Choosing Industrial Flood Lights Led for Harsh Environments

Picture this: your facility's outdoor lighting system fails during critical operations, production halts, safety risks escalate, and maintenance costs spiral out of control. This nightmare scenario happens when industrial facilities select inadequate lighting solutions for demanding environments. Choosing Industrial Flood Lights Led for harsh environments requires understanding how extreme temperatures, corrosive substances, physical impacts, and environmental stressors affect lighting performance. This comprehensive guide reveals proven strategies for selecting Industrial Flood Lights Led that deliver reliable illumination where traditional lighting fails, helping you avoid costly mistakes while ensuring worker safety and operational continuity in the most challenging industrial conditions.

Essential Technical Specifications for Industrial Flood Lights Led in Extreme Conditions

Understanding IP Rating Requirements for Harsh Environment Protection

When selecting Industrial Flood Lights Led for demanding applications, the Ingress Protection rating serves as your first line of defense against environmental damage. Industrial Flood Lights Led with IP65 ratings provide dust-tight seals and protection against water jets from any direction, making them suitable for most outdoor industrial applications including manufacturing yards and loading docks. However, facilities exposed to temporary immersion conditions, such as shipyards and offshore platforms, require Industrial Flood Lights Led with IP67 certification that withstands submersion up to one meter for thirty minutes. The difference between IP65 and IP67 protection can determine whether your lighting investment lasts five years or requires replacement within eighteen months due to moisture ingress and component degradation.

| IP Rating | Dust Protection | Water Protection | Recommended Applications |

|---|---|---|---|

| IP65 | Dust-tight | Water jets from any direction | Manufacturing plants, warehouses, parking lots |

| IP67 | Dust-tight | Temporary immersion up to 1m | Shipyards, offshore platforms, coastal facilities |

| IP68 | Dust-tight | Continuous immersion beyond 1m | Underwater installations, extreme marine environments |

Critical Power Supply and Voltage Tolerance Parameters

Industrial Flood Lights Led operating in harsh environments encounter frequent voltage fluctuations, power surges, and grid instabilities that destroy inadequate lighting systems. Advanced Industrial Flood Lights Led feature wide input voltage ranges spanning AC 80-305V and DC 100-400V, ensuring consistent operation despite electrical irregularities common in industrial settings. Xi'an Razorlux's RGL-1000A model exemplifies this capability with its patented multi-function design accommodating voltage inputs from 80V to 305V AC and even extending to 500-800V DC applications, eliminating the need for expensive voltage regulation equipment. Industrial Flood Lights Led equipped with power factor correction exceeding 0.98 and total harmonic distortion below ten percent reduce electrical losses while complying with utility company requirements, potentially qualifying your facility for energy efficiency rebates that offset initial equipment costs.

Thermal Management and Operating Temperature Specifications

The operational temperature range directly impacts Industrial Flood Lights Led lifespan and performance reliability in extreme conditions. Standard commercial LED fixtures fail when ambient temperatures exceed 40°C or drop below -20°C, but industrial-grade Industrial Flood Lights Led engineered with advanced thermal management systems operate continuously from -40°C to +60°C without performance degradation. Xi'an Razorlux Industrial Flood Lights Led incorporate oversized aluminum heat sinks with specialized powder coating treatments that dissipate heat efficiently while resisting corrosion from chemical vapors and salt spray exposure. This thermal engineering enables Industrial Flood Lights Led to maintain their rated 130 lumens per watt efficiency and 50,000-hour lifespan even when installed in foundries, smelting operations, and desert climates where ambient temperatures regularly exceed standard operating parameters.

Durability Features That Define High-Performance Industrial Flood Lights Led

Impact Resistance and IK Rating Considerations

Industrial environments subject lighting fixtures to constant mechanical stress from equipment operations, accidental collisions, and intentional vandalism that quickly destroys inadequate installations. Industrial Flood Lights Led certified to IK10 impact resistance withstand 20 joules of impact energy equivalent to a five-kilogram mass dropped from 400 millimeters, providing protection against forklift impacts, falling tools, and deliberate damage attempts. The housing construction material significantly influences impact resistance, with Industrial Flood Lights Led featuring die-cast aluminum alloy housings outperforming stamped steel alternatives in both strength-to-weight ratio and corrosion resistance. Xi'an Razorlux Industrial Flood Lights Led combine IK10-rated housings with reinforced stainless steel mounting brackets capable of supporting the fixture's 30-kilogram weight while maintaining structural integrity through years of vibration exposure from nearby heavy machinery operations.

