7 Things to Remember Before Investing in High Bay LED Lights

Picture this: You walk into your warehouse at dawn, flipping the switch, only to face dim corners, uneven lighting, and skyrocketing energy bills that drain your profits month after month. Poor lighting doesn't just waste money—it compromises worker safety, reduces productivity, and damages your bottom line. Choosing the right LED High Bay Lights transforms these pain points into powerful advantages, delivering brilliant illumination, dramatic energy savings, and long-term reliability for your industrial operations.

Understanding LED High Bay Lights Performance Requirements

Analyzing Your Facility Layout and Ceiling Height

Before investing in LED High Bay Lights, carefully evaluate your facility's unique architecture and operational demands. Warehouses with ceiling heights ranging from twenty to forty-five feet require specialized lighting solutions that deliver adequate foot-candle levels throughout the workspace. Storage areas typically need thirty foot-candles of illumination, while active manufacturing zones and assembly lines demand fifty to seventy foot-candles for optimal visibility and safety compliance. Ufo Warehouse Lights excel in open-plan facilities with uniform ceiling heights, providing circular beam patterns that distribute light evenly across large floor areas without creating harsh shadows or dark spots that compromise worker safety and productivity.

Determining Optimal Lumen Output for Your Application

Lumen output serves as the critical measurement for LED High Bay Lights performance, replacing outdated wattage-based calculations that dominated traditional lighting specifications. Modern industrial facilities require lighting systems delivering between ten thousand and thirty thousand lumens depending on mounting height, task complexity, and ambient light conditions. Razorlux UFO Warehouse Lights achieve exceptional system efficiency exceeding one hundred twenty lumens per watt, utilizing premium Lumileds and Samsung LED chips that maintain consistent output throughout their operational lifespan. This superior efficiency translates directly into reduced energy consumption, lower utility costs, and fewer fixtures required to achieve target illumination levels across your facility.

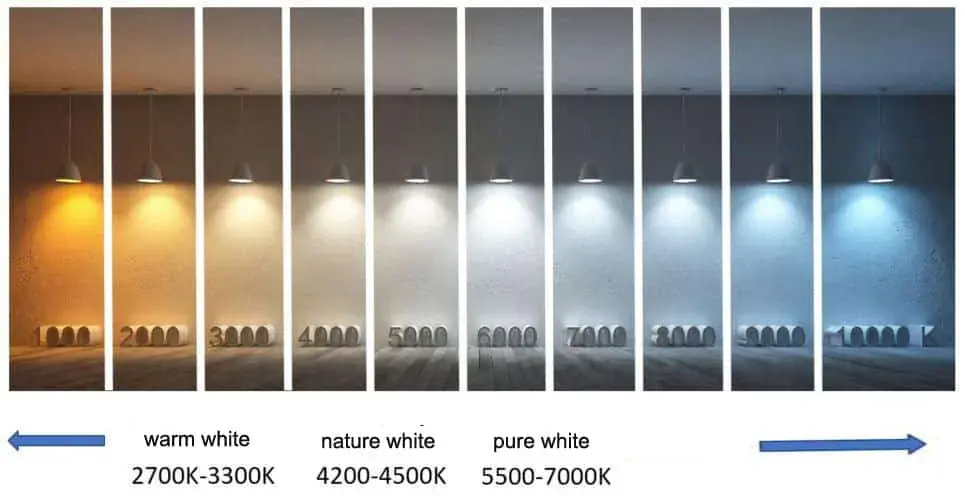

Evaluating Color Temperature and Color Rendering Index

Color temperature measured in Kelvin dramatically impacts workplace atmosphere, visual comfort, and task performance in industrial environments equipped with LED High Bay Lights. Neutral white temperatures between four thousand and five thousand Kelvin provide the ideal balance between visual acuity and worker comfort, closely mimicking natural daylight conditions that reduce eye strain during extended shifts. Color Rendering Index values above seventy-five ensure accurate color perception critical for quality control, inventory management, and safety compliance in manufacturing and warehouse operations. Razorlux products offer flexible color temperature options spanning three thousand to sixty-five hundred Kelvin, allowing facility managers to customize lighting characteristics matched precisely to their operational requirements and industry standards.

