What is a high mast light?

Picture this: you're managing a vast industrial complex, a sprawling port facility, or a major highway interchange that operates around the clock. Darkness falls, and suddenly visibility becomes your greatest challenge—workers' safety is at stake, operational efficiency plummets, and security concerns multiply. This is where LED High Mast Light technology transforms impossible lighting challenges into manageable solutions, illuminating acres of space from a single elevated point.

Understanding LED High Mast Light Technology and Applications

The Definition and Core Components of LED High Mast Light Systems

A high mast light represents a sophisticated area lighting solution engineered to illuminate expansive outdoor spaces from elevated mounting positions. These specialized lighting systems consist of tall poles typically ranging from 15 meters to 55 meters in height, equipped with multiple high-powered LED luminaires clustered at the top. The LED High Mast Light differs fundamentally from conventional street lighting through its exceptional mounting height, which enables uniform light distribution across vast areas while minimizing ground-level obstructions. Modern systems incorporate advanced components including durable steel or aluminum poles, high-efficiency LED fixtures, intelligent control mechanisms, and reinforced concrete foundations designed to withstand extreme weather conditions. The 400W Led High Mast Light configuration has emerged as an industry standard, offering optimal balance between illumination output and energy consumption for medium to large-scale applications.

Historical Development and Evolution of High Mast Lighting

The origins of high mast lighting trace back to 1950s Europe, where engineers pioneered elevated lighting solutions for expanding highway systems. As the United States interstate network grew during the 1960s, with increasingly complex multi-level interchanges requiring enhanced visibility, American engineers adopted and refined this technology. The Texas Transportation Institute conducted groundbreaking research in 1966, installing experimental towers reaching 120 feet in Fort Worth, demonstrating exceptional results that revolutionized highway illumination standards. Throughout subsequent decades, technological advancement transformed high mast systems from fixed metal halide and high-pressure sodium installations to sophisticated LED High Mast Light solutions featuring lowering mechanisms for simplified maintenance. The transition to LED technology represented a watershed moment, as 400W LED High Mast Light fixtures could now replace 800-1000W traditional HID lamps while delivering superior performance, dramatically reduced energy consumption, and extended operational lifespans exceeding 50,000 hours.

