How to Choose the Best Marine Flood Lights 1000W?

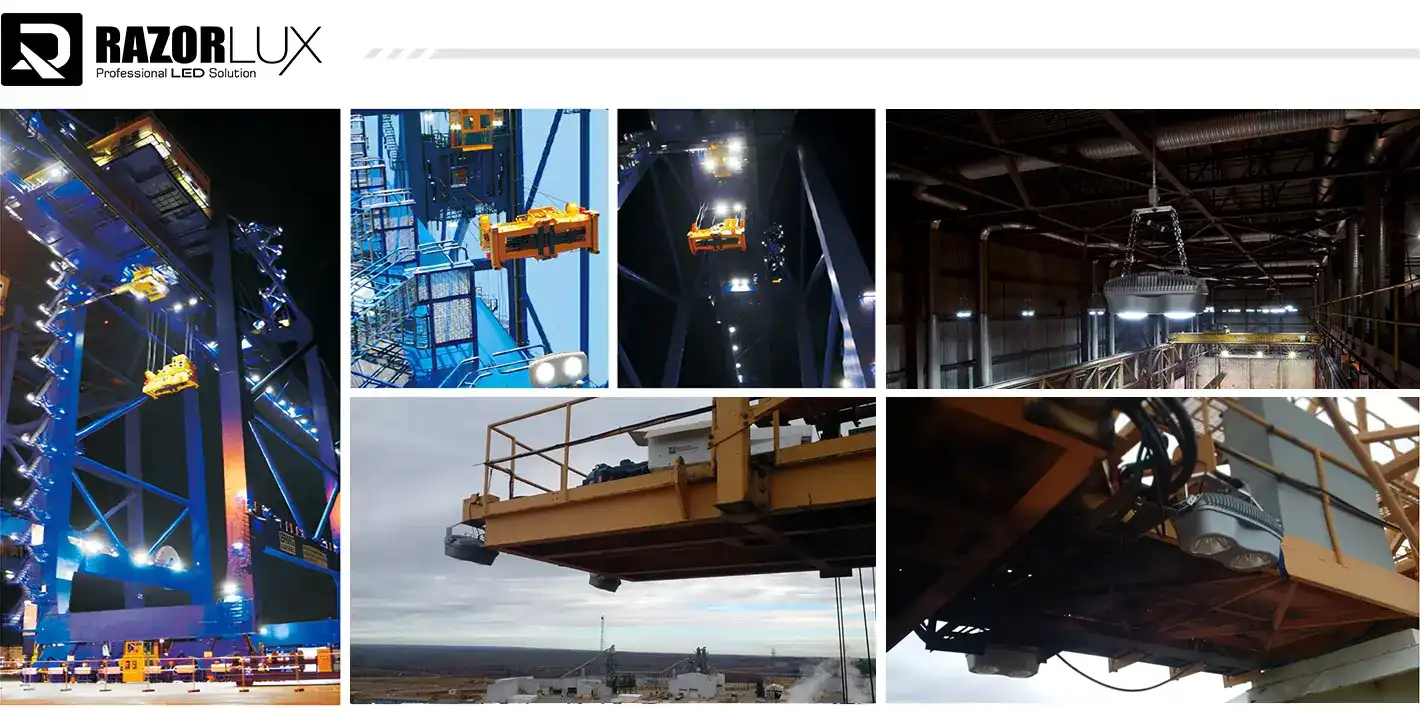

Picture this: You're managing a bustling shipyard where operations run around the clock, but inadequate lighting is causing safety concerns, productivity losses, and constant equipment replacements due to harsh marine corrosion. Selecting the right Marine Flood Lights 1000W isn't just about brightness—it's about finding a lighting solution that withstands saltwater corrosion, extreme temperatures, and delivers reliable performance for years. This comprehensive guide walks you through essential technical specifications, durability requirements, and cost-efficiency factors to help you make an informed decision that protects your investment and ensures optimal illumination in demanding maritime environments.

Understanding Marine Flood Lights 1000W Technical Specifications

Choosing Marine Flood Lights 1000W requires careful evaluation of technical parameters that directly impact performance and longevity. The right specifications ensure your lighting system meets operational demands while maximizing energy efficiency and reducing maintenance costs in harsh marine conditions.

