Best Practices for 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design

Paint booth operators face a critical challenge: achieving perfect finishes while maintaining absolute safety in volatile environments where a single spark could trigger disaster. Improper lighting not only compromises quality control but creates life-threatening ignition risks in spaces saturated with flammable vapors and combustible residues. The Best Practices for 305V 100w LED Explosion Proof Light Aluminum Paint Booth Lighting Design delivers comprehensive guidance on selecting, installing, and maintaining explosion-proof LED lighting systems that meet Class I Division 1 standards while providing superior illumination for precision coating operations. This advanced 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design approach combines wide-range voltage compatibility with robust aluminum construction and intelligent optical engineering to ensure worker safety, regulatory compliance, and exceptional paint application results across automotive, industrial, and marine finishing environments.

Critical Safety Standards for 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design

Understanding Hazardous Location Classifications for Paint Booth Environments

Paint spray booths represent some of the most dangerous industrial environments due to continuous exposure to volatile organic compounds and flammable particulates. The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design must comply with strict hazardous location classifications defined by the National Electrical Code and NFPA 33 standards. Class I Division 1 areas exist where explosive vapor concentrations are present continuously or intermittently during normal operations, requiring lighting fixtures engineered to contain internal explosions without external ignition. Class I Division 2 zones designate areas where hazardous concentrations occur only during abnormal conditions or equipment malfunctions. Understanding these classifications proves essential when implementing 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design solutions, as the wrong equipment selection creates catastrophic fire and explosion risks. Regulatory authorities mandate that all electrical equipment within twenty feet of spray operations must carry explosion-proof ratings appropriate for Class I Group D locations. The wide voltage input range of 90-305 VAC in advanced LED systems ensures compatibility across diverse electrical infrastructures without requiring expensive transformers or voltage conversion equipment, streamlining installation while maintaining safety standards.

NFPA 33 Compliance Requirements for Explosion-Proof Lighting Systems

The National Fire Protection Association's NFPA 33 standard establishes comprehensive requirements for spray application using flammable materials, with specific provisions governing lighting design and installation. Proper 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design implementation requires understanding that surface-mounted fixtures inside spray booths must meet Class I or II Division I ratings with UL 844 certification. NFPA 33 Section 5.1.3 specifically prohibits aluminum use for structural support members, walls, or ceilings that enclose spray areas, yet permits aluminum for interior components including lighting apparatus when properly engineered. This distinction becomes critical when specifying 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design solutions utilizing high-grade ADC12 die-cast aluminum housings with specialized powder coating for chemical resistance. The standard mandates that lighting fixtures use tempered glass or equivalent materials capable of withstanding thermal stress and mechanical impact without shattering. Recessed fixtures require interlock switches that automatically halt spray operations if lens assemblies become unsealed, preventing vapor ingress into electrical compartments. Temperature control represents another crucial NFPA 33 requirement, with operating temperatures maintained below the ignition point of finishing materials being applied. Modern LED technology in 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design addresses this concern through superior thermal management, dissipating heat through aluminum PCB substrates rated at 2.0mm thickness with thermal index 2.5, ensuring LED junction temperatures remain within safe operating parameters even during extended production runs.

UL 844 Certification and Temperature Classification Standards

The Underwriters Laboratories UL 844 standard serves as North America's definitive specification for explosion-proof electrical equipment, subjecting lighting fixtures to rigorous testing protocols that validate their ability to operate safely in hazardous atmospheres. Implementing Best Practices for 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design necessitates understanding UL 844's comprehensive eight-step certification process examining electrical safety, thermal performance, and mechanical integrity under extreme conditions. Temperature classification designations such as T6 indicate maximum surface temperatures that fixtures may reach during operation, with T6 rated equipment maintaining surface temperatures below 85°C (185°F) to prevent ignition of most common industrial vapors. The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design featuring MeanWell HLG series drivers incorporates multiple protection mechanisms including over-voltage, short-circuit, and over-temperature safeguards that automatically shut down power delivery when anomalies occur. Certified explosion-proof housings utilize copper-free aluminum alloy construction through high-pressure die casting at 1600 tons, creating seamless enclosures that contain internal combustion events without propagating flames to surrounding atmospheres. The integration of hardened borosilicate glass lenses provides exceptional impact resistance while maintaining 95% light transmittance for optimal illumination. IP68 ingress protection ratings guarantee complete dust-tightness and protection against continuous submersion, essential for paint booth environments exposed to high-pressure washing during cleaning cycles. These comprehensive safety features distinguish professional-grade 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design from inadequate solutions that compromise worker safety and facility compliance.

