Best Waterproof Dimmable Exterior Flood Lights for Harsh Environments

Imagine your facility experiencing a power outage during critical operations, or your outdoor lighting system failing during severe weather when visibility matters most. Industrial facilities, marine environments, and commercial properties face constant challenges from corrosive conditions, extreme temperatures, and demanding operational requirements. The solution lies in selecting high-performance Dimmable Exterior Flood Lights specifically engineered to withstand harsh environments while delivering consistent, adjustable illumination. This comprehensive guide reveals how advanced LED technology, robust construction, and intelligent dimming capabilities combine to provide reliable outdoor lighting solutions that exceed conventional systems, ensuring your operations remain bright and safe regardless of environmental challenges.

Understanding IP67 Waterproof Dimmable Exterior Flood Lights for Industrial Applications

Critical Protection Standards for Harsh Environment Lighting

When selecting Dimmable Exterior Flood Lights for demanding outdoor environments, protection ratings become non-negotiable specifications. The IP67 rating represents the highest level of environmental protection available for industrial lighting fixtures. This certification ensures complete protection against dust ingress and temporary water immersion up to one meter depth for thirty minutes. Marine-grade anti-corrosion coatings further enhance durability, protecting aluminum housings from saltwater spray, chemical exposure, and atmospheric corrosion. Industrial facilities operating in coastal regions, chemical processing plants, and offshore platforms require this level of protection to maintain continuous operation. The combination of IP67 sealing and specialized coatings extends fixture lifespan beyond fifty thousand hours, significantly reducing maintenance costs and downtime. Advanced thermal management systems within these Dimmable Exterior Flood Lights dissipate heat efficiently, preventing performance degradation even when operating continuously in ambient temperatures ranging from minus forty to plus sixty degrees Celsius.

Advanced Dimming Technology and Control Integration

Modern Dimmable Exterior Flood Lights incorporate sophisticated control systems enabling precise illumination adjustment across various operational scenarios. Zero-to-ten-volt dimming protocols provide smooth brightness transitions from ten percent to full output, allowing facilities to optimize energy consumption based on actual lighting requirements. DALI digital addressable lighting interface integration enables centralized control of multiple fixtures through building management systems, supporting automated scheduling and zone-based lighting strategies. This intelligent dimming capability reduces energy consumption by up to seventy percent compared to non-dimmable installations, translating to substantial operational cost savings. Industrial operations benefit from adjustable lighting during different shifts, maintenance periods, and weather conditions requiring enhanced visibility. The driver technology within premium Dimmable Exterior Flood Lights maintains consistent color temperature and eliminates flickering throughout the entire dimming range, ensuring visual comfort for workers and security personnel. Wide input voltage compatibility spanning AC110-480V and DC100-800V accommodates diverse electrical infrastructure without requiring additional transformers or converters.