Power Consumption and Energy Efficiency

When evaluating Marine Flood Lights 1000W, understanding the relationship between rated power and actual energy consumption is critical for calculating operational costs. A quality 1000W marine flood light typically consists of a 900W LED module paired with a 100W driver, delivering exceptional luminous efficacy of 130LM/W or higher. This configuration produces between 100,000 to 105,000 lumens while consuming significantly less energy than traditional HID lamps rated at 2200-3000W. The power factor of ≥0.98 ensures minimal energy waste, while Total Harmonic Distortion (THD) below 10% protects your electrical infrastructure from interference. Advanced Marine Flood Lights 1000W feature wide input voltage ranges (AC 80-360V or DC 100-400V) without requiring additional adapters, making them adaptable to various marine electrical systems worldwide. This flexibility eliminates compatibility concerns whether you're installing lights on offshore platforms with unstable power supplies or vessels with diverse electrical configurations.

Color Temperature and Rendering Options

The color temperature selection in Marine Flood Lights 1000W profoundly affects visibility, worker comfort, and task accuracy in maritime operations. Most professional-grade units offer adjustable color temperatures ranging from 2700K to 6500K, allowing customization based on specific application requirements. Warmer temperatures (2700-3500K) create comfortable ambient lighting for crew quarters and recreational areas, while cooler temperatures (5000-6500K) provide crisp, daylight-like illumination ideal for precision work in shipyards and maintenance operations. The Color Rendering Index (CRI) is equally crucial—Marine Flood Lights 1000W with CRI ≥Ra75 as standard (with Ra80 or Ra90 available upon request) ensure accurate color perception, essential for quality control inspections, paint matching, and safety signage recognition. Higher CRI values reduce eye strain during extended work periods and improve overall workplace safety by enabling workers to distinguish between color-coded equipment and warning indicators accurately.

