Best Crane Light Fixture Options for Heavy-Duty Harbor Cranes

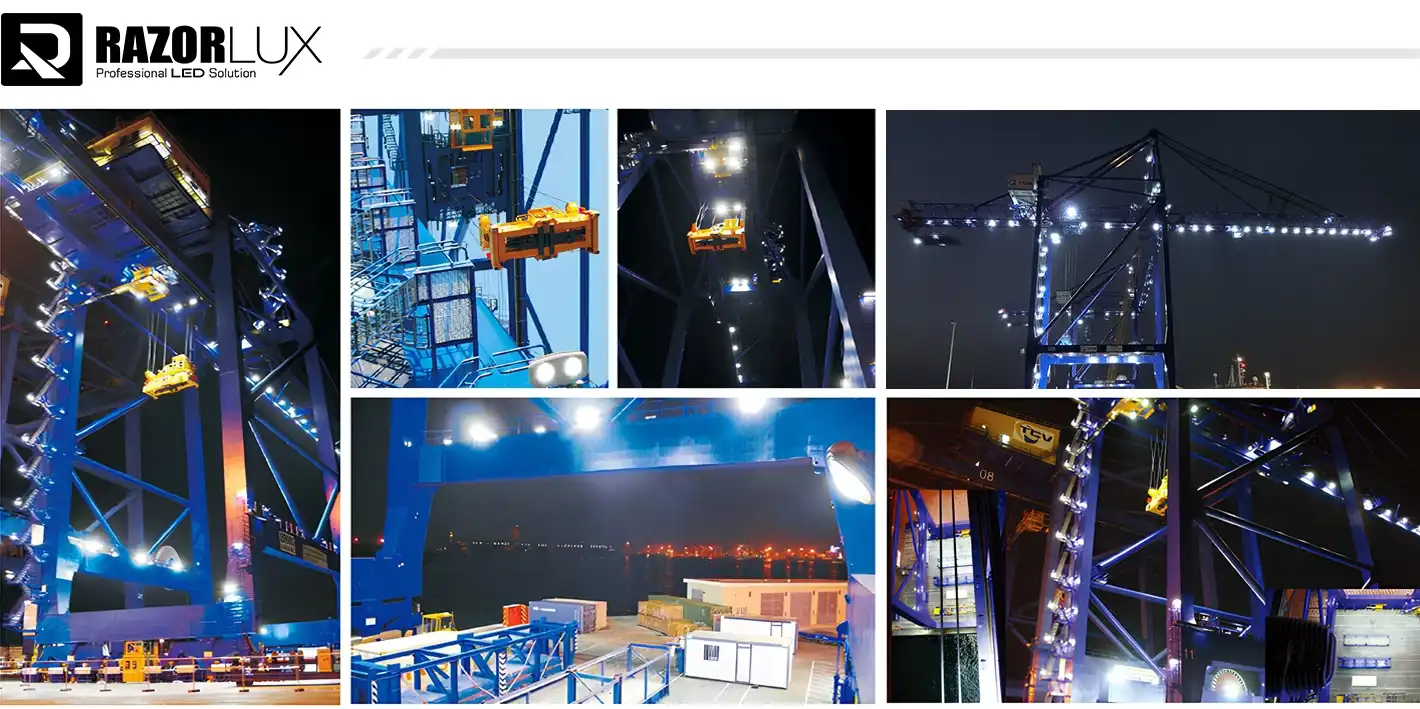

Picture a busy harbor at midnight where shipping deadlines demand nonstop operations, yet inadequate illumination puts workers at risk and causes costly delays. Selecting the best Crane Light Fixture for heavy-duty harbor cranes directly impacts operational safety, worker productivity, and your bottom line. This comprehensive guide explores the most reliable crane light fixture solutions engineered specifically for demanding maritime environments, helping you make informed decisions that ensure continuous 24/7 operations while protecting your workforce and equipment investments.

Essential Performance Features of Heavy-Duty Harbor Crane Light Fixtures

Superior Durability Standards for Maritime Environments

When selecting a crane light fixture for harbor applications, the fixture must withstand extreme maritime conditions that would destroy standard industrial lighting within months. Harbor crane light fixtures face constant exposure to corrosive salt spray, hurricane-force winds, temperature extremes, and relentless mechanical vibration from crane operations. Professional-grade crane light fixture options feature marine-grade anti-corrosion coatings, typically powder-coated aluminum housings or stainless steel construction that resists rust and deterioration even after years of saltwater exposure. The most reliable units carry IP67 waterproof ratings ensuring complete protection against dust infiltration and temporary water immersion, while IK10 impact resistance ratings guarantee the crane light fixture survives accidental collisions with cargo or equipment. These protective measures extend operational lifespan beyond 50,000 hours, dramatically reducing maintenance costs and minimizing dangerous fixture failures during critical loading operations.