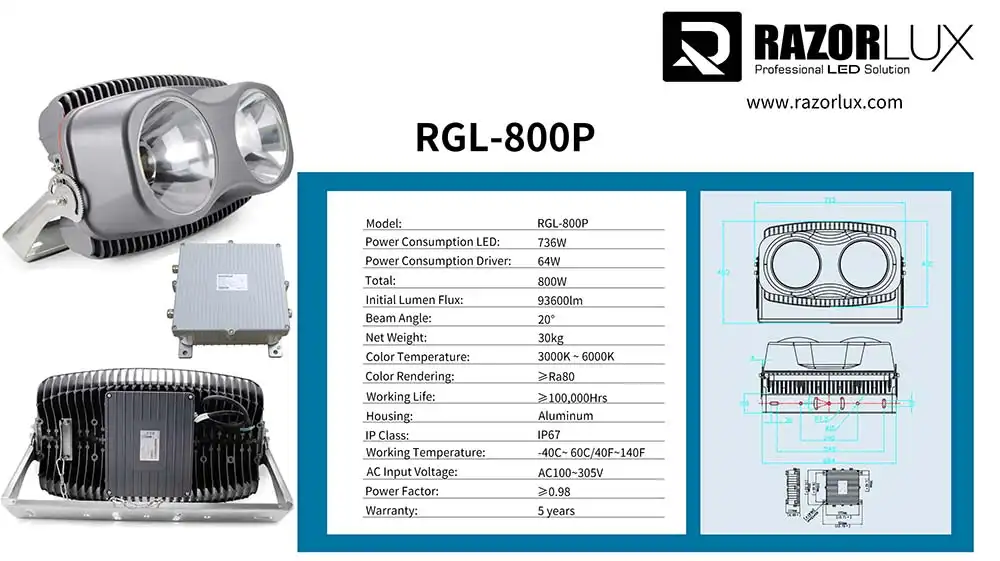

Key Technical Specifications and Performance Characteristics

Modern LED High Mast Light systems demonstrate remarkable technical capabilities that address diverse illumination requirements. Premium fixtures like those offered by Xi'an Razorlux Optoelectronic Technology Co., Ltd. feature multi-function designs accommodating universal voltage inputs (AC110-480Vac, DC100-800Vdc), enabling deployment across international markets without additional adapters. The 400W LED High Mast Light delivers exceptional luminous efficacy of 130 lumens per watt, generating 52,000 lumens of stable light output sufficient to replace 800-1000W traditional lamps. Adjustable beam angle options—including 40°, 60°, 120°, and specialized 140°x60° configurations—allow precise light distribution tailored to specific site geometries. Advanced thermal management systems maintain optimal operating temperatures from -40°C to 60°C, while IP67-rated enclosures provide complete protection against dust ingress and water immersion. Color temperature flexibility spanning 2700K to 6500K enables customization for different visual requirements, while high color rendering indices (Ra>75, with Ra>90 available) ensure accurate color perception crucial for security and operational applications.

Primary Applications and Installation Environments

LED High Mast Light installations serve critical functions across diverse sectors requiring reliable large-area illumination. Transportation infrastructure represents the largest application segment, with systems illuminating highway interchanges, toll plazas, railway yards, and bridge approaches where enhanced visibility directly improves traffic safety and flow efficiency. Port facilities and airports depend on high mast lighting for container yards, apron areas, and cargo handling zones operating continuously regardless of weather conditions. Industrial complexes including petroleum refineries, chemical plants, manufacturing facilities, and mining operations require robust lighting solutions capable of withstanding harsh environmental conditions while maintaining consistent performance. The 400W LED High Mast Light proves particularly effective for sports venues, stadiums, large parking facilities, and public spaces where uniform illumination coverage enhances user experience and security. Municipal applications extend to public parks, commercial centers, and event grounds where aesthetic considerations complement functional lighting requirements, demonstrating the versatility of modern LED technology.

Comparing LED High Mast Light with Traditional Lighting Solutions

| Feature | LED High Mast Light (400W) | Traditional HID (800-1000W) | Conventional Street Lighting |

|---|---|---|---|

| Energy Consumption | 400W total power | 800-1000W typical | Multiple 250W fixtures required |

| Luminous Efficacy | 130 lm/W | 64-110 lm/W (MH), 70-140 lm/W (HPS) | 80-100 lm/W average |

| Operational Lifespan | >50,000 hours | 15,000-20,000 hours | 20,000-30,000 hours |

| Start-up Time | Instant illumination | 5-10 minutes warm-up | 2-5 minutes |

| Color Quality | 2700K-6500K, Ra>75 | Limited CRI, orange tint (HPS) | Variable, often poor |

| Maintenance Requirements | Minimal, 5-year warranty | Frequent lamp replacement | Regular servicing needed |

| Environmental Impact | No toxic materials, RoHS compliant | Contains mercury, hazardous disposal | Moderate environmental concern |

| Light Distribution | Uniform, adjustable patterns | Uneven with hot spots | Limited coverage per fixture |

Performance Advantages of Modern LED Technology

The superiority of LED High Mast Light systems over traditional technologies extends far beyond simple energy efficiency metrics. Unlike metal halide lamps suffering from rapid lumen depreciation—often losing 30% of initial output within the first year—LED fixtures maintain consistent brightness throughout their operational life, with less than 10% degradation over 50,000 hours. The 400W LED High Mast Light eliminates the problematic warm-up and restrike periods inherent to HID technology, providing full illumination instantly upon activation, which proves critical for emergency response situations and security applications. Advanced LED optics utilizing precision-engineered lenses and multi-point light sources achieve remarkably uniform light distribution, eliminating the bright spots and dark zones characteristic of HID reflector systems. This uniformity translates directly into improved visibility for drivers navigating complex interchanges, enhanced security monitoring capabilities through consistent illumination levels, and reduced glare that can compromise visual comfort and safety.