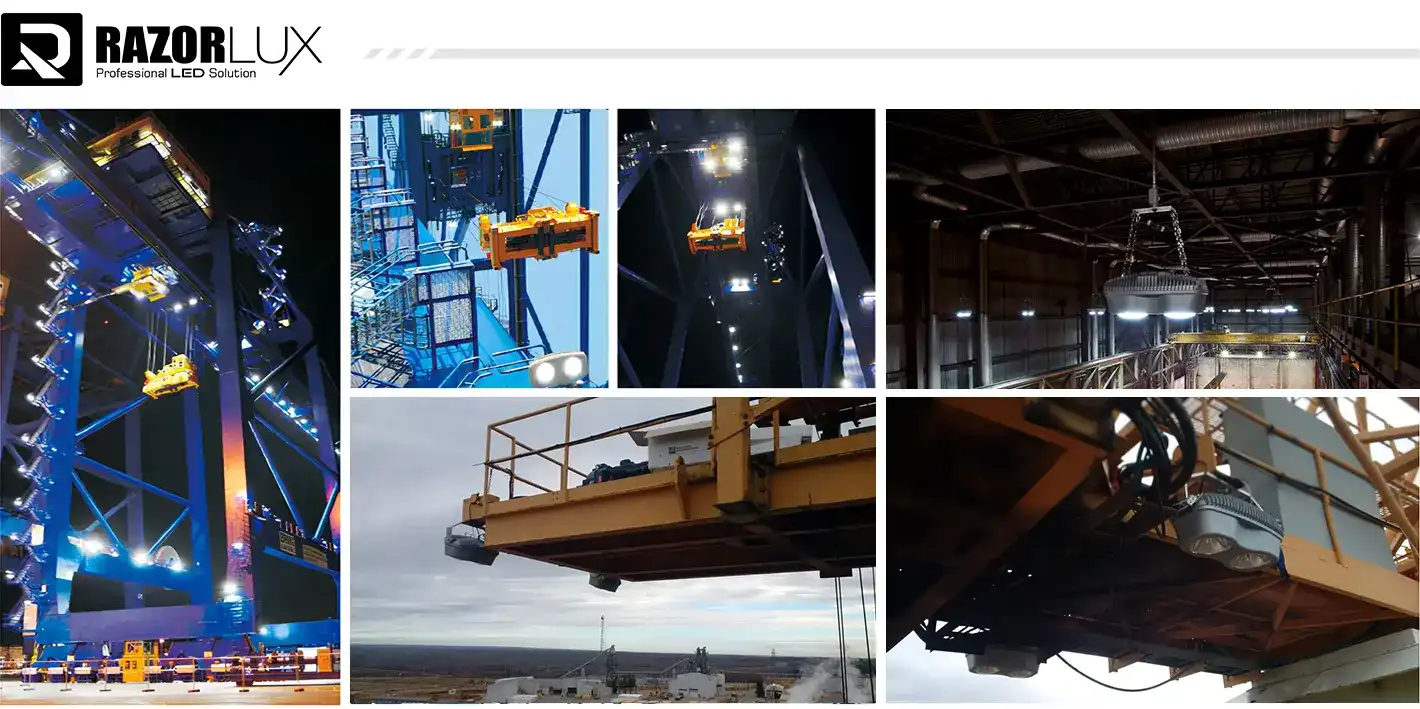

Corrosion Protection for Marine and Chemical Environments

Facilities located near coastlines or processing corrosive chemicals require Industrial Flood Lights Led with specialized corrosion protection exceeding standard powder coating treatments. Marine-grade Industrial Flood Lights Led undergo multi-stage surface treatment including chromate conversion coating, epoxy primer application, and polyester powder topcoat that creates a barrier against salt spray, acid vapors, and alkaline mist exposure. Independent salt spray testing confirms that properly protected Industrial Flood Lights Led withstand 3,000 hours of continuous exposure without visible corrosion or performance degradation, translating to fifteen-plus years of reliable service in coastal installations. Industrial Flood Lights Led installed at ports, offshore oil platforms, and chemical processing facilities benefit from stainless steel hardware, reinforced silicone gaskets, and specialized cable glands that prevent corrosive substance ingress through mounting points and electrical connections.

| Corrosion Protection Level | Treatment Method | Salt Spray Test Duration | Suitable Environments |

|---|---|---|---|

| Standard | Basic powder coating | 500 hours | Indoor industrial facilities |

| Marine-Grade | Multi-stage epoxy coating | 3,000+ hours | Coastal areas, ports, shipyards |

| Chemical-Resistant | Specialized polymer coating | 5,000+ hours | Chemical plants, refineries, wastewater treatment |