Vibration Resistance and Structural Integrity

Harbor crane operations generate intense vibrations that quickly destroy lighting fixtures not specifically engineered for this environment. The best crane light fixture models undergo rigorous 3G, 4G, or even 5G vibration testing per ANSI C136.31 standards, subjecting them to 100,000 or more vibration cycles at three to five times gravitational force. This certification ensures the crane light fixture internal components, LED arrays, drivers, and mounting brackets withstand the continuous shaking inherent in heavy-duty crane movements without premature failure. Quality manufacturers like Xi'an Razorlux Optoelectronic Technology incorporate patented multi-function designs with reinforced internal structures, shock-absorbing mounting systems, and vibration-dampening materials that maintain optimal performance throughout the fixture's service life. Additionally, professional crane light fixture installations include stainless steel safety cables and heavy-duty brackets that provide secondary attachment points, preventing dangerous falls should primary mounting points fail under extreme stress conditions.

Optimal Light Output and Efficiency Specifications

Achieving proper illumination across extensive harbor work areas requires crane light fixture solutions that deliver exceptional brightness while minimizing energy consumption. Modern LED Crane Light fixtures provide 130-160 lumens per watt efficiency, offering 70-80% energy savings compared to outdated 400W metal halide or high-pressure sodium lamps while producing superior light quality. For harbor cranes with booms extending 40-60 feet above ground level, fixtures delivering 13,000-20,000 lumens with narrow 15-30 degree beam angles concentrate light precisely where operators need it most, penetrating deep into ship holds without creating dangerous shadows. The best crane light fixture options feature adjustable color temperatures from 2700K to 6500K, allowing customization based on specific operational requirements—lower temperatures cutting through fog and precipitation more effectively, while higher temperatures improving color recognition for cargo identification and quality control inspections. Premium units maintain stable light output across wide voltage ranges (AC 80-315V or DC 80-400V) without requiring additional transformers, automatically compensating for voltage fluctuations during crane regeneration cycles that would cause traditional lighting to flicker or fail entirely.

Comprehensive Selection Guide for Harbor Crane Light Fixtures

Critical Technical Specifications Comparison

| Specification | Standard Requirements | Premium Performance |

|---|---|---|

| Power Rating | 100-200W | 150-300W |

| Luminous Efficacy | 100-120 LM/W | 130-160 LM/W |

| IP Protection Rating | IP65 (dust-tight, water-resistant) | IP67 (dust-proof, waterproof) |

| IK Impact Rating | IK08 (moderate impact) | IK10 (severe impact) |

| Vibration Testing | 3G certification | 4G-5G certification |

| Operating Temperature | -20°C to 50°C | -40°C to 60°C |

| Voltage Range | Single voltage (120V/277V) | Universal (80-400V AC/DC) |

| Warranty Coverage | 3 years standard | 5-10 years extended |

| Beam Angle Options | Fixed (60° or 90°) | Multiple options (15°-140°) |

Understanding these technical specifications helps you identify which crane light fixture best matches your harbor's operational requirements and environmental challenges. The specifications table demonstrates that investing in premium crane light fixture models with extended temperature ranges, broader voltage compatibility, and superior protection ratings delivers significantly better long-term value despite higher initial costs. Harbor managers should prioritize crane light fixture options with IP67 ratings and 4G-5G vibration certification for installations in particularly harsh coastal environments, while operations in more sheltered locations may find IP65 and 3G certification adequate for their needs.

