1000 Watt Led Stadium Lights – OEM Options for Bulk Stadium Projects

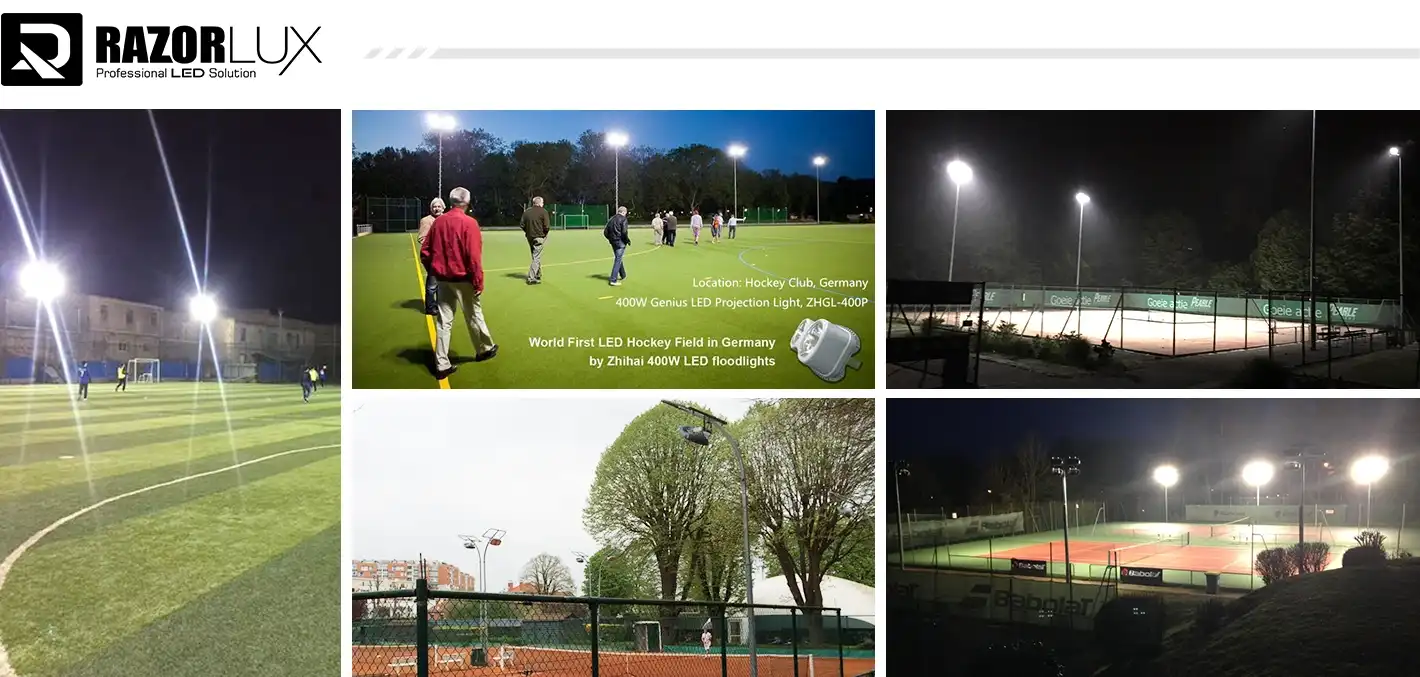

Picture this: your stadium project deadline is approaching, but your current lighting supplier can't deliver the brightness levels broadcasters demand, the energy bills are spiraling out of control, and you're facing complaints about poor visibility during evening games. These are real challenges that facility managers and project contractors face daily when dealing with inadequate stadium lighting solutions. This comprehensive guide addresses exactly how 1000 Watt LED Stadium Lights with OEM customization options can solve these critical pain points for bulk stadium projects, helping you achieve professional-grade illumination while maintaining budget control and meeting strict project timelines.

