Durable & Waterproof led loading lights for Harsh Sites

Picture this: it's 2 AM at your loading dock, rain pouring down, and your workforce is struggling to unload critical shipments under dim, failing lights. Accidents happen, productivity drops, and your operations grind to a halt. This scenario plays out daily at facilities using inadequate lighting solutions. When safety, efficiency, and operational continuity are on the line, you need led loading lights engineered specifically for harsh industrial environments. These specialized fixtures combine waterproof protection, exceptional brightness, and rugged construction to ensure your loading operations never compromise on visibility or safety, regardless of weather conditions or environmental challenges.

Essential Features of Industrial LED Loading Dock Lights

Modern led loading lights represent a significant advancement over traditional lighting technologies, incorporating features specifically designed to address the unique challenges of loading dock environments. Understanding these essential characteristics helps facility managers make informed decisions that directly impact operational safety and efficiency.

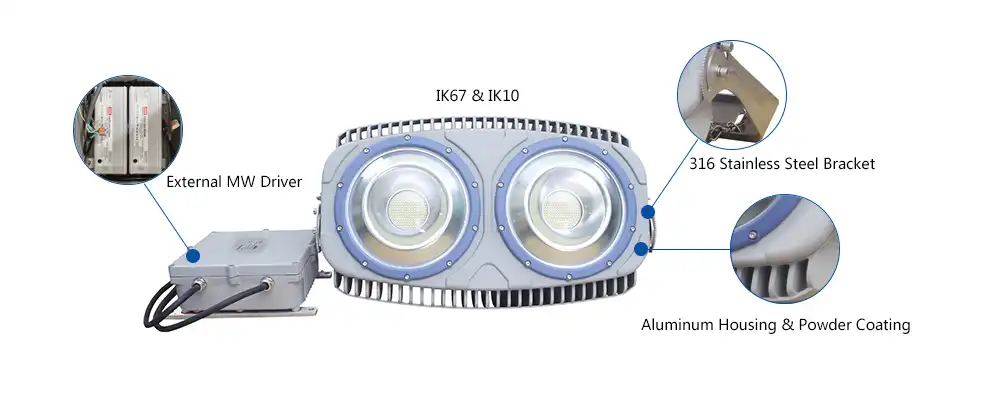

High IP Rating Protection Standards

The IP67 protection rating serves as the cornerstone of reliable led loading lights performance in demanding environments. This certification means the fixtures are completely dust-tight and can withstand temporary immersion in water up to one meter depth. For loading dock applications where pressure washing, rain exposure, and moisture accumulation are daily realities, IP67-rated led loading lights provide the necessary protection to maintain consistent performance. The rating ensures that internal components remain sealed against water jets from any direction, preventing moisture-related failures that plague lesser-rated fixtures. Advanced sealing technologies using marine-grade gaskets and corrosion-resistant hardware ensure long-term protection even in the most challenging conditions. Facilities operating in coastal areas particularly benefit from this level of protection, as salt-laden air poses additional corrosion risks that IP67 construction effectively mitigates.

Advanced Thermal Management Systems

Effective thermal management directly influences the longevity and performance consistency of led loading lights installations. Premium fixtures incorporate aluminum alloy housings with optimized fin designs that maximize surface area for passive heat dissipation. This thermal engineering maintains LED junction temperatures within optimal operating ranges, typically between 40-60°C, which significantly extends the useful life of the lighting system. The patented thermal management systems found in industrial-grade led loading lights utilize convection principles and high-conductivity materials to transfer heat away from critical components. Working temperature ranges from -40°F to 140°F (-40°C to 60°C) ensure reliable operation across extreme climate conditions, from arctic cold storage facilities to desert loading terminals. Enhanced thermal performance translates to maintained lumen output throughout the fixture's operational life, eliminating the gradual dimming that characterizes inferior products and ensuring consistent illumination for safety-critical loading operations.

