How long do LED high bay lights last?

Imagine walking into your warehouse at 2 AM because production can't continue—your lighting system has failed again. Downtime costs money, replacement parts are expensive, and your maintenance team is exhausted from constantly changing bulbs. If this scenario sounds familiar, you're likely dealing with outdated lighting technology. LED High Bay Lights offer a revolutionary solution, typically lasting 50,000 to 100,000 hours—that's over 11 years of continuous operation or up to 20 years with normal usage patterns. Understanding their lifespan and the factors that influence it can transform your operational efficiency and dramatically reduce long-term costs.

Understanding LED High Bay Lights Lifespan

What Determines the Lifespan of LED High Bay Lights?

The longevity of LED High Bay Lights depends on multiple interconnected factors that work together to determine overall performance duration. Unlike traditional lighting that simply burns out, LED High Bay Lights experience gradual lumen depreciation over time, meaning they slowly dim rather than suddenly fail. Quality LED High Bay Lights from reputable manufacturers are engineered to maintain at least 70% of their original brightness after 50,000 hours of operation, which is the industry standard known as L70 rating. The lifespan calculation considers not just when the light stops working completely, but when it reaches this 70% threshold, as lighting below this level may no longer meet your facility's illumination requirements. 100 Watt Ufo Led Lights from Xi'an Razorlux, for example, are built with premium Lumileds and Samsung LEDs that deliver exceptional longevity through superior chip quality and advanced engineering.

Component Quality and Manufacturing Standards

The quality of internal components significantly impacts how long LED High Bay Lights will serve your facility reliably. Premium LED chips from manufacturers like Lumileds and Samsung incorporate advanced materials and precise manufacturing processes that resist degradation far better than budget alternatives. The driver unit, which regulates power to the LED chips, is equally critical—Meanwell drivers, used in Razorlux's 100 Watt UFO Led Lights, are industry-recognized for reliability and stable performance across varying electrical conditions. Manufacturing standards also matter tremendously, as facilities with ISO 9001 certification and comprehensive quality control procedures produce LED High Bay Lights with consistent performance characteristics. Xi'an Razorlux's extensive testing protocols, including photometric analysis and aging tests, ensure every unit meets stringent performance benchmarks before shipment. Products certified to UL, CE, RoHS, and other international standards undergo additional verification, providing assurance of both safety and longevity.

Heat Management and Thermal Design

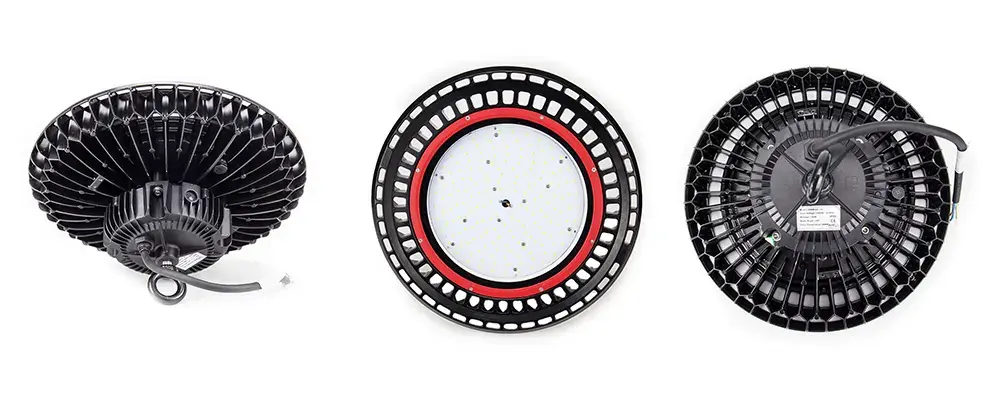

Effective thermal management is absolutely critical to maximizing the operational life of LED High Bay Lights, as excessive heat is the primary enemy of LED longevity. LED chips generate heat during operation, and if this thermal energy cannot dissipate efficiently, junction temperatures rise, accelerating lumen depreciation and potentially causing premature failure. Quality LED High Bay Lights incorporate sophisticated heat sink designs, typically constructed from aluminum alloys with optimized fin configurations that maximize surface area for heat transfer. The 100 Watt UFO Led Lights from Razorlux feature exterior Meanwell drivers specifically engineered for outstanding heat dissipation, allowing thermal energy to escape efficiently rather than building up within the fixture housing. This external driver placement also simplifies maintenance, as the driver can be accessed and replaced without disassembling the entire lighting fixture. Advanced thermal design ensures LED junction temperatures remain within optimal operating ranges, typically below 85°C, which is essential for achieving the full rated lifespan of 50,000+ hours.