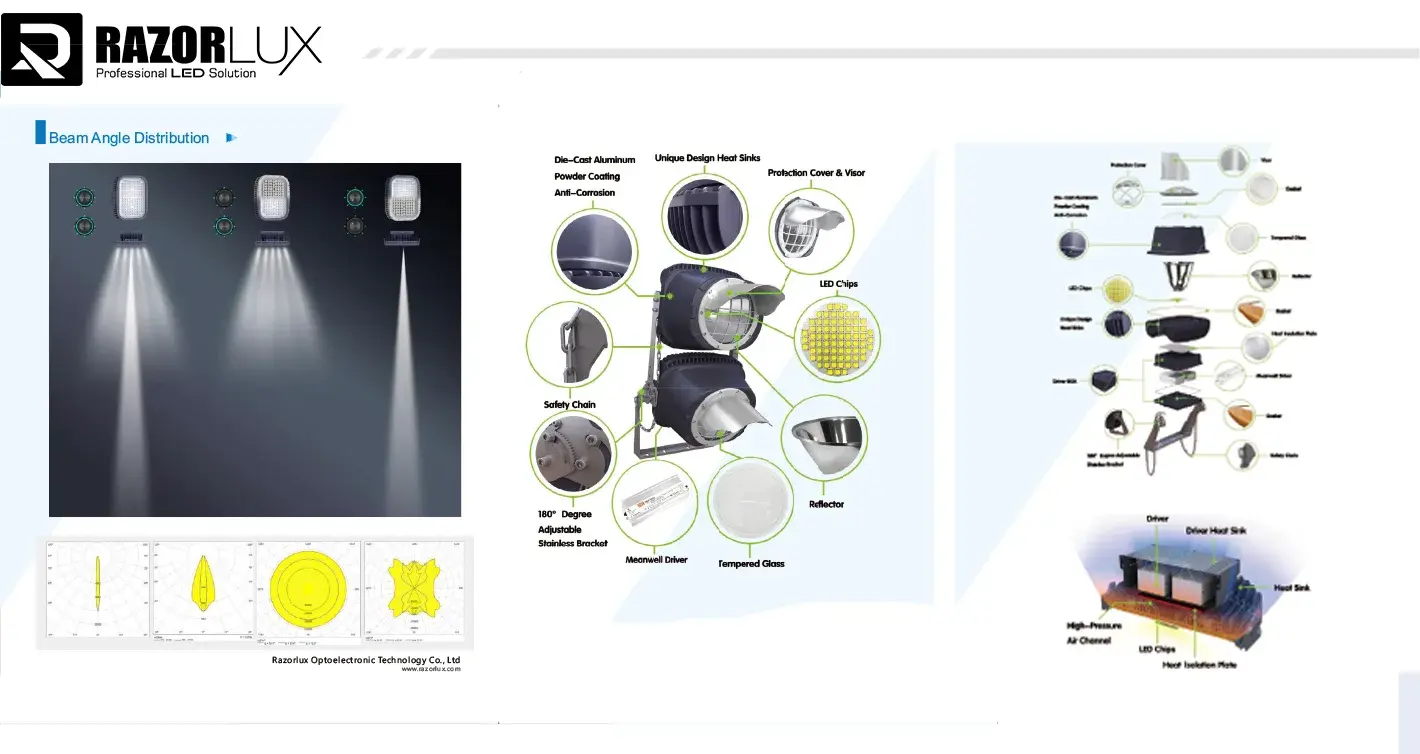

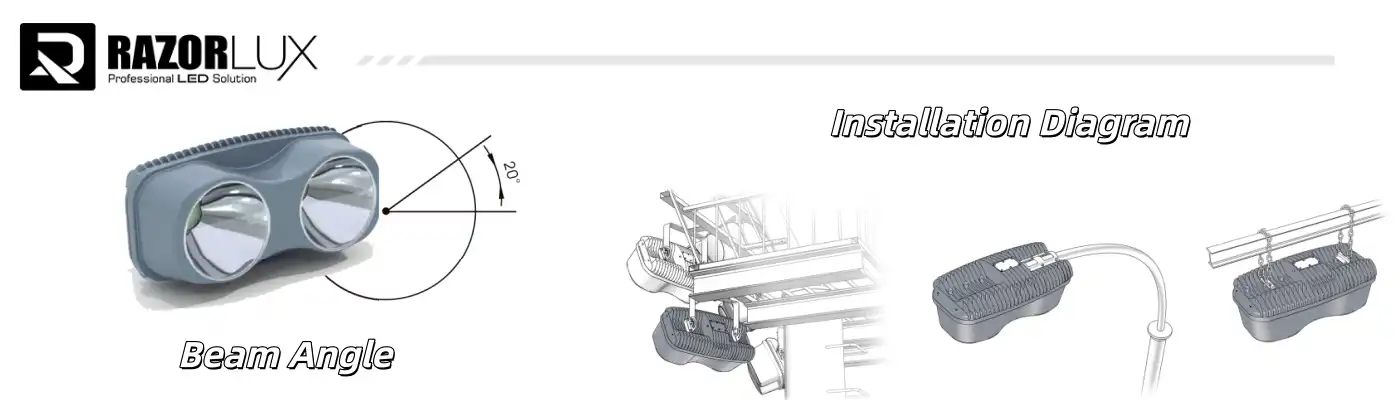

Beam Angle Configuration and Coverage

Selecting the appropriate beam angle for Marine Flood Lights 1000W determines the effective coverage area and light distribution pattern for your specific maritime application. Available beam angles typically include 15°, 20°, 30°, 40°, 60°, 120°, and asymmetric options like 140°x60°, each serving distinct purposes. Narrow beam angles (15°-20°) provide concentrated, long-distance illumination perfect for spotlighting distant vessel approaches, navigation channels, or perimeter security monitoring at ports. Medium beam angles (30°-60°) offer balanced coverage suitable for general area lighting in shipyards, loading docks, and offshore platform work decks. Wide beam angles (120° and above) deliver expansive floodlighting for large open spaces such as container terminals or dry dock facilities. The patented multi-function design in premium Marine Flood Lights 1000W allows beam angle customization or adjustment, providing operational flexibility as your lighting needs evolve. Consider mounting height, area dimensions, and overlap requirements when specifying beam angles—proper planning ensures uniform illumination without dark spots or excessive glare that could compromise safety.

Durability and Environmental Protection Standards

Marine environments present the harshest operating conditions for lighting equipment, making durability and environmental protection the most critical factors when selecting Marine Flood Lights 1000W. Understanding protection standards and construction quality directly impacts long-term reliability and total cost of ownership.

| Protection Standard | Rating | Performance Capability |

|---|---|---|

| Ingress Protection | IP67 | Complete dust protection; withstands immersion up to 1 meter for 30 minutes |

| Impact Resistance | IK10 | Survives 20 joules impact energy; resists vandalism and accidental strikes |

| Working Temperature | -40°C to 60°C | Maintains performance in extreme arctic to tropical conditions |

| Working Humidity | 10% to 95% | Operates reliably in high-moisture marine atmospheres |