Structural Durability and IK Impact Resistance

Beyond waterproofing, led loading lights must withstand significant physical impact from loading equipment, shifting cargo, and accidental collisions. The IK10 impact resistance rating indicates these fixtures can endure impacts of 20 joules, equivalent to a 5-kilogram mass dropped from 400mm height. This exceptional impact resistance protects the internal LED arrays and drivers from damage during the inevitable accidents that occur in busy loading environments. Stainless steel mounting brackets provide corrosion resistance and structural stability, maintaining secure fixture positioning even under vibration from nearby machinery and vehicle traffic. The aluminum alloy housing construction balances lightweight installation requirements with the robust strength needed to survive industrial environments. Tempered glass lenses offer superior optical clarity while providing additional protection against impacts, thermal shock, and UV degradation. These structural considerations ensure led loading lights maintain performance integrity throughout extended service periods, reducing replacement frequency and maintenance interruptions.

Technical Specifications and Performance Characteristics

| Specification | Value | Benefit |

|---|---|---|

| Rated Power | 120W (Range: 90W-1200W) | Flexible power options for various application scales |

| Input Voltage | AC 100-305V, DC 127-431V | Universal compatibility with global power systems |

| Lamp Efficiency | 130 LM/W | Superior energy efficiency reducing operational costs |

| Lumen Output | 21,600 LM (at 120W) | Exceptional brightness for safety-critical applications |

| Color Temperature | 2700K-6500K | Customizable lighting appearance for specific needs |

| CRI Rating | Ra>75 | Accurate color rendering for inspection tasks |

| LED Chip | Samsung/Philips | Premium components ensuring reliability and longevity |

| LED Driver | Meanwell | Industry-leading power management technology |

Optimized Beam Angle Configurations for Loading Applications

The strategic selection of beam angles fundamentally determines the effectiveness of led loading lights in specific operational contexts. Available beam angle options spanning 15°, 20°, 30°, 40°, 60°, 120°, and asymmetric 140°x60° configurations enable precise light distribution matching to physical dock layouts and operational requirements. Narrow beam angles of 15-30° provide concentrated illumination for specific work zones or high-mounting applications requiring focused light projection over extended distances. Medium beam angles of 40-60° offer balanced coverage suitable for standard loading dock configurations where fixtures mount at moderate heights and require coverage of typical truck trailer dimensions. Wide beam angles of 120° deliver expansive coverage ideal for general area illumination and applications where multiple activity zones require simultaneous lighting. The asymmetric 140°x60° pattern particularly suits loading dock applications, providing extended horizontal coverage along the dock face while controlling vertical spread to minimize light spillage and glare. This beam angle versatility ensures led loading lights can be precisely configured to maximize visibility where workers need it most while minimizing wasted light and associated energy consumption.

Wide Voltage Input Compatibility

The universal voltage input range of AC 100-305V and DC 127-431V incorporated into industrial led loading lights addresses the power supply variations encountered across global facility installations. This voltage flexibility eliminates the need for specialized transformers or voltage regulation equipment in most applications, simplifying installation and reducing system complexity. Facilities with fluctuating power quality benefit from the wide input tolerance, as the integrated Meanwell drivers maintain consistent light output despite supply variations that would cause flickering or failure in less sophisticated fixtures. The DC voltage compatibility proves particularly valuable for facilities incorporating backup power systems, emergency generators, or renewable energy installations where DC power sources predominate. This voltage versatility ensures led loading lights operate reliably across diverse electrical infrastructures, from North American 120V systems to European 230V networks and various industrial DC installations. The built-in power factor correction maintains electrical efficiency above 0.9, reducing harmonic distortion and maximizing usable power delivery while minimizing utility costs associated with poor power factor penalties.