| Safety Certification | Required Standard | Key Requirements for 305V 100w Systems |

|---|---|---|

| ATEX/IECEx | International explosion protection | Zone 1 & 2 certification, temperature class T6 |

| UL 844 | North American explosion-proof | Class I Div 1 Groups C,D rating, rigorous containment testing |

| CE & RoHS | European compliance | Low voltage directive, hazardous substance restrictions |

| IP67/IP68 | Ingress protection | Complete dust protection, submersion resistance |

Optimal Lighting Design Strategies for 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design

Calculating Proper Illumination Levels and Fixture Placement

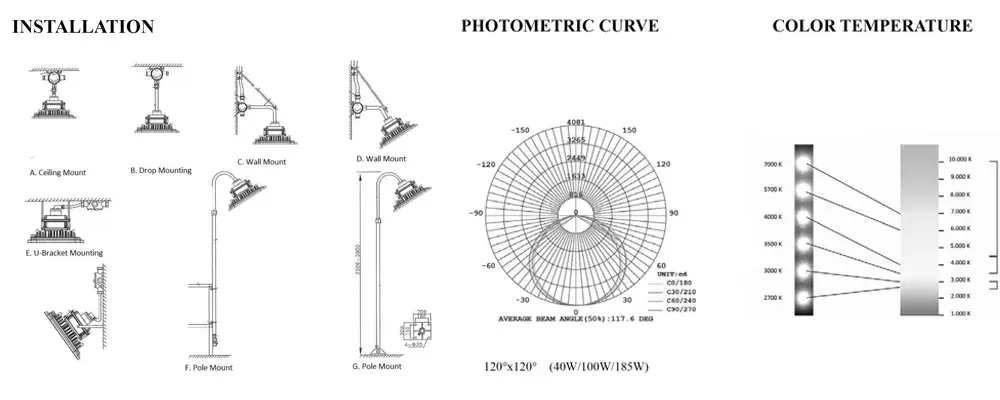

Achieving professional finishing results requires precise illumination engineering that balances light intensity, uniformity, and color rendering across the entire work envelope. Best Practices for 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design recommend minimum illumination levels of 100 foot-candles (1076 lux) at work surface height, with premium installations targeting 150-200 foot-candles for critical color-matching operations. The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design delivers 11,600 lumens with 116 lm/W system efficacy, replacing traditional 300-350W high-pressure sodium fixtures while consuming 67% less energy and generating significantly reduced heat loading. Fixture quantity calculations must account for booth dimensions, ceiling height, and mounting configuration, with standard three-meter high spray booths typically requiring one 100-watt unit per 15-20 square meters of floor area. Strategic positioning at 45-degree angles from booth corners ensures uniform light distribution without creating harsh shadows that obscure surface imperfections during inspection. The wide-angle optical reflector design in 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design systems distributes light evenly across horizontal and vertical surfaces, eliminating the hotspots and dark zones that compromise quality control. Pendant mounting generally provides superior light uniformity compared to surface mounting, allowing operators to adjust fixture height for optimal coverage of varying workpiece sizes. Avoiding placement directly above spray guns prevents overspray accumulation on lens surfaces while maintaining unobstructed sightlines for painters evaluating wet film appearance.

Color Temperature Selection and Color Rendering Index Optimization

Color temperature selection dramatically impacts paint application accuracy, with different Kelvin ratings affecting how operators perceive wet and cured finishes. The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design offers 5000K daylight color temperature as standard, providing neutral white illumination that closely mimics natural outdoor lighting conditions under which finished products will typically be viewed. This color temperature proves ideal for automotive refinishing, industrial equipment coating, and marine applications where accurate color matching against manufacturer specifications is critical. Some operations prefer 4000K neutral white for slightly warmer working conditions, particularly in facilities where painters spend extended shifts under artificial lighting. The Color Rendering Index (CRI) measures how accurately lighting reveals true object colors compared to natural sunlight, with values above 75 considered acceptable for paint booth applications and ratings exceeding 80 preferred for precision color-matching work. The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design featuring original Bridgelux LED sources delivers CRI ratings above 75, ensuring painters can reliably detect subtle color variations, blend lines, and surface defects during application and curing phases. Poor color rendering from inadequate lighting leads to costly rework when finishes appear correct under booth illumination but show obvious defects in natural light. Advanced optical reflector design in 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design systems incorporates anti-glare engineering that focuses light output while creating comfortable viewing conditions, reducing eye strain during prolonged inspection tasks and improving overall painter productivity through enhanced visual comfort.

