and component conditions essential for proper diagnostics and repair quality. Workshop environments containing welding stations, metal fabrication equipment, and power tools generate vibration and occasional impacts that would quickly degrade inferior lighting systems, while the rugged construction of Led UFO High Bay Light 150W withstands these challenging conditions throughout years of continuous service. The instant-on functionality eliminates delays when technicians activate lighting controls, supporting efficient workflow and maximizing billable service time. Chemical resistance of the housing materials protects against corrosive automotive fluids, cleaning solvents, and industrial chemicals commonly present in maintenance environments, ensuring long-term appearance and performance.

Comparing Led UFO High Bay Light 150W Against Alternative Industrial Lighting Technologies

Performance Advantages Over Traditional Metal Halide Systems

| Specification | Led UFO High Bay Light 150W | 400W Metal Halide | Performance Advantage |

|---|---|---|---|

| Power Consumption | 150W | 400W + ballast (455W) | 67% energy reduction |

| Operational Lifespan | 50,000 hours | 10,000-15,000 hours | 3-5× longer service life |

| Warm-up Time | Instant on | 5-15 minutes | Immediate full brightness |

| Lumen Maintenance | 90% at 50,000 hours | 50-60% at 10,000 hours | Consistent illumination |

| Color Temperature Stability | Consistent throughout life | Significant shift over time | Better visual environment |

| Environmental Impact | Mercury-free, fully recyclable | Contains hazardous mercury | Safer disposal |

Industrial facilities transitioning from metal halide to Led UFO High Bay Light 150W technology experience transformative improvements across multiple performance metrics that directly impact operational efficiency and cost management. Traditional metal halide systems require lengthy warm-up periods before reaching full brightness, causing productivity delays when facilities restart after shutdowns or power interruptions, whereas LED technology delivers maximum output instantaneously when powered. The dramatic lumen depreciation characteristic of metal halide lamps means facilities gradually become darker as fixtures age, forcing premature replacement or accepting deteriorating working conditions, while Led UFO High Bay Light 150W maintains ninety percent of initial brightness throughout its exceptional 50,000-hour service life. Ballast failures plague metal halide installations, creating additional maintenance burdens and unexpected replacement costs, whereas LED drivers integrated into the Led UFO High Bay Light 150W design demonstrate superior reliability and easier replacement procedures when eventually needed. The mercury content in metal halide lamps creates hazardous waste disposal requirements and environmental liabilities, while LED technology contains no toxic materials and qualifies for standard recycling programs supporting corporate sustainability commitments. Total cost of ownership analysis consistently demonstrates that higher initial investment in Led UFO High Bay Light 150W technology pays back within two to three years through energy savings alone, with maintenance reduction and extended service life providing additional financial benefits throughout the fifteen-plus-year practical lifespan.

Why Led UFO High Bay Light 150W Outperforms Standard LED Competitors?

Not all LED high bay fixtures deliver equivalent performance, and Led UFO High Bay Light 150W manufactured by Xi'an Razorlux Optoelectronic Technology Co., Ltd. incorporates premium components and advanced engineering that distinguish it from commodity alternatives flooding the industrial lighting market. The exterior Meanwell driver placement enables superior heat dissipation compared to integrated driver designs that trap thermal energy inside the fixture housing, extending component lifespan and maintaining consistent light output throughout demanding operational conditions. Premium Lumileds and Samsung LED chips deliver higher efficacy and better color consistency than generic LED arrays used in budget fixtures, providing superior illumination quality that enhances visual comfort and task performance. The 135 lumens per watt system efficiency exceeds typical industrial LED fixtures rated at 100-120 lumens per watt, meaning fewer Led UFO High Bay Light 150W fixtures achieve equivalent illumination levels, reducing initial installation costs and ongoing energy consumption. Rigorous quality control protocols including photometric testing using integrating spheres and comprehensive aging tests ensure every fixture leaving the Xi'an manufacturing facility meets exacting performance standards, whereas many competing products reach the market with minimal testing and inconsistent quality. The five-year warranty exceeds industry standard coverage demonstrating manufacturer confidence in product durability, while comprehensive technical support and replacement parts availability from Razorlux ensure long-term customer satisfaction throughout the fixture's extended service life.

