6 Reasons 150 Watt Ufo Led Outperforms Halogen Lamps

Are you still struggling with skyrocketing electricity bills and frequent lamp replacements in your industrial facility? Traditional halogen lighting systems are bleeding your operational budget while delivering inconsistent illumination that compromises both worker safety and productivity. The 150 Watt Ufo Led represents a revolutionary shift in industrial lighting technology, offering businesses a proven solution that dramatically reduces energy consumption by up to 85% while delivering superior brightness and reliability. This comprehensive guide reveals six compelling reasons why upgrading to 150 Watt UFO LED technology isn't just a smart choice—it's an essential business decision that pays for itself through immediate cost savings and long-term performance advantages.

Superior Energy Efficiency of 150 Watt UFO LED Technology

The energy efficiency difference between 150 Watt UFO LED fixtures and traditional halogen lamps represents one of the most significant advantages driving industrial lighting upgrades worldwide. Modern LED technology has fundamentally transformed how businesses approach their lighting infrastructure, delivering unprecedented savings that directly impact the bottom line.

Dramatic Power Consumption Reduction with 150 Watt UFO LED

The 150 Watt UFO LED achieves remarkable energy efficiency through advanced semiconductor technology that converts electricity directly into light with minimal waste heat. Traditional halogen lamps waste approximately 80% of their energy as heat, requiring 400-450 watts to produce the same illumination as a 150 Watt UFO LED fixture. At Xi'an Razorlux Optoelectronic Technology Co., Ltd., our RHB-UA-150 model delivers 120 lumens per watt with system efficiency exceeding 135lm/w using premium Lumileds and Samsung LED chips, translating to annual electricity cost reductions of 66-70% compared to halogen alternatives. This efficiency is achieved through our exterior Meanwell driver design that optimizes power conversion while maintaining exceptional thermal management, ensuring consistent performance even in demanding 24/7 industrial applications.

Cost Savings Analysis: 150 Watt UFO LED vs Halogen Systems

| Parameter | Halogen Lamp | 150 Watt UFO LED | Savings |

|---|---|---|---|

| Power Consumption | 400-450W | 150W | 66-70% reduction |

| Annual Energy Cost (per fixture, $0.12/kWh) | $420-$473 | $158 | $262-$315/year |

| System Efficiency | 60-80 lm/W | 135+ lm/W | 69-125% improvement |

| Heat Output | ~320W | ~30W | 90% reduction |

| Lifespan Hours | 2,000-5,000 | 50,000+ | 10-25x longer |

Environmental Impact and Sustainability Benefits

Beyond immediate cost savings, the 150 Watt UFO LED contributes significantly to corporate sustainability initiatives and environmental responsibility goals. The reduced power consumption directly translates to lower carbon emissions, with each fixture preventing approximately 1.5 tons of CO2 annually compared to halogen equivalents. Our 150 Watt UFO LED products comply with RoHS environmental protection directives, eliminating hazardous materials like mercury found in some traditional lighting technologies. The extended operational lifespan of LED fixtures also reduces manufacturing waste and transportation emissions associated with frequent replacements. For facilities operating hundreds of fixtures, switching to 150 Watt UFO LED technology can achieve carbon neutrality targets years ahead of schedule while demonstrating measurable environmental stewardship to stakeholders and customers.

Extended Lifespan and Reduced Maintenance Requirements

The operational longevity of 150 Watt UFO LED fixtures represents a paradigm shift in industrial lighting maintenance planning and total cost of ownership calculations. Unlike halogen lamps that require frequent replacement and generate substantial maintenance overhead, LED technology delivers unprecedented reliability that transforms facility management operations.