Economic Benefits and Total Cost of Ownership Analysis

Financial considerations strongly favor LED High Mast Light adoption when analyzing total cost of ownership across complete system lifecycles. Initial investment in 400W LED High Mast Light fixtures typically recovers within 2-3 years through dramatic operational savings, as LED systems consume 50-70% less electricity than equivalent HID installations. A single 1000W HPS high mast fixture operating 12 hours daily at $0.12/kWh costs approximately $525 annually in electricity alone, while the 400W LED High Mast Light alternative reduces this to roughly $175, yielding $350 annual savings per fixture. Maintenance cost reductions prove equally impressive—traditional HID fixtures require lamp replacement every 1-2 years at $200-500 per service call including labor, equipment, and traffic management for roadway installations. LED systems from manufacturers like Xi'an Razorlux Optoelectronic Technology Co., Ltd. feature 5-year comprehensive warranties covering both LED modules and drivers, effectively eliminating maintenance expenses during the warranty period while extending service intervals to 7-10 years for routine inspections.

Environmental Sustainability and Regulatory Compliance

Contemporary environmental regulations and sustainability initiatives increasingly mandate LED High Mast Light adoption for public infrastructure projects. LED technology contains no hazardous materials such as mercury found in HID lamps, eliminating special disposal requirements and environmental contamination risks. The 400W LED High Mast Light meets stringent international standards including RoHS directives restricting hazardous substances, CE conformity requirements for European markets, UL safety certifications for North American installations, and DLC qualifications enabling utility rebate eligibility. Reduced energy consumption directly translates to lower carbon footprints—replacing a single 1000W HID fixture with a 400W LED High Mast Light prevents approximately 2.6 metric tons of CO2 emissions annually when powered by typical grid electricity. Advanced control capabilities including dimming, scheduling, and adaptive lighting further optimize energy utilization by reducing output during low-activity periods, potentially achieving additional 20-40% energy savings beyond base LED efficiency improvements while maintaining adequate illumination for safety and security requirements.