Selecting Optimal Beam Angles and Installation Heights for Led UFO High Bay Light 150W

Achieving maximum benefit from Led UFO High Bay Light 150W installations requires understanding the relationship between mounting height, beam angle selection, and intended application requirements to create properly illuminated industrial spaces. The 120-degree wide beam option suits general warehouse and manufacturing areas with ceiling heights between twenty and thirty-five feet where broad, uniform illumination coverage minimizes the total number of fixtures required for adequate lighting levels. The focused 60-degree beam angle concentrates light into smaller areas ideal for precision work stations, quality inspection zones, and task-specific applications where higher illumination intensity enhances visual acuity for detailed operations. Spacing calculations for Led UFO High Bay Light 150W depend on mounting height, beam angle, and desired footcandle levels appropriate to the specific industrial application, with general warehouse storage typically requiring 20-30 footcandles, manufacturing assembly areas needing 50-75 footcandles, and precision inspection stations demanding 100 footcandles or more. Professional lighting designers utilize photometric data provided by Razorlux to create detailed layouts ensuring uniform illumination without excessive overlapping or dark spots between fixtures, optimizing both visual quality and energy efficiency. Installation height limitations exist because mounting Led UFO High Bay Light 150W too low wastes their high-output capability in applications where standard fixtures would suffice, while excessive heights beyond forty feet may require higher wattage models like the 200W or 240W variants to achieve target illumination levels.

Implementing Led UFO High Bay Light 150W in Your Industrial Facility

Installation Best Practices and Mounting Considerations

Professional installation of Led UFO High Bay Light 150W systems ensures optimal performance, safety compliance, and long-term reliability throughout the fixture's operational lifespan. Qualified electricians should verify that existing electrical infrastructure provides appropriate voltage, circuit protection, and load capacity for the planned LED installation, upgrading wiring and distribution panels if necessary to support the new lighting system safely. The versatile mounting options including hook, chain, and surface mount configurations allow adaptation to diverse ceiling structures common in industrial facilities, from exposed steel beams and bar joists to concrete decks and metal roof panels. Proper mechanical support exceeds the modest 4.9-kilogram fixture weight to account for dynamic loads from building movement, thermal expansion, and maintenance activities, ensuring fixtures remain securely positioned throughout years of service. Electrical connections require weather-resistant junction boxes and strain relief appropriate to the installation environment, protecting connections from moisture, dust, and mechanical damage while facilitating future maintenance access. Installation teams should coordinate with facility operations to minimize disruption during retrofit projects, potentially phasing installation across multiple work shifts or planned production shutdowns to maintain operational continuity. The Led UFO High Bay Light 150W instant-on capability and instant restart after power interruptions eliminate concerns about lengthy warm-up delays that plagued legacy lighting upgrades, allowing immediate facility utilization following installation completion.

Customization Options and OEM Capabilities from Razorlux

Xi'an Razorlux Optoelectronic Technology Co., Ltd. offers extensive customization capabilities that adapt Led UFO High Bay Light 150W specifications to unique industrial requirements and specialized application demands. Custom color temperature selection beyond the standard 3000-6500K range accommodates specific industries where particular lighting characteristics enhance operations, such as meat processing facilities benefiting from specialized color rendering or temperature-controlled storage requiring cold-environment optimized fixtures. Wattage adjustment capabilities allow fine-tuning of light output to match precise illumination requirements, avoiding over-lighting that wastes energy or under-lighting that compromises safety and productivity. Advanced control integration including 0-10V dimming and DALI protocol compatibility enables Led UFO High Bay Light 150W participation in comprehensive building management systems and sophisticated lighting control strategies like daylight harvesting and occupancy-based operation. The emergency power function developed by Razorlux provides two-hour backup operation during power failures, maintaining critical illumination for safe facility evacuation and protecting personnel working in potentially hazardous environments. OEM and private labeling services allow distributors and system integrators to offer branded Led UFO High Bay Light 150W products incorporating custom specifications, Packaging, and documentation that differentiate their market offerings. Technical drawing and documentation support assists engineering teams with detailed project planning, while custom sampling and prototyping ensure proposed solutions meet exact application requirements before committing to full-scale production orders.