IP67 Protection and Corrosion Resistance

The IP67 rating represents the gold standard for Marine Flood Lights 1000W operating in wet, dusty, and corrosive maritime environments. This certification guarantees complete protection against dust ingress and the ability to withstand temporary submersion up to one meter depth for thirty minutes—critical for deck-mounted fixtures exposed to wave spray, storm conditions, and pressure washing during maintenance. However, IP rating alone doesn't tell the complete story. Premium Marine Flood Lights 1000W incorporate marine-grade anti-corrosion coatings on aluminum housings combined with stainless steel brackets and mounting hardware that resist saltwater corrosion even after years of continuous exposure. The powder-coated aluminum construction provides an additional protective barrier while facilitating superior heat dissipation. Internal sealing technology using marine-grade gaskets prevents moisture infiltration at connection points, ensuring electronic components remain protected throughout the fixture's operational lifetime. When evaluating Marine Flood Lights 1000W, verify that manufacturers conduct salt spray resistance testing per international standards—units that pass 1000+ hour salt spray tests demonstrate proven durability for demanding offshore installations.

Thermal Management and Housing Design

Effective thermal management is paramount for Marine Flood Lights 1000W longevity, as excessive heat accelerates LED degradation and driver failure. Advanced housing designs incorporate precision-engineered heat sinks with optimized fin geometry that maximizes surface area for natural convection cooling without requiring vulnerable moving parts like fans. The aluminum construction typical in quality Marine Flood Lights 1000W provides excellent thermal conductivity, efficiently transferring heat from LED junctions to the external environment. Robust fixtures maintain junction temperatures well below critical thresholds even in tropical conditions (60°C ambient), ensuring the rated 50,000+ hour operational lifespan. The housing's structural integrity is equally important—Marine Flood Lights 1000W must withstand vibration from vessel engines, mechanical equipment, and rough sea conditions without compromising optical alignment or seal integrity. IK10 impact resistance rating indicates the fixture can endure 20 joules of impact energy, protecting against accidental strikes from cargo handling equipment, tools, or storm-driven debris. The combination of superior thermal management and rugged construction ensures Marine Flood Lights 1000W maintain consistent performance throughout demanding multi-shift operations in the world's most challenging maritime environments.

Installation Flexibility and Mounting Options

Professional-grade Marine Flood Lights 1000W offer versatile mounting configurations to accommodate diverse maritime installation requirements. The standard stainless steel floodlight bracket provides secure, adjustable positioning with multiple axis rotation, allowing precise beam aiming for optimal coverage. Mounting versatility is essential because maritime installations vary dramatically—from horizontal deck surfaces and vertical bulkheads to overhead crane structures and mast-mounted positions. Quality Marine Flood Lights 1000W include comprehensive mounting hardware designed for marine applications, featuring corrosion-resistant fasteners and reinforced attachment points capable of withstanding dynamic loads from vessel motion and wind forces. The fixture's center of gravity and weight distribution (typically 29kg/64lbs including bracket) should be considered during installation planning to ensure structural adequacy of mounting surfaces. Advanced designs may incorporate quick-disconnect features for rapid maintenance access without complete fixture removal, minimizing operational downtime. When specifying Marine Flood Lights 1000W, confirm compatibility with existing mounting infrastructure or factor in any necessary structural reinforcement to safely support the fixture weight and wind loading in your specific installation environment.

Certification Compliance and Quality Assurance

Regulatory compliance and quality certification are non-negotiable requirements for Marine Flood Lights 1000W in professional maritime applications. Understanding certification requirements protects your organization from liability while ensuring equipment reliability and worker safety.

International Marine Certifications

Marine Flood Lights 1000W destined for commercial maritime service must carry relevant certifications from recognized authorities. The Russian Maritime Register of Shipping (RMRS) certification is essential for vessels and offshore installations operating in Russian territories or international waters under Russian flag. European markets require CE marking demonstrating conformity with EU safety, health, and environmental protection standards, while RoHS compliance confirms the absence of hazardous substances. Australian installations need SAA and C-Tick certifications, whereas North American projects often specify UL listing for safety and DLC qualification for energy efficiency rebate eligibility. The CB Scheme certificate facilitates international market access by providing mutual recognition across participating countries. Premium Marine Flood Lights 1000W manufacturers maintain ISO 9001 certification, demonstrating commitment to quality management systems and consistent production standards. These certifications aren't merely paperwork—they represent rigorous third-party testing and ongoing compliance monitoring that validates product safety and performance claims. When comparing Marine Flood Lights 1000W options, verify that manufacturers can provide authentic certification documentation and that their products are listed in official databases maintained by certification bodies. Counterfeit certifications are unfortunately common in the lighting industry, potentially exposing your organization to significant legal and safety risks.