Installation and Maintenance Considerations

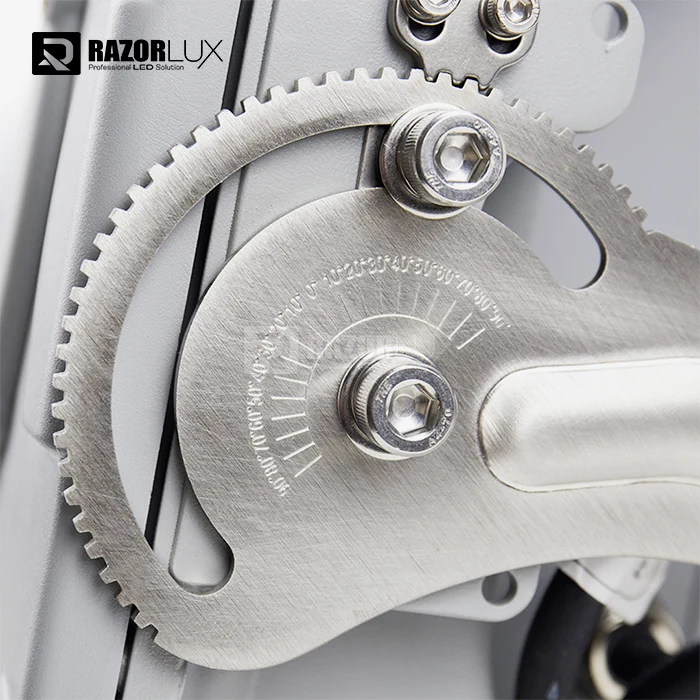

Successful LED High Mast Light implementation requires careful attention to installation practices and long-term maintenance planning. Pole foundations must extend 15-25 feet into stable soil or bedrock, with engineering calculations accounting for wind loading, seismic requirements, and luminaire weight to ensure structural integrity throughout the system's design life. Modern high mast poles incorporate lowering mechanisms enabling complete luminaire assemblies to descend to ground level for maintenance, eliminating dangerous elevated work and traffic disruption associated with conventional servicing methods. The 400W LED High Mast Light from reputable manufacturers features modular construction allowing field replacement of individual components without complete fixture removal, significantly reducing service time and costs. Electrical infrastructure must accommodate the LED High Mast Light's universal voltage capabilities (AC110-480Vac), with proper surge protection, grounding, and lightning arrestor systems protecting sensitive LED drivers from power anomalies. Photometric testing during installation verifies compliance with lighting design specifications, ensuring uniform illumination levels meet safety standards and operational requirements for the specific application.

Advanced Features and Customization Options for LED High Mast Light

Intelligent Control Systems and Smart Lighting Integration

Modern LED High Mast Light systems incorporate sophisticated control technologies that transform static illumination into dynamic, responsive lighting environments. Advanced control platforms support multiple communication protocols including DALI (Digital Addressable Lighting Interface), 0-10V analog dimming, and wireless systems such as ZigBee, enabling seamless integration with building management systems and smart city infrastructure. The 400W LED High Mast Light can be programmed with astronomical timers automatically adjusting operation based on sunset/sunrise calculations, eliminating manual intervention while maximizing energy efficiency. Motion sensing capabilities allow fixtures to operate at reduced output during low-activity periods, increasing to full brightness upon detecting vehicle or pedestrian movement, achieving energy savings up to 50% in intermittently used areas. Real-time monitoring systems track individual fixture performance, energy consumption, and operational hours, providing maintenance alerts before failures occur and optimizing replacement scheduling. Emergency lighting protocols can override normal operation during power outages, with optional battery backup systems maintaining critical illumination for 2-hour durations as developed by Xi'an Razorlux Optoelectronic Technology Co., Ltd., ensuring continuous safety and security during infrastructure disruptions.