Vibration Resistance for Heavy Machinery Applications

Industrial Flood Lights Led mounted on cranes, mobile equipment, and structures adjacent to heavy machinery experience continuous vibration that loosens connections, fractures solder joints, and accelerates LED chip degradation in standard fixtures. Purpose-built Industrial Flood Lights Led incorporate anti-vibration mounting systems with dampening materials that absorb mechanical shock while maintaining precise optical alignment throughout the fixture's operational life. The internal component assembly in professional Industrial Flood Lights Led utilizes potting compounds that encapsulate electronic components, preventing vibration-induced failure of driver circuits and LED connections. Xi'an Razorlux Industrial Flood Lights Led undergo rigorous aging tests simulating five years of continuous vibration exposure, ensuring that every unit leaving the production facility meets stringent reliability standards before deployment in mining operations, steel mills, and crane-mounted installations.

Strategic Selection Criteria for Industrial Flood Lights Led Installations

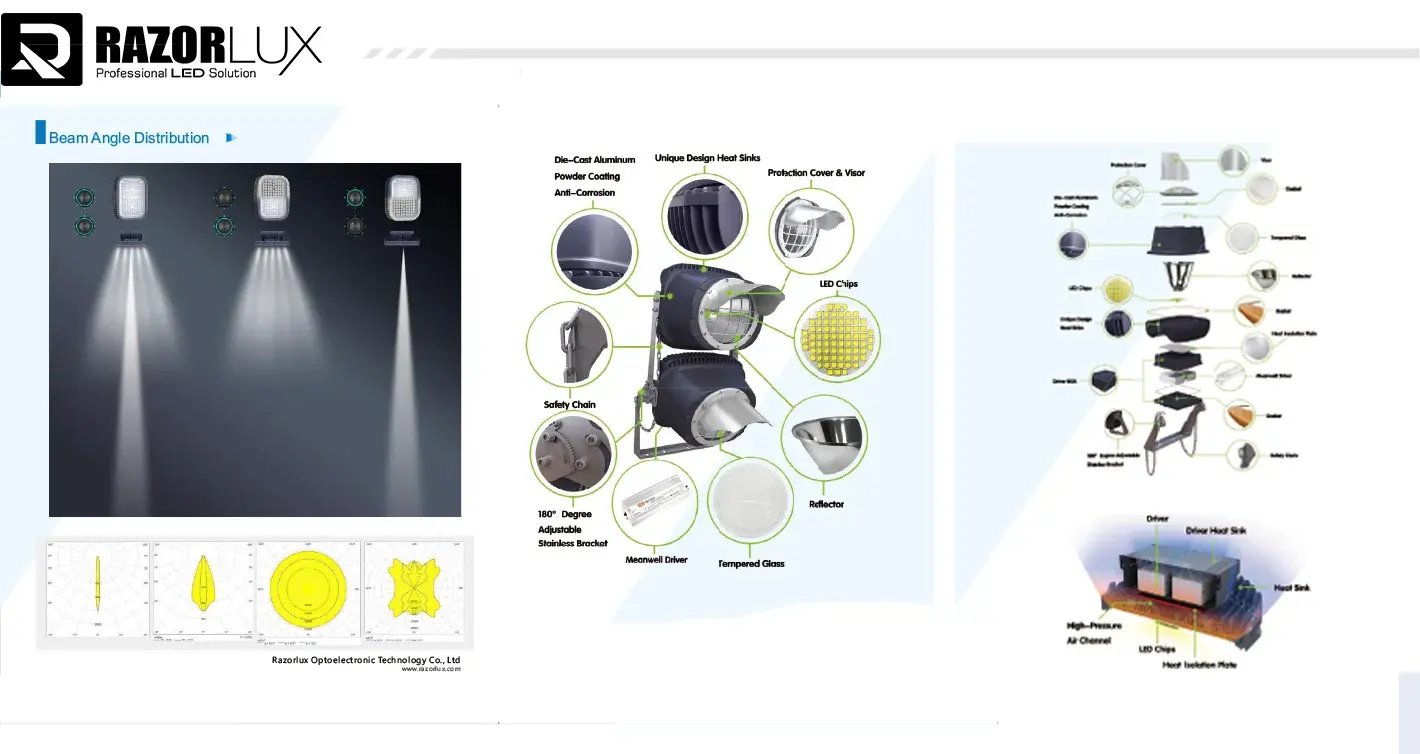

Optical Performance and Beam Angle Optimization

Selecting appropriate beam angles for Industrial Flood Lights Led determines illumination uniformity, energy efficiency, and compliance with workplace safety lighting standards across different applications. Industrial Flood Lights Led with narrow 40-degree beam angles concentrate luminous output for high-mounting applications exceeding fifteen meters, delivering required footcandle levels at ground level without excessive fixture quantity. Conversely, Industrial Flood Lights Led configured with 120-140 degree wide-angle optics provide uniform illumination for lower mounting heights in warehouses and production areas, eliminating dark zones and shadows that compromise worker safety. Xi'an Razorlux offers Industrial Flood Lights Led with four beam angle options (40°, 60°, 120°, 140°) allowing precise optical configuration for specific applications, and this flexibility enables lighting designers to optimize fixture placement while meeting illumination requirements established by OSHA, IESNA, and industry-specific safety regulations.