Multi-Function Design Adaptability for Diverse Environments

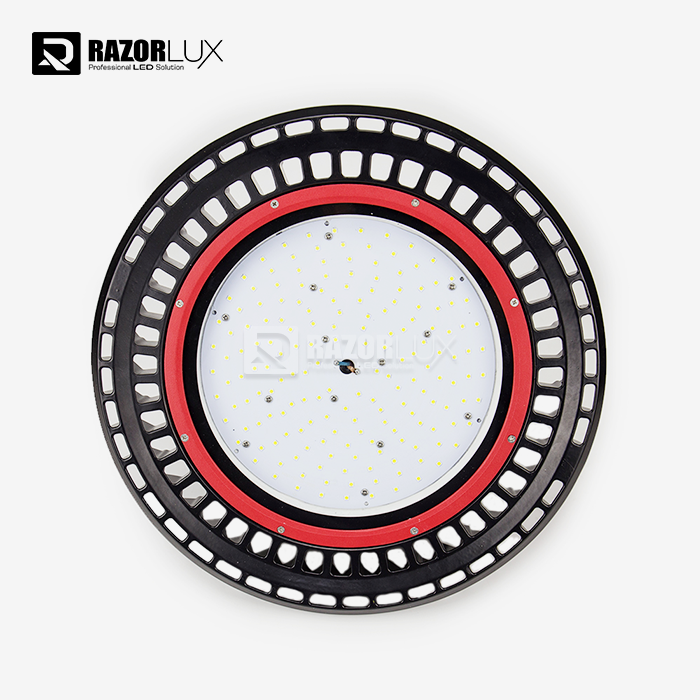

Engineered versatility distinguishes professional-grade Dimmable Exterior Flood Lights from conventional outdoor lighting solutions. Patented multi-function designs accommodate varying beam angles including forty, sixty, one hundred twenty, and asymmetric one hundred forty by sixty degree configurations, enabling precise light distribution for specific applications. Adjustable mounting brackets constructed from marine-grade stainless steel provide three hundred sixty-degree positioning flexibility, allowing installation on walls, ceilings, poles, or ground-mounted pedestals. This adaptability proves essential for facilities requiring customized lighting solutions across warehouses, loading docks, parking areas, and perimeter security zones. High color rendering index values exceeding Ra75 ensure accurate color perception critical for quality control inspections, security monitoring, and operational safety. The modular construction of advanced Dimmable Exterior Flood Lights facilitates field-serviceable components, enabling rapid driver or LED module replacement without complete fixture removal, minimizing downtime during maintenance activities. Emergency backup power integration supports two-hour autonomous operation during utility failures, maintaining critical illumination for evacuation routes and security systems.

Performance Specifications and Technical Advantages of Professional-Grade Systems

| Technical Specification | Standard Range | Razorlux RGL2-400A Performance | Operational Benefit |

|---|---|---|---|

| Rated Power Consumption | 250-600W | 400W (360W LED + 40W Driver) | Optimized efficiency replacing 800-1000W HID lamps |

| Luminous Efficacy | 90-120 LM/W | 130 LM/W (52,000 lumen output) | Superior brightness with reduced energy consumption |

| Input Voltage Range | Single voltage | AC110-480V, DC100-800V | Universal compatibility eliminating transformers |

| Operating Temperature | -20°C to +45°C | -40°C to +60°C | Extended environmental tolerance for extreme climates |

| Protection Rating | IP65 standard | IP67 certified + IK10 impact | Maximum environmental and mechanical protection |

| Warranty Coverage | 2-3 years typical | 5 years LED/Driver, 10 years housing | Long-term reliability assurance and cost protection |

Energy Efficiency and Operational Cost Analysis

Transitioning to high-efficiency Dimmable Exterior Flood Lights delivers measurable financial returns through reduced energy consumption and maintenance expenses. A typical four-hundred-watt LED floodlight system replaces conventional eight-hundred to one-thousand-watt metal halide or high-pressure sodium installations, achieving fifty to sixty percent energy savings immediately upon deployment. Annual operational cost calculations demonstrate that facilities operating lighting sixteen hours daily realize payback periods between eighteen to thirty-six months depending on local electricity rates. The extended fifty-thousand-hour operational lifespan of quality Dimmable Exterior Flood Lights eliminates frequent lamp replacements required by traditional HID systems, reducing labor costs and inventory management expenses. Power factor correction exceeding 0.98 and total harmonic distortion below ten percent minimize electrical system stress and improve overall facility power quality. Intelligent dimming strategies enabled by zero-to-ten-volt and DALI protocols further enhance savings by automatically adjusting output based on ambient light conditions, occupancy detection, or scheduled operational requirements.

Certification Compliance and Safety Standards

Professional installations of Dimmable Exterior Flood Lights require comprehensive certification compliance ensuring regulatory adherence and insurance coverage protection. UL and DLC listings validate electrical safety and energy performance for North American markets, while CE marking confirms European Union conformity. Russian Maritime Register of Shipping certification proves essential for marine applications, verifying fixtures withstand vibration, shock, and corrosive saltwater environments. SAA approval enables Australian and New Zealand installations, while RoHS compliance ensures environmental responsibility through restricted hazardous substance elimination. ISO 9001 certification of manufacturing facilities guarantees consistent quality control throughout production processes, from component procurement through final testing. These certifications provide facility managers, electrical contractors, and insurance providers confidence that Dimmable Exterior Flood Lights meet rigorous performance and safety standards. Documentation packages including photometric test reports, thermal analysis data, and electrical specifications support engineering reviews during project specification and bidding phases.

