How to choose high bay LED lights?

Are your warehouse floors too dark? Are workers complaining about visibility issues that slow productivity? Choosing the right LED High Bay Lights can transform your industrial space from a dimly-lit liability into a well-illuminated, efficient workspace. Whether you're upgrading outdated metal halide fixtures or designing a new facility, understanding how to select proper LED High Bay Lights ensures optimal brightness, energy savings, and workplace safety for years to come.

Understanding Key Performance Specifications for LED High Bay Lights

When evaluating LED High Bay Lights, technical specifications determine whether your investment delivers the performance your facility requires. Understanding these critical parameters prevents costly mistakes and ensures your lighting system meets operational demands.

Lumen Output Requirements Based on Ceiling Height

LED High Bay Lights must deliver adequate illumination based on your mounting height and application needs. For facilities with 10-15 feet ceilings, fixtures producing 10,000-15,000 lumens provide sufficient brightness for basic storage operations. Warehouses with 15-20 feet ceilings typically require 16,000-20,000 lumens to maintain visibility standards. High-ceiling applications ranging from 25-35 feet demand robust fixtures like the 150 Watt Led Ufo High Bay Light generating 33,000+ lumens. At Razorlux, our high bay models achieve 120lm/w system efficiency using premium Lumileds and Samsung LEDs, ensuring every watt translates into maximum illumination. Manufacturing facilities requiring detailed inspection work may need even higher lumen outputs to eliminate shadows and support precision tasks.

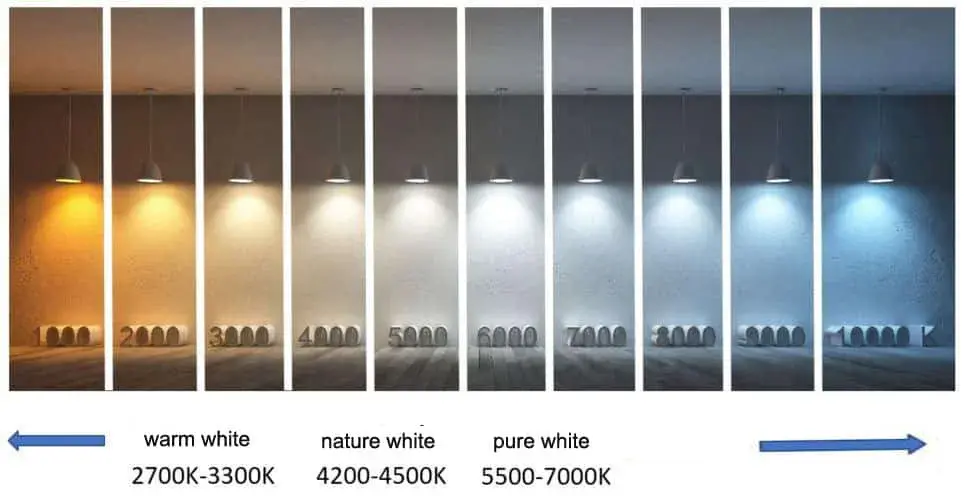

Color Temperature Selection for Different Work Environments

Color temperature dramatically affects worker comfort and productivity when selecting LED High Bay Lights. Measured in Kelvin, this specification determines whether your lighting appears warm, neutral, or cool. For general warehousing and storage, 4000K neutral white replicates natural daylight, reducing eye strain during extended shifts. Retail environments benefit from 5000K cool white temperatures that enhance product visibility and create an inviting atmosphere. The 150 Watt LED UFO High Bay Light from Razorlux offers customizable color temperatures from 3000-6500K, allowing facilities to match lighting to specific operational requirements. Manufacturing spaces requiring color-critical work should select fixtures with 5000K+ temperatures and high CRI ratings above 75 to ensure accurate color representation. Break rooms and administrative areas work best with warmer 3000K temperatures that promote relaxation during downtime.