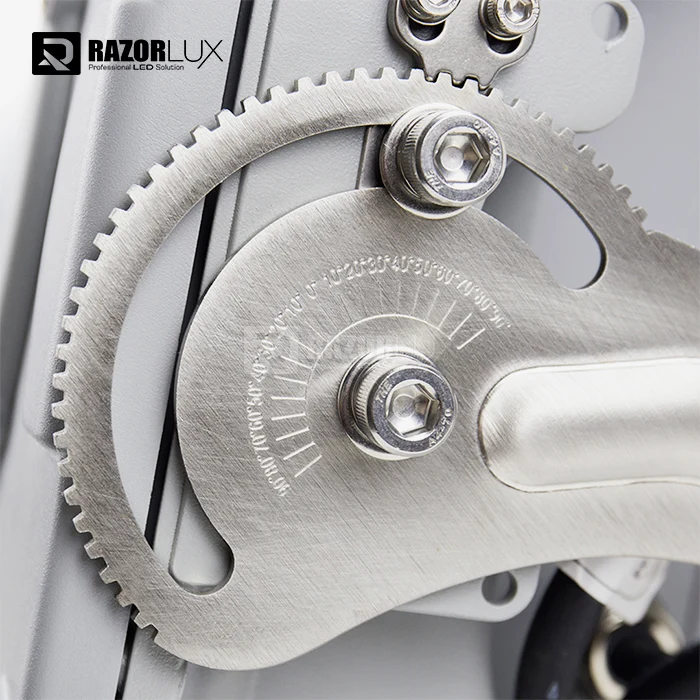

Selecting Appropriate Beam Angles for Coverage

Beam angle selection fundamentally determines how LED High Bay Lights distribute illumination throughout your workspace, directly affecting uniformity, efficiency, and fixture quantity requirements. UFO Warehouse Lights typically offer sixty-degree and one hundred twenty-degree beam angle options, with narrower angles concentrating light intensity for high-mounting applications and wider angles providing broader coverage for lower ceilings. Facilities with ceiling heights exceeding thirty feet benefit from sixty-degree beam angles that project concentrated light downward, minimizing lumen loss and maintaining adequate floor-level illumination. Lower mounting heights between twenty and thirty feet pair ideally with one hundred twenty-degree beam angles that spread light across wider areas, reducing the total fixture count required while maintaining uniform illumination patterns.

Technical Specifications and Quality Standards

| Specification | Requirement | Razorlux Performance |

|---|---|---|

| System Efficiency | ≥130 lm/W | 120-135 lm/W |

| Color Temperature | 4000-5000K optimal | 3000-6500K range |

| Color Rendering Index | ≥75 minimum | Ra>75 certified |

| Beam Angle Options | 60°, 120° | Multiple options available |

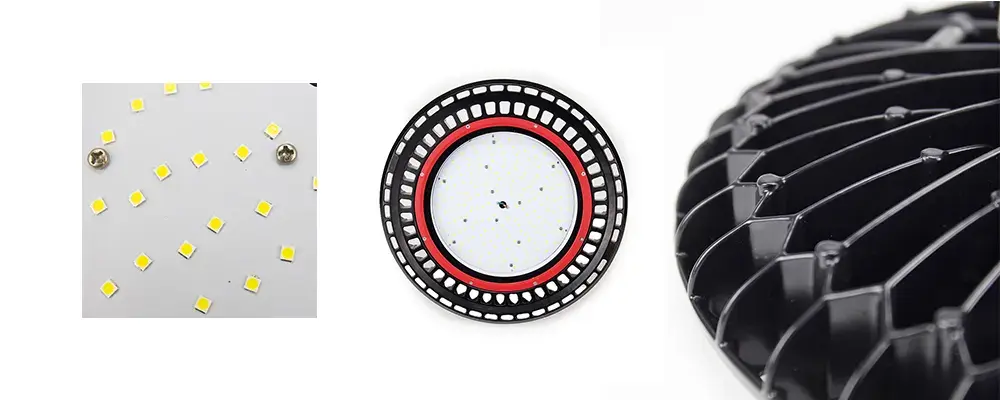

Understanding Driver Quality and Heat Management

Driver quality represents the single most critical component determining LED High Bay Lights lifespan, reliability, and performance consistency throughout years of continuous operation. Inferior drivers cause premature failure, flickering, and gradual lumen depreciation that compromises lighting quality and increases maintenance costs significantly over time. Razorlux UFO Warehouse Lights feature exterior-mounted Meanwell drivers recognized globally for exceptional reliability, superior heat dissipation, and extended operational life exceeding fifty thousand hours. The external driver configuration facilitates effortless maintenance and replacement without disturbing the sealed optical assembly, reducing service time and minimizing operational disruptions when routine maintenance becomes necessary.

