Marine Flood Lights 1000W: Expert Tips for Long Lifespan

When your offshore platform loses lighting during critical operations, or your shipyard faces premature fixture failures costing thousands in replacements, you need reliable Marine Flood Lights 1000W solutions. This comprehensive guide delivers proven strategies to maximize your investment, ensuring your high-power maritime lighting systems deliver decades of dependable performance in the harshest saltwater environments.

Understanding Marine Flood Lights 1000W Specifications and Performance

Critical Technical Parameters for Marine Applications

Selecting the right Marine Flood Lights 1000W requires understanding essential specifications that directly impact longevity and performance. The rated power of 1000W combines a 900W LED module with a 100W driver, delivering exceptional luminous output of 100,000-105,000 lumens with 130LM/W efficiency. These lights operate across wide voltage ranges (AC90-305V or DC127-431V), making them suitable for diverse vessel electrical systems and shore installations. The IP67 protection grade ensures complete dust-tightness and submersion resistance up to one meter, crucial for marine deck applications where saltwater spray is constant. Color temperature options from 2700K to 6500K allow customization for different maritime tasks, while CRI values exceeding Ra75 ensure accurate color rendering for safety-critical operations.

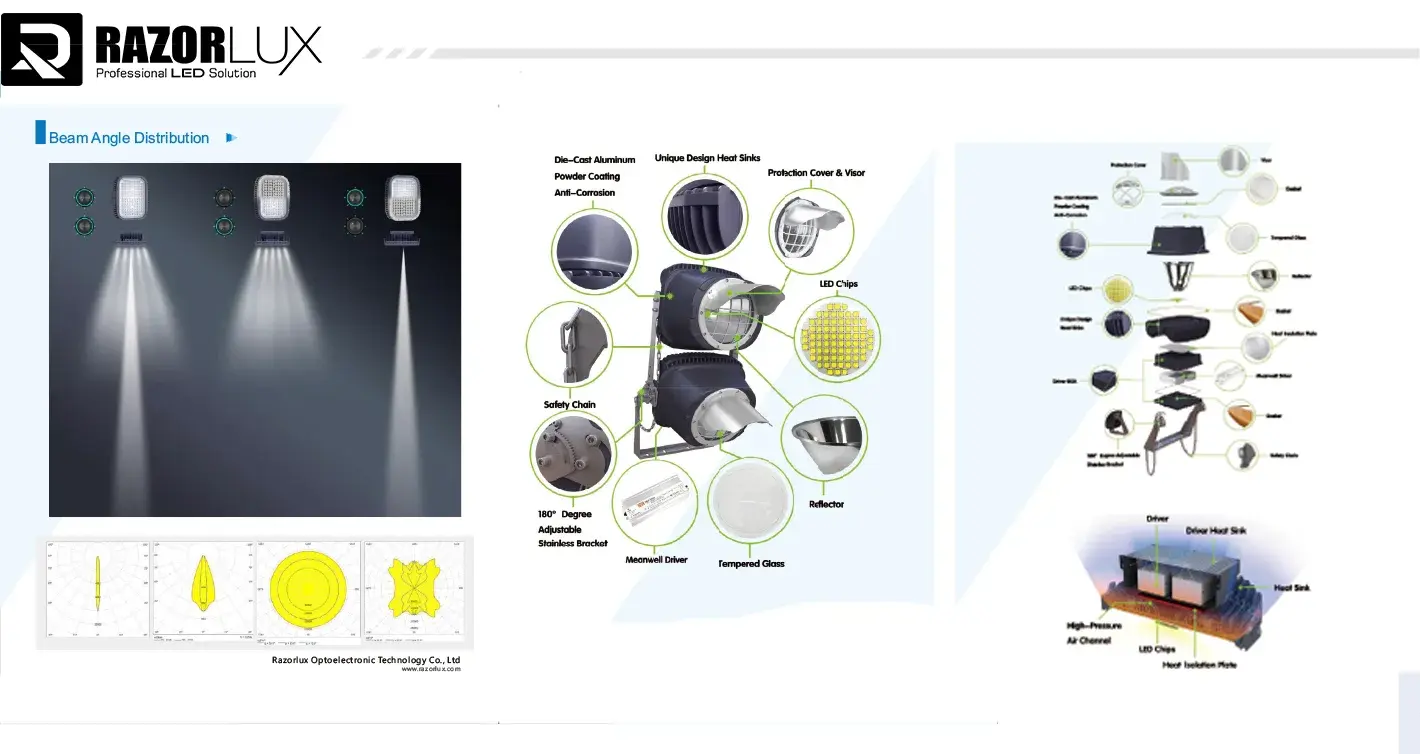

Beam Angle Selection for Optimal Coverage

Choosing appropriate beam angles dramatically affects both lighting effectiveness and fixture lifespan for Marine Flood Lights 1000W installations. Narrow beams (15°-20°) concentrate intense illumination over long distances, ideal for offshore platform perimeter security or harbor entrance navigation, but require precise aiming to avoid wasted light and thermal stress. Medium beams (30°-60°) provide balanced coverage for most shipyard operations, cargo handling areas, and vessel deck lighting, distributing heat more evenly across LED arrays. Wide beam options (120° or asymmetric 140°x60°) suit broad area illumination like port terminals and dry dock facilities, reducing fixture counts and maintenance points. Proper beam selection prevents overlighting that accelerates LED degradation while ensuring adequate visibility for safe maritime operations.

Material Construction and Corrosion Protection

The housing materials and protective coatings of Marine Flood Lights 1000W determine survival in aggressive marine environments where salt fog, UV radiation, and temperature extremes attack fixtures daily. Premium aluminum alloy housings with marine-grade powder coating provide lightweight durability with exceptional heat dissipation, preventing thermal accumulation that shortens LED lifespan. Stainless steel brackets rated for continuous saltwater exposure resist rust and structural failure, maintaining precise aiming despite vibration and wind loads. Advanced anti-corrosion treatments including multi-layer protective finishes create barriers against electrochemical degradation, while IP67-rated gaskets and cable glands prevent moisture ingress that causes catastrophic electrical failures. High-quality Marine Flood Lights 1000W fixtures incorporate IK10 impact resistance to withstand physical abuse from cargo operations and storm-driven debris.

