305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design Maintenance Guide

Paint booth operators face a critical challenge: maintaining optimal illumination while preventing catastrophic ignition risks in volatile environments filled with flammable vapors and combustible particles. The 305V 100w LED Explosion Proof Light Aluminum Paint Booth Lighting Design delivers the solution through advanced engineering that combines safety-certified explosion protection with maintenance-optimized construction, ensuring your facility achieves consistent color accuracy and regulatory compliance without compromising worker safety or operational uptime.

Understanding 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design Safety Standards

Hazardous Area Classification Requirements for Paint Booth Operations

Paint booths operate as Class 1 Division 1 hazardous locations where flammable vapor concentrations exist continuously during normal spraying operations. The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design meets ATEX, IECEx, and UL 844 certifications specifically engineered for these demanding environments. These fixtures employ intrinsically safe electrical components that limit both electrical and thermal energy available for ignition, preventing spark generation even during component failure scenarios. The wide voltage input range of 90-305 VAC accommodates global power standards while maintaining consistent performance across varying supply conditions. Facilities utilizing the 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design benefit from IP68 ingress protection that prevents vapor penetration into electrical compartments, ensuring explosive atmospheres remain isolated from potential ignition sources throughout the fixture's operational lifetime.

Explosion Containment Technology in Aluminum Housing Construction

The die-cast ADC12 aluminum housing of the 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design provides explosion containment through engineered structural integrity that withstands internal detonation without external rupture. This explosion-proof design philosophy differs fundamentally from vapor-tight construction, as the aluminum alloy housing possesses the mechanical strength to contain combustion events while cool flanged joints prevent flame propagation beyond the enclosure. The 2.0mm aluminum PCB with thermal index 2.5 facilitates rapid heat dissipation, maintaining LED junction temperatures below critical thresholds even in ambient conditions reaching 50°C. Powder-coated surface treatment delivers chemical resistance against paint solvents, overspray accumulation, and corrosive cleaning agents commonly employed in booth maintenance procedures. When selecting the 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design, operators gain a fixture engineered specifically for the thermal cycling, vibration exposure, and chemical aggression characteristic of industrial painting environments.

Certification Compliance Documentation and Inspection Protocols

Regulatory compliance verification requires comprehensive documentation demonstrating the 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design meets applicable safety standards. Facilities should maintain certification documents including ATEX certificates, IECEx test reports, UL 844 listings, and CE declarations of conformity accessible for inspection by authorities having jurisdiction. Installation must conform to National Electrical Code Article 501 for Class 1 locations, with conduit seals positioned within prescribed distances from the fixture to prevent vapor migration through wiring pathways. The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design carries markings indicating temperature classification, ensuring surface temperatures remain below autoignition thresholds for solvents present in the specific application. Annual inspections should verify gasket integrity, lens condition, and housing seal performance to maintain the explosion protection reliability throughout the fixture's service life.

| Safety Feature | Specification | Compliance Benefit |

|---|---|---|

| Explosion Rating | Class 1 Division 1 & 2 | Prevents ignition in hazardous atmospheres |

| Ingress Protection | IP68 | Blocks vapor penetration into electrical components |

| Temperature Class | T6 (-30°C to +50°C) | Operates safely below solvent autoignition temperatures |

| Certification | ATEX, IECEx, UL 844, CE, RoHS | Meets international hazardous location standards |

| Housing Strength | ADC12 Die-Cast Aluminum | Contains internal explosions without external rupture |

Maintenance Protocols for 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design Systems

Scheduled Inspection Procedures and Component Verification

Systematic maintenance extends the operational life of the 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design while preserving explosion protection integrity. Quarterly inspections should assess tempered glass lens clarity, checking for overspray accumulation, chemical etching, or impact damage that compromises light transmission. The scientific optical reflector design requires periodic cleaning to maintain the focused, uniform beam distribution essential for accurate color evaluation during painting operations. Gasket seals demand visual examination for compression set, cracking, or degradation that could compromise the IP68 rating, with replacement recommended when deformation exceeds manufacturer specifications. The MeanWell HLG series driver, representing the highest tier of MeanWell's product line, typically operates maintenance-free throughout its rated 100,000+ hour lifespan, though voltage verification at fixture terminals confirms proper power delivery. Facilities operating the 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design should document inspection findings, maintenance actions, and component replacements in compliance logs demonstrating ongoing safety management.