Understanding 1000 Watt LED Stadium Light Specifications for Large-Scale Projects

Core Technical Parameters of High-Power Stadium LED Lighting

When planning bulk stadium projects, understanding the technical specifications of 1000 Watt Led Stadium Lights becomes absolutely critical for project success. The rated power of 1000W represents the total consumption, typically divided between 900W for the LED modules and 100W for the driver system, ensuring optimal performance and longevity. This professional-grade stadium lighting solution delivers an impressive 105,000 lumens at 5700K color temperature after one hour of stable operation, providing the exceptional brightness required for professional sports venues, broadcast-quality events, and large-scale outdoor facilities. The input voltage flexibility ranges from AC 80-305Vac to DC 100-400Vdc and even 500-800Vdc, making these lights adaptable to various power infrastructure conditions across different countries and regions. The lamp efficiency of 130LM/W significantly outperforms traditional metal halide systems, which is why 1000 Watt LED Stadium Lights can effectively replace 2000-3000W HID lamps while reducing energy consumption by up to 60%. The beam angle of 20 degrees provides focused, precise illumination perfect for targeting specific playing field areas, while the color rendering index (CRI) of Ra>75 ensures accurate color representation crucial for HD broadcasting and slow-motion replays. These technical parameters aren't just numbers on a specification sheet; they directly translate to operational cost savings, improved visibility, and enhanced spectator experience that justify the initial investment in quality stadium lighting infrastructure.

Durability Features and Environmental Protection Standards

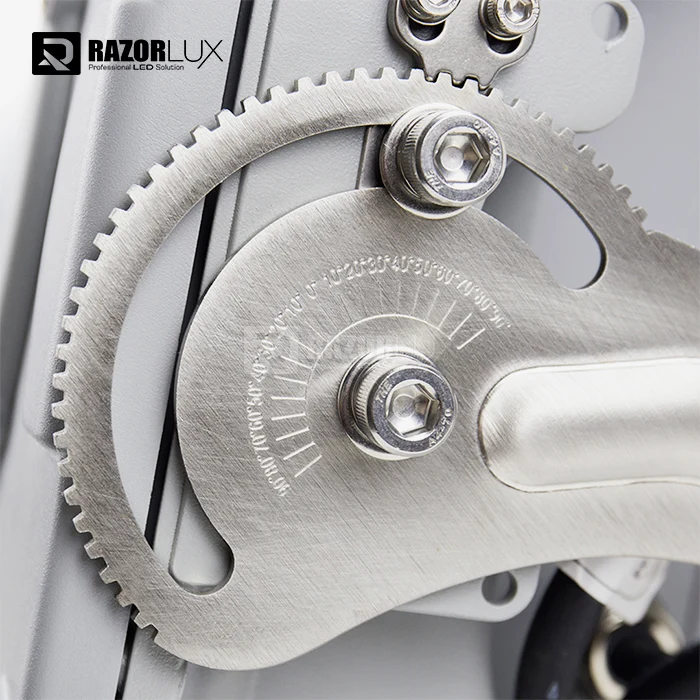

The construction quality and environmental protection rating of 1000 Watt LED Stadium Lights determine their suitability for demanding outdoor applications and harsh weather conditions. With an IP65/IP67 rating, these stadium lights offer complete protection against dust ingress and powerful water jets, ensuring reliable operation during heavy rain, snow, and extreme weather events that would compromise inferior lighting systems. The IK10 impact resistance rating means these fixtures can withstand mechanical impacts up to 20 joules, providing essential protection in sports environments where stray balls and equipment pose constant threats to lighting infrastructure. The housing material combines high-grade aluminum construction with powder coating treatment, delivering excellent heat dissipation properties while resisting corrosion from salt spray in coastal venues or chemical exposure in industrial areas. The stainless steel mounting bracket adds another layer of durability, supporting the substantial 29kg weight while maintaining precise aiming angles throughout the fixture's 50,000+ hour operational lifespan. Working temperature range from -40°C to 60°C (-40°F to 140°F) and humidity tolerance from 10% to 95% demonstrate the robust engineering that allows 1000 Watt LED Stadium Lights to function reliably across diverse climate zones from arctic conditions to tropical environments. The patented multi-function design incorporates advanced thermal management systems that prevent overheating and maintain consistent light output even during extended operation periods. Furthermore, the emergency power function developed by Razorlux enables these lights to continue operating for two hours during power outages, ensuring safety and continuity during critical events. These durability features aren't marketing hype; they represent the difference between lighting systems that require constant maintenance and those that deliver years of trouble-free operation in your stadium facility.