Integration with Ventilation Systems and Airflow Management

Effective paint booth operation requires seamless coordination between lighting and ventilation systems to maintain proper air exchange rates while preserving safe operating conditions. Best Practices for 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design emphasize that fixture placement must not disrupt designed airflow patterns that capture overspray and exhaust volatile organic compounds. NFPA 33 mandates minimum ventilation rates of 100 linear feet per minute across booth face openings, with systems providing 4-6 complete air changes hourly to dilute and remove contaminated air. The low thermal output of LED technology in 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design solutions generates minimal heat compared to legacy metal halide or high-pressure sodium systems, reducing the burden on climate control systems and maintaining stable booth temperatures critical for proper paint flow and curing. Strategic mounting locations should position explosion-proof fixtures to receive adequate cooling airflow without creating turbulence that disturbs spray patterns or causes contamination from airborne particles. The robust construction of 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design with IP68 ingress protection ensures reliable operation despite exposure to high-velocity air streams and occasional overspray contact during normal operations. When specifying lighting layouts, engineers must verify that fixture housings remain accessible for periodic cleaning and maintenance without requiring partial ventilation system shutdown. The wide voltage input range of 90-305 VAC accommodates electrical infrastructure variations across different booth zones and simplifies circuit planning when coordinating with makeup air unit installations that may operate on different voltage standards.

| Mounting Configuration | Advantages | Ideal Applications for 305V 100w Systems |

|---|---|---|

| Pendant Mount | Superior light uniformity, adjustable height | Large vehicle painting, marine vessels |

| Surface Mount | Lower profile, simplified installation | Low-ceiling booths, compact work areas |

| Wall Mount | Perimeter illumination, reduced ceiling load | Open-front booths, supplemental lighting |

| Recessed Mount | Flush appearance, protected from overspray | Premium installations, cleanroom environments |

Installation and Maintenance Protocols for 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design

Professional Installation Requirements and Electrical Connection Standards

Proper installation of explosion-proof lighting demands strict adherence to National Electrical Code requirements and manufacturer specifications to ensure both safety and optimal performance. Best Practices for 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design mandate that all electrical work be performed by licensed electricians familiar with hazardous location wiring methods and capable of verifying compliance with local fire marshal requirements. The wide voltage input specification of 90-305 VAC in 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design systems accommodates global electrical standards without requiring voltage conversion equipment, simplifying international installations and retrofit projects. All wiring within twenty feet of spray operations must utilize approved conduit systems with sealed fittings that prevent vapor migration through electrical pathways, with junction boxes rated for Class I Division 1 or 2 locations as appropriate. The MeanWell HLG series driver integrated into 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design delivers 0.98 power factor and less than 10% total harmonic distortion, ensuring compatibility with sensitive electrical systems while maximizing energy efficiency. Surge protection compliant with IEC/EN 61000-4-5 standards protects expensive LED components from voltage spikes common in industrial environments with heavy motor loads and welding equipment. Installation teams must verify proper grounding of all fixture housings to building ground systems, preventing static electricity accumulation that could create ignition sources in flammable atmospheres. The 2.0mm aluminum PCB substrate with heat index 2.5 in 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design enables efficient thermal transfer from LED junction to housing, but adequate clearance around fixtures ensures convective cooling maintains operating temperatures within the -30°C to +50°C specification range.

Preventive Maintenance Schedules and Cleaning Procedures

Maintaining optimal performance from explosion-proof lighting requires systematic inspection and cleaning protocols that address overspray accumulation and verify continued safety compliance. The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design features powder-coated aluminum surfaces resistant to salt and chemical exposure, yet regular cleaning prevents residue buildup that reduces light transmission and creates potential ignition sources. Monthly visual inspections should examine lens surfaces for coating accumulation, scratches, or cracks that compromise protective seals, with immediate fixture replacement required when damage is detected. The tempered glass lens in 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design maintains 95% light transmittance when clean but can lose 30-40% output when coated with overspray, dramatically reducing effective illumination levels and creating uneven lighting that impacts finish quality. Approved cleaning procedures typically employ lint-free cloths dampened with isopropyl alcohol or approved glass cleaner, never abrasive materials or harsh solvents that damage protective coatings or compromise gasket seals. The IP68 rating of properly maintained 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design systems withstands high-pressure washing during booth cleaning cycles, but cleaning teams must verify that housing seals remain intact and all fasteners maintain proper torque specifications after exposure to cleaning chemicals. Quarterly electrical inspections by qualified technicians should verify proper grounding continuity, check for signs of overheating or discoloration around connection points, and confirm that protective conduit seals remain effective. The rated 100,000+ hour lifespan of LED sources in 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design translates to approximately 11 years of continuous operation or 22+ years at standard industrial duty cycles, dramatically reducing maintenance burden compared to legacy lighting requiring frequent lamp replacement. Documentation of all maintenance activities proves essential for insurance compliance and regulatory inspections, with facility managers maintaining detailed records of cleaning dates, inspection findings, and any repairs performed.

