305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design for OEM Projects

When paint vapors fill your workspace and a single spark could trigger disaster, you need more than just lighting—you need protection. The 305V 100w LED Explosion Proof Light Aluminum Paint Booth Lighting Design delivers both safety and performance in hazardous painting environments. This specialized lighting solution eliminates ignition risks while providing superior illumination for precision color matching and flawless finish application. Designed specifically for OEM projects requiring reliable explosion-proof technology, this 100-watt system combines wide voltage compatibility with aluminum housing construction to meet the demanding standards of industrial paint booth operations worldwide.

Understanding 305V 100w Led Explosion Proof Light Technology for Paint Booth Applications

Wide Voltage Input Capabilities in Aluminum Paint Booth Lighting Design

The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design features an exceptional 90-305 VAC input voltage range, making it adaptable to virtually any global electrical infrastructure. This wide voltage compatibility eliminates the need for additional transformers or voltage regulators, significantly reducing installation complexity and overall project costs for OEM applications. The advanced driver technology maintains consistent luminous output across the entire voltage spectrum, ensuring stable illumination regardless of power fluctuations common in industrial facilities. With a power factor exceeding 0.98 and total harmonic distortion below 10 percent, this lighting system maximizes energy efficiency while minimizing electrical interference with other sensitive equipment. The MeanWell HLG series driver represents the highest tier of power supply technology, delivering reliable performance with built-in surge protection compliant with IEC/EN 61000-4-5 standards. For OEM partners seeking dependable lighting solutions across multiple international markets, this voltage flexibility proves invaluable for standardization efforts and inventory management optimization.

Explosion-Proof Aluminum Housing Construction for Hazardous Locations

At the core of the 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design lies its robust ADC12 die-cast aluminum housing, engineered specifically to contain internal explosions and prevent external ignition of flammable vapors. The aluminum alloy construction provides exceptional heat dissipation properties, maintaining LED junction temperatures well below critical thresholds even during continuous operation in ambient temperatures ranging from negative 30 degrees Celsius to positive 50 degrees Celsius. The powder-coated surface treatment delivers outstanding resistance to salt corrosion and chemical exposure, crucial attributes for paint booth environments where solvents and aggressive compounds are constantly present. With an IP68 ingress protection rating, this fixture completely prevents dust penetration and withstands prolonged water immersion, ensuring reliable operation even during pressure washing and maintenance procedures. The shock and vibration resistant tempered glass lens offers 95 percent light transmission while protecting the LED array and optical components from physical damage. The entire assembly achieves IK10 impact resistance, capable of withstanding significant mechanical stress without compromising the explosion-proof integrity essential for Class 1 Division 1 and Division 2 hazardous location classifications.

High-Efficacy LED Technology and Optical Performance

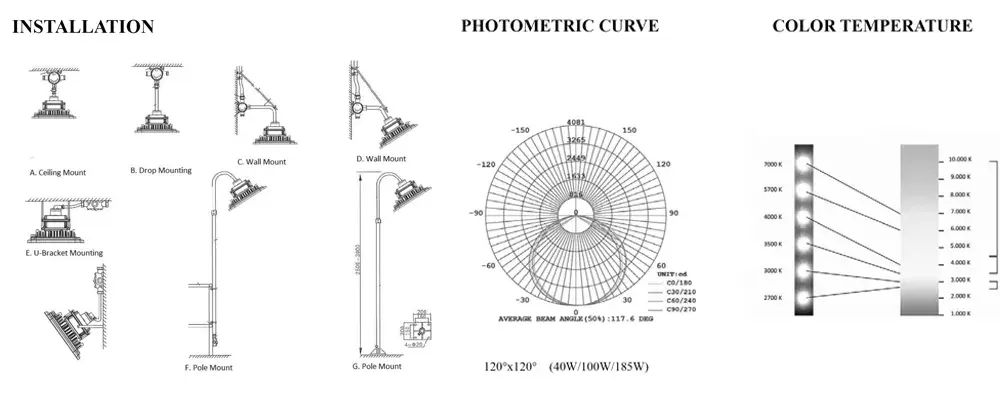

The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design incorporates original Bridgelux LED chips operating at 700 milliamperes, delivering an impressive system efficacy of 116 lumens per watt. This translates to 11,600 nominal lumens from the 100-watt model, providing illumination equivalent to 300-350 watt high-pressure sodium fixtures while consuming significantly less energy. The scientific optical reflector design creates focused, uniform light distribution with wide-angle coverage, eliminating harsh shadows and dark spots critical for accurate color evaluation during painting operations. With a Color Rendering Index exceeding 75 and available color temperatures including 2700K, 4000K, and 5700K options, this lighting system enables precise color matching essential for automotive refinishing and industrial coating applications. The anti-glare optical design reduces eye strain during extended work periods, improving worker productivity and reducing errors. The 2.0-millimeter aluminum PCB with thermal index 2.5 ensures efficient heat transfer from LED junctions, maintaining optimal operating temperatures that preserve luminous efficacy and extend rated service life beyond 100,000 hours. For OEM projects requiring consistent photometric performance across large-scale installations, this combination of high-efficacy LEDs and advanced thermal management delivers unmatched reliability and long-term value.