Compliance Certifications for International Stadium Projects

For bulk stadium projects spanning multiple countries and regions, certification compliance becomes a non-negotiable requirement that can make or break project approval and insurance coverage. The 1000 Watt LED Stadium Lights from Xi'an Razorlux carry comprehensive international certifications including CE, RoHS, SAA, C-Tick, UL, DLC, CB, and ISO:9001, demonstrating compliance with safety and performance standards across European, North American, Australian, and Asian markets. The UL certification particularly matters for North American projects, as it verifies electrical safety and fire prevention standards that insurance companies and building inspectors require before approving stadium installations. DLC listing ensures eligibility for utility rebate programs that can offset 20-40% of project costs in many jurisdictions, making these 1000 Watt LED Stadium Lights financially attractive beyond their inherent energy savings. CE marking indicates conformity with European Union directives covering electromagnetic compatibility (EMC), low voltage directives, and environmental regulations that govern commercial lighting installations across EU member states. The RoHS compliance guarantees that these fixtures contain no hazardous substances like lead, mercury, or cadmium, addressing environmental concerns and disposal regulations that increasingly affect procurement decisions for government-funded stadium projects. SAA and C-Tick certifications open doors to Australian and New Zealand markets where strict electrical safety standards apply to all commercial lighting installations. Beyond individual product certifications, the ISO:9001 certification of Razorlux's manufacturing facilities provides assurance of consistent quality control processes, documented procedures, and continuous improvement systems that reduce defect rates and ensure batch-to-batch consistency critical for large-scale stadium lighting projects. These certifications represent thousands of hours of testing, documentation, and factory audits that protect your project from compliance issues, liability concerns, and costly retrofits that plague installations using uncertified lighting products.

OEM Customization Capabilities for Bulk Stadium Lighting Orders

Tailored Specifications Matching Project Requirements

| Customization Parameter | Standard Options | Custom Range Available | Typical Application |

|---|---|---|---|

| Wattage | 1000W | 500W-1500W | Different venue sizes |

| Color Temperature | 2700K-6500K | Custom Kelvin values | Broadcast requirements |

| Beam Angle | 20° | 10°-90° | Field coverage patterns |

| Control System | Standard | 0-10V, DALI, DMX512 | Smart stadium integration |

| Housing Color | Standard powder coat | Custom RAL colors | Architectural matching |

| Mounting Options | Standard bracket | Custom mounting solutions | Unique installation needs |

OEM customization transforms standard 1000 Watt LED Stadium Lights into precisely tailored solutions that address specific project challenges and unique venue requirements. Xi'an Razorlux's flexible manufacturing capabilities enable wattage adjustments from 500W to 1500W, allowing project managers to optimize light levels for different areas within the same facility—perhaps using higher wattage for main playing fields and lower wattage for practice areas or parking zones. Color temperature customization beyond the standard 2700K-6500K range accommodates special broadcast requirements where specific Kelvin values enhance camera performance or match existing lighting infrastructure in phased renovation projects. Beam angle modification from narrow 10-degree spots to wide 90-degree floods enables optimal light distribution patterns that eliminate dark zones and reduce the total number of fixtures required, directly impacting project budgets and structural load considerations. Control system integration including 0-10V dimming, DALI addressable controls, and DMX512 dynamic effects opens possibilities for smart stadium applications where lighting responds to different event types, creates pre-game atmosphere effects, or reduces consumption during low-attendance events. Housing color customization using any RAL color code allows these 1000 Watt LED Stadium Lights to blend seamlessly with architectural aesthetics, satisfying municipal design review boards and maintaining visual harmony in historically significant venues. Custom mounting solutions address unusual installation scenarios like temporary structures, retrofit applications with limited mounting points, or specialized aiming requirements for irregularly shaped venues. The OEM approach extends beyond simple parameter changes to include complete product development partnerships where Razorlux's R&D team collaborates on entirely new fixture designs incorporating your specific technological requirements, branding elements, and performance criteria. This level of customization capability distinguishes professional OEM manufacturers from simple product suppliers, providing the flexibility that complex stadium projects demand while maintaining the quality standards and certifications that ensure project success and long-term operational reliability.