Color Temperature Selection for Optimal Visual Performance

Color temperature selection for led loading lights significantly influences worker visual comfort, task performance, and overall operational efficiency. The available range spanning 2700K warm white through 6500K cool white accommodates varied application preferences and specific operational requirements. Warm white temperatures of 2700-3000K create comfortable environments for indoor loading docks where workers spend extended periods, reducing eye strain and promoting alertness during long shifts. Neutral white temperatures of 4000-4500K offer balanced color rendering suitable for applications requiring accurate color discrimination during inspection or quality control processes integrated with loading operations. Cool white temperatures of 5000-6500K maximize visual acuity and perceived brightness, making them ideal for outdoor loading docks, security-critical applications, and environments where maximum visibility takes precedence over ambiance considerations. The CRI rating exceeding Ra>75 ensures accurate color reproduction crucial for identifying product labels, assessing cargo condition, and detecting potential safety hazards. Advanced led loading lights installations can incorporate multiple color temperature zones, addressing diverse functional requirements within complex loading facilities through strategic fixture specification.

Application Scenarios and Industry-Specific Solutions

Transportation and Logistics Facilities

Distribution centers and freight terminals represent the primary application domain for specialized led loading lights installations, where continuous 24/7 operations demand absolutely reliable illumination. These facilities typically feature dozens or hundreds of loading dock positions serving constant vehicle traffic, requiring lighting systems that maintain consistent performance despite continuous operation. The led loading lights installations in these environments must accommodate varying vehicle heights, from small delivery vans to full-size semi-trailers, necessitating adjustable mounting configurations and appropriate beam angle selections. Modern logistics facilities increasingly incorporate automated handling systems and robotics that require specific lighting characteristics to function optimally, with led loading lights specifications coordinated with vision system requirements. The emergency backup power capability allowing two-hour autonomous operation proves critical in logistics operations where power interruptions could create catastrophic supply chain delays. Energy efficiency considerations take on heightened importance in these large-scale operations, with 130LM/W efficiency ratings translating to substantial operational savings across extensive lighting installations. Warehouses operating cold storage sections particularly benefit from the -40°F operating capability of industrial-grade led loading lights, maintaining full performance in refrigerated environments where standard fixtures fail.

Marine Terminal and Port Operations

Marine terminals and shipping ports present particularly demanding environments for led loading lights installations, combining saltwater exposure, extreme weather conditions, and round-the-clock operational requirements. The marine-grade anti-corrosion coatings applied to premium led loading lights provide essential protection against the accelerated degradation that salty air causes to standard fixtures. Cargo handling operations in these settings involve massive cranes, gantries, and mobile equipment creating vibration, impacts, and potential damage to lighting infrastructure, requiring the exceptional structural integrity that IK10-rated fixtures provide. The IP67 waterproofing becomes critically important in marine applications where fixtures face direct exposure to rain, spray, and occasional wave action during severe weather events. International maritime certification standards including RMRS (Russian Maritime Register of Shipping) approval ensure led loading lights meet the specific requirements for marine industry installations. The wide voltage input capability proves valuable in port facilities where power quality can vary significantly, particularly in developing regions or facilities supplied by temporary generator installations. Container terminals benefit from the high lumen output and precise beam control that led loading lights provide, enabling accurate positioning and safe navigation of cargo handling equipment in nighttime operations. The five-year warranty coverage reflects manufacturer confidence in fixture durability under these challenging conditions, providing facility operators with long-term cost certainty.

Cold Storage and Refrigerated Warehouse Environments

Cold storage facilities present unique challenges for led loading lights installations, with temperature extremes, thermal cycling, and condensation creating conditions that quickly destroy unsuitable fixtures. The -40°F to 140°F operating temperature range enables these specialized lights to function reliably in even the coldest refrigerated environments where standard lighting fails within months. Thermal shock resistance proves critical as fixtures transition between ambient dock temperatures and sub-zero storage areas, with premium led loading lights construction designed to accommodate these extreme temperature gradients without seal failure or housing cracks. Condensation management becomes paramount in cold storage applications where warm, humid air meeting cold surfaces creates moisture accumulation that can penetrate lesser-protected fixtures, making IP67 sealing absolutely essential. Food safety regulations in many jurisdictions require lighting fixtures installed in food handling areas to be shatter-resistant and constructed from food-safe materials, specifications that industrial led loading lights readily satisfy with tempered glass lenses and food-grade gasket materials. The instant-on capability of LED technology eliminates the warm-up period required by traditional HID lighting, providing immediate full brightness critical for intermittent-use cold storage loading docks. Energy efficiency takes on added importance in refrigerated facilities where lighting heat must be removed by expensive refrigeration equipment, with efficient led loading lights reducing both electrical and cooling costs simultaneously.