Operating Environment and Installation Conditions

The environment where LED High Bay Lights operate profoundly influences their functional lifespan and performance consistency. Facilities with extreme temperatures, whether excessively hot or cold, challenge LED components and may accelerate degradation if the fixtures aren't properly rated for such conditions. Humidity and corrosive atmospheres pose additional risks, potentially damaging electronic components and compromising seals that protect sensitive circuitry. Razorlux's LED High Bay Lights carry IP65 ratings, providing robust protection against dust ingress and water jets, making them suitable for demanding industrial environments including manufacturing plants, warehouses, and even semi-outdoor applications. Proper installation height and mounting also affect performance—LED High Bay Lights should be installed at manufacturer-recommended heights to ensure optimal light distribution while allowing adequate airflow around heat sinks. Vibration from nearby machinery can potentially damage solder joints and connections over time, so fixtures intended for industrial use should incorporate vibration-resistant construction. Environmental factors also include voltage stability, as power surges and fluctuations can stress driver components, making surge protection advisable in facilities with unstable electrical supply.

Factors That Extend LED High Bay Lights Lifespan

| Factor | Impact on Lifespan | Recommended Action |

|---|---|---|

| Quality LED Chips | Directly determines degradation rate | Choose products with Lumileds or Samsung LEDs |

| Driver Quality | Controls power stability and efficiency | Select fixtures with Meanwell drivers |

| Heat Dissipation | Prevents accelerated aging from heat | Ensure proper ventilation and external drivers |

| Operating Hours | Affects total lifespan calculation | Monitor usage patterns for replacement planning |

| Voltage Stability | Protects against component stress | Install surge protection devices |

| Environmental Protection | Guards against moisture and dust | Use IP65-rated fixtures in harsh conditions |

| Regular Maintenance | Maintains optimal operating conditions | Clean fixtures and inspect connections quarterly |

| Installation Quality | Ensures proper electrical connections | Use certified electricians for installation |

Proper Installation Practices for Maximum Longevity

Professional installation following manufacturer specifications is essential for achieving the full rated lifespan of LED High Bay Lights. Electrical connections must be secure and properly sized to handle the fixture's power requirements without creating resistance that generates additional heat. The 100 Watt UFO Led Lights from Razorlux are designed with user-friendly mounting systems, but proper mechanical support is crucial to prevent vibration damage and ensure long-term stability. Installation height should match the recommended range for your specific model—typically 15 to 50 feet for high bay applications—to achieve optimal light distribution while maintaining appropriate ambient temperatures around the fixture. Adequate spacing between fixtures prevents thermal interference where heat from one unit affects neighboring lights, potentially elevating operating temperatures beyond optimal ranges. Following these installation best practices, combined with using high-quality LED High Bay Lights, establishes the foundation for decades of reliable service with minimal maintenance requirements.

Strategic Maintenance and Cleaning Protocols

Implementing regular maintenance schedules significantly extends the functional life of LED High Bay Lights and maintains consistent illumination levels throughout their service life. Dust accumulation on heat sinks and lenses reduces both light output and thermal efficiency, so quarterly cleaning using compressed air or soft cloths removes debris that impedes performance. Inspection of electrical connections should occur annually to identify any loosening that might create resistance and heat, while visual examination of fixture housings can reveal signs of corrosion or seal degradation before they become serious problems. Xi'an Razorlux designs their 100 Watt UFO Led Lights with maintenance accessibility in mind, featuring exterior drivers that can be inspected and replaced without special tools or extensive disassembly. Documenting maintenance activities and tracking performance over time helps identify fixtures approaching end-of-life before they impact operations, allowing proactive replacement rather than reactive emergency service calls. These systematic maintenance practices, while requiring modest investment of time and resources, deliver substantial returns through extended fixture life and reduced total cost of ownership.