Branding and Private Label Solutions for Distributors

For distributors and large-scale contractors managing multiple stadium projects, private label and branded 1000 Watt LED Stadium Lights create market differentiation and build brand equity while leveraging proven manufacturing expertise. Xi'an Razorlux offers comprehensive ODM (Original Design Manufacturer) services that allow partners to market these high-performance stadium lights under their own brand identity, complete with custom Packaging, product literature, and technical documentation reflecting their corporate image. The process begins with collaborative design sessions where Razorlux's experienced team helps translate your market positioning and target customer requirements into concrete product specifications and visual designs that distinguish your offering from competitors. Custom housing designs can incorporate unique aesthetic elements, proprietary mounting systems, or integrated features that become signature elements of your branded product line, protected by design patents and trademarks that prevent copying. Laser engraving or embossed branding on fixture housings ensures permanent identification that survives years of outdoor exposure, building brand recognition with every installation and generating word-of-mouth referrals when facility managers see these lights performing reliably in existing venues. Packaging customization extends beyond simple logo placement to include branded cartons, custom foam inserts showcasing your company name, multilingual instruction manuals, and promotional materials that support your sales process and reinforce quality perceptions with end customers. For large volume commitments, Razorlux can dedicate production lines to your specifications, ensuring absolute consistency across thousands of 1000 Watt LED Stadium Lights that carry your brand promise to markets worldwide. The private label approach particularly benefits regional distributors who need products certified for their specific markets but lack the resources to establish manufacturing operations or navigate complex certification processes independently. Technical support documentation, warranty cards, and customer service materials can all be co-branded or fully customized to present a seamless brand experience where customers interact exclusively with your company while benefiting from Razorlux's two decades of LED manufacturing expertise, extensive patent portfolio covering over 200 innovations, and proven quality control systems. This partnership model allows ambitious companies to compete effectively against established lighting brands without the capital investment and time required to develop proprietary manufacturing capabilities, accelerating market entry and building sustainable competitive advantages in the growing stadium lighting sector.

Volume Production and Lead Time Management

Managing bulk orders of 1000 Watt LED Stadium Lights requires sophisticated production planning, inventory management, and logistics coordination that separates capable OEM partners from suppliers who overpromise and underdeliver. Xi'an Razorlux's manufacturing capacity and production systems are specifically designed to handle large-scale stadium projects requiring hundreds or thousands of fixtures delivered according to strict construction schedules where delays trigger penalty clauses and jeopardize project completion bonuses. The production process begins with DFMEA (Design Failure Mode and Effects Analysis) to identify and eliminate potential quality issues before mass production starts, reducing defect rates and ensuring that bulk orders meet specifications without requiring extensive sorting or rework. Flexible MOQ (Minimum Order Quantity) options accommodate both initial sample testing phases and subsequent full-scale production runs, allowing project managers to validate performance in actual installation conditions before committing to complete orders. Advanced production scheduling systems coordinate raw material procurement, component manufacturing, assembly operations, and quality testing to optimize throughput while maintaining the rigorous standards that stadium lighting applications demand. The production capacity supports rapid scaling for urgent projects while maintaining consistent quality across thousands of units, with dedicated assembly lines ensuring that your 1000 Watt LED Stadium Lights receive focused attention rather than competing for resources with unrelated product lines. Lead time management incorporates buffer inventory of long-lead components like specialized LED modules and Meanwell power supplies, preventing supply chain disruptions from delaying your project even when global component availability tightens. Transparent communication systems provide real-time production status updates, allowing project managers to coordinate installation crews, electricians, and other contractors with confidence that lighting fixtures will arrive as scheduled. For phased stadium projects where different sections require lighting at different times, Razorlux can coordinate staggered deliveries that match construction progress, reducing on-site storage requirements and minimizing exposure to theft or weather damage before installation. Rush production capabilities exist for emergency situations where unexpected failures require rapid replacement or where accelerated project schedules demand compressed manufacturing timelines, though proper planning typically makes such expensive measures unnecessary. The combination of production capacity, quality systems, and project management expertise ensures that your bulk stadium lighting order progresses smoothly from initial specifications through final delivery, supporting successful project completion and establishing the foundation for ongoing partnerships on future stadium developments.