Manufacturing Quality Control Processes

Behind every reliable Marine Flood Lights 1000W unit lies a comprehensive quality control system ensuring consistent performance and longevity. Leading manufacturers implement multi-stage testing protocols beginning with incoming material inspection and continuing through every production phase. Assembly line quality checks verify proper LED module installation, driver connection integrity, and seal placement before units advance to functional testing. Photometric testing using integrating spheres measures actual lumen output, beam distribution, and color characteristics against specifications—ensuring every Marine Flood Lights 1000W delivers advertised performance. Aging tests subject completed fixtures to extended operation under controlled conditions, identifying infant mortality failures and confirming stable performance over time. Environmental stress testing includes vibration testing simulating vessel motion and mechanical equipment proximity, shock testing validating impact resistance claims, and thermal cycling between extreme temperatures verifying seal integrity and material compatibility. Salt spray testing specifically addresses marine corrosion resistance, with premium units enduring 1000+ hours of continuous salt fog exposure. Manufacturers with ISO 9001 certification maintain documented quality procedures, calibrated test equipment, and traceability systems linking every Marine Flood Lights 1000W to its production records and test results. This systematic approach to quality assurance dramatically reduces field failures and warranty claims while building customer confidence in product reliability.

Warranty Coverage and Support

Comprehensive warranty protection for Marine Flood Lights 1000W demonstrates manufacturer confidence in product quality and provides financial protection for your lighting investment. Industry-leading warranties typically offer five years coverage on both LED modules and drivers, with extended ten-year protection for housing components. This tiered warranty structure reflects the different expected lifespans of various fixture components while ensuring complete protection throughout the critical operational period. However, warranty terms matter as much as duration—verify whether coverage includes parts and labor, shipping costs for replacement units, and on-site service for complex installations. Some manufacturers offer expedited warranty processing with advance replacement programs minimizing operational downtime. The warranty should clearly define coverage exclusions such as damage from improper installation, unauthorized modifications, or operation outside specified parameters. Equally important is the manufacturer's after-sales support infrastructure. Access to knowledgeable technical support for installation guidance, troubleshooting assistance, and maintenance advice extends effective fixture lifespan beyond warranty periods. Manufacturers with global presence and local support networks provide faster response times and better understand regional requirements. When evaluating Marine Flood Lights 1000W suppliers, investigate their warranty claim history, customer satisfaction ratings, and responsiveness to support inquiries—these factors often prove more valuable than warranty duration alone in ensuring long-term satisfaction with your lighting investment.

Cost Analysis and Return on Investment

Understanding the total cost of ownership for Marine Flood Lights 1000W extends far beyond initial purchase price. A comprehensive financial analysis considering energy consumption, maintenance requirements, and operational lifespan reveals the true economic impact of your lighting investment.

| Cost Factor | Traditional HID | LED Marine Flood Lights 1000W | Savings |

|---|---|---|---|

| Initial Cost per Unit | $800-1200 | $1800-2800 | Higher upfront |

| Annual Energy Cost (8760 hrs) | $2,628 @ 3000W | $876 @ 1000W | $1,752/year |

| Replacement Frequency | 2-3 years | 10+ years | 70% fewer replacements |

| Maintenance Hours/Year | 8-12 hours | 1-2 hours | 80% labor reduction |

| 10-Year Total Cost | $28,000+ | $12,000-15,000 | 50% savings |

Energy Efficiency and Operational Savings

The superior energy efficiency of LED-based Marine Flood Lights 1000W generates substantial operational cost savings compared to traditional lighting technologies. While conventional HID fixtures require 2200-3000W to produce comparable illumination, advanced Marine Flood Lights 1000W deliver equivalent or superior light output using only 1000W—representing 60-70% energy reduction. Operating continuously (8760 hours annually) at typical industrial electricity rates ($0.12/kWh), this translates to $1,752 annual savings per fixture. For large-scale maritime facilities with dozens or hundreds of lights, cumulative savings reach tens of thousands of dollars yearly. The wide input voltage range (AC 80-360V, DC 100-400V) eliminates expensive voltage regulation equipment, while high power factor (≥0.98) reduces utility demand charges and improves electrical system efficiency. Many jurisdictions offer incentive programs for energy-efficient lighting upgrades—DLC-qualified Marine Flood Lights 1000W often qualify for substantial rebates that offset initial costs. Additionally, reduced heat generation from LED technology decreases HVAC loads in enclosed spaces, providing secondary energy savings. When calculating return on investment for Marine Flood Lights 1000W, factor in electricity cost escalation over the fixture's lifespan—energy prices historically increase 3-5% annually, magnifying long-term savings from efficient lighting systems.