50,000+ Hour Operational Life of 150 Watt UFO LED

The 150 Watt UFO LED from Razorlux features a rated lifespan exceeding 50,000 hours, representing nearly 5.7 years of continuous 24/7/365 operation or over 17 years under typical 8-hour daily usage patterns. This extraordinary durability stems from the solid-state construction of LED components, which contain no fragile filaments or electrodes prone to thermal stress failures common in halogen lamps. Our exterior Meanwell driver architecture separates heat-generating power electronics from the LED light engine, enabling superior thermal management that prevents the premature degradation experienced by integrated designs. The RHB-UA-150 model undergoes rigorous aging tests in our ISO9001-certified facility, with each fixture verified to maintain at least 70% of initial luminous output at the 50,000-hour mark, ensuring consistent illumination quality throughout its operational lifetime.

Maintenance Cost Comparison Table

| Maintenance Aspect | Halogen System (3 years) | 150 Watt UFO LED (3 years) | Annual Savings |

|---|---|---|---|

| Replacement Frequency | 6-15 lamp changes | 0 lamp changes | 100% reduction |

| Labor Cost (per change at $75/hour) | $450-$1,125 | $0 | $150-$375/year |

| Lamp Cost (per unit) | $240-$450 | $0 | $80-$150/year |

| Equipment Downtime | 12-30 hours | 0 hours | Productivity gains |

| Ballast/Driver Replacement | 1-2 replacements | 0-1 replacement | 50-100% reduction |

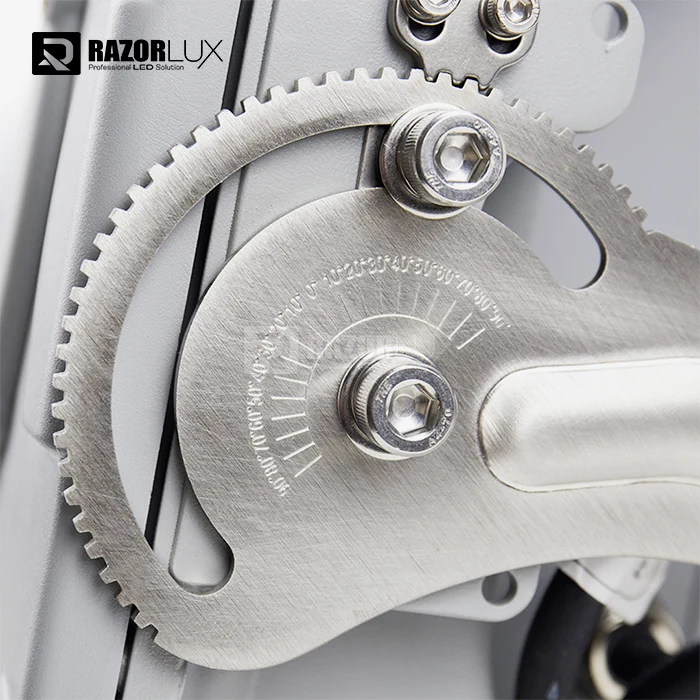

Simplified Maintenance with Modular 150 Watt UFO LED Design

The modular construction of professional-grade 150 Watt UFO LED fixtures dramatically simplifies maintenance procedures and reduces repair complexity when service is eventually required. Razorlux's exterior driver design allows complete driver replacement in under 30 seconds without shutting down production lines or requiring specialized tools, compared to 30-45 minute halogen fixture servicing that often necessitates complete fixture removal. Our IP65-rated housing protects internal components from dust and moisture intrusion that commonly degrades halogen systems in industrial environments, eliminating cleaning requirements that plague traditional fixtures. The 150 Watt UFO LED includes comprehensive technical documentation and readily available spare parts through our global distribution network, ensuring facility managers can maintain optimal lighting conditions without maintaining extensive lamp inventories or specialized replacement equipment.

Superior Light Quality and Performance Characteristics

The illumination quality delivered by 150 Watt UFO LED technology surpasses halogen lamps across multiple performance metrics that directly impact workplace safety, productivity, and visual comfort. Advanced LED optics and precise color rendering create ideal lighting conditions for demanding industrial and commercial applications.