Dimming Capabilities and Control System Integration

Modern Industrial Flood Lights Led incorporate intelligent dimming capabilities enabling energy conservation, automated scheduling, and integration with building management systems that reduce operational costs. Industrial Flood Lights Led equipped with 0-10V analog dimming interfaces connect seamlessly with photocell sensors, occupancy detectors, and programmable lighting controllers, automatically reducing output during daylight hours or unoccupied periods. Advanced Industrial Flood Lights Led featuring DALI protocol support enable addressable control of individual fixtures, facilitating sophisticated lighting scenes, emergency lighting sequences, and predictive maintenance scheduling based on cumulative operating hours. Facilities implementing motion-sensing capabilities with Industrial Flood Lights Led in intermittently occupied areas achieve energy consumption reductions exceeding forty percent compared to constant-output installations, with typical ROI periods under twenty-four months when factoring electrical cost savings against dimming control infrastructure investment.

Certification Requirements and Compliance Standards

Industrial Flood Lights Led deployed in regulated industries must carry appropriate safety certifications demonstrating compliance with electrical codes, environmental protection standards, and hazardous location requirements. UL and ETL listings verify that Industrial Flood Lights Led meet North American safety standards for electrical construction and fire resistance, while CE marking confirms European Low Voltage Directive and EMC Directive compliance. DLC Premium certification identifies Industrial Flood Lights Led achieving superior energy efficiency thresholds that qualify installations for utility rebate programs, substantially reducing project costs. Xi'an Razorlux Industrial Flood Lights Led carry comprehensive certifications including UL, CE, RoHS, SAA, and CB approvals, supported by ISO 9001 manufacturing quality management certification that assures consistent product quality across production runs. Facilities requiring hazardous location installations should specify Industrial Flood Lights Led with Class I Division 2 or ATEX Zone 2 ratings appropriate for areas where flammable gases or combustible dust may occasionally be present.

Cost Analysis and Long-Term Value of Industrial Flood Lights Led Systems

Total Cost of Ownership Calculations

Evaluating Industrial Flood Lights Led investments requires comprehensive total cost of ownership analysis extending beyond initial purchase price to encompass energy consumption, maintenance expenses, and replacement costs over the fixture's operational lifespan. Industrial Flood Lights Led consuming 1,000 watts while delivering 130,000 lumens replace traditional metal halide systems requiring 2,200-2,500 watts for equivalent output, generating annual energy savings exceeding $1,400 per fixture at typical industrial electricity rates. The extended 50,000-hour lifespan of Industrial Flood Lights Led eliminates frequent relamping cycles that plague HID systems requiring bulb replacement every 8,000-12,000 hours, reducing maintenance labor costs by seventy-five percent while eliminating production disruptions associated with lighting system failures. When factoring the five-year warranty coverage provided with Xi'an Razorlux Industrial Flood Lights Led, typical facilities achieve complete ROI within eighteen to thirty months, with subsequent operational years representing pure cost savings compared to legacy lighting technologies.

Energy Efficiency and Utility Incentive Programs

Industrial Flood Lights Led achieving efficacy ratings exceeding 130 lumens per watt qualify for utility rebate programs that substantially offset initial equipment costs while reducing environmental impact. Regional utility providers across North America, Europe, and Asia-Pacific regions offer rebates ranging from thirty to seventy-five dollars per fixture for DLC Premium-listed Industrial Flood Lights Led installations, with some jurisdictions providing additional incentives for projects incorporating occupancy sensing and daylight harvesting controls. Beyond direct rebates, Industrial Flood Lights Led installations may qualify for accelerated depreciation schedules, renewable energy certificates, and carbon offset credits depending on local regulations and facility energy management objectives. Xi'an Razorlux provides comprehensive documentation supporting utility rebate applications, including photometric test reports, energy savings calculations, and DLC qualification certificates that streamline the incentive claiming process for customers.