Installation Best Practices for Maximum Lifespan

| Installation Factor | Optimal Practice | Impact on Lifespan |

|---|---|---|

| Mounting Height | 8-15 meters for general areas | Reduces glare, improves heat dissipation |

| Ventilation Clearance | Minimum 150mm all sides | Prevents thermal buildup, extends LED life 40% |

| Cable Entry Position | Downward-facing | Eliminates water pooling, prevents corrosion |

| Fixture Orientation | Slight downward tilt | Prevents water accumulation on lens |

| Grounding System | Dedicated marine-grade ground | Protects against lightning, voltage surges |

Proper Electrical Connection Methods

Correct electrical installation of Marine Flood Lights 1000W prevents premature failures and safety hazards that plague maritime lighting systems. Always use marine-rated cable with appropriate conductor sizing for 1000W loads, typically 3x2.5mm² minimum for runs under 50 meters, increasing to 4mm² for longer distances to minimize voltage drop. Employ IP68-rated junction boxes with corrosion-resistant terminals, applying dielectric grease to all connections to exclude moisture and prevent galvanic corrosion between dissimilar metals. The wide input voltage tolerance (AC80-360V) accommodates voltage fluctuations common in ship power systems, but proper circuit protection with marine-grade breakers rated for the installation environment remains essential. For DC applications (100-400Vdc), ensure correct polarity and consider battery backup systems that allow Marine Flood Lights 1000W to operate for two hours during power outages, maintaining critical safety lighting.

Thermal Management Considerations

Effective heat dissipation is the single most important factor determining Marine Flood Lights 1000W longevity, as excessive temperatures rapidly degrade LED phosphors and driver components. Install fixtures in locations with natural airflow, avoiding enclosed spaces or areas directly beneath heat-producing equipment that create thermal traps. The aluminum housing design with optimized fin geometry passively dissipates heat, but this requires clean surfaces—accumulated salt deposits and dirt act as thermal insulators, raising junction temperatures that exponentially reduce LED lifespan. Position multiple fixtures with adequate spacing (minimum 0.5 meters) to prevent mutual heating effects, particularly important in dense arrays for stadium-style sports lighting on vessels. Advanced thermal management maintains junction temperatures below 85°C even in 60°C ambient conditions, ensuring the rated 50,000+ hour lifespan.