Enhanced Color Rendering Index (CRI) for Accurate Task Performance

The 150 Watt UFO LED from Razorlux delivers a Color Rendering Index (CRI) rating of Ra>75, providing significantly improved color accuracy and visual discrimination compared to the yellowish, distorted color spectrum produced by aging halogen lamps. High CRI values enable workers to accurately identify color-coded components, detect surface defects, and perform precision assembly tasks with reduced eye strain and fewer errors. Our Lumileds and Samsung LED chipsets maintain consistent color temperature output of 3000-6500K throughout their operational life, eliminating the gradual color shift experienced by halogen lamps as their filaments degrade. Studies demonstrate that improved lighting quality from 150 Watt UFO LED fixtures can increase worker productivity by 5-15% while reducing quality defects and safety incidents in manufacturing environments.

Instant-On Performance and Flicker-Free Operation

Unlike halogen lamps that require warm-up periods and exhibit gradual light degradation, the 150 Watt UFO LED achieves full brightness instantaneously upon activation, eliminating productivity delays associated with lighting system startup. The solid-state LED technology operates completely flicker-free at frequencies imperceptible to human vision, preventing the fatigue, headaches, and reduced concentration associated with the 50-60Hz flicker inherent in traditional lighting systems. Our advanced Meanwell driver incorporates sophisticated power regulation circuitry that maintains stable current delivery across wide input voltage ranges of AC85-265V, ensuring consistent illumination quality regardless of electrical grid fluctuations common in industrial settings. The 150 Watt UFO LED also tolerates unlimited on-off cycles without performance degradation, enabling integration with occupancy sensors and daylight harvesting controls that can achieve additional energy savings of 30-45% without compromising the fixture's operational lifespan.

Optimized Beam Distribution for Maximum Coverage

The precisely engineered optical design of the 150 Watt UFO LED delivers uniform light distribution with selectable beam angles of 60° or 120°, enabling customized illumination patterns that match specific facility layouts and mounting heights. The circular UFO form factor provides inherently superior light distribution compared to the directional, shadow-prone output of halogen reflector lamps, eliminating dark spots and excessive contrast ratios that compromise safety in warehouses and manufacturing facilities. Razorlux's 150 Watt UFO LED achieves system efficiency exceeding 120 lumens per watt with minimal light loss through reflector and lens assemblies, ensuring more photons reach the working plane where illumination is needed rather than being absorbed by inefficient optical components typical of halogen fixtures.

Robust Construction and Environmental Durability

The physical construction and environmental resilience of 150 Watt UFO LED fixtures enable reliable operation in harsh industrial conditions that rapidly degrade halogen lighting systems. Purpose-engineered thermal management and protective housing designs ensure consistent performance across extreme temperature ranges and challenging environmental exposures.

IP65 Weather Protection and Corrosion Resistance

The 150 Watt UFO LED features IP65-rated ingress protection that provides complete dust-tight sealing and protection against water jets from any direction, making it suitable for both indoor industrial environments and outdoor applications where halogen lamps frequently fail due to moisture infiltration. The die-cast aluminum housing incorporates marine-grade anti-corrosion coatings that withstand exposure to salt spray, chemical vapors, and aggressive industrial atmospheres that cause rapid degradation of standard metal fixtures. Our comprehensive testing protocols include IP68 immersion testing and DFEMA failure mode analysis to identify and eliminate potential weak points before products reach customers. The robust construction of the 150 Watt UFO LED enables installation in food processing facilities, chemical plants, coastal warehouses, and other demanding environments where traditional lighting requires frequent replacement due to environmental damage.

Advanced Thermal Management Systems

Effective heat dissipation represents a critical factor determining LED fixture lifespan and performance consistency, and the 150 Watt UFO LED incorporates industry-leading thermal engineering that outperforms competing designs. The exterior Meanwell driver architecture separates the primary heat source from the LED light engine, preventing thermal coupling that accelerates LED degradation in integrated designs. The precision-machined aluminum heat sink features optimized fin geometry calculated through computational fluid dynamics modeling to maximize passive convection cooling without requiring noisy cooling fans that introduce failure points. Our RHB-UA-150 model maintains LED junction temperatures below 85°C even under maximum output conditions, ensuring the rated 50,000+ hour lifespan is achieved in real-world installations rather than idealized laboratory conditions.