Quality Assurance and After-Sales Support for Stadium Lighting Projects

Comprehensive Testing Procedures Ensuring Performance

| Test Procedure | Purpose | Standard Applied | Pass Criteria |

|---|---|---|---|

| Photometric Testing | Light output verification | LM-79 | ±5% of rated lumens |

| Aging Test | Reliability validation | 100% units, 48+ hours | Zero failures |

| IP67 Testing | Water resistance | IEC 60529 | No ingress detected |

| EMC Testing | Electromagnetic compatibility | EN 55015, EN 61547 | Within limits |

| Thermal Cycling | Temperature stress | -40°C to +60°C cycles | Maintains function |

| Vibration Testing | Mechanical durability | IEC 60068-2-6 | No structural damage |

Quality assurance processes for 1000 Watt LED Stadium Lights extend far beyond basic functionality checks to encompass rigorous testing protocols that simulate years of real-world operation and extreme conditions these fixtures will encounter in actual stadium environments. The photometric testing phase utilizes integrating spheres and spectroradiometers to precisely measure light output, color temperature consistency, and beam pattern accuracy, ensuring that every fixture delivers the 105,000 lumens and spectral characteristics specified rather than relying on sample testing that might miss batch variations. The aging test represents one of the most critical quality control measures, where 100% of finished 1000 Watt LED Stadium Lights undergo continuous operation for 48+ hours at full power in controlled thermal chambers, revealing infant mortality failures, component weaknesses, and assembly defects that would otherwise cause premature field failures and expensive warranty claims. IP67 waterproof testing subjects sealed fixtures to sustained high-pressure water jets from multiple angles, then immediate inspection for any moisture ingress that would compromise electrical safety or accelerate LED degradation in outdoor stadium installations exposed to rain, snow, and humidity. Electromagnetic compatibility (EMC) testing verifies that these high-power lights neither generate excessive electromagnetic interference that could disrupt wireless communication systems, scoreboards, or broadcast equipment, nor prove susceptible to external electromagnetic disturbances common in modern stadiums with extensive electronic infrastructure. Thermal cycling tests expose fixtures to repeated temperature extremes from -40°C to +60°C, simulating seasonal variations and daily thermal shocks that cause expansion and contraction stresses potentially leading to solder joint failures, optical misalignment, or housing cracks in inferior products. Vibration testing replicates the mechanical stresses from wind loading, structural movements, and nearby construction activities that stadium lights must withstand throughout their operational life without developing loose connections, rattling components, or optical element displacement. Beyond standardized testing, Xi'an Razorlux employs advanced DFMEA methodology during the design phase to proactively identify potential failure modes and implement preventive design features, reducing the likelihood that any 1000 Watt LED Stadium Lights will fail during their rated 50,000+ hour lifespan. This comprehensive testing investment substantially increases manufacturing costs compared to competitors who ship products based on minimal sampling, but the resulting reliability dramatically reduces total cost of ownership through eliminated warranty claims, avoided emergency replacements, and maintained reputation that supports repeat business and referrals from satisfied customers.