Verifying IP Rating and Environmental Protection

Industrial environments expose LED High Bay Lights to dust, moisture, temperature extremes, and mechanical impacts that rapidly degrade inferior lighting products lacking adequate environmental protection. IP sixty-five rated fixtures provide complete dust ingress protection and resistance to water jets from any direction, ensuring reliable operation in demanding warehouse, manufacturing, and cold storage applications. Razorlux UFO Warehouse Lights exceed IP sixty-five standards, incorporating marine-grade anti-corrosion coatings and robust aluminum die-cast housings that withstand harsh industrial conditions, coastal environments, and temperature fluctuations while maintaining optimal performance throughout their extended service life.

Examining LED Chip Quality and Binning Standards

LED chip quality varies dramatically across manufacturers, with premium-grade chips delivering superior efficiency, color consistency, and operational longevity compared to lower-binning alternatives sold at reduced prices. Top-tier LED manufacturers like Lumileds and Samsung employ rigorous binning processes that segregate chips by performance characteristics, pricing premium bins significantly higher than inferior grades produced during the same manufacturing runs. Razorlux exclusively specifies premium-binning Lumileds and Samsung LED chips in their UFO Warehouse Lights, ensuring consistent color temperature, maximum lumen output, and minimal depreciation throughout the fixture's rated fifty-thousand-hour lifespan backed by comprehensive five-year warranty coverage.

Confirming Certification and Safety Compliance

Legitimate LED High Bay Lights manufacturers provide comprehensive third-party certifications demonstrating compliance with international safety, performance, and environmental standards that protect facility owners from liability and ensure product reliability. Essential certifications include CE marking for European markets, RoHS compliance for hazardous substance restrictions, and UL listing for North American electrical safety standards. Razorlux maintains certification across all major international standards including UL, RMRS, TUV, CE, SAA, and RoHS, supported by over two hundred patents covering LED Packaging, power control, and structural design innovations developed through their extensive research and development capabilities established since nineteen ninety-eight.

Financial Considerations and Return on Investment

Calculating Total Cost of Ownership

Total cost of ownership extends far beyond initial LED High Bay Lights purchase prices, encompassing installation expenses, energy consumption, maintenance requirements, and replacement cycles throughout the lighting system's operational lifespan. Traditional metal halide and high-pressure sodium fixtures consume significantly more electricity, require frequent lamp replacements, and generate excessive heat that increases facility cooling costs dramatically compared to modern LED alternatives. UFO Warehouse Lights reduce energy consumption by up to eighty-five percent compared to conventional technologies, eliminating lamp replacement labor, and minimizing cooling loads through superior thermal management that converts electrical energy into visible light rather than waste heat that burdens HVAC systems unnecessarily.

Analyzing Energy Savings and Payback Periods

Energy savings represent the primary financial benefit driving LED High Bay Lights adoption across industrial facilities seeking to reduce operational expenses and improve profitability in competitive markets. A typical warehouse operating twenty-four hours daily, seven days weekly can achieve annual energy savings exceeding thousands of dollars per fixture when replacing four-hundred-watt metal halide lamps with equivalent one-hundred-fifty-watt Razorlux UFO Warehouse Lights that deliver superior illumination using seventy-five percent less electricity. Payback periods typically range from twelve to thirty-six months depending on existing fixture types, electricity rates, operating hours, and available utility rebate programs that accelerate return on investment through immediate cash incentives for energy-efficient lighting upgrades.

Exploring Available Rebates and Incentives

Utility companies and government agencies worldwide offer substantial financial incentives encouraging businesses to adopt energy-efficient LED High Bay Lights that reduce peak demand, lower carbon emissions, and defer expensive infrastructure upgrades required to support inefficient legacy lighting technologies. Rebate programs frequently cover twenty to fifty percent of project costs, significantly reducing initial capital requirements and accelerating payback periods for LED lighting conversions. Razorlux provides comprehensive technical documentation, photometric data, and certification packages that streamline rebate application processes, ensuring customers receive maximum available incentives while benefiting from expert guidance navigating complex utility program requirements and submission procedures.