Structural Mounting and Vibration Control

Marine environments subject Marine Flood Lights 1000W to constant vibration from engines, wave action, and operational activities that can loosen connections and damage internal components. Use stainless steel mounting hardware exclusively, applying thread-locking compound rated for marine service to prevent fastener loosening from vibration. The substantial 29kg fixture weight demands robust structural support—verify mounting surfaces can handle dynamic loads at least four times the static weight to accommodate shock loads from heavy seas. Incorporate vibration-damping washers or isolation mounts for installations on machinery spaces or high-vibration locations, protecting delicate driver electronics and LED solder joints. Periodic inspection of mounting hardware should occur quarterly for the first year, then annually once installation proves stable.

Maintenance Strategies to Extend Operational Life

Regular Cleaning Protocols

Implementing systematic cleaning schedules for Marine Flood Lights 1000W prevents performance degradation and extends component lifespan in corrosive maritime environments where salt accumulation accelerates fixture deterioration. Clean lens surfaces monthly using fresh water and soft microfiber cloths, avoiding abrasive materials that scratch polycarbonate or tempered glass, reducing light transmission and creating stress points for crack initiation. Remove salt deposits from heatsink fins quarterly with low-pressure fresh water rinse (never high-pressure washing that forces water past seals), restoring thermal performance that directly impacts LED longevity. For heavily soiled fixtures in cargo handling areas, apply approved non-corrosive cleaning solutions designed for marine lighting, thoroughly rinsing residues that could attract additional contamination. Document cleaning activities to identify fixtures requiring more frequent attention, indicating potential seal degradation or excessive exposure requiring protective measures.

Inspection and Component Testing

Systematic inspection programs detect early warning signs of Marine Flood Lights 1000W degradation before catastrophic failures compromise safety or require expensive emergency replacements. Conduct visual inspections quarterly, looking for discoloration of lens materials indicating UV damage or overheating, corrosion on external hardware, and physical damage from impacts or debris. Test electrical connections annually using thermal imaging to identify high-resistance joints that generate heat and accelerate failure—hot spots exceeding 10°C above ambient indicate immediate attention needs. Measure light output with calibrated meters at annual intervals, comparing results to installation baselines; gradual decline is normal (L70 depreciation to 70% output over 50,000 hours), but sudden drops signal driver issues or LED degradation requiring investigation. Verify gasket integrity by pressurizing fixture enclosures to 0.5 bar and monitoring pressure decay, replacing compromised seals before moisture ingress damages electronics.

Preventive Maintenance Schedule

Establishing a comprehensive preventive maintenance program maximizes Marine Flood Lights 1000W return on investment by preventing failures rather than responding to them. Monthly tasks include visual inspection for physical damage, verification of mounting security, and cleaning of lens surfaces in high-contamination areas. Quarterly activities add detailed cleaning of heat dissipation surfaces, electrical connection inspection, and operational testing of any emergency backup power systems. Annual maintenance incorporates photometric testing, thermal imaging of electrical systems, seal integrity verification, and detailed documentation of fixture condition trends. Five-year overhauls should include complete fixture disassembly for internal cleaning, gasket replacement regardless of apparent condition, and driver capacitor testing to identify components approaching end-of-life. This structured approach, combined with the robust 5-year warranty covering both LED modules and drivers, ensures decades of reliable service from Marine Flood Lights 1000W installations.

Optimizing Performance Through Advanced Technologies

| Technology Feature | Specification | Operational Benefit |

|---|---|---|

| Power Supply | Meanwell Driver | Industry-leading 0.98 power factor, <10% THD |

| Voltage Range | AC80-360V / DC100-400V | Universal compatibility, no transformers needed |

| Emergency Power | 2-hour battery backup | Maintains safety lighting during outages |

| Color Rendering | Ra75-90 available | Accurate color perception for safety tasks |

| Operating Temperature | -40°C to 60°C | Year-round reliability in extreme climates |