Installation and Mounting Configuration Options

Proper installation significantly impacts crane light fixture performance, safety, and longevity in demanding harbor environments. The best crane light fixture manufacturers provide comprehensive mounting solutions including adjustable stainless steel brackets that accommodate various crane structural configurations, allowing precise positioning to eliminate shadows and optimize light distribution across work surfaces. Professional installations require mounting crane light fixtures on stable structural members capable of supporting fixture weight plus dynamic loads from wind and crane movements, with all fasteners using marine-grade stainless steel hardware that resists corrosion in saltwater environments. Electrical connections must utilize waterproof junction boxes with IP67-rated cable glands, while cable routing should include strain relief supports every 3-5 feet preventing damage from constant movement and vibration. For ship-to-shore cranes where fixtures mount 60+ feet above ground, installations typically combine narrow-beam crane light fixtures on the main girder for penetrating deep into ship holds with wide-beam units on trolleys providing uniform illumination across container surfaces. Every crane light fixture installation should incorporate redundant safety cables rated for twice the fixture weight, creating critical secondary attachment preventing catastrophic falls that could injure workers or damage expensive equipment below.

Power Supply and Control System Integration

Modern harbor operations demand crane light fixture solutions that integrate seamlessly with existing electrical infrastructure while providing advanced control capabilities. The most versatile crane light fixture models feature universal voltage drivers automatically detecting and adjusting to facility power systems ranging from 80-315VAC to 80-400VDC, eliminating costly transformer installations and accommodating voltage fluctuations common in harbor electrical systems. Advanced crane light fixture control options include 0-10V analog dimming, DALI (Digital Addressable Lighting Interface) protocols, and DMX systems allowing operators to adjust brightness based on ambient conditions, reducing energy consumption during dawn and dusk while maintaining optimal visibility. Some premium crane light fixture installations incorporate emergency battery backup systems maintaining illumination for 2+ hours during power failures, ensuring operations continue safely until backup generators activate or normal power restores. Integration with crane control systems enables automated lighting sequences where crane light fixtures activate only when specific cranes operate, maximizing energy savings across large port facilities with multiple cranes. High-quality crane light fixture drivers maintain power factors exceeding 0.98 with total harmonic distortion below 10%, ensuring electrical efficiency while preventing interference with sensitive electronic equipment commonly found in modern automated harbor facilities.

Beam Angle Selection and Light Distribution Strategies

Selecting appropriate beam angles represents one of the most critical decisions in crane light fixture specification, directly impacting operational safety and efficiency. For ship-to-shore harbor cranes with trolley heights exceeding 50 feet, narrow beam crane light fixtures with 15-30 degree angles concentrate light output into focused columns penetrating deep into ship holds where operators must identify container numbers and lashing points. Conversely, rubber-tired gantry cranes operating at 20-30 foot heights benefit from wide 60-90 degree beam crane light fixtures providing broader coverage across container stacking areas, reducing the total number of fixtures required while maintaining uniform illumination levels. Optimal harbor installations typically combine multiple crane light fixture beam angles creating layered lighting strategies—narrow beams for primary work surfaces and precision tasks, supplemented by wide-angle fixtures eliminating shadows and providing peripheral awareness for safety. Professional lighting engineers utilize DIALux simulation software analyzing specific crane configurations, mounting heights, and operational requirements to determine the ideal combination of crane light fixture beam angles, power ratings, and placement positions. This scientific approach ensures adequate lux levels across all work surfaces while avoiding over-lighting that wastes energy or creates glare impairing operator vision during nighttime operations.

Advanced Technologies and Future-Ready Harbor Lighting Solutions

Smart Monitoring and Predictive Maintenance Systems

Leading crane light fixture manufacturers now integrate intelligent monitoring technologies that revolutionize maintenance approaches in harbor environments. Advanced crane light fixture models incorporate IoT sensors continuously monitoring operating temperatures, light output degradation, driver performance, and vibration exposure, transmitting real-time data to centralized management systems. These smart crane light fixtures enable predictive maintenance strategies where facility managers receive advance warning when components approach failure thresholds, scheduling replacements during planned downtime rather than responding to emergency failures during critical operations. Monitoring systems identify individual failing crane light fixtures within large installations containing hundreds of units, eliminating time-consuming manual inspections across extensive harbor facilities. Some premium crane light fixture solutions feature self-diagnostic capabilities automatically adjusting power output to compensate for LED degradation, maintaining consistent illumination levels throughout the fixture's operational life. Integration with facility management systems allows crane light fixture performance data correlation with operational metrics, identifying lighting quality impacts on productivity and helping justify investments in superior lighting solutions. These technologies transform crane light fixtures from passive infrastructure into active assets providing valuable operational intelligence while reducing total cost of ownership through optimized maintenance scheduling and extended equipment lifespans.