| Cost Factor | Traditional Lighting | LED High Bay Lights | Savings |

|---|---|---|---|

| Initial Cost | Lower | Higher | N/A |

| Energy Consumption | 400W typical | 150W typical | 62.5% |

| Lamp Replacement | Every 10,000 hrs | 50,000+ hrs | 80% |

| Maintenance Labor | Frequent | Minimal | 75% |

Evaluating Warranty Coverage and Manufacturer Support

Comprehensive warranty coverage provides essential financial protection safeguarding your LED High Bay Lights investment against premature failure, manufacturing defects, and performance degradation that compromises lighting quality and increases unexpected replacement costs. Standard warranties range from three to five years depending on product specifications and manufacturer confidence in their component quality and assembly processes. Razorlux offers five-year warranty coverage on their UFO Warehouse Lights backed by responsive technical support, replacement parts availability, and global service infrastructure spanning operations in China, USA, and Hong Kong that ensures rapid issue resolution regardless of installation location or project scale.

Installation and Maintenance Considerations

Choosing Appropriate Mounting Methods

Mounting flexibility determines how easily LED High Bay Lights integrate into existing facility infrastructure, affecting installation time, labor costs, and long-term maintenance accessibility throughout the fixture's operational lifespan. UFO Warehouse Lights accommodate multiple mounting options including pendant suspension using adjustable cables or chains, direct surface mounting to structural beams, and hook mounting for quick installation in facilities with existing mounting hardware. Pendant mounting offers maximum flexibility for facilities with complex ceiling structures, allowing precise positioning that optimizes light distribution while maintaining adequate clearance for overhead cranes, conveyor systems, and material handling equipment operating within the illuminated workspace.

Planning for Future Control Integration

Modern facilities increasingly demand intelligent lighting control capabilities including occupancy sensing, daylight harvesting, and network connectivity that enable dramatic additional energy savings beyond basic LED High Bay Lights efficiency improvements. Forward-thinking facility managers specify fixtures supporting industry-standard control protocols like zero-to-ten-volt dimming and DALI systems that accommodate future upgrades without requiring complete fixture replacement when operational requirements evolve. Razorlux products feature flexible control options supporting various dimming protocols and sensor integration, ensuring your lighting investment remains relevant and valuable throughout decades of technological advancement and changing operational requirements.

Establishing Maintenance Schedules and Procedures

Proactive maintenance schedules maximize LED High Bay Lights performance, extend operational lifespan, and identify potential issues before they escalate into costly failures disrupting facility operations. Regular cleaning removes accumulated dust and debris that reduce light output, while periodic inspections verify driver function, check mounting hardware integrity, and confirm proper thermal management preventing premature component degradation. The exterior driver design featured in Razorlux UFO Warehouse Lights simplifies maintenance procedures, allowing technicians to service or replace driver modules without opening the sealed optical housing or disturbing the LED array, reducing maintenance time and minimizing disruption to ongoing facility operations.

Training Staff on Safety and Operation

Comprehensive staff training ensures safe LED High Bay Lights operation, appropriate use of control features, and early identification of potential issues requiring professional attention. Training programs should cover basic troubleshooting procedures, safety protocols for working near electrical equipment, proper cleaning methods that avoid damaging optical components, and understanding of warranty terms and manufacturer support resources. Razorlux provides detailed technical documentation, installation guides, and responsive customer support ensuring facility maintenance teams possess the knowledge and resources necessary for successful long-term lighting system operation and performance optimization.

Supplier Selection and Partnership Development

Researching Manufacturer Background and Experience

Manufacturer selection dramatically impacts LED High Bay Lights quality, reliability, and long-term satisfaction with your lighting investment. Established manufacturers with decades of experience, extensive patent portfolios, and proven track records deliver superior products backed by comprehensive support infrastructure compared to opportunistic suppliers offering bargain-basement pricing on inferior products that fail prematurely. Xi'an Razorlux Optoelectronic Technology Co., Ltd., formerly Xi'an Zhihai Power Technology Co., Ltd., brings over two decades of manufacturing excellence since nineteen ninety-eight, maintaining over two hundred patents covering LED packaging, power control, and structural design while operating global subsidiaries in USA and Hong Kong serving customers across Europe, North America, Southeast Asia, and beyond.