Technical Specifications and Certification Standards for OEM Integration

| Specification Category | Parameter | Value/Description |

|---|---|---|

| Electrical Ratings | Input Voltage | 90-305 VAC |

| Total Power | 100W (RLEP-J100 Model) | |

| Power Factor | 0.98 | |

| Driver Current | 350mA | |

| Number of LEDs | 84 | |

| Optical Performance | Nominal Lumens | 11,600 lm |

| System Efficacy | 116 LM/W | |

| Color Temperature | 5000K (Daylight), Optional 4000K/2700K | |

| CRI (Ra>) | 75 | |

| Beam Angle | Wide angle distribution |

Comprehensive Safety Certifications for Global Markets

The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design carries an extensive portfolio of international safety certifications essential for OEM project compliance across diverse regulatory jurisdictions. ATEX and IECEx certifications validate the fixture's suitability for explosive atmospheres according to European and international standards, while UL 844 compliance ensures adherence to North American requirements for hazardous locations. The CE marking confirms conformity with European health, safety, and environmental protection standards, complemented by RoHS certification guaranteeing the absence of restricted hazardous substances. Additional certifications include SAA approval for Australian and New Zealand markets, PSE certification for Japanese electrical safety requirements, and C-tick electromagnetic compatibility compliance. These comprehensive certifications eliminate regulatory barriers for OEM partners developing projects across multiple countries, streamlining approval processes and accelerating deployment timelines. The IP68 rating combined with IK10 impact resistance provides dual protection against both environmental ingress and mechanical damage, crucial for demanding industrial environments where equipment faces constant exposure to harsh conditions. For pharmaceutical cleanrooms and food processing facilities requiring GMP compliance, the sealed explosion-proof construction prevents contamination while maintaining hazardous area protection standards.

Physical Dimensions and Installation Specifications

| Model Number | Power | Replacement Capacity | Dimensions | Weight | Reflector Angle |

|---|---|---|---|---|---|

| RLEP-J40 | 30W | 150W HPS | 200×200×270mm | 4KG | 120° |

| RLEP-J100 | 100W | 300-350W HPS | 300×300×175mm | 7.5KG | Wide angle |

| RLEP-J200 | 185W | 700-1000W HPS | 400×400×185mm | 12KG | Wide angle |

The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design offers versatile mounting configurations suitable for ceiling suspension, wall bracket installation, and portable stand applications. The compact 300×300×175-millimeter footprint of the RLEP-J100 model facilitates retrofit installations in existing paint booth infrastructure without requiring structural modifications. At 7.5 kilograms, the fixture maintains manageable weight for overhead mounting while providing sufficient mass to resist vibration in high-airflow environments typical of downdraft booth designs. Pre-drilled mounting points accommodate standard industrial brackets and chains, with accessory compartments included in Packaging for organized hardware storage during transportation and installation. The integrated junction box simplifies electrical connections while maintaining explosion-proof integrity, with clearly marked terminals for line, neutral, and ground conductors. For OEM projects requiring customization, Razorlux offers flexible housing materials, mounting adapter designs, and control system integration including 0-10V dimming and DALI protocol compatibility for intelligent lighting management systems.

Performance Characteristics and Environmental Resilience

The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design demonstrates exceptional performance across extreme environmental conditions commonly encountered in industrial painting operations. The operating temperature range from negative 30 degrees Celsius to positive 50 degrees Celsius accommodates both climate-controlled indoor facilities and harsh outdoor installations without performance degradation. Surge protection circuits conforming to IEC/EN 61000-4-5 standards safeguard internal electronics from transient overvoltage events, while thermal management systems prevent overheating even during continuous 24-hour operation cycles. The tempered glass lens maintains optical clarity despite exposure to paint overspray, solvents, and cleaning chemicals, with surface coatings that inhibit dust accumulation and simplify maintenance procedures. Low-decay LED technology ensures luminous flux maintains greater than 70 percent of initial output after 50,000 operating hours, significantly reducing maintenance frequency and lifecycle costs compared to conventional lighting technologies. For critical applications requiring uninterrupted operation, optional emergency battery backup systems provide up to two hours of illumination during power outages, ensuring worker safety and enabling orderly shutdown procedures during facility emergencies.

Customization Options and OEM Service Capabilities

Tailored Solutions for Diverse Paint Booth Lighting Design Requirements

Xi'an Razorlux Optoelectronic Technology Co., Ltd. provides comprehensive customization services for the 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design, enabling OEM partners to develop differentiated products aligned with specific market requirements. Pre-sales consultation includes detailed application analysis, photometric calculations using DIALux Evo software, and lighting circuit design services that optimize fixture placement for uniform illumination distribution. Custom sampling and prototyping allow clients to evaluate performance characteristics under actual operating conditions before committing to volume production, ensuring complete satisfaction with luminous intensity, color rendering accuracy, and mechanical integration. Technical drawing services provide detailed CAD documentation supporting engineering workflows, including mounting dimensions, electrical schematics, and material specifications essential for project planning and regulatory submissions. Wattage customization enables optimization of light output for specific booth dimensions, with available power levels ranging from 30 watts to 185 watts within the explosion-proof platform architecture. Color temperature selection accommodates regional preferences and application-specific requirements, with options spanning warm white 2700K for residential automotive refinishing to cool white 5700K for industrial production environments requiring maximum visual acuity.