Operating Conditions Optimization

Creating optimal operating conditions for LED High Bay Lights involves controlling environmental factors within practical limits to minimize stress on components. Maintaining ambient temperatures within manufacturer specifications prevents thermal stress that accelerates aging, which may require adjusting facility HVAC systems or providing supplemental cooling in particularly hot locations. Voltage regulation through quality electrical infrastructure ensures LED High Bay Lights receive clean, stable power without surges or significant fluctuations that stress driver components. For facilities with problematic power quality, installing surge suppressors and voltage regulators protects lighting investments from electrical anomalies. The 100 Watt UFO Led Lights from Razorlux operate reliably across AC85-265V input ranges, providing tolerance for voltage variations, but stable power still contributes to maximum longevity. Managing operating schedules to avoid unnecessary run time extends lifespan proportionally—implementing occupancy sensors or daylight harvesting controls reduces hours of operation without compromising facility lighting when needed. These optimization strategies collectively create an environment where LED High Bay Lights can achieve or even exceed their rated lifespans.

Comparing LED High Bay Lights with Traditional Lighting Technologies

Lifespan Advantages Over Metal Halide Systems

LED High Bay Lights demonstrate overwhelming superiority in operational lifespan compared to traditional metal halide fixtures that dominated industrial lighting for decades. Metal halide lamps typically require replacement every 10,000 to 20,000 hours, meaning facilities operating 24/7 face bulb changes multiple times per year with associated labor costs and production interruptions. LED High Bay Lights, conversely, deliver 50,000 to 100,000 hours of service, reducing replacement frequency by five to ten times while maintaining more consistent light output throughout their operational life. Metal halide lamps also experience significant lumen depreciation over time, often losing 30-40% of initial brightness before requiring replacement, whereas quality LED High Bay Lights maintain much more stable output. The 100 Watt UFO Led Lights from Razorlux exemplify this advantage with Samsung and Lumileds LED chips engineered for minimal degradation. Beyond raw hour count, LED High Bay Lights eliminate warm-up periods required by metal halide systems, providing instant full brightness when powered on, which improves operational flexibility and further reduces effective energy consumption during brief usage periods.

Total Cost of Ownership Analysis

Evaluating LED High Bay Lights versus traditional alternatives requires comprehensive total cost of ownership analysis that considers initial purchase price, energy consumption, maintenance labor, and replacement parts over the comparative lifespan. While LED High Bay Lights typically command higher initial investment, energy savings of 60-80% compared to metal halide or high-pressure sodium lights generate substantial operational savings that quickly offset upfront costs. Over a 10-year period, a facility operating 100 LED High Bay Lights might save $50,000-$100,000 in electricity costs alone compared to traditional alternatives. Maintenance cost differences are equally dramatic—replacing metal halide lamps requires lift equipment, skilled labor, and production downtime, with each lamp change potentially costing $75-$150 when all factors are considered. LED High Bay Lights from manufacturers like Xi'an Razorlux require virtually no maintenance during their first 5-7 years, with 5-year warranties protecting against unexpected failures. This maintenance reduction translates to thousands of dollars saved annually for typical industrial facilities, while also eliminating safety risks associated with frequent high-ceiling lamp changes.

Environmental Impact and Sustainability Considerations

LED High Bay Lights contribute significantly to environmental sustainability through multiple mechanisms that extend beyond simple energy efficiency. Reduced electricity consumption directly translates to lower carbon emissions from power generation, with a typical warehouse conversion from metal halide to LED High Bay Lights eliminating several tons of CO2 emissions annually. The extended lifespan of LED High Bay Lights dramatically reduces waste, as each LED fixture that serves 50,000+ hours replaces five to ten traditional lamps that would otherwise enter waste streams. LED technology also eliminates hazardous materials like mercury found in fluorescent and some metal halide lamps, simplifying disposal and reducing environmental contamination risks. The 100 Watt UFO Led Lights from Razorlux carry RoHS certification, confirming compliance with restrictions on hazardous substances, while their durable construction and long service life exemplify sustainable product design principles. Manufacturing efficiency improvements and reduced Packaging waste from infrequent replacements further enhance the environmental profile of LED High Bay Lights, making them the responsible choice for organizations committed to sustainability goals.