Energy Efficiency and Power Consumption Analysis

Traditional metal halide fixtures consume excessive energy while generating significant heat that strains HVAC systems. Modern LED High Bay Lights like Razorlux's RHB-UA series dramatically reduce operating costs through superior efficiency ratings. Our 150 Watt LED UFO High Bay Light consumes just 150W while producing brightness equivalent to 400W metal halide fixtures, creating immediate savings on monthly electricity bills. The exterior Meanwell driver design ensures outstanding heat dissipation that extends component lifespan beyond 50,000 operational hours. Wide input voltage compatibility (AC85-265V) protects against power fluctuations common in industrial environments. When calculating total cost of ownership, LED High Bay Lights deliver return on investment within 18-24 months through combined energy savings and reduced maintenance expenses. Facilities operating 24/7 experience even faster payback periods that justify the initial investment in quality lighting infrastructure.

IP Rating and Environmental Protection Standards

Industrial environments expose lighting fixtures to harsh conditions including dust, moisture, chemicals, and temperature extremes. LED High Bay Lights must feature appropriate IP ratings to ensure reliable long-term performance. IP65-rated fixtures like Razorlux's 150 Watt LED UFO High Bay Light provide complete dust protection and resistance to water jets from any direction, making them suitable for most warehouse applications. Facilities with high moisture levels or frequent washdown procedures should consider IP67-rated options that withstand temporary submersion. Our marine-grade anti-corrosion coating extends durability in coastal locations where salt exposure degrades standard fixtures. Temperature ratings matter equally—quality LED High Bay Lights operate reliably in environments ranging from -40°C to +50°C without performance degradation. Razorlux fixtures undergo rigorous environmental testing including thermal cycling, vibration resistance, and impact testing to verify they withstand demanding industrial conditions throughout their rated lifespan.

Comparing LED High Bay Light Types and Configurations

| Feature | UFO High Bay Lights | Linear High Bay Lights |

|---|---|---|

| Shape | Compact round/disc design | Elongated rectangular panel |

| Ideal Ceiling Height | 20-45 feet | 15-25 feet |

| Light Distribution | 360° radial coverage | Directional linear spread |

| Installation | Single mounting point | Multiple mounting points |

| Best Applications | Open warehouses, large retail | Aisle-based storage, production lines |

| Beam Angle Options | 60°, 90°, 120° | Typically 120° fixed |

| Maintenance Access | Easy single-unit replacement | Individual panel servicing |

UFO Style High Bay Lights for Large Open Spaces

UFO-style LED High Bay Lights dominate warehouse and industrial applications where ceiling heights exceed 20 feet and open floor plans require broad, uniform illumination. These compact disc-shaped fixtures concentrate powerful LED arrays within aerodynamic housings that optimize thermal management. The 150 Watt LED UFO High Bay Light from Razorlux measures just Ø340×187mm yet delivers commanding brightness across expansive areas. UFO configurations excel as direct replacements for traditional metal halide fixtures, mounting identically to existing infrastructure and eliminating costly retrofitting expenses. The round design distributes light evenly in 360-degree patterns, minimizing dark spots between fixtures and reducing total fixture count requirements. Razorlux UFO models feature selectable beam angles (60°, 120°) allowing customization for specific ceiling heights and coverage needs. Installation simplicity represents another advantage—single-point pendant mounting enables quick deployment even in challenging elevated locations. For facilities prioritizing energy efficiency, UFO LED High Bay Lights incorporate advanced driver technology and premium LED chips achieving 135lm/w+ system efficiency.