Cleaning Methodologies for Hazardous Location Fixtures

Proper cleaning procedures for the 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design require de-energization protocols that eliminate ignition risks during maintenance activities. After lockout/tagout procedures isolate electrical supply, the powder-painted aluminum surfaces accept cleaning with isopropyl alcohol or approved solvent cleaners that dissolve accumulated overspray without attacking the protective coating. The tempered glass lens achieves 95% light transmission when clean, but overspray buildup progressively reduces illumination levels and alters color rendering characteristics critical for quality control. Cleaning frequency depends on booth usage intensity, with high-volume operations potentially requiring monthly attention while lighter-duty applications may extend intervals to quarterly schedules. The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design surface treatment specifically resists dust accumulation, though periodic removal of particulate matter maintains optimal heat dissipation from the aluminum housing. Never apply excessive force during cleaning that could compromise gasket seals or crack the tempered glass lens, as either condition jeopardizes explosion protection integrity.

Driver Performance Monitoring and Emergency Backup Integration

The MeanWell driver powering the 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design delivers 0.98 power factor with total harmonic distortion below 10%, characteristics that minimize electrical interference and maximize efficiency across the 90-305 VAC input range. Monitoring for gradual light output reduction indicates LED degradation or driver aging, with the fixture's 116 LM/W system efficacy providing baseline comparison for performance assessment. Integration of emergency power functionality enables two-hour operation during electrical supply interruptions, maintaining illumination for safe booth evacuation and work-in-progress protection. This emergency capability requires periodic testing to verify battery charge retention and automatic transfer switch operation, ensuring reliability when needed. Facilities maximizing uptime with the 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design should establish preventive replacement schedules rather than reactive failure responses, as planned maintenance windows minimize production disruption compared to emergency repairs during critical operations.

| Maintenance Task | Frequency | Critical Focus Areas |

|---|---|---|

| Visual Inspection | Quarterly | Lens clarity, gasket condition, housing integrity |

| Lens Cleaning | Monthly (high-use) / Quarterly (moderate-use) | Remove overspray, restore 95% transmission rate |

| Gasket Assessment | Semi-annually | Check compression, cracking, chemical degradation |

| Emergency System Test | Monthly | Verify 2-hour backup operation capability |

| Performance Verification | Annually | Measure lumen output, compare to baseline 11,600 lm |

Installation Optimization for 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design

Strategic Positioning for Uniform Illumination Coverage

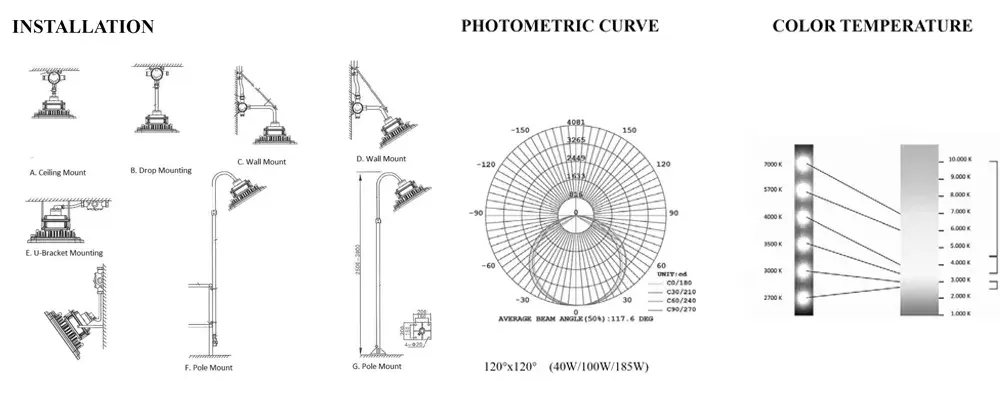

Proper fixture placement maximizes the 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design 11,600 lumen output across work surfaces while eliminating shadows that obscure surface defects during quality inspection. The wide-angle beam distribution of 120 degrees provides broad coverage from elevated mounting positions, with standard 3-meter ceiling heights requiring strategic spacing calculations based on booth dimensions and target illumination levels. Corner-mounted installations at 45-degree angles deliver cross-illumination that minimizes shadowing behind three-dimensional objects, a critical consideration for automotive panels and complex assemblies. The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design replaces 300-350W high-pressure sodium fixtures while delivering superior color rendering index above 75, enabling accurate color matching essential for premium finish work. Lighting design software such as DIALux Evo facilitates precise calculations incorporating fixture photometric data, booth geometry, and target illuminance levels to optimize fixture quantity and positioning before installation begins.