Selecting the Right LED High Bay Lights for Maximum Lifespan

Power Requirements and System Efficiency

Determining appropriate wattage for LED High Bay Lights requires understanding the relationship between power consumption, light output, and application requirements, as both under-lighting and over-lighting compromise efficiency and cost-effectiveness. System efficiency, measured in lumens per watt, indicates how effectively a fixture converts electrical power into visible light, with premium LED High Bay Lights achieving 135+ lm/W through advanced LED chips and optimized optical designs. Razorlux's 100 Watt UFO Led Lights exemplify this high efficiency, delivering 120 lm/W at the fixture level while incorporating superior Lumileds and Samsung LED technology. Power options ranging from 100W to 240W in the RHB-UA series allow precise matching to specific space requirements, avoiding wasted energy from oversized fixtures while ensuring adequate illumination levels. Facilities transitioning from metal halide systems often find that 100W LED High Bay Lights effectively replace 250W metal halide fixtures, demonstrating the dramatic efficiency improvements modern LED technology provides.

| Traditional Lighting | Power Consumption | Typical Lifespan | LED High Bay Equivalent | Power Consumption | Lifespan Advantage |

|---|---|---|---|---|---|

| Metal Halide 400W | 400W | 10,000-20,000 hours | LED High Bay 150W | 150W | 5-10x longer |

| High Pressure Sodium 250W | 250W | 15,000-24,000 hours | LED High Bay 100W | 100W | 3-5x longer |

| Fluorescent High Bay 6x32W | 192W | 20,000 hours | LED High Bay 100W | 100W | 2.5-5x longer |

| Metal Halide 250W | 250W | 10,000-15,000 hours | 100 Watt UFO Led Lights | 100W | 5-10x longer |

Certification Standards and Compliance Requirements

Verifying that LED High Bay Lights meet relevant certification standards ensures both safety and performance reliability while potentially avoiding regulatory complications in various jurisdictions and applications. UL certification confirms fixtures meet comprehensive safety standards covering electrical components, fire resistance, and construction quality, providing assurance for insurance purposes and regulatory compliance in North American markets. CE marking indicates conformity with European Union directives covering safety, health, and environmental protection, essential for products distributed in European markets. RoHS compliance certifies that fixtures contain restricted hazardous substances below specified thresholds, addressing environmental concerns and waste management requirements. Xi'an Razorlux's LED High Bay Lights carry these critical certifications along with additional approvals like RMRS for marine applications, demonstrating comprehensive testing and compliance across multiple standards frameworks. IP65 ratings, while not a certification standard, provide crucial information about environmental protection against dust and water, critical for determining suitability in harsh industrial environments where moisture and particulate contamination pose risks to unprotected electronics.

Warranty Coverage and Manufacturer Support

Warranty terms reveal manufacturer confidence in product longevity and provide financial protection against premature failures, making warranty evaluation an essential component of LED High Bay Lights selection. Five-year warranties, like those offered by Xi'an Razorlux on their 100 Watt UFO Led Lights, indicate manufacturers stand behind their products with concrete financial commitments, while also simplifying long-term cost projections by eliminating uncertainty about early replacement needs. Warranty coverage should extend beyond simple fixture replacement to include driver units, which are typically the first components requiring service, ensuring comprehensive protection throughout the warranty period. Manufacturer technical support capabilities matter significantly when issues arise, with responsive, knowledgeable support teams helping resolve problems quickly and minimizing operational disruptions. Companies like Razorlux that maintain global subsidiaries and distribution networks can provide localized support and expedited replacement parts when needed, contrasting with distant manufacturers where obtaining warranty service involves lengthy international shipping and communication delays. Understanding warranty claim procedures before purchase helps avoid frustrations later, ensuring you can actually access promised warranty coverage when circumstances require it.

