explosion proof led high bay lights

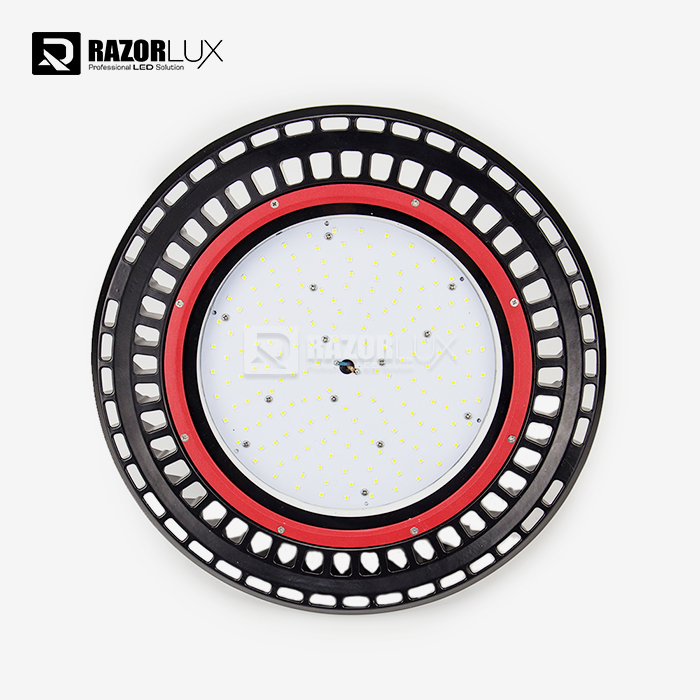

Model No.: RHB-UA-200

Rated Power: 100W, 150W, 200W,240W

Input Voltage: AC85-265V

Color Temperature: 3000-6500K Lamp Efficiency: 120lm/w Beam Angle: 60°, 120°

CRI: Ra>75

IP Grade: IP65

Dimension: Ø280*185 mm(100W), Ø340*187mm (150W), Ø400*196 mm(200W)

Net Weight: 3.8kg, 4.9kg, 6.8kg Certificate: CE, RoHS

Warranty: 5 Years

- Product Description

Industrial Explosion Proof LED High Bay Lights - Professional Safety Lighting Solutions

Product Introduction

When your office requires solid, secure lighting in unsafe situations, our explosion proof LED High Bay Lights convey uncompromising execution where security things most. These industrial-grade lighting arrangements combine progressed Driven innovation with strong explosion-proof lodging planned for Zone 1 and Zone 2 perilous locations.

Built with premium Lumileds and Samsung LEDs, our lights accomplish exceptional vitality effectiveness whereas keeping up the most noteworthy security measures. Each installation highlights an outside Meanwell driver for predominant warm dissemination and disentangled upkeep access.

| Specification | Details |

|---|---|

| Model | RHB-EX-200 Series |

| Power Options | 100W, 150W, 200W, 240W |

| Input Voltage | AC85-265V |

| Luminous Efficacy | 120lm/w |

| Color Temperature | 3000K-6500K |

| Beam Angle | 60°, 120° |

| CRI | Ra>75 |

| Protection Rating | IP66/IP67 |

| Explosion Proof | Ex d IIC T6 Gb |

| Dimensions | Ø280×185mm (100W), Ø340×187mm (150W), Ø400×196mm (200W) |

| Weight | 5.2kg, 6.8kg, 8.5kg |

| Warranty | 5 Years |

Why Choose Our Explosion Proof LED High Bay Lights?

Superior Security Building: Our installations meet rigid ATEX and IECEx guidelines for dangerous area lighting. Each unit experiences thorough testing to guarantee solid operation in unstable atmospheres.

Advanced Warm Administration: The outside driver plan advances amazing warm dissemination, amplifying Driven life expectancy whereas keeping up reliable light yield all through the product's operational life.

Energy Effectiveness: Accomplish up to 70% vitality investment funds compared to conventional Stowed away lighting whereas conveying predominant brightening quality for your mechanical operations.

Durable Development: Marine-grade aluminum lodging with specialized powder coating gives extraordinary erosion resistance and mechanical security in cruel mechanical environments.