Environmental Sustainability and Energy Management

Modern harbor operations increasingly prioritize environmental sustainability, making energy-efficient crane light fixture selection both economically and ecologically responsible. LED crane light fixtures delivering 130-160 lumens per watt reduce electrical consumption by 70-80% compared to legacy metal halide and high-pressure sodium technologies, translating to substantial carbon footprint reductions across major port facilities. For reference, replacing a single 400W metal halide crane light fixture with a 150W LED equivalent saves approximately 250W per hour—across a harbor facility operating 100 cranes continuously, this represents 600,000 kWh annual energy savings and prevents roughly 400 tons of CO2 emissions yearly. Advanced crane light fixture designs incorporate sophisticated thermal management systems maximizing LED efficiency and longevity even in extreme temperature environments, with some models featuring passive cooling designs eliminating mechanical fans that require maintenance and create additional failure points. Environmentally conscious crane light fixture specifications should verify RoHS compliance ensuring products contain no hazardous materials like mercury or lead, simplifying end-of-life disposal and recycling. Forward-thinking harbor operators increasingly specify crane light fixtures with modular designs allowing LED array and driver component replacement extending fixture lifespan beyond 100,000 hours, dramatically reducing electronic waste generation while maintaining optimal performance through technology upgrades during the fixture's extended service life.

Emergency Backup and Safety-Critical Illumination

Harbor operations demand absolute lighting reliability where crane light fixture failures could endanger workers or cause catastrophic accidents with multi-million-dollar consequences. Premium crane light fixture solutions incorporate integrated emergency battery backup systems maintaining full illumination for 2-3 hours during power failures, ensuring operators safely complete in-progress lifts and secure loads before operations cease. These emergency-equipped crane light fixtures prove particularly valuable during hurricane evacuations or other emergency situations requiring crane operations under adverse conditions when grid power becomes unreliable. Beyond primary illumination, comprehensive harbor safety strategies incorporate specialized crane light fixtures creating visible warning zones around moving loads—blue or red LED projectors casting colored spots or lines on ground surfaces alerting workers to dangerous areas beneath active cranes. Advanced crane light fixture warning systems project dynamic patterns that move with the load, maintaining constant position awareness even as cranes traverse work areas. Installation of redundant crane light fixture arrays ensures adequate illumination continues even when individual fixtures fail, preventing dangerous situations where crane operators lose visibility mid-operation. Quality crane light fixture manufacturers provide detailed failure mode analyses demonstrating how their designs prevent common failure mechanisms like driver failure, thermal runaway, or connection degradation that could cause sudden, dangerous lighting losses during critical operations.

Comparing Leading Harbor Crane Light Fixture Options

Performance Specifications of Top-Tier Industrial Solutions

| Performance Metric | Economy Models | Professional Grade | Premium Solutions |

|---|---|---|---|

| Luminous Output | 10,000-12,000 lm | 13,000-15,000 lm | 16,000-20,000+ lm |

| Power Consumption | 150-180W | 120-150W | 100-150W |

| Efficacy Rating | 85-100 LM/W | 110-130 LM/W | 130-160 LM/W |

| Rated Lifespan | 30,000 hours | 50,000 hours | 60,000-100,000 hours |

| Operating Voltage | Single voltage | Dual voltage | Universal (80-400V) |

| Color Temperature | Fixed (5000K) | Selectable (4000K-6000K) | Custom (2700K-6500K) |

| Beam Angle Options | 1-2 options | 3-4 options | 6+ customizable |

| CRI (Color Rendering) | Ra>70 | Ra>75 | Ra>80-90 |

| Warranty Period | 2-3 years | 5 years | 5-10 years |

| Emergency Backup | Not available | Optional | Integrated |

This comprehensive comparison reveals significant performance differences between crane light fixture categories that directly impact operational costs and reliability. While economy crane light fixtures may appear cost-effective initially, their lower efficiency, shorter lifespans, and limited features result in higher total cost of ownership through increased energy consumption and more frequent replacements. Professional-grade crane light fixtures like the Razorlux RGL-150P model strike an optimal balance, delivering 13,200 lumens at 130 LM/W efficiency with proven 50,000+ hour lifespans backed by comprehensive 5-year warranties—specifications meeting or exceeding most harbor operational requirements. Premium crane light fixture solutions justify their elevated costs in the most demanding applications where maximum reliability, extended lifespans, and advanced features like emergency backup prove essential. Harbor operators should evaluate crane light fixture options based on total cost of ownership calculations considering energy costs, maintenance expenses, and operational downtime risks rather than focusing solely on initial purchase prices.