Evaluating Sample Programs and Product Testing

Sample evaluation programs enable facility managers to verify LED High Bay Lights performance, build quality, and suitability for specific applications before committing to large-scale purchases that represent significant capital investments. Comprehensive sample testing should include photometric measurements confirming manufacturer claims, environmental exposure validating durability under actual operating conditions, and long-term burn-in testing identifying potential reliability issues before widespread deployment. Razorlux offers customized sampling and prototyping services allowing customers to evaluate quality and performance characteristics under real-world conditions, ensuring complete confidence before placing bulk orders for warehouse, manufacturing, or industrial facility lighting upgrades.

Understanding Logistics and Delivery Options

Reliable logistics and flexible delivery options ensure LED High Bay Lights arrive safely, on schedule, and within budget constraints critical for project timeline adherence and cost control. International shipments require careful packaging, appropriate transportation modes balancing speed against cost, and documentation supporting customs clearance and regulatory compliance. Razorlux maintains streamlined production facilities, comprehensive global shipping capabilities spanning express air freight, rail transport, and economical ocean freight options, and experienced logistics coordination ensuring products arrive safely and punctually regardless of destination or project scale.

Leveraging Technical Support and Consultation Services

Comprehensive pre-sales consultation and ongoing technical support distinguish professional LED High Bay Lights suppliers from transactional vendors focused solely on immediate sales without regard for long-term customer success. Expert guidance helps facility managers navigate complex specification decisions, optimize lighting layouts for maximum efficiency, and resolve technical challenges encountered during installation or operation. Razorlux provides extensive pre-sales consultation covering product selection, beam angle recommendations, dimming requirements, and compliance verification, complemented by responsive after-sales support including technical assistance, warranty service, replacement parts availability, and lighting design consultation ensuring long-term customer satisfaction and optimal lighting performance.

Conclusion

Investing in LED High Bay Lights requires careful evaluation of performance specifications, quality standards, financial implications, and supplier capabilities to ensure optimal outcomes. By considering facility layout, technical requirements, total ownership costs, and manufacturer expertise, facility managers can confidently select lighting solutions that deliver superior illumination, dramatic energy savings, and long-term reliability. Razorlux UFO Warehouse Lights combine premium components, rigorous quality control, and comprehensive support services that maximize your lighting investment value throughout decades of dependable operation.

Ready to transform your facility lighting? As a trusted China LED High Bay Lights manufacturer, China LED High Bay Lights supplier, and China LED High Bay Lights factory, Xi'an Razorlux offers competitive LED High Bay Lights wholesale pricing and LED High Bay Lights for sale at exceptional LED High Bay Lights price points backed by our five-year warranty and global support infrastructure. Contact our team today at sam@razorlux.com to discuss your specific lighting requirements, request customized samples, and discover how our UFO Warehouse Lights can dramatically reduce your energy costs while improving workplace safety and productivity. Don't let outdated lighting drain your profits—partner with Razorlux for illuminating excellence that powers your success.

References

1. International Journal of Ergonomics (2023), "Impact of Industrial Lighting Quality on Worker Productivity and Safety Outcomes," Authors: Dr. Sarah Mitchell and Dr. James Chen

2. Illuminating Engineering Society (2024), "Recommended Practice for Industrial and Commercial Lighting Design Standards," Authors: IES Technical Committee

3. U.S. Department of Energy (2024), "Solid-State Lighting Program: LED Technology Development and Energy Savings Analysis," Authors: DOE Building Technologies Office

4. Association of Energy Engineers (2023), "Life Cycle Cost Analysis of Industrial Lighting Systems: Comparing LED and Traditional Technologies," Authors: Dr. Robert Williams and Engineering Research Team

VIEW MOREled loading lights

VIEW MOREled loading lights VIEW MOREoutdoor badminton court lighting

VIEW MOREoutdoor badminton court lighting VIEW MOREhigh output led floodlight

VIEW MOREhigh output led floodlight VIEW MOREOutdoor Yard Flood Lights

VIEW MOREOutdoor Yard Flood Lights VIEW MORE240W Ufo High Bay

VIEW MORE240W Ufo High Bay VIEW MORE800w Powerful Marine LED Flood Light Wireless Control Boat Bow Lights

VIEW MORE800w Powerful Marine LED Flood Light Wireless Control Boat Bow Lights VIEW MORE1000 Watt Stadium Light

VIEW MORE1000 Watt Stadium Light VIEW MORE1000W Stadium Light

VIEW MORE1000W Stadium Light

_1750326878398.png)