Maintenance Cost Reduction

The extended operational lifespan of Marine Flood Lights 1000W dramatically reduces maintenance costs compared to traditional lighting technologies. With rated lifetimes exceeding 50,000 hours, these fixtures operate for more than a decade under typical maritime duty cycles before requiring replacement—five times longer than conventional HID lamps. This longevity eliminates frequent relamping expenses including labor costs for accessing difficult-to-reach maritime installations, disposal fees for spent lamps, and inventory carrying costs for replacement parts. Marine environments make maintenance particularly expensive due to specialized equipment requirements (lifts, scaffolding, rope access), production shutdown costs during maintenance windows, and safety protocols for working at height or in hazardous areas. The solid-state design of Marine Flood Lights 1000W eliminates fragile filaments and electrodes prone to failure from vibration and shock common in maritime settings. Advanced thermal management prevents premature degradation, while robust IP67-rated construction protects internal components from environmental contamination that causes conventional fixture failures. Maintenance reduction extends beyond lamp replacement—the corrosion-resistant housing and stainless steel mounting hardware maintain structural integrity for decades without the rust, pitting, and degradation requiring fixture replacement in traditional marine lighting. When evaluating Marine Flood Lights 1000W suppliers, consider manufacturers offering comprehensive warranties (5-year LED and driver, 10-year housing) that transfer maintenance risk and further enhance economic benefits.

Customization Options and OEM Services

Professional Marine Flood Lights 1000W suppliers offer extensive customization capabilities to match specific application requirements and differentiate branded product offerings. Standard customization options include wattage adjustment, color temperature selection (2700K-6500K), beam angle configuration, and dimming system integration (0-10V, DALI, DMX protocols). Housing finish options accommodate aesthetic preferences or functional requirements such as high-visibility safety colors or low-reflectance coatings for security applications. Mounting bracket configurations adapt to unique installation constraints, while custom cable lengths and connector types simplify integration with existing electrical infrastructure. For equipment manufacturers and distributors, OEM and ODM services enable development of branded Marine Flood Lights 1000W that meet market-specific demands. This includes custom housing designs incorporating proprietary aesthetic elements, integrated control systems, specialized lens configurations, or unique feature combinations unavailable in standard products. Leading manufacturers maintain flexible production capabilities supporting small-batch custom orders alongside volume production, accommodating projects ranging from boutique yacht lighting to large-scale port infrastructure developments. Customization extends to Packaging and documentation—branded cartons, multilingual instruction manuals, and custom labeling enhance market presentation and end-user experience. When pursuing customized Marine Flood Lights 1000W, partner with manufacturers demonstrating strong R&D capabilities (200+ patents), in-house engineering resources, and proven track records delivering custom solutions. Request samples and prototypes for evaluation before committing to volume orders, ensuring custom specifications meet performance expectations and quality standards.

Conclusion

Selecting the optimal Marine Flood Lights 1000W requires balancing technical specifications, durability requirements, certification compliance, and total cost of ownership to identify solutions delivering superior performance and long-term value in demanding maritime environments.

Ready to upgrade your maritime lighting with industry-leading Marine Flood Lights 1000W? As a China Marine Flood Lights 1000W factory, China Marine Flood Lights 1000W supplier, and China Marine Flood Lights 1000W manufacturer, Xi'an Razorlux offers premium Marine Flood Lights 1000W for sale at competitive Marine Flood Lights 1000W prices with China Marine Flood Lights 1000W wholesale options. Contact our team at sam@razorlux.com today for customized quotes, technical specifications, and sample evaluation. Bookmark this guide for future reference when planning your next lighting project!

References

1. Maritime Safety Committee. "International Standards for Marine Electrical Installations and Lighting Systems." International Maritime Organization Technical Guidelines. 2024.

2. Chen, J., Wang, L., and Zhang, H. "LED Lighting Performance and Reliability in Marine Environments: A Comprehensive Analysis." Journal of Maritime Engineering & Technology. 2023.

3. National Electrical Manufacturers Association. "High-Intensity Discharge to LED Retrofit Guide for Industrial and Marine Applications." NEMA Lighting Systems Division. 2024.

4. Thompson, R. and Anderson, M. "Life Cycle Cost Analysis of Industrial Lighting Systems in Corrosive Environments." International Journal of Industrial Engineering and Management. 2023.

_1750326878398.png)

_1750410540049.webp)