Optical Design and Beam Pattern Configuration

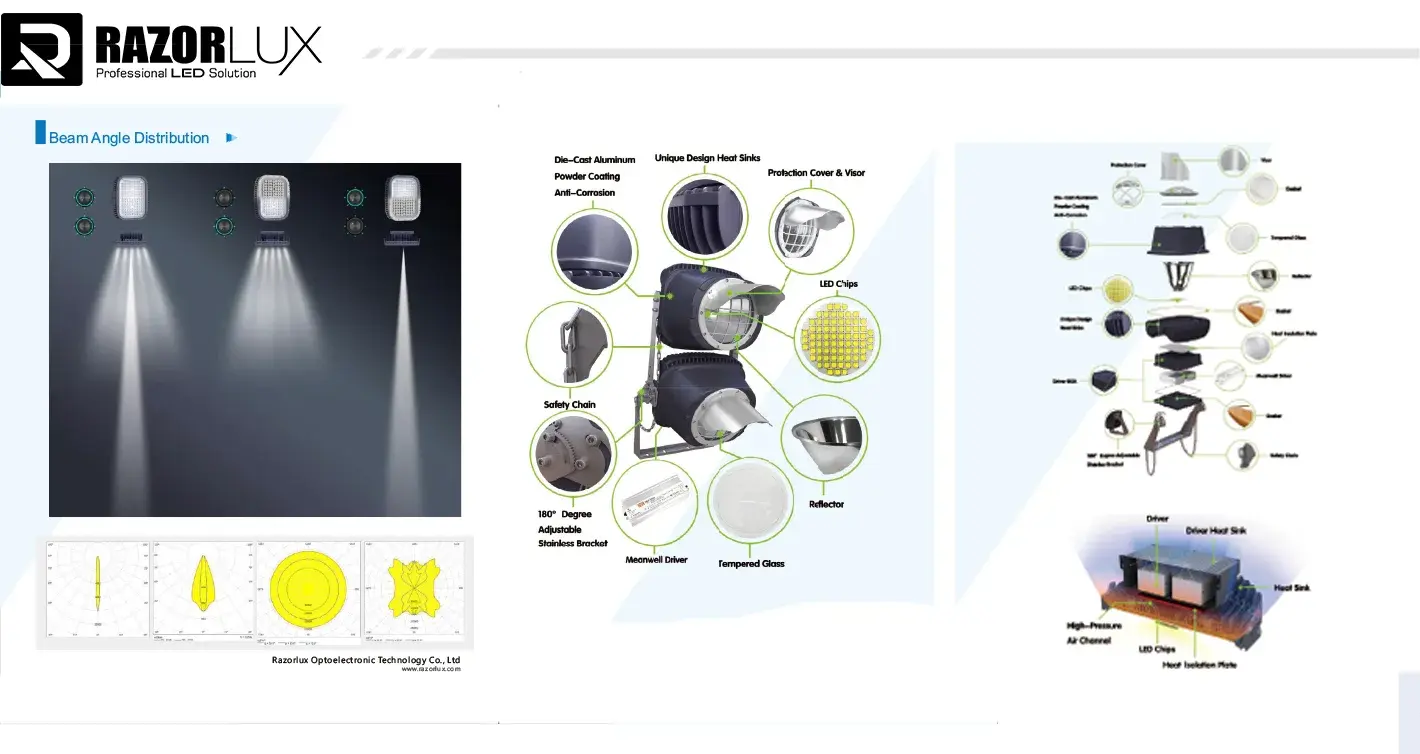

Sophisticated optical engineering distinguishes superior LED High Mast Light products from generic alternatives, with precision-designed lens systems controlling light distribution for optimal performance. Multiple beam angle configurations—40° for concentrated spot illumination, 60° for general area coverage, 120° for expansive floodlighting, and specialized asymmetric patterns like 140°x60°—address diverse application requirements through different lens assemblies. The 400W LED High Mast Light utilizes multi-point LED architecture distributing light sources across the fixture face rather than relying on a single central source, inherently producing more uniform illumination with reduced glare compared to HID reflector systems. Advanced computational optics employ ray-tracing algorithms optimizing lens geometry for specific mounting heights and coverage areas, maximizing useful lumens delivered to target surfaces while minimizing light trespass into adjacent properties. Anti-glare features including cutoff shields, louvers, and backlight control options address concerns about light pollution and residential complaints near high mast installations, enabling compliance with dark sky regulations and municipal ordinances without compromising functional illumination requirements.

Durability Features and Environmental Protection

The demanding environments where LED High Mast Light systems operate necessitate exceptional durability exceeding standard commercial lighting specifications. Premium fixtures feature die-cast aluminum housings with powder coating providing superior corrosion resistance essential for marine environments, chemical processing facilities, and coastal installations exposed to salt air. The 400W LED High Mast Light incorporates IP67-rated sealing protecting internal components against complete dust ingress and water immersion up to 1 meter depth, ensuring reliable operation during heavy rain, snow, and flooding conditions. Impact resistance rated IK10—the maximum protection level—enables fixtures to withstand severe mechanical impacts from flying debris, vandalism attempts, and accidental contact during maintenance operations. Advanced thermal management systems utilizing precision-engineered heat sinks and convection cooling maintain LED junction temperatures within optimal ranges, preventing premature failure from thermal stress while maximizing luminous efficacy. Marine-grade stainless steel mounting brackets and hardware resist corrosion even in aggressive atmospheric conditions, with optional specialized coatings available for extreme environments such as offshore platforms and chemical plants where standard materials prove inadequate.