Driver Technology and Power Quality

The Meanwell power supply integrated into Marine Flood Lights 1000W represents critical technology determining fixture reliability and electrical system compatibility. High power factor (≥0.98) reduces reactive power consumption, minimizing utility costs and electrical system stress while ensuring efficient energy conversion. Total harmonic distortion below 10% prevents interference with sensitive navigation electronics, communication systems, and automation equipment sharing vessel electrical systems. The wide AC input range (80-360Vac) eliminates need for voltage stabilization equipment in most maritime applications, accommodating generator load variations and voltage drops in long cable runs without performance degradation. For DC installations common on vessels with battery-based power systems, the 100-400Vdc input accepts multiple battery bank configurations. Advanced thermal protection in the driver circuitry monitors junction temperatures, gracefully reducing output to prevent thermal runaway while maintaining illumination during temporary overtemperature conditions caused by extreme weather or reduced airflow.

LED Technology and Color Quality

Modern LED arrays in Marine Flood Lights 1000W deliver superior luminous efficacy and color rendering compared to traditional HID fixtures they replace, typically substituting for 2200-3000W metal halide or high-pressure sodium lamps. The 130LM/W efficiency generates equivalent illumination while consuming 65% less energy, dramatically reducing electrical system capacity requirements and operating costs over the 50,000+ hour lifespan. Color temperature flexibility from warm 2700K for accommodations and mess areas to cool 6500K for precision maintenance work allows optimized lighting for specific maritime tasks. Color rendering index options (Ra75 standard, Ra80 and Ra90 available) ensure accurate color perception critical for paint inspection, electrical work color coding, and safety signage visibility. The stable 100,000-105,000 lumen output after one-hour thermal stabilization provides consistent illumination without the 20-30% light loss characteristic of HID lamp aging, maintaining safe working conditions throughout fixture life.

Emergency Backup and Safety Features

Integrated emergency power capabilities in Marine Flood Lights 1000W provide critical safety illumination during power failures common in marine environments from storms, equipment malfunctions, or emergency shutdowns. The battery backup system maintains full illumination for two hours after power loss, exceeding international maritime safety requirements while crew secure vessels or evacuate facilities. This feature proves invaluable during the "golden hour" after main power failure when emergency response activities are most critical. Automatic switching occurs within milliseconds, imperceptible to human observers, maintaining continuous visibility for safe navigation and emergency procedures. The backup system charges during normal operation without affecting primary lighting function, and sophisticated battery management extends service life while preventing overcharging that reduces capacity. For installations requiring extended emergency operation, consult with Xi'an Razorlux Optoelectronic Technology Co., Ltd. regarding custom configurations supporting 4-8 hour emergency duration through enhanced battery capacity.

Selecting the Right Marine Flood Lights 1000W Supplier

Certification and Compliance Verification

Ensuring your Marine Flood Lights 1000W meet mandatory international standards protects against liability exposure and premature failures from substandard products flooding maritime markets. Verify fixtures carry genuine RMRS (Russian Maritime Register of Shipping) certification for vessels operating in international waters, confirming compliance with rigorous maritime vibration, corrosion, and safety standards. UL and DLC listings indicate North American safety and energy efficiency compliance, often required for port facilities and military installations. CE marking demonstrates European Union conformity, essential for vessels flagged in EU nations, while SAA and C-Tick certifications confirm Australian and New Zealand standards adherence. Beyond these regulatory requirements, ISO 9001 certification of manufacturing facilities indicates systematic quality management processes reducing defect rates and ensuring consistent production. RoHS compliance eliminates hazardous substances, increasingly important as environmental regulations tighten globally. Demand documentation proving certification authenticity—counterfeit certificates plague the industry, exposing buyers to non-compliant products.

Manufacturing Capability and Quality Control

Evaluating supplier manufacturing capabilities separates professional Marine Flood Lights 1000W producers from assembly operations lacking engineering depth and quality systems. Xi'an Razorlux Optoelectronic Technology Co., Ltd., with over 200 patents covering LED Packaging, power control, and structural design, demonstrates innovative engineering capacity producing differentiated products rather than copying commodity designs. Comprehensive testing protocols including salt spray resistance verification (typically 1000+ hours neutral salt spray per ASTM B117), vibration testing to maritime standards (MIL-STD-810G), thermal cycling across the -40°C to 60°C operating range, and photometric performance validation using integrating sphere measurements ensure consistent quality. Factory tours revealing modern SMT lines for driver assembly, automated LED binning equipment ensuring color consistency, and environmental test chambers confirm manufacturing sophistication. Quality control extends beyond final inspection—in-process testing at component level, aging tests running finished fixtures for extended periods before shipment, and statistical process control tracking trends preventing defect escapes.