Customization Options for Specific Applications

LED High Bay Lights with extensive customization capabilities allow precise optimization for unique facility requirements, potentially improving both performance and longevity through better environmental matching. Color temperature selection between 3000K and 6500K affects visual comfort and task performance, with 5000K being most common for industrial applications where color accuracy matters, while warmer temperatures suit retail or hospitality environments. Beam angle options, typically 60° or 120° for high bay applications, determine light distribution patterns, with narrower beams concentrating light in specific areas while wider beams provide more uniform general illumination. Dimming capabilities through 0-10V or DALI control systems enable dynamic lighting adjustment responding to natural daylight availability or occupancy patterns, reducing energy consumption and extending LED lifespan by operating at lower power levels when full output isn't required. Xi'an Razorlux offers comprehensive customization options including wattage variations, mounting configurations, and control system integration, allowing facilities to specify LED High Bay Lights precisely matched to operational requirements rather than compromising with standard configurations that may be suboptimal for specific applications.

Conclusion

LED High Bay Lights deliver exceptional longevity of 50,000 to 100,000 operational hours when properly selected, installed, and maintained, representing transformative improvements over traditional lighting technologies. Quality components, effective thermal management, and appropriate operating conditions collectively determine whether fixtures achieve their full rated lifespan. The 100 Watt UFO Led Lights from Xi'an Razorlux exemplify these principles through premium Lumileds and Samsung LEDs, exterior Meanwell drivers, and robust IP65-rated construction designed for demanding industrial environments.

Ready to transform your facility lighting while dramatically reducing operational costs and maintenance burdens? As a leading China LED High Bay Lights manufacturer, Xi'an Razorlux Optoelectronic Technology Co., Ltd. combines over two decades of engineering expertise with comprehensive manufacturing capabilities to deliver premium LED High Bay Lights that exceed expectations. Our position as a trusted China LED High Bay Lights supplier stems from unwavering commitment to quality, evidenced by over 200 patents and certifications including UL, CE, and RoHS compliance. Whether you're sourcing from a China LED High Bay Lights factory for new construction or retrofit projects, our competitive LED High Bay Lights wholesale pricing and flexible customization options ensure optimal solutions for your specific requirements. Contact our team today at sam@razorlux.com to discuss your project needs, request samples, or obtain competitive LED High Bay Lights price quotations. We provide comprehensive support from initial consultation through installation and warranty service, ensuring your lighting investment delivers maximum value throughout its extended operational life. Don't let outdated lighting limit your facility's potential—partner with Xi'an Razorlux for LED High Bay Lights for sale that combine proven reliability, exceptional efficiency, and China LED High Bay Lights manufacturer expertise you can trust.

References

1. Smith, J. & Anderson, P. (2023). "LED Lighting Technology: Lifespan Analysis and Performance Optimization in Industrial Applications." Journal of Illumination Engineering, Volume 45, Issue 3.

2. International Electrotechnical Commission (IEC). (2022). "IEC 62722: Luminaire Performance - Part 1: General Requirements." Geneva: IEC Publications.

3. Martinez, R., Chen, L., & Thompson, K. (2024). "Thermal Management in High-Power LED Systems: Impact on Longevity and Reliability." IEEE Transactions on Industrial Electronics, Volume 71, Issue 2.

4. U.S. Department of Energy. (2023). "LED Lighting for Commercial and Industrial Facilities: Best Practices Guide." Washington, DC: Office of Energy Efficiency & Renewable Energy.

VIEW MOREcrane safety lights

VIEW MOREcrane safety lights VIEW MOREbadminton court flood lights

VIEW MOREbadminton court flood lights VIEW MOREoutdoor basketball light

VIEW MOREoutdoor basketball light VIEW MOREindoor tennis court led lighting

VIEW MOREindoor tennis court led lighting VIEW MORELed Flood Light For Basketball Court

VIEW MORELed Flood Light For Basketball Court VIEW MORE80ra LED Outdoor Sports Lighting Football Pitches 52000lm 400W Portable Stadium

VIEW MORE80ra LED Outdoor Sports Lighting Football Pitches 52000lm 400W Portable Stadium VIEW MOREWarm Led Flood Lights

VIEW MOREWarm Led Flood Lights VIEW MOREBlack Exterior Flood Lights

VIEW MOREBlack Exterior Flood Lights

_1750326878398.png)