Quality Assurance and Manufacturing Excellence

Comprehensive Production Testing Protocols

The manufacturing process for industrial-grade led loading lights incorporates multiple quality verification stages ensuring every fixture meets rigorous performance standards before shipment. Assembly line procedures follow documented work instructions derived from over 22 years of ISO9001-certified quality management system development and refinement. Skilled technicians assemble components in controlled environments minimizing contamination risks that could compromise seal integrity or optical performance. Every completed fixture undergoes photometric testing using integrating sphere equipment that precisely measures lumen output, beam pattern, color temperature, and CRI values, verifying compliance with published specifications. Aging tests simulate extended operational periods under full power conditions, identifying potential early failures and validating the thermal management system performance under sustained load conditions. The DFMEA (Design Failure Mode and Effects Analysis) methodology applied throughout the manufacturing process systematically identifies potential failure points and implements preventive controls ensuring long-term reliability. Electrical safety testing verifies proper grounding, insulation resistance, and protection against electrical faults that could pose safety hazards in installation. Environmental testing subjects fixtures to temperature cycling, humidity exposure, vibration, and impact conditions simulating years of harsh operational service within accelerated timeframes.

Advanced Component Selection and Integration

The selection of Samsung or Philips LED chips as the light-generating elements in premium led loading lights reflects the commitment to performance and reliability that distinguishes industrial-grade products from consumer-oriented alternatives. These premium LED manufacturers maintain stringent binning processes ensuring consistent color temperature, flux output, and efficiency across production batches, eliminating the color variation that plagued early LED installations. The integration of Meanwell LED drivers provides industry-leading power management with active power factor correction, wide voltage input tolerance, and protection circuitry preventing damage from electrical transients and surges. The aluminum alloy housing construction utilizes high-thermal-conductivity alloys optimized for heat dissipation while maintaining the structural strength needed for industrial applications. Tempered glass lenses undergo heat treatment processes that increase impact resistance and thermal shock tolerance well beyond standard glass capabilities, ensuring optical integrity throughout the fixture service life. Stainless steel mounting brackets resist corrosion in marine and chemical environments where carbon steel components would fail rapidly, maintaining secure fixture positioning throughout extended service periods. The careful selection and integration of these premium components explains the five-year warranty coverage that demonstrates manufacturer confidence in long-term reliability.

Shipping, Logistics, and Global Support Infrastructure

Professional Packaging for Transit Protection

| Transportation Method | Timeline | Recommended Weight | Cost Efficiency |

|---|---|---|---|

| International Express (DHL, FedEx, UPS) | 3-7 days | 0.5kg-300kg | Optimal for small urgent orders |

| Air Freight (Airport-to-Port/Door) | 5-10 days | 300kg+ | Economical for medium shipments |

| Rail (China-Europe Express) | 18-22 days | 2CBM/500kg+ | Balanced cost and speed |

| Sea Freight (FCL/LCL) | 15-50 days | 2CBM/500kg+ | Most cost-effective for bulk orders |

The protective Packaging system developed for led loading lights ensures fixtures arrive at installation sites in perfect condition regardless of shipping method or distance traveled. Individual fixtures receive placement in custom-cut foam bases that immobilize the unit within the carton, preventing movement that could cause damage during handling and transit. Plastic bag enclosure provides additional moisture protection during ocean freight shipments where container condensation could compromise unprotected fixtures. Top foam layers incorporate dedicated compartments securely holding mounting brackets, fasteners, and accessories, ensuring all components arrive organized and readily accessible for installation teams. High-strength packing tape and reinforced plastic strapping secure cartons against accidental opening during handling, while clear labeling facilitates efficient customs clearance and delivery routing. Optional wooden crate solutions provide enhanced protection for bulk shipments, particularly for sea freight where handling frequency and potential for rough treatment necessitate maximum packaging robustness. The packaging system design reflects understanding that even the most robust led loading lights can be damaged by inadequate transit protection, with packaging costs representing sound insurance against replacement expenses and installation delays.