Easy Upkeep: Outside driver arrangement rearranges overhauling without compromising the explosion-proof judgment of the lighting system.

Applications

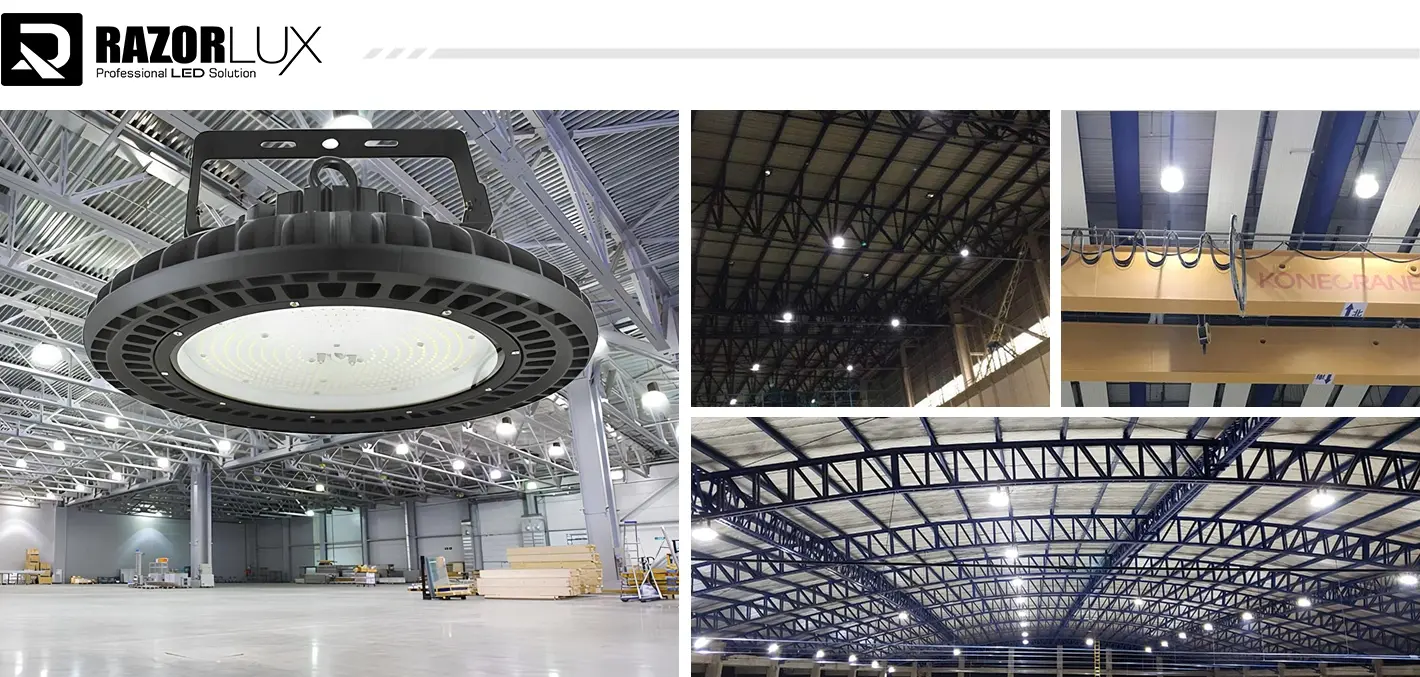

Our mechanical blast verification driven tall narrows lights serve basic security lighting needs over different dangerous environments:

• Oil and Gas Refineries: Stage lighting, preparing zones, tank ranches, and seaward penetrating operations

• Chemical Handling Plants: Reactor lobbies, blending zones, capacity offices, and research facility spaces

• Paint and Coating Offices: Splash booths, drying ranges, dissolvable capacity, and blending rooms

• Pharmaceutical Fabricating: Clean rooms, powder taking care of ranges, and dissolvable handling zones

• Nourishment Handling Businesses: Grain lifts, flour plants, sugar preparing, and liquor generation facilities

• Mining Operations: Underground burrows, handling plants, coal planning regions, and upkeep shops