Linear High Bay Lights for Aisle and Production Areas

Linear LED High Bay Lights provide targeted illumination for facilities with defined aisle configurations and production workflows. These elongated fixtures align with warehouse racks and assembly lines, directing light precisely where workers need it most. Linear configurations work exceptionally well in spaces with 15-25 foot ceilings where their broad footprint creates even light distribution without excessive mounting points. Manufacturing facilities benefit from linear LED High Bay Lights positioned above conveyor systems and workbenches, eliminating shadows that compromise quality control processes. The extended form factor allows fixtures to span wider areas with fewer units compared to equivalent UFO installations. When retrofitting fluorescent T5HO or T8 high bay systems, linear LED replacements mount directly into existing positions, simplifying upgrade projects. Razorlux offers customization options including adjustable mounting brackets and linkable configurations that create continuous light runs. For cold storage applications where traditional fluorescents fail, linear LED High Bay Lights maintain full brightness at sub-zero temperatures. Distribution centers with narrow aisles particularly appreciate how linear fixtures concentrate illumination vertically, improving visibility for forklift operators and order pickers.

Beam Angle Considerations for Optimal Light Distribution

Beam angle selection critically affects how LED High Bay Lights distribute illumination across your facility floor. Narrow 60-degree beams concentrate light intensity directly beneath fixtures, ideal for high-ceiling applications above 30 feet where broader angles would scatter excessively. Standard 90-degree beams balance coverage and intensity for most warehouse scenarios with 20-25 foot mounting heights. Wide 120-degree beam angles spread light across larger floor areas, reducing fixture requirements in facilities with lower ceilings or open layouts. The 150 Watt LED UFO High Bay Light from Razorlux offers selectable beam angles allowing facilities to optimize coverage for their specific geometry. Achieving proper light distribution requires considering fixture spacing relative to beam angles—narrow beams necessitate closer spacing while wide angles allow greater distance between units. Crossover lighting principles recommend positioning fixtures so beams overlap from multiple directions, eliminating harsh shadows and creating more uniform illumination. Razorlux engineering teams perform photometric calculations to recommend precise fixture layouts that meet illumination standards while minimizing equipment costs.

Dimming and Control Integration Options

Advanced control systems transform LED High Bay Lights from simple on-off fixtures into intelligent components of facility management infrastructure. Dimming capabilities enable facilities to adjust brightness based on natural daylight contribution, reducing energy consumption during peak sunlight hours. The 150 Watt LED UFO High Bay Light supports both 0-10V analog dimming and DALI digital addressable lighting interface protocols for flexible integration with building automation systems. Motion sensors detect occupancy in infrequently accessed areas, automatically illuminating spaces only when personnel are present and reducing runtime hours substantially. Daylight harvesting sensors measure ambient light levels and dim fixtures proportionally, maintaining consistent illumination while maximizing energy savings. Programmable schedules allow different brightness levels during production shifts versus maintenance periods, optimizing both visibility and efficiency. Razorlux control-ready LED High Bay Lights simplify smart facility implementations with pre-wired connections and compatible driver circuitry. Emergency backup functionality provides two hours of illumination during power failures, ensuring worker safety and enabling continued critical operations. Facilities implementing comprehensive lighting controls typically achieve additional 20-30% energy savings beyond baseline LED efficiency improvements.

Evaluating Quality Standards and Long-Term Reliability

| Certification | Purpose | Importance for LED High Bay Lights |

|---|---|---|

| CE (European Conformity) | Product safety and EMC compliance | Required for European market access |

| RoHS (Restriction of Hazardous Substances) | Environmental protection, limits toxic materials | Ensures eco-friendly disposal |

| UL (Underwriters Laboratories) | North American safety certification | Critical for US commercial installations |

| DLC (DesignLights Consortium) | Energy efficiency verification | Qualifies for utility rebate programs |

| IP65/IP67 Rating | Ingress protection against dust/water | Guarantees durability in harsh environments |

| LM-80/TM-21 Testing | LED lumen maintenance prediction | Validates lifespan claims scientifically |