Warranty Coverage and Technical Support Services

Professional stadium lighting installations represent significant capital investments where comprehensive warranty coverage and responsive technical support directly impact total project value and long-term ownership costs. Xi'an Razorlux provides industry-leading warranty terms for 1000 Watt LED Stadium Lights including 5 years coverage on both LED modules and drivers, plus 10 years on housing components, demonstrating confidence in product durability and manufacturing quality that inferior competitors cannot match. This warranty structure addresses the complete fixture rather than creating complicated exclusions where customers discover that failures fall into uncovered categories, ensuring genuine protection against premature failures and manufacturing defects throughout the critical early operational period when any quality issues typically manifest. The warranty process emphasizes simplicity and speed, with straightforward claim procedures, minimal documentation requirements, and rapid response times that minimize downtime when issues occur, recognizing that dark sections of stadiums during events create safety hazards, generate complaints, and potentially trigger contractual penalties for facility operators. Technical support extends beyond warranty repair obligations to include pre-installation consultation where experienced lighting engineers review your project plans, identify potential issues, recommend optimal fixture placement and aiming angles, and provide detailed installation specifications that help electricians and contractors avoid common mistakes that compromise performance or void warranties. The support team includes English-speaking specialists available through multiple channels including email (sam@razorlux.com), phone, and video conferencing, capable of addressing complex technical questions about electrical integration, control system programming, photometric calculations, and troubleshooting unusual issues that arise during installation or operation. For large stadium projects, on-site installation assistance can be arranged where Razorlux technicians travel to your location, train local crews on proper installation procedures, supervise critical mounting and aiming operations, and commission the completed system to verify all 1000 Watt LED Stadium Lights perform according to specifications before final acceptance. Spare parts availability represents another crucial support dimension, with strategic inventory of replacement drivers, LED modules, optical components, and mounting hardware ensuring that any necessary repairs can be completed quickly without waiting weeks for overseas shipping of specialized components. The commitment to after-sales support reflects understanding that customer relationships extend far beyond initial product delivery, and that satisfied customers operating reliable stadium lighting systems become the most valuable marketing assets through referrals, testimonials, and repeat orders for additional projects. This comprehensive support infrastructure differentiates professional OEM manufacturers from transactional suppliers who disappear after receiving payment, leaving customers struggling with technical challenges and warranty claims that go unanswered.