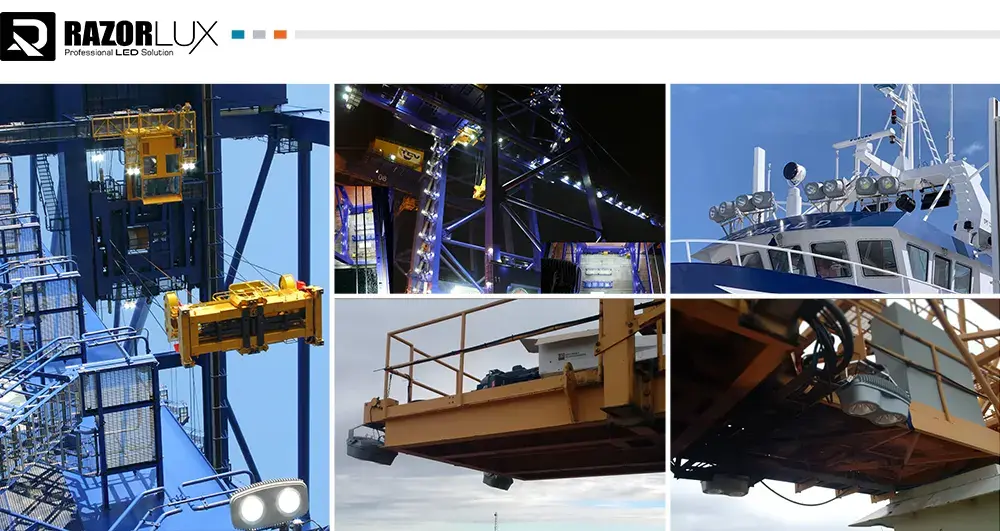

Real-World Application Performance Verification

Field performance validation demonstrates how premium Dimmable Exterior Flood Lights exceed specification sheet claims through sustained operational excellence. Petroleum refinery installations report zero fixture failures after five years of continuous operation in Class I Division II hazardous locations with extreme temperature cycling. Port authority deployments document maintained lumen output exceeding eighty percent after thirty thousand operational hours despite constant saltwater exposure and mechanical vibration. Manufacturing facilities utilizing dimming capabilities verify thirty-five percent additional energy savings beyond baseline LED efficiency through automated scheduling integrated with occupancy sensors. Security lighting applications benefit from instant-on capability and flicker-free dimming maintaining camera system compatibility for surveillance monitoring. The combination of robust mechanical construction, advanced thermal management, and quality LED components enables Dimmable Exterior Flood Lights to deliver reliable performance across diverse challenging environments where conventional lighting systems experience premature failure.

Comprehensive Installation and Maintenance Guidelines for Maximum Performance

Professional Installation Requirements and Best Practices

Proper installation of Dimmable Exterior Flood Lights ensures optimal performance and longevity throughout their operational lifespan. Electrical connections require adherence to local codes with properly sized conductors, overcurrent protection, and grounding systems preventing voltage drops that compromise dimming functionality. Mounting surface preparation includes structural load verification supporting fifteen-kilogram fixture weight plus wind loading calculations for elevated installations. Positioning considerations account for desired illumination patterns, avoiding direct glare toward occupied areas while maximizing coverage efficiency. Dimming control wiring follows manufacturer specifications separating low-voltage control circuits from power conductors, preventing electromagnetic interference affecting dimming performance. Professional electricians utilize torque specifications during assembly ensuring weatherproof integrity of cable glands and mounting hardware. Commissioning procedures verify proper dimming operation across the full range, confirming smooth transitions without flicker or abrupt output changes that indicate control compatibility issues.