Driver Quality and Thermal Management Systems

LED driver components determine whether LED High Bay Lights deliver reliable long-term performance or fail prematurely under industrial operating conditions. Premium drivers like the exterior-mounted Meanwell units in Razorlux's 150 Watt LED UFO High Bay Light regulate power precisely, protecting LED arrays from voltage fluctuations and current spikes. External driver placement provides dual benefits—superior cooling that extends electronic lifespan and simplified maintenance allowing quick driver replacement without disturbing the entire fixture. Thermal management represents the critical factor limiting LED longevity; excessive junction temperatures accelerate lumen depreciation and shorten operational life. Razorlux fixtures incorporate oversized aluminum heat sinks with optimized fin geometry that dissipates heat through natural convection without requiring cooling fans. Die-cast construction ensures intimate thermal contact between LED modules and heat sink surfaces, efficiently transferring waste heat away from sensitive junctions. Quality LED High Bay Lights maintain junction temperatures below 85°C under full-load operation, preserving lumen output throughout their rated 50,000+ hour lifespan. Cheaper fixtures compromise on thermal design, leading to rapid brightness loss and color shift that necessitates premature replacement.

LED Chip Quality and Lumen Maintenance

LED chip selection separates professional-grade LED High Bay Lights from inferior products that promise performance but deliver disappointment. Razorlux exclusively utilizes Lumileds and Samsung LED chips renowned for superior efficacy, consistent color rendering, and exceptional lumen maintenance characteristics. These premium components achieve 135lm/w+ system efficiency while maintaining 90%+ lumen output after 50,000 operational hours. The 150 Watt LED UFO High Bay Light incorporates these high-performance LEDs arranged in optimized arrays that balance brightness, uniformity, and thermal loading. Cheaper LED High Bay Lights employ generic Chinese chips that initially appear bright but rapidly degrade, losing 30-40% brightness within 20,000 hours. Color consistency matters equally—quality chips maintain stable color temperature throughout their lifespan while inferior alternatives shift noticeably blue or yellow. LM-80 testing data from chip manufacturers combined with TM-21 calculations provides scientific basis for lifespan claims. Razorlux publishes complete photometric reports for our LED High Bay Lights, giving specifiers confidence that fixtures will perform as promised throughout their operational life.

Warranty Coverage and After-Sales Support

Comprehensive warranty protection demonstrates manufacturer confidence in LED High Bay Lights quality and provides financial safeguards against premature failures. Razorlux backs our 150 Watt LED UFO High Bay Light with five-year warranty coverage encompassing both LED arrays and driver electronics, significantly exceeding industry-standard three-year terms. This extended protection reflects our commitment to using premium components and rigorous quality control throughout manufacturing. Beyond warranty duration, response procedures matter critically—Razorlux maintains dedicated technical support teams ready to troubleshoot issues and expedite replacement shipments when necessary. Our after-sales service includes installation guidance, photometric analysis assistance, and maintenance recommendations that maximize fixture lifespan. Global facilities benefit from Razorlux's international presence with subsidiaries in USA and Hong Kong providing local support backed by our Xi'an headquarters manufacturing capabilities. When warranty claims arise, our streamlined process ensures rapid resolution without endless bureaucratic delays that leave facilities operating with failed lighting. Pre-sales consultation helps customers specify appropriate LED High Bay Lights for their applications, preventing mismatches that lead to dissatisfaction and warranty disputes.

Testing and Quality Control Procedures

Manufacturing excellence separates reliable LED High Bay Lights from products plagued by inconsistent performance and premature failures. At Razorlux's GMP-certified facility, every 150 Watt LED UFO High Bay Light undergoes comprehensive testing protocols before shipment authorization. Our assembly line workers build fixtures following documented procedures with quality checkpoints verifying proper component installation at each stage. Finished units enter photometric testing chambers where integrating sphere measurements confirm lumen output, color temperature, and beam pattern specifications. Aging tests subject fixtures to extended burn-in periods identifying infant mortality failures before products reach customers. Electrical safety testing verifies insulation resistance, ground continuity, and voltage withstand capacity meeting international standards. Environmental chambers cycle fixtures through temperature extremes confirming reliable operation from -40°C to +50°C. Vibration testing simulates transportation stresses and installation environments, ensuring structural integrity under real-world conditions. This rigorous quality control investment means customers receive LED High Bay Lights that consistently perform as specified, backed by documentation proving compliance with CE, RoHS, UL, and other applicable certifications.