Customization Capabilities and OEM Services

Leading manufacturers like Xi'an Razorlux Optoelectronic Technology Co., Ltd. offer extensive customization options enabling LED High Mast Light solutions precisely tailored to specific project requirements. Power configurations span from 200W for smaller applications to 750W for massive areas requiring extreme illumination levels, with the 400W LED High Mast Light representing the optimal balance for most standard installations. Color temperature customization accommodates diverse preferences and functional requirements—warm 2700K for hospitality environments, neutral 4000K for general industrial use, and cool 5700K for security applications demanding maximum visual acuity. Housing finishes beyond standard powder coat include anodized aluminum, marine-grade anti-corrosion treatments, and custom color matching for architectural integration or corporate branding requirements. OEM and ODM services enable private labeling, custom mechanical designs integrating specific mounting interfaces, and specialized electrical configurations addressing unique voltage requirements or control system compatibility. Pre-sales consultation services include photometric analysis and lighting design calculations utilizing professional software, generating detailed illumination predictions ensuring proposed LED High Mast Light configurations meet all project specifications before manufacturing begins.

Technical Specifications Comparison Table for LED High Mast Light Options

| Specification Category | 400W LED High Mast Light (RGL2-400A) | 300W Variant | 600W High-Output Model |

|---|---|---|---|

| Total Power Consumption | 400W (360W LED + 40W driver) | 300W total | 600W total |

| Luminous Output | 52,000 lumens stable | 39,000 lumens | 78,000 lumens |

| Efficacy | 130 lm/W | 130 lm/W | 130 lm/W |

| HID Replacement | 800-1000W equivalent | 600-750W equivalent | 1200-1500W equivalent |

| Beam Angle Options | 40°, 60°, 120°, 140°x60° | 40°, 60°, 120° | 40°, 60°, 120°, 140°x60° |

| Color Temperature Range | 2700K-6500K | 3000K-6000K | 2700K-6500K |

| Operating Voltage | AC110-480V / DC100-800V | AC110-277V | AC110-480V / DC100-800V |

| Operational Lifespan | >50,000 hours | >50,000 hours | >50,000 hours |

| Weight with Bracket | 15 kg | 12 kg | 18 kg |

| Warranty Coverage | 5 years LED/driver, 10 years housing | 5 years LED/driver | 5 years LED/driver, 10 years housing |

| Typical Installation Height | 15-30 meters | 12-25 meters | 20-40 meters |

| Coverage Area (at 20m height) | ~2,500 sq meters | ~1,800 sq meters | ~3,500 sq meters |

Quality Assurance and Manufacturing Excellence

The reliability of LED High Mast Light systems depends fundamentally on manufacturing quality and rigorous testing protocols. Xi'an Razorlux Optoelectronic Technology Co., Ltd., with over 200 patents covering LED Packaging, power control, and structural design, exemplifies industry-leading manufacturing practices ensuring consistent product performance. ISO 9001-certified production facilities implement comprehensive quality control at every manufacturing stage—from incoming component inspection through final photometric testing in integrating sphere laboratories. Each 400W LED High Mast Light undergoes aging tests simulating extended operational periods, identifying potential failure modes before products reach customers and ensuring published specifications reflect real-world performance rather than theoretical maximums. Photometric testing verifies actual luminous output, beam patterns, and color characteristics match design specifications, with detailed test reports available for critical projects requiring documentation. Driver quality proves particularly critical for LED system reliability, with premium manufacturers utilizing Meanwell or equivalent power supplies featuring >0.98 power factor, <10% total harmonic distortion, and comprehensive protection circuits guarding against voltage surges, thermal overload, and short circuit conditions that could compromise system integrity.

Certification Compliance and International Standards

Global deployment of LED High Mast Light systems requires compliance with diverse regional safety and performance standards. Comprehensive certification portfolios enable single product designs serving multiple markets, reducing engineering costs and simplifying international procurement. The 400W LED High Mast Light from established manufacturers holds UL listings for North American markets, ensuring electrical safety and fire prevention compliance. European CE marking demonstrates conformity with EU directives covering electromagnetic compatibility, low voltage safety, and environmental requirements. Australian SAA and C-Tick certifications enable deployment throughout Oceania markets, while Russian Maritime Register Society (RMRS) approval qualifies fixtures for marine and offshore applications. DLC (DesignLights Consortium) qualification enables utility rebate eligibility throughout North America, often offsetting 20-30% of initial installation costs through incentive programs promoting energy efficiency. Environmental certifications including RoHS compliance confirm absence of hazardous substances, while CB scheme certificates facilitate acceptance across 54 countries participating in this mutual recognition system, dramatically simplifying approval processes for multinational projects.