Global Logistics and Delivery Solutions

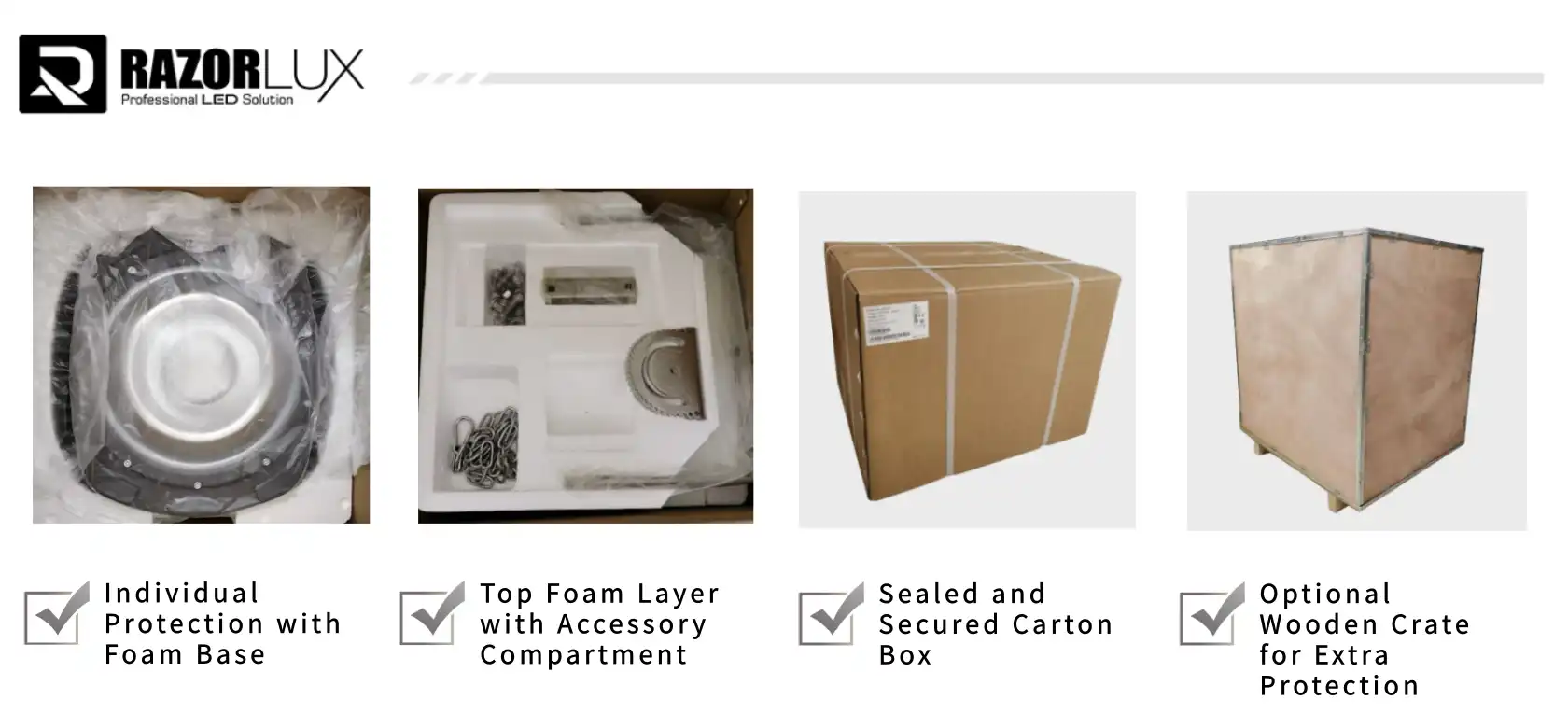

Efficient logistics and reliable delivery systems are essential for bulk stadium lighting projects where construction schedules depend on timely equipment arrival and delays cascade through multiple dependent activities. Xi'an Razorlux offers comprehensive global shipping solutions tailored to project requirements, budget constraints, and timeline urgency, ensuring your 1000 Watt LED Stadium Lights arrive safely and on schedule regardless of destination. International express shipping via DHL, FedEx, or UPS provides 3-7 day delivery for urgent sample orders or emergency replacement needs, with door-to-door service and full tracking capability, optimally handling shipments from 0.5kg to 300kg where contracted express rates offer cost efficiency. Air freight options deliver 300kg+ shipments in 5-10 days through airport-to-port or airport-to-door services, providing significantly better economics than express shipping for heavier cartons while maintaining reasonable transit times suitable for projects with moderate urgency. China-Europe Railway Express offers 18-22 day transit times for shipments exceeding 2CBM/500KG, balancing cost and speed for large orders where air freight becomes prohibitively expensive but ocean shipping seems excessively slow, particularly benefiting European projects where rail connections provide reliable schedules and reasonable rates. Ocean freight via full container loads (FCL) or less-than-container loads (LCL) represents the most economical shipping method for non-urgent bulk orders, with 15-50 day transit times depending on destination ports, ideal for planned stadium construction projects where advance ordering allows extended shipping periods. The packaging system protects these substantial fixtures during international transport through multiple protective layers including individual plastic bags, custom-cut foam bases providing secure cushioning, foam top layers with dedicated accessory compartments for brackets and mounting hardware, heavy-duty cartons sealed with reinforced packing tape and plastic strapping, and optional wooden crate solutions for customers requiring extra protection during bulk shipments or particularly rough handling conditions. Palletized shipments for large orders optimize container utilization while facilitating efficient unloading with forklifts, reducing labor costs and minimizing handling damage at destination. Customs documentation assistance streamlines import processes, with experienced shipping coordinators preparing accurate commercial invoices, packing lists, certificates of origin, and product compliance declarations that prevent customs delays and unexpected duty assessments. For complex projects spanning multiple delivery locations, coordinated logistics can stage shipments to different job sites according to construction progress, ensuring that 1000 Watt LED Stadium Lights arrive exactly when installation crews are ready to mount them rather than requiring extended on-site storage with associated security and weather protection concerns. This comprehensive logistics capability reflects Xi'an Razorlux's experience supporting international projects across Europe, North America, Southeast Asia, and beyond, understanding that successful product delivery requires more than simply shipping boxes but rather coordinating complex international supply chains that align with project schedules and customer expectations.