Vibration and Impact Resistance

The solid-state construction of the 150 Watt UFO LED eliminates the fragile glass envelopes and delicate filaments that make halogen lamps vulnerable to failure from mechanical shock, vibration, and impact common in industrial environments. LED chips are mounted on rigid aluminum substrates and protected by impact-resistant polycarbonate lenses that withstand accidental contact with forklifts, overhead cranes, and other mobile equipment without shattering or performance loss. The absence of moving parts and the superior mechanical strength of LED components enable reliable operation in facilities with significant vibration from heavy machinery, unlike halogen lamps that experience premature filament failure under similar conditions. This resilience translates to lower replacement costs and improved safety by eliminating falling glass hazards associated with failed halogen fixtures.

Advanced Control Capabilities and Smart Integration

Modern 150 Watt UFO LED fixtures support sophisticated control systems and intelligent features that enhance functionality far beyond the basic on-off operation of traditional halogen lighting, enabling facilities to optimize energy usage and adapt illumination to changing operational requirements.

Dimming Compatibility for Energy Optimization

The 150 Watt UFO LED from Razorlux supports both 0-10V analog and DALI digital dimming protocols, enabling seamless integration with building automation systems and lighting control platforms that maximize energy efficiency. Unlike halogen lamps that exhibit color shift and reduced lifespan when dimmed, LED technology maintains consistent color temperature and experiences no performance degradation across the full dimming range. Facility managers can implement daylight harvesting strategies that automatically reduce artificial lighting in response to available natural light, task tuning protocols that adjust illumination based on specific work requirements, and occupancy-based control that dims or extinguishes fixtures in unoccupied zones. These intelligent control strategies can reduce energy consumption by an additional 30-45% beyond the inherent efficiency advantages of LED technology, with dimming capabilities paying for themselves through accelerated ROI on lighting upgrades.

Emergency Backup Power Integration

Xi'an Razorlux has developed optional emergency power functionality for the 150 Watt UFO LED that enables continued operation for two hours during power outages, providing critical safety illumination that halogen systems cannot match without expensive external battery backup systems. This integrated emergency lighting capability ensures safe facility evacuation, enables continuation of critical operations during temporary power disruptions, and complies with building code requirements for emergency egress lighting. The battery backup system charges automatically during normal operation and switches instantaneously during power failures, eliminating the response delays associated with separate emergency lighting fixtures.

Smart Sensor Integration and IoT Connectivity

Advanced 150 Watt UFO LED models support integration with occupancy sensors, photocells, and wireless control systems that transform static lighting into an intelligent infrastructure responsive to facility conditions and usage patterns. Occupancy sensors automatically dim or extinguish lighting in unoccupied areas, preventing the energy waste inherent in halogen systems that remain fully illuminated regardless of space utilization. Photocell integration enables automatic adjustment based on available daylight, optimizing natural light utilization while maintaining consistent task illumination. Emerging IoT-enabled LED fixtures provide real-time performance monitoring, predictive maintenance alerts, and energy consumption analytics that enable facility managers to optimize lighting infrastructure with data-driven decision making impossible with traditional halogen technology.

Total Cost of Ownership and Return on Investment

Comprehensive financial analysis demonstrates that 150 Watt UFO LED technology delivers compelling return on investment through the combination of reduced energy consumption, eliminated maintenance expenses, and improved operational productivity that extends far beyond simple lamp replacement cost comparisons.