Global Supply Chain and Logistics Support

Successful LED High Mast Light procurement requires reliable global logistics capabilities ensuring timely delivery regardless of project location. Xi'an Razorlux Optoelectronic Technology Co., Ltd. operates comprehensive supply chain infrastructure including subsidiaries in the USA and Hong Kong, strategically positioned to serve North American, European, and Asian markets efficiently. Multiple transportation options accommodate diverse project timelines and budgets—international express services (DHL, FedEx, UPS) deliver small orders weighing 0.5-300kg within 3-7 days, optimal for urgent sample requirements or replacement parts. Air freight options provide economical 5-10 day delivery for shipments exceeding 300kg, significantly reducing costs compared to express services while maintaining reasonable transit times. China-Europe Railway Express offers 18-22 day delivery for shipments exceeding 2 cubic meters or 500kg, providing cost-effective intermediate option between premium air freight and extended ocean shipping. Sea freight remains the most economical choice for large orders, with 15-50 day transit times depending on destination port, suitable for non-urgent projects where cost optimization outweighs delivery speed considerations. Protective packaging utilizing custom-cut foam bases, accessory compartments, reinforced cartons, and optional wooden crates ensures 400W LED High Mast Light fixtures arrive undamaged despite lengthy international journeys.

Conclusion

LED High Mast Light technology represents the optimal solution for large-area illumination challenges across transportation, industrial, and municipal applications. The 400W LED High Mast Light delivers exceptional performance combining energy efficiency, reliability, and advanced features that traditional lighting systems simply cannot match.

Ready to upgrade your facility with cutting-edge LED High Mast Light solutions? Xi'an Razorlux Optoelectronic Technology Co., Ltd., a leading China LED High Mast Light manufacturer and China LED High Mast Light supplier, offers comprehensive solutions backed by over 20 years of experience and 200+ patents. As a trusted China LED High Mast Light factory, we provide competitive LED High Mast Light wholesale pricing with LED High Mast Light for sale globally. Contact our professional team today for China LED High Mast Light supplier quotes and competitive LED High Mast Light price information at sam@razorlux.com to discuss your specific requirements and receive customized lighting solutions.

References

1. Texas Transportation Institute. "High Mast Lighting Systems for Highway Applications: Design, Installation, and Maintenance Guidelines." Texas Department of Transportation Research Report, 1970.

2. Illuminating Engineering Society of North America. "Recommended Practice for Roadway Lighting (ANSI/IES RP-8-18)." IES Technical Standards Committee, 2018.

3. U.S. Department of Energy. "LED Lighting for High Mast Applications: Energy Savings and Performance Evaluation." Solid-State Lighting Program Gateway Demonstrations, 2016.

4. International Commission on Illumination. "Lighting of Roads for Motor and Pedestrian Traffic (CIE 115:2010)." Commission Internationale de l'Eclairage Technical Report, 2010.

VIEW MOREoutdoor riding arena lights

VIEW MOREoutdoor riding arena lights VIEW MOREled ball field lights

VIEW MOREled ball field lights VIEW MOREoutdoor court lights

VIEW MOREoutdoor court lights VIEW MOREoutdoor basketball court lighting

VIEW MOREoutdoor basketball court lighting VIEW MOREled flood light for football field

VIEW MOREled flood light for football field VIEW MOREMarine Led Spotlights For Boats

VIEW MOREMarine Led Spotlights For Boats VIEW MOREHot Products Aluminum Alloy floodlight 1000w led flood light for Indoor Outdoor Sports Venue

VIEW MOREHot Products Aluminum Alloy floodlight 1000w led flood light for Indoor Outdoor Sports Venue VIEW MORE1000 Watt Stadium Light

VIEW MORE1000 Watt Stadium Light

_1750326878398.png)