| Transportation Time | Shipping Option Details | Recommend Weight |

| 3-7 days | International Express(DHL, FedEx, UPS, TNT, etc.) | 0.5KG-300KG(optimal for cost efficiency under our contarated express rates) |

| 5-10 days | By Air (Airport-to-port or Airport-to-door) | 300KG+(Significantly more economical than express shipping for heavy cargo) |

| 18-22 days | By Rail(China-Europe Railway Express) | 2CBM/500KG+(More economical than air freight for large shipment with flexible timelines) |

| 15-50 days | By Sea(FLC/LCL) | 2CBM/500KG+(Much more economical than rail,suit for non-urgent cargo, also the most cost-effective shipping method) |

Conclusion

Selecting the right 1000 Watt LED Stadium Lights with comprehensive OEM customization capabilities fundamentally transforms bulk stadium projects from risky ventures into successful installations that deliver superior performance, cost efficiency, and long-term reliability. Xi'an Razorlux Optoelectronic Technology Co., Ltd. combines proven manufacturing excellence, extensive certification compliance, flexible customization options, and comprehensive support services that address every challenge facing stadium lighting projects from initial specification through years of operational service.

Ready to transform your stadium lighting project with professional-grade 1000 Watt LED Stadium Lights backed by OEM customization and reliable support? As a leading China 1000 Watt Led Stadium Lights manufacturer, Xi'an Razorlux serves as your trusted China 1000 Watt Led Stadium Lights supplier offering competitive 1000 Watt Led Stadium Lights price for bulk orders. Our China 1000 Watt Led Stadium Lights factory specializes in China 1000 Watt Led Stadium Lights wholesale solutions with high-quality 1000 Watt Led Stadium Lights for sale worldwide. Contact our expert team today at sam@razorlux.com to discuss your specific requirements, request customized samples, and discover how our OEM capabilities can optimize your next stadium project. Don't let inadequate lighting compromise your facility's performance—partner with Razorlux and illuminate success. Bookmark this guide for future reference as you plan your stadium lighting investments, and reach out whenever questions arise about specifications, customization options, or project implementation strategies.

References

1. "LED Stadium Lighting: Design Considerations and Best Practices" - Illuminating Engineering Society (IES), Technical Memorandum TM-24-17, authored by Sports and Recreational Areas Lighting Committee

2. "Energy Efficiency in Sports Facilities: LED Lighting Implementation Guidelines" - U.S. Department of Energy, Federal Energy Management Program, prepared by Lawrence Berkeley National Laboratory

3. "International Standards for Sports Lighting: Broadcast and Competition Requirements" - Commission Internationale de l'Éclairage (CIE), Publication 169:2020, authored by Technical Committee TC 5-29

4. "Comparative Life Cycle Assessment of Stadium Lighting Technologies" - Journal of Cleaner Production, Volume 287, authored by Dr. Sarah Mitchell and Dr. James Chen, Environmental Engineering Research Institute

5. "OEM Manufacturing Strategies in the LED Lighting Industry: Quality Control and Supply Chain Management" - International Journal of Production Economics, Volume 235, authored by Professor David Wang, Industrial Engineering Department, Tsinghua University

_1750326878398.png)