Emergency Backup Power Integration and Continuous Operation Requirements

Mission-critical paint booth operations require lighting systems that maintain functionality during power interruptions to prevent production delays and ensure worker safety during evacuation scenarios. The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design can integrate emergency battery backup systems providing two hours of continuous illumination during utility power loss, enabling safe shutdown of spray operations and proper booth ventilation before facility evacuation. Emergency power integration typically employs separate battery packs connected through automatic transfer switches that detect power failures within milliseconds and seamlessly transition to battery operation without perceptible interruption. The low power consumption of 100-watt LED systems in 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design enables practical battery backup solutions that would prove prohibitively expensive and physically impractical with legacy 300-350 watt high-intensity discharge lighting. Installation teams must verify that emergency lighting circuits meet National Fire Protection Association NFPA 101 Life Safety Code requirements for illumination levels, duration, and automatic activation reliability. Monthly functional testing of emergency backup systems validates battery health and transfer switch operation, with annual capacity discharge testing confirming that batteries maintain specified two-hour runtime under full load conditions. Advanced 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design incorporating emergency functionality often includes visual indicators that confirm backup system readiness and alert maintenance personnel when battery replacement becomes necessary. Facilities operating multiple paint booths may implement centralized emergency power distribution systems rather than individual fixture-level backup, with the low power requirements of LED lighting enabling protection of numerous booths from shared battery banks. The combination of wide voltage input compatibility (90-305 VAC), low power consumption, and emergency backup capability positions 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design as the optimal solution for industrial operations demanding maximum uptime and comprehensive safety protection.

| Maintenance Task | Recommended Frequency | Critical Checkpoints for 305V 100w Systems |

|---|---|---|

| Visual Inspection | Weekly | Lens clarity, visible damage, accumulation buildup |

| Detailed Cleaning | Monthly | Remove overspray, verify seal integrity, check mounting |

| Electrical Testing | Quarterly | Ground continuity, connection tightness, surge protection |

| Emergency System Test | Monthly | Battery backup activation, runtime verification |

| Complete Recertification | Annually | Professional inspection, documentation, compliance verification |

Conclusion

Implementing Best Practices for 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design protects workers, ensures regulatory compliance, and delivers the precise illumination essential for professional finishing operations. The combination of wide voltage compatibility, explosion-proof construction, and advanced LED technology provides superior performance compared to legacy lighting systems while dramatically reducing energy consumption and maintenance requirements. Facilities investing in properly specified 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design benefit from enhanced safety, improved finish quality, and substantial operational cost savings throughout the fixture's extended service life.

Transform your paint booth lighting with proven explosion-proof solutions from Xi'an Razorlux Optoelectronic Technology Co., Ltd. As a leading China 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design manufacturer with over two decades of industry experience, Razorlux delivers comprehensive lighting solutions backed by 200+ patents and complete ATEX, UL 844, CE, and RoHS certifications. Our China 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design factory produces systems tested to withstand the harshest industrial environments, featuring MeanWell HLG drivers, original Bridgelux LED sources, and die-cast aluminum housings engineered for maximum durability. Every China 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design supplier relationship includes comprehensive technical support, detailed DIALux layout design services, and responsive after-sales assistance. Contact our expert team for competitive 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design wholesale pricing and customized solutions meeting your specific application requirements. Whether you need standard configurations or specialized 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design for sale with custom mounting options and control systems, Razorlux provides end-to-end manufacturing excellence with 3-year or 5-year warranty coverage. Discover why global industrial clients trust our 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design price value proposition combining premium quality components, proven reliability, and professional service. Request your detailed technical specifications and project quotation today at sam@razorlux.com.

References

1. National Fire Protection Association, "NFPA 33: Standard for Spray Application Using Flammable or Combustible Materials," NFPA Standards Council

2. Underwriters Laboratories, "UL 844: Standard for Electric Lighting Fixtures for Use in Hazardous Locations," UL Safety Standards

3. Chen, Robert and Williams, Patricia, "LED Technology Applications in Hazardous Industrial Environments: Safety and Performance Analysis," Journal of Industrial Lighting Engineering

4. Occupational Safety and Health Administration, "OSHA 1910.107: Spray Finishing Using Flammable and Combustible Materials," U.S. Department of Labor

5. International Electrotechnical Commission, "IEC 60079: Explosive Atmospheres - Equipment Protection Standards," IEC Technical Committee

VIEW MORE500W Halogen Floodlight Led Equivalent

VIEW MORE500W Halogen Floodlight Led Equivalent VIEW MOREled football stadium lights

VIEW MOREled football stadium lights VIEW MOREoverhead crane safety lights

VIEW MOREoverhead crane safety lights VIEW MOREoutdoor hockey rink lighting

VIEW MOREoutdoor hockey rink lighting VIEW MOREindoor tennis court led lighting

VIEW MOREindoor tennis court led lighting VIEW MOREsport court flood lights

VIEW MOREsport court flood lights VIEW MORELed Sports Flood Lights

VIEW MORELed Sports Flood Lights VIEW MORELarge Outdoor Led Flood Lights

VIEW MORELarge Outdoor Led Flood Lights

_1750326878398.png)