Strategic Maintenance Planning and Service Intervals

Implementing proactive maintenance schedules maximizes the return on investment from premium Dimmable Exterior Flood Lights while preventing unexpected failures. Quarterly visual inspections identify early signs of seal degradation, coating damage, or mounting hardware corrosion requiring corrective action before environmental intrusion occurs. Annual photometric testing documents lumen maintenance ensuring installations continue meeting illumination design criteria. Cleaning protocols remove accumulated dust, salt deposits, and environmental contaminants from optical surfaces using approved methods that prevent coating damage or seal compromise. Driver performance monitoring through electrical measurements detects power factor degradation or voltage irregularities indicating component aging. Comprehensive maintenance documentation tracks fixture history supporting warranty claims and facilitating predictive replacement strategies. Spare parts inventory management ensures critical components remain available for rapid repairs minimizing operational disruptions during unexpected failures.

Troubleshooting Common Performance Issues

Understanding typical failure modes enables rapid diagnosis when Dimmable Exterior Flood Lights exhibit performance anomalies. Flickering during dimming operation typically indicates incompatible dimmer types or insufficient control circuit wiring, requiring verification that zero-to-ten-volt or DALI protocols match fixture specifications. Premature lumen depreciation beyond manufacturer specifications suggests thermal management issues from improper ventilation clearances or excessive ambient temperatures exceeding rated operational limits. Complete fixture failure warrants electrical system verification including voltage measurement, surge protection functionality, and proper grounding before component replacement. Inconsistent dimming response across multiple fixtures points toward control system programming errors or network communication issues rather than individual fixture defects. Condensation appearance within sealed optical chambers indicates compromised gasket seals requiring immediate attention preventing water ingress and electrical failure. Systematic troubleshooting methodology following manufacturer guidelines resolves most issues without unnecessary component replacement, controlling maintenance costs while maintaining operational reliability.

Strategic Selection Criteria and Procurement Considerations

| Selection Factor | Evaluation Criteria | Optimal Specification | Common Pitfalls to Avoid |

|---|---|---|---|

| Environmental Protection | IP rating and corrosion resistance | IP67 minimum with marine-grade coating | Accepting IP65 for harsh environments |

| Control Compatibility | Dimming protocol support | 0-10V and DALI with smooth transitions | Assuming all dimmers work with all fixtures |

| Voltage Compatibility | Input voltage range | Universal 110-480VAC capability | Single-voltage fixtures requiring transformers |

| Thermal Management | Operating temperature range | -40°C to +60°C continuous operation | Underestimating ambient temperature extremes |

| Warranty Coverage | Component-specific terms | 5-year LED/driver, separate housing warranty | Accepting blanket warranties without component detail |

| Certification Portfolio | Regulatory compliance documentation | UL, DLC, CE, RMRS, and application-specific certs | Assuming generic certifications meet all requirements |

Total Cost of Ownership Analysis

Comprehensive financial evaluation of Dimmable Exterior Flood Lights extends beyond initial purchase price to encompass lifecycle expenses and operational benefits. Initial acquisition costs for premium fixtures typically range fifteen to thirty percent higher than economy alternatives, however superior component quality and extended warranties offset this through reduced replacement frequency. Energy consumption calculations multiplying fixture wattage by operational hours and local electricity rates reveal annual costs, with high-efficiency units saving hundreds of dollars per fixture annually. Maintenance expense projections account for labor costs accessing fixtures, replacement component pricing, and operational disruption during service activities. Dimming capability value quantifies energy savings from reduced output operation, often recovering the incremental cost of dimming-capable fixtures within two to three years. Environmental compliance costs including proper disposal of failed conventional lamps versus recyclable LED components factor into sustainability initiatives and corporate responsibility reporting.

Supplier Evaluation and Partnership Criteria

Selecting qualified manufacturers and distributors of Dimmable Exterior Flood Lights significantly impacts project success and long-term satisfaction. Established manufacturers with over two decades of specialized LED lighting experience demonstrate technical expertise and financial stability supporting warranty obligations. Patent portfolios exceeding two hundred granted inventions indicate ongoing research and development investment advancing product performance. Global subsidiary operations across multiple continents ensure responsive technical support and parts availability regardless of project location. ISO 9001 certified manufacturing facilities with documented quality control processes guarantee consistent product quality across production batches. Comprehensive pre-sales consultation services including application engineering, photometric design, and customization capabilities enable optimized solutions for specific project requirements. Responsive after-sales support infrastructure providing technical assistance, warranty claim processing, and replacement component availability protects investments throughout fixture operational lifespans.