• Marine Applications: Motor rooms, fuel capacity ranges, pump rooms, and deck lighting on tanker vessels

• Air ship Storages: Support zones, fuel frameworks, and specialized air ship adjusting zones

• Squander Water Treatment: Methane handling regions, digester offices, and chemical treatment zones

• Material Fabricating: Fiber handling, coloring operations, and chemical treatment areas

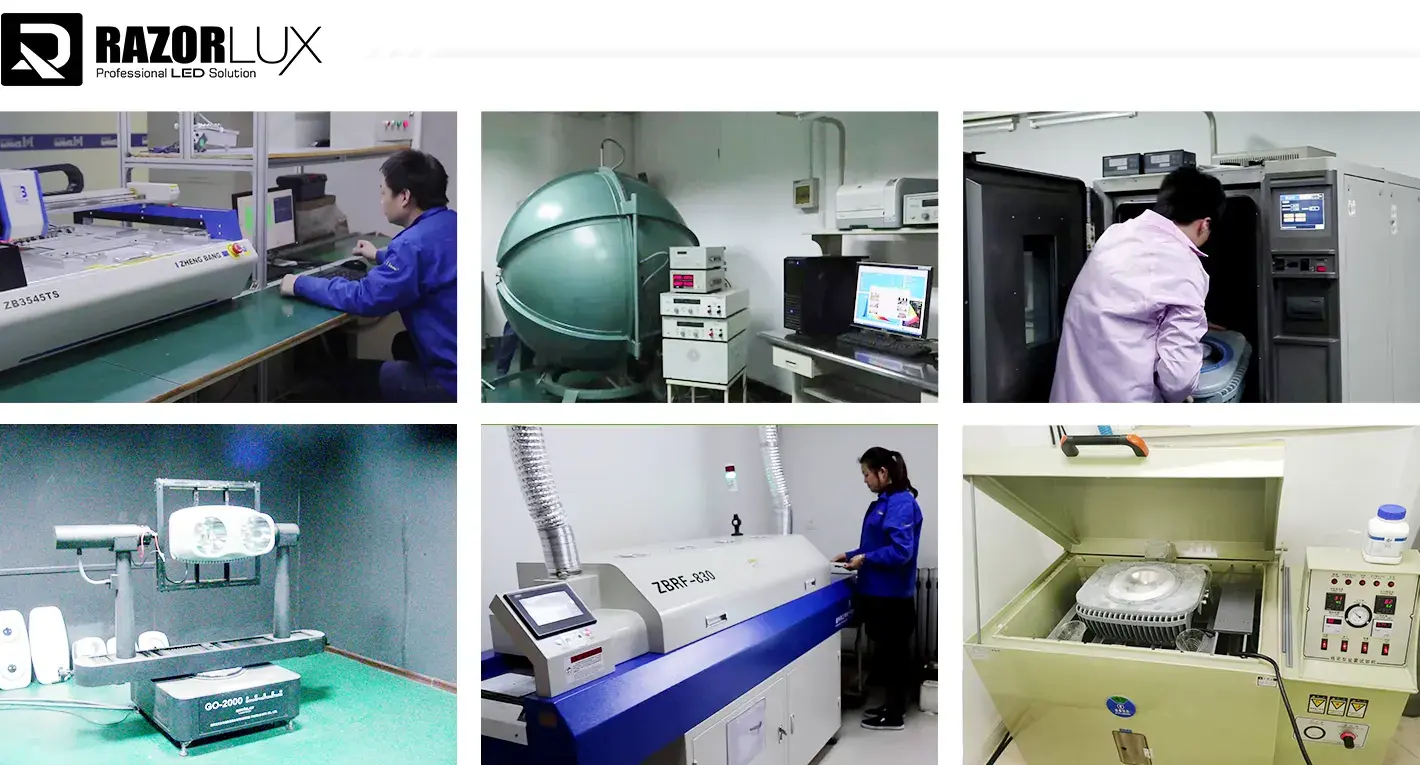

Quality Control

At Razorlux, we keep up ISO9001 certification for over 22 sequential a long time. Our military-grade quality control framework guarantees each blast verification driven tall cove lights unit meets the most elevated security and execution standards.