Installation Planning and Total Cost Analysis

Professional installation planning ensures LED High Bay Lights deliver expected performance while minimizing project complications and unexpected expenses. Successful implementations begin with accurate facility assessments including ceiling height measurements, structural capacity verification, and electrical infrastructure evaluation.

Calculating Required Fixture Quantities

Determining proper fixture quantities prevents both over-lighting that wastes capital and under-lighting that compromises safety and productivity. Professional photometric analysis considers multiple factors including ceiling height, desired foot-candle levels, fixture spacing ratios, and surface reflectance values. Storage areas typically require 30-50 foot-candles while assembly zones need 70+ foot-candles and inspection areas demand 100+ foot-candles. The 150 Watt LED UFO High Bay Light producing 18,000 lumens with 120-degree beam angle can effectively cover approximately 400-500 square feet when mounted at 25 feet with proper overlap. Razorlux provides complimentary layout assistance using industry-standard AGi32 software, generating detailed reports showing illumination contours, uniformity ratios, and fixture coordinates. Spacing-to-mounting-height ratios guide fixture placement—UFO-style LED High Bay Lights generally follow 1:1 spacing ratios meaning 25-foot mounting allows 25-foot spacing between units. Irregularly shaped facilities or areas with obstructions require customized layouts that account for shadowing and reflection patterns. Accurate quantity calculations prevent costly change orders and ensure first-time-right installations that meet building codes and insurance requirements.

Mounting Options and Structural Requirements

LED High Bay Lights offer multiple mounting configurations accommodating various ceiling types and installation preferences. Pendant mounting suspends fixtures on cables or rigid conduit, providing the most common installation method for warehouses and factories. This approach allows precise height adjustment achieving optimal illumination patterns regardless of structural ceiling variations. The 150 Watt LED UFO High Bay Light includes standard pendant mounting hardware supporting flexible installation at customer-specified heights. Hook and chain mounting provides simple deployment in facilities with exposed trusses or structural members, enabling quick repositioning if layout changes occur. Surface mounting directly to ceiling structures works for lower-bay applications where pendant drops create headroom concerns or aesthetic issues. Wall mounting serves specialized applications like loading docks and building perimeters requiring directional lighting. Structural capacity verification ensures existing ceilings safely support LED High Bay Lights weighing 4.9kg plus mounting hardware, critical in retrofit scenarios where original designs accommodated lighter fixtures. Razorlux provides detailed mounting instructions and load calculations assisting contractors with proper installation planning and execution.

Electrical Infrastructure and Voltage Compatibility

Successful LED High Bay Lights installations require compatible electrical infrastructure delivering appropriate voltage and amperage to fixtures. Most industrial facilities operate 277V or 480V three-phase systems requiring LED High Bay Lights with appropriate voltage ratings. The 150 Watt LED UFO High Bay Light accepts wide input voltage (AC85-265V) accommodating variations in facility electrical systems without requiring transformers or additional components. This universal compatibility simplifies international deployments where voltage standards differ between regions—Razorlux ships identical fixtures to European 230V systems and North American 120V/277V installations. Circuit planning considers fixture power consumption and quantity, ensuring branch circuits don't exceed breaker ratings or voltage drop limitations. LED High Bay Lights draw significantly less current than legacy metal halide fixtures, potentially allowing more fixtures per circuit or reducing wire gauge requirements in new construction. Emergency backup features require separate circuitry providing battery-backed power maintaining illumination during utility failures. Razorlux technical documentation includes complete electrical specifications assisting engineers and electricians with proper system design and installation. Pre-installation site surveys identify potential compatibility issues allowing resolution before equipment arrives and installation begins.