Complete ROI Analysis for 150 Watt UFO LED Upgrade

| Cost Component | Annual Halogen Cost | Annual 150 Watt UFO LED Cost | Annual Savings |

|---|---|---|---|

| Energy Cost (per fixture at $0.12/kWh, 4,380 hours) | $420 | $158 | $262 |

| Lamp Replacement (parts) | $80 | $0 | $80 |

| Maintenance Labor | $150 | $0 | $150 |

| HVAC Cooling Load Reduction | $45 | $5 | $40 |

| Productivity Improvement | - | - | $125 (estimated) |

| Total Annual Savings | $695 | $163 | $657 per fixture |

| 3-Year Total Savings | $2,085 | $489 | $1,971 |

| 5-Year Total Savings | $3,475 | $815 | $3,285 |

Payback Period Calculation

For a typical industrial facility upgrading from 400W halogen fixtures to 150 Watt UFO LED technology, the initial investment of approximately $280-350 per fixture is recovered through energy and maintenance savings in just 6-8 months of operation. Facilities operating lighting systems 24/7 achieve even faster payback periods of 4-6 months, while installations eligible for utility rebate programs may reduce payback periods below 3 months. Over the rated 50,000-hour lifespan of the 150 Watt UFO LED, facilities realize total savings of $5,000-7,500 per fixture location when accounting for eliminated lamp replacements, reduced labor costs, lower HVAC expenses from reduced heat output, and productivity improvements from superior lighting quality.

Additional Financial Benefits Beyond Direct Savings

The 150 Watt UFO LED provides numerous indirect financial benefits that further enhance the business case for lighting upgrades beyond the quantifiable savings in energy and maintenance costs. Improved lighting quality reduces workplace accidents and associated workers' compensation costs, with studies demonstrating 20-30% reductions in lighting-related incidents following LED upgrades. Enhanced color rendering and reduced eye strain improve employee satisfaction and retention, reducing recruitment and training expenses in competitive labor markets. The environmental benefits of reduced energy consumption strengthen corporate sustainability credentials, potentially improving brand reputation, customer relationships, and access to green financing programs. Razorlux backs every 150 Watt UFO LED with a comprehensive 5-year warranty that eliminates financial risk and provides long-term performance guarantees that halogen lighting cannot match.

Conclusion

The evidence overwhelmingly supports the superiority of 150 Watt UFO LED technology over traditional halogen lighting across every meaningful performance and economic metric. From dramatic 66-85% energy consumption reductions and maintenance cost elimination to superior lighting quality and environmental durability, the 150 Watt UFO LED represents an essential upgrade for any facility serious about operational efficiency and workplace safety. Xi'an Razorlux Optoelectronic Technology Co., Ltd. combines over 200 patents, 22 years of ISO9001-certified manufacturing excellence, and comprehensive customer support to deliver industrial lighting solutions that transform facility operations while delivering measurable ROI in months rather than years.

Ready to transform your facility with cutting-edge 150 Watt UFO LED technology? As a leading China 150 Watt UFO LED factory, China 150 Watt UFO LED supplier, and China 150 Watt UFO LED manufacturer, Razorlux offers competitive China 150 Watt UFO LED wholesale pricing with transparent 150 Watt UFO LED for sale options and 150 Watt UFO LED price structures tailored to project requirements. Contact our expert team today at sam@razorlux.com to discuss your specific lighting challenges, request detailed technical specifications, or arrange custom sampling that demonstrates the Razorlux difference. Our comprehensive pre-sales consultation, flexible OEM/ODM capabilities, and responsive after-sales support ensure your lighting upgrade delivers maximum value from initial inquiry through decades of reliable operation. Don't let outdated halogen technology drain your profitability—bookmark this guide and reach out to discover how 150 Watt UFO LED solutions can revolutionize your facility's lighting infrastructure and bottom-line performance.

References

1. U.S. Department of Energy. "LED Lighting Technology Overview and Energy Efficiency Benefits." Office of Energy Efficiency & Renewable Energy, Building Technologies Program. 2024.

2. Illuminating Engineering Society (IES). "Industrial Lighting Applications: Best Practices for High Bay and Manufacturing Environments." Technical Memorandum TM-15-24. 2024.

3. Lawrence Berkeley National Laboratory. "Life-Cycle Cost Analysis of Commercial LED Lighting Systems Versus Conventional Technologies." Environmental Energy Technologies Division. 2023.

4. International Association of Lighting Designers (IALD). "Color Rendering and Visual Performance in Industrial Work Environments." Professional Development Series, Volume 12. 2024.

_1750326878398.png)