Electrical Integration and Conduit Seal Requirements

Electrical installation of the 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design demands strict adherence to Class 1 Division 1 wiring methods that prevent vapor migration from hazardous areas into non-hazardous spaces. Threaded rigid metal conduit or intermediate metal conduit provides mechanical protection and grounding continuity, with conduit seals installed within 18 inches of the fixture enclosure entry to block vapor passage through the raceway system. The wide 90-305 VAC input voltage accommodates diverse facility electrical systems without requiring voltage transformation, simplifying installation while reducing component count and potential failure points. Junction boxes serving multiple fixtures must carry equivalent explosion-proof ratings and proper sealing to maintain area classification integrity throughout the distribution system. Facilities installing the 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design should engage licensed electricians familiar with hazardous location requirements, as improper installation compromises both explosion protection and regulatory compliance regardless of fixture certification credentials.

Mounting Hardware Selection and Vibration Isolation

Mounting configuration options for the 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design include pendant, surface mount, and pole mount arrangements accommodating diverse booth architectures and ceiling construction types. The 7.5 kg fixture weight requires structural support capable of handling dynamic loading from vibration transmitted through building structures during nearby industrial operations. Pendant installations typically provide superior illumination uniformity through precise aim adjustment, positioning the 300mm x 300mm x 175mm fixture dimensions optimally relative to work surfaces. The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design shock and vibration resistant construction tolerates the mechanical disturbances common in industrial environments, though excessive vibration accelerates fastener loosening and connection degradation. Mounting hardware should incorporate vibration-dampening elements where installation locations experience significant mechanical disturbance, protecting both the fixture integrity and electrical connection reliability. Proper installation ensures the original Bridgelux LED source with high luminous efficacy and long lifespan delivers rated performance throughout the 100,000+ hour operational life without premature failure from installation deficiencies.

Conclusion

The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design represents engineered excellence for hazardous location illumination, combining explosion-proof safety, maintenance-optimized construction, and superior optical performance. Proper maintenance protocols and installation practices maximize this fixture's operational reliability while ensuring continuous regulatory compliance throughout demanding paint booth applications.

Xi'an Razorlux Optoelectronic Technology Co., Ltd. stands as your trusted China 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design manufacturer with over 20 years of industry expertise and 200+ patents covering LED Packaging, power control, and structural design. As a leading China 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design supplier and China 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design factory, we deliver comprehensive lighting solutions backed by UL, RMRS, TUV, CE, SAA, and RoHS certifications. Our China 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design wholesale options include flexible customization in wattage, color temperature, and mounting configurations, with competitive 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design price structures supporting projects of any scale. The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design for sale through Razorlux includes comprehensive pre-sales consultation, custom sampling, technical documentation, and 5-year warranty coverage ensuring long-term operational success. Our professional R&D team, GMP-certified factory, extensive inventory, and expedited delivery capabilities through air, rail, and sea transportation guarantee your lighting requirements receive expert attention from inquiry through installation. Contact our experienced sales team at sam@razorlux.com to discuss your specific paint booth lighting challenges and discover how Razorlux's proven solutions deliver safety, efficiency, and unmatched reliability for your critical operations.

References

1. National Fire Protection Association, "NFPA 33: Standard for Spray Application Using Flammable or Combustible Materials," National Fire Protection Association Standards Council

2. Underwriters Laboratories, "UL 844: Standard for Electric Lighting Fixtures for Use in Hazardous Locations," UL Standards and Engagement

3. International Electrotechnical Commission, "IEC 60079: Explosive Atmospheres - Equipment Protection by Flameproof Enclosures," IEC Technical Committee 31

4. Occupational Safety and Health Administration, "OSHA 1910.107: Spray Finishing Using Flammable and Combustible Materials," U.S. Department of Labor

5. Illuminating Engineering Society, "IES RP-7: Recommended Practice for Lighting Industrial Facilities," Illuminating Engineering Society Technical Review Council

VIEW MOREsport field lights

VIEW MOREsport field lights VIEW MORELed Outdoor Arena Lights

VIEW MORELed Outdoor Arena Lights VIEW MORETennis Court Led Flood Lights

VIEW MORETennis Court Led Flood Lights VIEW MOREOutdoor Tennis Court Lighting

VIEW MOREOutdoor Tennis Court Lighting VIEW MORELED softball field lighting high mast flood light systems

VIEW MORELED softball field lighting high mast flood light systems VIEW MORE240W 120lm/W Led Tennis Lights 347V Portable Floodlights

VIEW MORE240W 120lm/W Led Tennis Lights 347V Portable Floodlights VIEW MORELed Ufo High Bay 200W

VIEW MORELed Ufo High Bay 200W VIEW MORESingle Head Flood Light

VIEW MORESingle Head Flood Light

_1750326878398.png)