OEM and ODM Partnership Opportunities

Razorlux's extensive OEM and ODM capabilities transform the 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design into branded lighting solutions that differentiate partner products in competitive markets. With over 200 patents covering LED packaging, power control systems, and structural design innovations, the company provides intellectual property protection for custom developments while accelerating time-to-market for new product introductions. Private labeling services include custom branding, packaging design, and marketing collateral development that align with partner brand identities and positioning strategies. Manufacturing flexibility supports order quantities from small-batch prototype runs to high-volume production exceeding 3,000 units monthly, with scalable capacity accommodating growth trajectories of emerging and established market participants. Quality management systems compliant with ISO 9001 standards ensure consistent manufacturing excellence across production batches, while comprehensive testing protocols including photometric evaluation, aging tests, and environmental simulation validate performance specifications before shipment. For partners requiring specialized features such as wireless controls, integrated sensors, or IoT connectivity, Razorlux's in-house R&D team collaborates on custom development projects that incorporate advanced technologies while maintaining explosion-proof certifications and hazardous location compliance.

Global Logistics and Delivery Infrastructure

| Transportation Time | Shipping Method | Recommended Weight | Cost Efficiency |

|---|---|---|---|

| 3-7 days | International Express (DHL, FedEx, UPS) | 0.5kg - 300kg | Optimal for contracted rates |

| 5-10 days | Air Freight (Airport-to-Port/Door) | 300kg+ | Economical for heavy cargo |

| 18-22 days | Rail (China-Europe Railway Express) | 2CBM/500KG+ | Economical with flexible timelines |

| 15-50 days | Sea Freight (FCL/LCL) | 2CBM/500KG+ | Most cost-effective option |

The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design benefits from Razorlux's sophisticated global distribution network, with shipping ports in Tianjin, Shanghai, and Shenzhen providing access to major international shipping routes. Packaging protocols employ multi-layer protection systems including foam base inserts, accessory compartments with dedicated slots for brackets and hardware, and reinforced carton sealing with plastic strapping to prevent transit damage. For customers with specialized shipping requirements, optional wooden crate solutions provide enhanced protection during bulk shipments and long-distance transportation, particularly valuable for projects involving multiple container loads. Delivery terms including FOB, EX-Work, CFR, and CIF accommodate various logistics preferences and cost allocation structures, while sample orders ship within three to five days following payment confirmation to support rapid evaluation timelines. Full insurance coverage during transit protects customer investments, with comprehensive documentation supporting claims resolution in the unlikely event of shipping damage. Real-time tracking capabilities and proactive communication keep OEM partners informed throughout the logistics process, ensuring predictable delivery schedules that align with project installation timelines and customer commitments.

Conclusion

The 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design represents the convergence of safety engineering, energy efficiency, and operational performance essential for modern industrial painting operations. Through wide voltage compatibility, robust aluminum construction, and comprehensive international certifications, this lighting solution addresses the critical requirements of OEM projects across global markets while delivering exceptional value through reduced energy consumption and extended service life.

Ready to elevate your paint booth lighting project with industry-leading explosion-proof technology? As a China 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design factory with over two decades of manufacturing excellence, Xi'an Razorlux Optoelectronic Technology Co., Ltd. stands as your trusted China 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design supplier and China 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design manufacturer. Whether you're seeking China 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design wholesale opportunities or evaluating 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design for sale, our comprehensive service portfolio ensures your success. With competitive 305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design price structures, mature R&D capabilities, GMP-certified manufacturing facilities, extensive inventory, complete international certifications, expedited delivery options, professional sales support, and industry-leading 5-year warranty coverage, Razorlux delivers complete peace of mind for your critical lighting investments. contact us today at sam@razorlux.com to discuss your specific requirements and discover how our explosion-proof lighting solutions can transform your paint booth operations with unmatched safety, efficiency, and performance.

References

1. "Explosion-Proof Lighting Standards and Applications in Industrial Environments" - National Fire Protection Association (NFPA), Technical Committee on Classification of Gases, Vapors, and Dusts

2. "LED Technology Advances in Hazardous Location Lighting Systems" - Illuminating Engineering Society (IES), Industrial Lighting Committee

3. "Paint Spray Booth Design and Safety Requirements" - American Conference of Governmental Industrial Hygienists (ACGIH), Ventilation Committee

4. "Thermal Management in High-Power LED Luminaires for Hazardous Areas" - Institute of Electrical and Electronics Engineers (IEEE), Power Electronics Society

5. "International Certification Standards for Explosion-Proof Electrical Equipment" - International Electrotechnical Commission (IEC), Technical Committee 31

_1750326878398.png)