Return on Investment Through Energy Savings

LED High Bay Lights justify initial investments through substantial operational cost reductions accumulating over fixture lifespans. Replacing 400W metal halide fixtures with 150 Watt LED UFO High Bay Lights saves 250W per fixture—a 100-fixture warehouse reduces power consumption by 25,000W continuously. At typical industrial electricity rates of $0.12/kWh operating 6,000 hours annually, this translates into $18,000 annual savings. Over the 50,000-hour LED lifespan, cumulative savings exceed $150,000 while avoiding disposal costs and labor expenses associated with replacing short-lived metal halide lamps. Maintenance reduction contributes significantly—traditional fixtures require lamp replacement every 10,000-15,000 hours plus ballast replacements, whereas LED High Bay Lights operate maintenance-free for 50,000+ hours. Facilities requiring lift equipment or scaffolding for lamp changes experience even greater savings when switching to long-life LED technology. Utility rebate programs in many regions provide additional incentives for qualifying LED High Bay Lights carrying DLC certifications, reducing net acquisition costs by 20-40%. Razorlux assists customers with rebate applications and energy savings calculations demonstrating compelling financial benefits justifying LED investments. Most facilities achieve complete payback within 18-24 months, after which continued savings flow directly to bottom-line profitability.

Conclusion

Selecting appropriate LED High Bay Lights requires balancing technical specifications, quality standards, and total cost considerations that impact both immediate performance and long-term operational expenses. Prioritize fixtures with proven LED chips, quality drivers, appropriate IP ratings, and comprehensive warranties ensuring reliable service throughout extended lifespans.

Ready to upgrade your facility with premium LED High Bay Lights? Xi'an Razorlux Optoelectronic Technology Co., Ltd. stands ready as your trusted China LED High Bay Lights manufacturer and China LED High Bay Lights supplier. With over 200 patents and 20+ years of expertise, we deliver high-performance LED High Bay Lights for sale backed by 5-year warranties and competitive LED High Bay Lights price structures. As a leading China LED High Bay Lights factory, we offer comprehensive support from pre-sales consultation through after-sales service. Our China LED High Bay Lights wholesale programs provide volume pricing for large projects. Contact our team at sam@razorlux.com today for customized lighting solutions, technical specifications, and quotations tailored to your facility requirements. Bookmark this guide for future reference—your complete resource for making informed LED High Bay Lights decisions.

References

1. Illuminating Engineering Society (IES). Lighting Handbook: Reference and Application. 10th Edition. Illuminating Engineering Society of North America.

2. U.S. Department of Energy. LED Lighting for High Bay Applications. Building Technologies Office, Energy Efficiency and Renewable Energy Division.

3. Chen, Michael and Roberts, David. Industrial Lighting Design: Best Practices for LED High Bay Applications. Society of Light and Lighting Technical Report Series.

4. International Commission on Illumination (CIE). Guide on the Maintenance of Indoor Electric Lighting Systems. CIE Technical Report 197:2019.

VIEW MOREoutdoor rink flood lights

VIEW MOREoutdoor rink flood lights VIEW MORELed Mine

VIEW MORELed Mine VIEW MORE120 Volt Led Outdoor Flood Lights

VIEW MORE120 Volt Led Outdoor Flood Lights VIEW MORE400w Dimmable LED Flood Light High Lumen Narrow Beam

VIEW MORE400w Dimmable LED Flood Light High Lumen Narrow Beam VIEW MORE5700K Outdoor Garden Led Light Ip67 100000lm Flood Lights For Volleyball Court

VIEW MORE5700K Outdoor Garden Led Light Ip67 100000lm Flood Lights For Volleyball Court VIEW MOREPortable 1000w Led Stadium Lights

VIEW MOREPortable 1000w Led Stadium Lights VIEW MOREMost Powerful Flood Light

VIEW MOREMost Powerful Flood Light VIEW MORETennis Floodlights

VIEW MORETennis Floodlights

_1750326878398.png)