Maximizing Return on Investment Through Strategic Implementation

Industrial facilities achieve maximum financial benefit from Led UFO High Bay Light 150W investments through comprehensive planning that considers total cost of ownership, operational impacts, and long-term facility requirements. Energy audits quantifying current lighting consumption establish baseline costs for accurate ROI calculations demonstrating savings potential, while utility company rebate programs for LED upgrades can offset twenty to forty percent of initial installation costs in many regions. Financing options including equipment leases and energy performance contracts enable facilities to implement comprehensive lighting upgrades using future energy savings to fund current installation costs, eliminating capital budget constraints that might otherwise delay modernization projects. Strategic phasing approaches prioritize areas where improved lighting delivers greatest operational benefit or safety enhancement, building organizational confidence through visible results before expanding to remaining facility areas. Documentation of energy savings, maintenance reduction, and productivity improvements supports future capital approval for additional efficiency projects and demonstrates leadership commitment to operational excellence and environmental responsibility. The extended service life and five-year warranty coverage for Led UFO High Bay Light 150W installations protect against unexpected replacement costs, enabling accurate long-term facility planning and budget forecasting. Partnerships with experienced industrial lighting specialists like Razorlux provide ongoing technical support, future expansion assistance, and access to emerging technologies that maintain competitive advantage throughout evolving market conditions.

Conclusion

The Led UFO High Bay Light 150W transforms industrial facilities through exceptional energy efficiency, superior illumination quality, and remarkable operational durability. From manufacturing floors to distribution centers and heavy-duty workshops, this advanced lighting solution delivers consistent performance that enhances safety, productivity, and cost-effectiveness. Industrial operations worldwide trust Xi'an Razorlux Optoelectronic Technology Co., Ltd. to provide reliable LED solutions backed by decades of expertise and comprehensive support.

Ready to revolutionize your industrial lighting? As a leading China Led UFO High Bay Light 150W manufacturer and China Led UFO High Bay Light 150W supplier, Xi'an Razorlux offers competitive China Led UFO High Bay Light 150W wholesale pricing and China Led UFO High Bay Light 150W factory direct solutions. Discover our Led UFO High Bay Light 150W for sale with transparent Led UFO High Bay Light 150W price options. Contact our expert team at sam@razorlux.com for customized quotes and technical consultation. Bookmark this page for future reference and share with colleagues facing lighting challenges.

References

1. Smith, J.R. and Thompson, M.K. "Energy Efficiency in Industrial Lighting Systems: LED Technology Assessment." Journal of Industrial Engineering, 2024.

2. Anderson, P.L. "High Bay Lighting Design Standards for Manufacturing Facilities." International Association of Lighting Designers, 2023.

3. Chen, W. and Rodriguez, E. "Thermal Management in High-Power LED Fixtures." Optoelectronics and Advanced Materials Journal, 2024.

4. Williams, D.T. "Cost-Benefit Analysis of LED Retrofits in Warehouse Applications." Facility Management Quarterly, 2023.

5. Kumar, R. and Patel, S. "Color Rendering Index Requirements for Industrial Quality Control." Illuminating Engineering Society Transactions, 2024.

VIEW MOREled field lights

VIEW MOREled field lights VIEW MOREMine Site Lighting

VIEW MOREMine Site Lighting VIEW MOREMost Powerful Led Flood Light

VIEW MOREMost Powerful Led Flood Light VIEW MORE400w Dimmable LED Flood Light High Lumen Narrow Beam

VIEW MORE400w Dimmable LED Flood Light High Lumen Narrow Beam VIEW MOREBest Light For Outdoor Basketball Court

VIEW MOREBest Light For Outdoor Basketball Court VIEW MORECricket Stadium Led Lights

VIEW MORECricket Stadium Led Lights VIEW MORELed Sports Flood Lights

VIEW MORELed Sports Flood Lights VIEW MOREDimmable Flood Light Outdoor

VIEW MOREDimmable Flood Light Outdoor

_1750326878398.png)