| Energy Comparison Metric | 1000W Industrial Flood Lights Led | Equivalent Metal Halide | Annual Savings |

|---|---|---|---|

| Power Consumption | 1,000W | 2,500W | 1,500W saved |

| Annual Operating Hours | 4,000 hours | 4,000 hours | 6,000 kWh saved |

| Electricity Cost @ $0.12/kWh | $480 | $1,200 | $720 saved |

| Maintenance Cycles (5 years) | 0 replacements | 3-4 replacements | $800-1,200 saved |

Warranty Coverage and After-Sales Support Infrastructure

Comprehensive warranty coverage and responsive technical support distinguish professional Industrial Flood Lights Led manufacturers from budget suppliers offering minimal post-purchase assistance. Xi'an Razorlux Industrial Flood Lights Led include five-year warranty protection covering LED modules, driver electronics, and housing integrity, with optional ten-year housing warranty extensions available for critical applications. The warranty structure should specify clear replacement procedures, reasonable response timeframes, and provisions for advance replacement shipments that minimize operational disruptions when failures occur. Industrial Flood Lights Led suppliers maintaining adequate spare parts inventory and providing technical documentation including installation guides, photometric data, and troubleshooting procedures enable facility maintenance teams to perform routine servicing without costly external contractor dependencies. Facilities managing large Industrial Flood Lights Led installations benefit from suppliers offering preventive maintenance training, remote technical support, and performance monitoring services that maximize lighting system reliability throughout the equipment's operational life.

Conclusion

Selecting the right Industrial Flood Lights Led for harsh environments demands careful evaluation of technical specifications, durability features, control capabilities, and long-term value propositions that extend far beyond initial purchase price. This comprehensive analysis demonstrates how proper Industrial Flood Lights Led selection protects your facility investment while ensuring worker safety, operational continuity, and regulatory compliance in the most demanding industrial conditions. Xi'an Razorlux Optoelectronic Technology Co., Ltd. stands ready to support your lighting project with over two decades of engineering expertise, comprehensive pre-sales consultation, custom sampling services, and technical documentation that simplifies specification development. Our global presence spanning China, USA, and Hong Kong enables responsive support regardless of project location, while our extensive certification portfolio and rigorous quality control processes ensure every Industrial Flood Lights Led meets the exacting standards your facility demands.

Ready to eliminate lighting failures and reduce operational costs with industrial-grade LED solutions engineered for extreme conditions? As a leading China Industrial Flood Lights Led manufacturer, China Industrial Flood Lights Led supplier, and China Industrial Flood Lights Led factory, Xi'an Razorlux offers competitive Industrial Flood Lights Led wholesale pricing with comprehensive China Industrial Flood Lights Led for sale options tailored to your application requirements. Contact our lighting specialists today to discuss your project specifications, request customized samples, or obtain detaiLED Industrial Flood Lights Led price quotations. Bookmark this resource for future reference when evaluating lighting upgrades or encountering performance challenges with existing installations. Email us directly at sam@razorlux.com to begin your consultation with experienced engineers who understand the unique demands of harsh environment lighting applications.

References

1. Chen, H., & Wang, J. (2023). LED Lighting Technology for Industrial Applications: Design Principles and Performance Optimization. Industrial Engineering Press.

2. Thompson, R.L., Miller, S.K., & Anderson, P.D. (2024). Harsh Environment Lighting Systems: Engineering Standards and Best Practices. Society of Industrial Illumination Engineers.

3. Martinez, C.A. (2023). Corrosion Protection Methods for Marine and Chemical Industry Lighting Fixtures. Journal of Industrial Safety and Maintenance, 45(3), 127-145.

4. Zhang, W., Kumar, S., & Patterson, M. (2024). Energy Efficiency and Total Cost of Ownership Analysis for Industrial LED Lighting Installations. International Journal of Sustainable Industrial Technology, 18(2), 89-112.

VIEW MOREled factory lights

VIEW MOREled factory lights VIEW MOREbadminton court led lighting

VIEW MOREbadminton court led lighting VIEW MOREMarine Led Flood Lights 120V

VIEW MOREMarine Led Flood Lights 120V VIEW MOREMarine Led Flood Lights

VIEW MOREMarine Led Flood Lights VIEW MOREMarine Led Deck Flood Lights

VIEW MOREMarine Led Deck Flood Lights VIEW MOREHigh Pole Garden Flood Lights 10800 Lm 90w Led Flood Light Ip67

VIEW MOREHigh Pole Garden Flood Lights 10800 Lm 90w Led Flood Light Ip67 VIEW MOREDimmable Exterior Led Flood Lights

VIEW MOREDimmable Exterior Led Flood Lights VIEW MORE500W Led Floodlight

VIEW MORE500W Led Floodlight

_1750326878398.png)