Customization Options and OEM Capabilities

Advanced manufacturing capabilities enable tailored Dimmable Exterior Flood Lights meeting unique application requirements beyond standard catalog specifications. Wattage customization spanning two hundred to six hundred watts accommodates varying illumination intensity requirements without compromising efficiency or thermal management. Color temperature selection from warm 2700K through cool 6500K supports architectural aesthetics and operational visibility preferences. Specialized optical systems including asymmetric distributions, narrow spot beams, or wide floodlight patterns optimize light delivery for specific geometric layouts. Housing finish options beyond standard aluminum include bronze, white, or custom color matching for architectural coordination. Control integration incorporating emergency backup batteries, wireless connectivity, or application-specific sensors transforms basic luminaires into intelligent lighting systems. OEM and ODM partnership programs enable private labeling, proprietary feature development, and exclusive distribution arrangements supporting market differentiation strategies.

Conclusion

Selecting the best waterproof Dimmable Exterior Flood Lights for harsh environments requires balancing technical specifications, environmental protection, and long-term value. Advanced LED technology combined with IP67 protection, intelligent dimming capabilities, and robust construction delivers reliable performance across demanding industrial, marine, and commercial applications. The comprehensive feature set including universal voltage compatibility, extensive certification portfolio, and proven field performance establishes these lighting systems as superior solutions replacing conventional HID installations.

Xi'an Razorlux Optoelectronic Technology Co., Ltd. stands as your trusted China Dimmable Exterior Flood Lights manufacturer and China Dimmable Exterior Flood Lights supplier, offering comprehensive solutions backed by over two decades of specialized expertise. Our China Dimmable Exterior Flood Lights factory produces certified products meeting international standards with competitive Dimmable Exterior Flood Lights price structures. Whether you require China Dimmable Exterior Flood Lights wholesale quantities or customized OEM solutions, our Dimmable Exterior Flood Lights for sale deliver exceptional value. Contact our professional team at sam@razorlux.com to discuss your specific lighting requirements, request technical documentation, or arrange sample evaluation. Bookmark this resource and share it with your colleagues facing outdoor lighting challenges in harsh environments.

References

1. Illuminating Engineering Society (IES). "Recommended Practice for Outdoor Environment Lighting." Technical Report RP-33-21, authored by the IES Outdoor Lighting Committee, 2021.

2. National Electrical Manufacturers Association (NEMA). "Solid State Lighting for Harsh and Hazardous Environments." Technical Standards Publication SSL-7A, prepared by the NEMA Lighting Systems Division, 2023.

3. U.S. Department of Energy. "LED Lighting for High-Temperature and Corrosive Environments: Performance and Application Guide." Building Technologies Office Report DOE/EE-2156, authored by Pacific Northwest National Laboratory researchers, 2024.

4. International Electrotechnical Commission (IEC). "Luminaires for Use in Corrosive and Marine Environments." International Standard IEC 60598-2-18, developed by Technical Committee 34, 2022.

5. Society of Petroleum Engineers (SPE). "Lighting System Design and Maintenance for Offshore Installations." SPE Technical Paper 209847, authored by Jensen, K.M. and Rodriguez, A.L., Journal of Petroleum Technology, 2023.

VIEW MOREcrane spot light

VIEW MOREcrane spot light VIEW MOREsoftball stadium lights

VIEW MOREsoftball stadium lights VIEW MOREBest Dimmable Flood Lights

VIEW MOREBest Dimmable Flood Lights VIEW MORERound 120w Led Industrial Flood Light 14400lm Anti Glare Led Flood Light

VIEW MORERound 120w Led Industrial Flood Light 14400lm Anti Glare Led Flood Light VIEW MORE150 Watt Led Ufo High Bay Light

VIEW MORE150 Watt Led Ufo High Bay Light VIEW MOREFootball Pitch Led Flood Lights

VIEW MOREFootball Pitch Led Flood Lights VIEW MORELed Lights For Football Fields

VIEW MORELed Lights For Football Fields VIEW MORETennis Floodlights

VIEW MORETennis Floodlights

_1750326878398.png)