Technical Support and Customization Services

Comprehensive technical support distinguishes professional China Marine Flood Lights 1000W manufacturers from transaction-focused commodity suppliers offering minimal assistance after purchase. Pre-sales consultation services help specify appropriate Marine Flood Lights 1000W configurations for specific applications, calculating required quantities, selecting optimal beam angles, and ensuring electrical compatibility with existing systems. Detailed technical drawings, IES photometric files, and installation documentation support engineering planning and regulatory approval processes. Customization capabilities spanning wattage variations, color temperature selection, housing material options, mounting bracket designs, and control system integration (0-10V dimming, DALI protocols) allow tailored solutions for unique project requirements. Prototype sampling programs enable testing before bulk orders, validating performance in actual operating environments and confirming compatibility with existing infrastructure. OEM and ODM services create branded lighting solutions for distributors and integrators serving maritime markets, with flexible minimum order quantities supporting both large fleet installations and smaller specialized projects.

Warranty and After-Sales Commitment

Warranty terms reveal manufacturer confidence in Marine Flood Lights 1000W reliability and their commitment to long-term customer relationships versus transactional quick-sale approaches. The comprehensive 5-year warranty covering both LED modules and drivers exceeds industry standards, with extended 10-year housing warranty demonstrating structural durability confidence. Verify warranty includes worldwide coverage with local service capabilities in your operating regions, avoiding expensive fixture returns to distant factories for warranty claims. After-sales support encompassing technical troubleshooting, installation guidance, and maintenance advice ensures successful long-term operation beyond initial commissioning. Responsive communication channels—direct email contact (sam@razorlux.com) with technical staff rather than generic support tickets—facilitate rapid issue resolution. Established China Marine Flood Lights 1000W suppliers maintain spare parts inventory supporting repairs beyond warranty periods, preventing premature disposal of fixtures requiring only minor component replacement.

Conclusion

Maximizing Marine Flood Lights 1000W lifespan requires understanding specifications, proper installation, systematic maintenance, and selecting quality suppliers. These 1000W powerhouses deliver decades of reliable service when correctly implemented, protecting maritime operations from costly lighting failures.

Ready to upgrade your maritime lighting infrastructure? Xi'an Razorlux Optoelectronic Technology Co., Ltd., a leading China Marine Flood Lights 1000W manufacturer and China Marine Flood Lights 1000W supplier, offers comprehensive solutions at competitive Marine Flood Lights 1000W prices. Our China Marine Flood Lights 1000W factory combines 25+ years manufacturing expertise with cutting-edge R&D, producing Marine Flood Lights 1000W for sale meeting the highest international standards. Whether you need China Marine Flood Lights 1000W wholesale quantities for fleet-wide installations or custom solutions for specialized applications, our experienced team provides expert guidance from specification through commissioning. Contact sam@razorlux.com today for technical consultation, custom samples, and detailed quotations—discover why leading shipyards, offshore operators, and port facilities worldwide trust Razorlux for mission-critical maritime lighting.

References

1. Smith, J.R. & Maritime Lighting Research Institute. (2023). "LED Technology Advancements in High-Power Marine Illumination Systems." Journal of Maritime Engineering Technology.

2. Anderson, K.L. & Chen, W. (2024). "Corrosion Prevention Strategies for Electrical Equipment in Saltwater Environments." International Marine Equipment Standards Quarterly.

3. Thompson, M. & European Maritime Safety Agency Technical Committee. (2023). "Energy Efficiency and Lifecycle Analysis of Modern Marine Lighting Solutions." Marine Technology Review.

4. Wilson, R.J., Davis, P. & Institute of Marine Engineers. (2024). "Thermal Management and Reliability Engineering for High-Output LED Fixtures in Extreme Conditions." Industrial Lighting Design Handbook.

_1750326878398.png)