Manufacturer Reputation and Quality Certifications

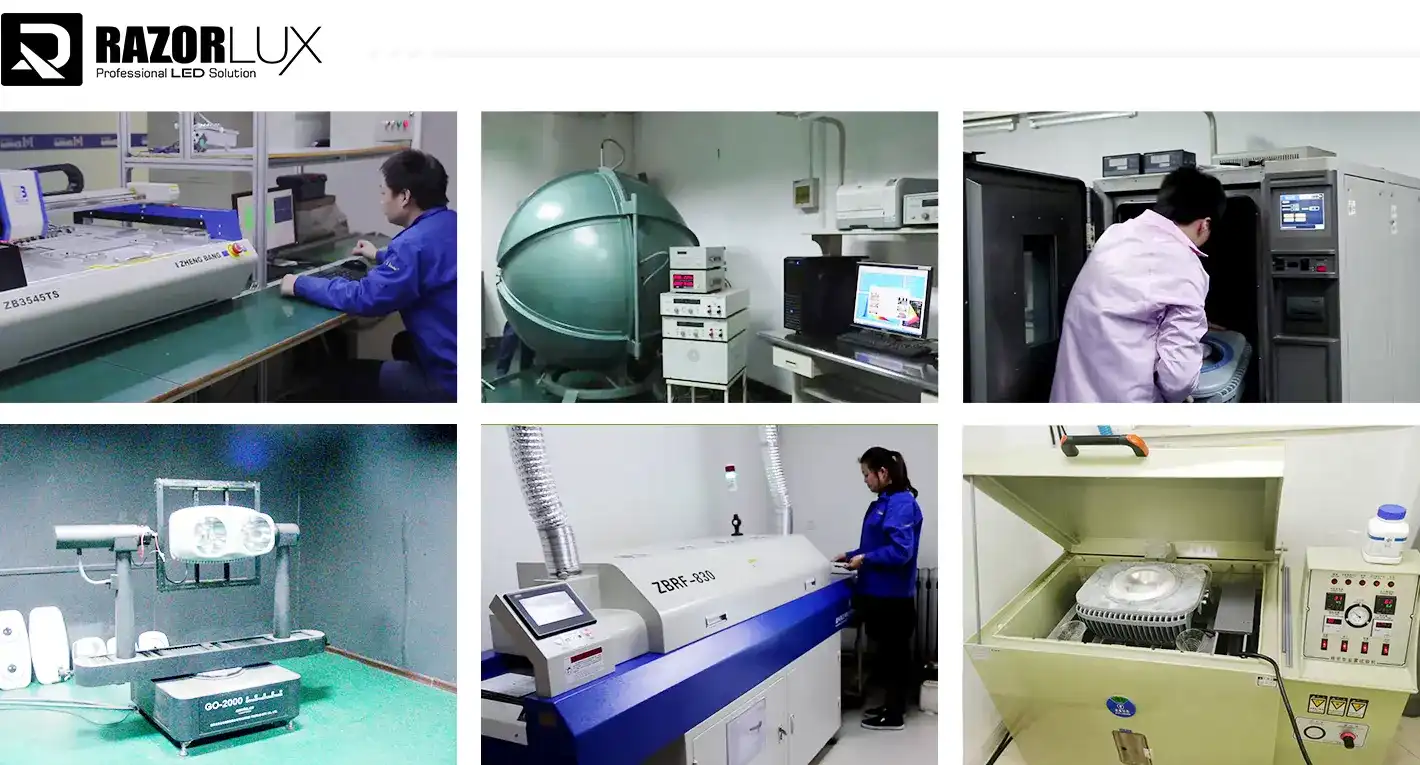

Selecting crane light fixtures from established manufacturers with proven track records in maritime applications significantly reduces risk and ensures reliable performance. Leading crane light fixture suppliers like Xi'an Razorlux Optoelectronic Technology Co., Ltd., founded in 1998, bring decades of specialized experience developing lighting solutions specifically engineered for marine, industrial, and heavy-duty applications. Reputable crane light fixture manufacturers maintain comprehensive quality certifications including ISO 9001 management systems, UL safety standards, CE European compliance, RoHS environmental regulations, and marine-specific certifications like RMRS (Russian Maritime Register of Shipping) demonstrating products meet rigorous industry requirements. Companies holding over 200 patents covering LED Packaging, power control, and structural design bring innovative solutions addressing real-world challenges faced in harbor environments, rather than simply rebranding generic industrial lighting. Established crane light fixture manufacturers typically operate dedicated R&D facilities, ISO-certified production lines, and comprehensive quality control processes including photometric testing, aging tests, and environmental simulation ensuring consistent product performance. When evaluating crane light fixture suppliers, verify they maintain global presence with regional support offices, local inventory for rapid replacement part availability, and technical support teams capable of assisting with installation troubleshooting and customized lighting designs. Manufacturers offering OEM and ODM services demonstrate engineering flexibility to develop customized crane light fixture solutions addressing unique operational requirements that standard catalog products cannot satisfy.

Total Cost of Ownership and Return on Investment Analysis

Understanding the complete financial picture beyond initial purchase price enables informed crane light fixture investment decisions delivering optimal value. A comprehensive total cost of ownership analysis for crane light fixtures must include acquisition costs, installation expenses, ongoing energy consumption, routine maintenance, emergency repairs, and eventual replacement cycles. Consider a typical harbor crane operating 6,000 hours annually: replacing a 400W metal halide fixture consuming $240 yearly in electricity with a 150W LED crane light fixture reduces annual energy costs to just $90—a $150 annual savings per fixture. Across a 100-crane harbor facility, this represents $15,000 in annual energy savings alone, typically recovering premium crane light fixture investment costs within 18-24 months. Maintenance cost reductions prove equally significant—traditional metal halide crane light fixtures require bulb replacement every 6,000-10,000 hours plus ballast replacement every 15,000-20,000 hours, with each maintenance event involving expensive lift equipment rental, electrician labor, and operational downtime. LED crane light fixtures with 