Each installation experiences comprehensive testing counting weight testing, temperature cycling, vibration resistance, and photometric confirmation some time recently taking off our facility.

Shipment Samples

We give pre-production tests for assessment and endorsement. Test lead time is regularly 7-10 commerce days, permitting you to confirm execution and compatibility some time recently bulk generation begins.

Packaging and Transportation

Each unit gets person defensive bundling with shock-absorbing materials. We offer adaptable shipping choices counting discuss cargo for pressing ventures and ocean cargo for cost-effective bulk orders. All shipments incorporate comprehensive documentation for traditions clearance.

Transaction Feedback

Our clients reliably report progressed security compliance, diminished upkeep costs, and upgraded operational proficiency after introducing our lighting frameworks. We keep up long-term organizations with major mechanical administrators worldwide.

After Sales Service

We stand behind our items with comprehensive 5-year guarantee scope. Our specialized bolster group gives establishment direction, investigating help, and substitution portion administrations all through the item lifecycle.

Qualification Certification

Our explosion proof led high bay lights frameworks hold ATEX, IECEx, UL844, CSA certifications for dangerous area applications. Extra certifications incorporate CE, RoHS, and marine classification society endorsements.

FAQ

Q: What explosion-proof certifications do these high bay lights hold?

A: Our fixtures are certified to Ex d IIC T6 Gb standards with ATEX and IECEx approvals for Zone 1 and Zone 2 applications.

Q: Can the color temperature be customized for specific applications?

A: Yes, we offer color temperatures from 3000K to 6500K to meet your specific lighting requirements.

Q: What is the expected lifespan of these LED high bay lights?

A: Our LEDs are rated for 50,000+ hours of operation with L80 lumen maintenance, backed by our 5-year warranty.

Q: Are dimming controls available for these fixtures?

A: Yes, we offer 0-10V and DALI dimming options for applications requiring variable lighting levels.

Q: What mounting options are available?

A: We provide pendant mounting, surface mounting, and custom bracket options to suit various installation requirements.

Q: How do these compare to traditional HID lighting in hazardous locations?

A: Our LED solutions offer immediate full brightness, no warm-up time, significantly lower heat generation, and up to 70% energy savings compared to metal halide alternatives.

Contact Us

For technical specifications, custom solutions, or project consultation, please contact our explosion proof led high bay lights specialists at: sam@razorlux.com

VIEW MOREEnergy Saving Dimmable LED Flood Light With Stainless Steel Bracket

VIEW MOREEnergy Saving Dimmable LED Flood Light With Stainless Steel Bracket VIEW MOREWaterproof Dimmable LED Flood Light Aluminum Housing 200W

VIEW MOREWaterproof Dimmable LED Flood Light Aluminum Housing 200W VIEW MOREWaterpoof IP67 Reflector Flood Light 100w Outdoor Ex Proof Led Flood Light

VIEW MOREWaterpoof IP67 Reflector Flood Light 100w Outdoor Ex Proof Led Flood Light VIEW MORE400w Dimmable LED Flood Light High Lumen Narrow Beam

VIEW MORE400w Dimmable LED Flood Light High Lumen Narrow Beam VIEW MOREIP67 Super Bright Security Light Outdoor Flood 6500K 400W

VIEW MOREIP67 Super Bright Security Light Outdoor Flood 6500K 400W VIEW MOREHigh Pole Garden Flood Lights 10800 Lm 90w Led Flood Light Ip67

VIEW MOREHigh Pole Garden Flood Lights 10800 Lm 90w Led Flood Light Ip67 VIEW MORE5000K Navigation Led Boat Deck Light IP65 Led Flood Lights 12 Volt Marine

VIEW MORE5000K Navigation Led Boat Deck Light IP65 Led Flood Lights 12 Volt Marine VIEW MOREFootball Field 140F Led Stadium Lights 1000 Watt 5700K Sports Lighting Fixtures

VIEW MOREFootball Field 140F Led Stadium Lights 1000 Watt 5700K Sports Lighting Fixtures

_1750326878398.png)