International Shipping Options and Logistics Coordination

The comprehensive shipping infrastructure supporting global led loading lights distribution enables flexible delivery schedules matching diverse project requirements and budget constraints. International express services through carriers like DHL, FedEx, and UPS provide the fastest delivery option for urgent requirements, with 3-7 day transit times suitable for emergency replacements or fast-track project schedules. Air freight services offer economical solutions for medium-weight shipments exceeding express carrier weight breaks, with 5-10 day transit times providing reasonable speed at significantly reduced per-kilogram costs. The China-Europe Railway Express route offers innovative middle-ground logistics combining reasonable transit times of 18-22 days with costs substantially below air freight, particularly suitable for European projects with moderate urgency requirements. Sea freight remains the most cost-effective option for bulk shipments and projects with flexible timelines, with 15-50 day transit times depending on destination and routing allowing substantial savings on large installations. Experienced freight forwarders coordinate customs documentation, duty payment, and final-mile delivery, ensuring smooth transaction completion without involvement requirements from purchasers lacking international trade expertise. Real-time tracking information provided for all shipments enables project managers to coordinate installation schedules and resource allocation based on confirmed delivery timelines.

Conclusion

Selecting durable and waterproof led loading lights represents a critical investment in operational safety, efficiency, and long-term cost management for industrial facilities. The combination of IP67 protection, premium components, and comprehensive warranty coverage ensures reliable performance throughout extended service periods. When you need lighting solutions engineered specifically for harsh loading dock environments, Xi'an Razorlux Optoelectronic Technology delivers proven performance backed by over 200 patents and 22 years of manufacturing excellence.

Ready to upgrade your loading dock lighting? As a leading China led loading lights manufacturer, Xi'an Razorlux Optoelectronic Technology operates as a trusted China led loading lights supplier serving global markets. Our position as a premier China led loading lights factory enables competitive led loading lights wholesale pricing without compromising quality. Browse our complete led loading lights for sale catalog to find solutions matching your specific requirements, with transparent led loading lights price structures and flexible ordering options. Contact our technical team at sam@razorlux.com to discuss your project requirements, request customized samples, and discover how our led loading lights solutions enhance your facility operations. Save this article for future reference when planning your lighting upgrades or sharing specifications with your procurement team.

References

1. Henderson, J.M. "Industrial Lighting Standards for Loading Dock Operations" - Journal of Occupational Safety Engineering, 2023

2. Chen, L. & Wang, Y. "LED Technology Advances in Marine-Grade Industrial Applications" - International Marine Engineering Society, 2024

3. Thompson, R.K. "Thermal Management Systems in High-Power LED Fixtures" - Lighting Design and Technology Review, 2024

4. Martinez, S.A. "Waterproof Rating Standards and Their Application in Industrial Environments" - International Electrotechnical Commission Technical Report, 2023

5. Kumar, P. & Anderson, D.L. "Energy Efficiency Analysis of Modern LED Loading Dock Lighting Systems" - Industrial Energy Management Quarterly, 2024

VIEW MOREMarine Flood Lights 1000W

VIEW MOREMarine Flood Lights 1000W VIEW MORE305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design

VIEW MORE305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design VIEW MOREworkshop light fixtures

VIEW MOREworkshop light fixtures VIEW MOREtennis court flood lights

VIEW MOREtennis court flood lights VIEW MORELed Mine

VIEW MORELed Mine VIEW MOREMarine Led Deck Flood Lights

VIEW MOREMarine Led Deck Flood Lights VIEW MORE6000K 270w Dimmable Outdoor Light 60 Degree Flood Light For Basketball Court

VIEW MORE6000K 270w Dimmable Outdoor Light 60 Degree Flood Light For Basketball Court VIEW MOREMast Led

VIEW MOREMast Led

_1750326878398.png)