50,000-100,000 hour lifespans essentially eliminate routine maintenance for 8-16 years, saving thousands per crane in avoided maintenance costs. Premium crane light fixture models with 10-year warranties provide financial certainty, transferring failure risk to manufacturers rather than harbor operators. Progressive harbor facilities conduct detailed ROI analyses factoring in avoided accident costs from improved visibility, productivity gains from superior light quality, and environmental credits from reduced energy consumption, often revealing that premium crane light fixture investments deliver positive returns within 12-18 months while providing benefits extending decades.

Conclusion

Selecting optimal crane light fixtures for heavy-duty harbor cranes requires balancing performance specifications, environmental durability, energy efficiency, and total cost of ownership. Premium solutions like those from Xi'an Razorlux Optoelectronic Technology deliver IP67 protection, 130+ LM/W efficiency, and proven 50,000+ hour lifespans backed by comprehensive warranties—specifications ensuring reliable operations in the harshest maritime environments while maximizing return on investment through reduced energy consumption and minimal maintenance requirements.

Ready to upgrade your harbor crane lighting with professional solutions designed specifically for demanding maritime applications? As a leading China crane light fixture manufacturer, China crane light fixture supplier, and China crane light fixture factory, Xi'an Razorlux Optoelectronic Technology offers competitive crane light fixture prices with wholesale options available for large projects. Our crane light fixture for sale inventory includes the proven RGL-150P model and customized solutions tailored to your exact operational requirements. Contact our technical team at sam@razorlux.com to receive a complimentary DIALux lighting simulation, detailed product specifications, and personalized recommendations ensuring your harbor operations benefit from optimal illumination, enhanced safety, and maximum energy efficiency. Bookmark this guide for future reference when planning crane lighting upgrades or troubleshooting existing installations.

References

1. Illuminating Engineering Society, "Recommended Practice for Outdoor Environment Lighting," IES RP-33-14, Illuminating Engineering Society of North America

2. National Institute for Occupational Safety and Health, "Preventing Worker Injuries and Deaths from Mobile Crane Tip-Over, Boom Collapse, and Uncontrolled Hoisted Loads," DHHS (NIOSH) Publication No. 2006-142

3. International Commission on Illumination, "Lighting of Work Places - Part 2: Outdoor Work Places," CIE S 015/E:2018, Commission Internationale de l'Eclairage

4. American National Standards Institute, "American National Standard for Roadway and Area Lighting Equipment - Luminaire Vibration," ANSI C136.31-2010, National Electrical Manufacturers Association

5. International Labour Organization, "Safety and Health in Ports: ILO Code of Practice," International Labour Office Geneva, Revised Edition

_1750326878398.png)