Marine-Grade Crane Light Fixture: What Makes It Seaworthy?

Picture this nightmare scenario: your port crane lighting fails mid-operation during a critical nighttime cargo transfer, leaving operators working blind in hazardous conditions. This reality costs maritime operations thousands in downtime, creates severe safety risks, and damages client relationships. Marine-Grade Crane Light Fixtures solve this pain point by delivering industrial-strength illumination engineered specifically to withstand saltwater corrosion, constant vibrations, extreme weather, and 24/7 operational demands that destroy conventional lighting within months.

Essential Features That Define Marine-Grade Crane Light Fixtures

Superior IP Protection Ratings for Maritime Environments

When operating Crane Light Fixtures in marine environments, protection against water and dust ingress becomes absolutely critical for long-term reliability and safety. The IP67 protection rating represents the industry gold standard for maritime crane applications, providing complete dust protection and safeguarding against temporary water immersion up to one meter depth. This exceptional sealing capability ensures that internal electronic components, LED modules, and driver circuits remain completely protected even during severe weather events, heavy rain, or accidental submersion scenarios that commonly occur in port and shipyard operations. Advanced multi-layer gasket systems incorporating primary seals, secondary backup seals, and pressure relief valves work together to prevent condensation buildup while maintaining superior water resistance throughout the fixture's operational lifespan. The comprehensive weatherproofing extends beyond the housing to include tempered glass lenses with hydrophobic coatings that actively repel water droplets and prevent salt crystal formation that could otherwise reduce light output and optical performance over time.

Anti-Corrosion Engineering and Marine-Grade Materials

Marine environments present the most aggressive corrosive conditions that industrial Crane Light Fixtures will ever encounter, with salt-laden air and constant spray exposure accelerating deterioration of standard equipment. Premium marine-grade fixtures utilize 316 stainless steel construction throughout all structural components, fasteners, and mounting brackets, providing maximum resistance against electrochemical corrosion processes that rapidly degrade inferior materials in saltwater environments. Specialized powder coating and epoxy-based protective finishes create multiple barrier layers that shield aluminum housings from environmental attack, while internal wiring harnesses feature marine-grade insulation specifications that prevent moisture infiltration at connection points. The comprehensive corrosion resistance approach includes sealed connector systems with conformal coatings on electronic driver circuits, ensuring that every vulnerable component receives appropriate protection against the relentless corrosive forces present in maritime operations. Professional-grade Crane Light Fixtures undergo rigorous salt spray testing according to ASTM B117 standards, with top-tier products demonstrating no visible corrosion after 1000 hours of continuous exposure to salt fog conditions equivalent to the most aggressive marine environments.

Vibration Resistance and Mechanical Durability

The constant mechanical stresses generated by crane operations create unique challenges for lighting equipment, with vibrations and shock loads capable of destroying conventional fixtures within months of installation. Marine-Grade Crane Light Fixtures incorporate solid-state LED technology that eliminates fragile filaments and glass envelopes found in traditional lighting, while robust driver circuits feature conformal coatings protecting electronic components from vibration-induced stress and mechanical fatigue. Advanced fixtures undergo comprehensive testing according to ANSI C136.31 standards, with premium products successfully withstanding 3G vibration testing through 100,000 cycles without performance degradation or structural failure. The mounting hardware utilizes anti-vibration compounds, locking mechanisms, and flexible cable management systems that prevent loosening under constant movement while accommodating dynamic motion without creating stress concentration points. Professional installations consider resonance frequencies during fixture placement, ensuring mounting systems avoid harmonic amplification effects that could accelerate component wear and reduce operational lifespan in demanding crane applications.

Performance Specifications for Maritime Crane Light Fixtures

| Specification | Standard Range | Premium Performance | Marine Application Benefit |

|---|---|---|---|

| IP Rating | IP65-IP67 | IP67 | Complete water/dust protection |

| Corrosion Resistance | Salt spray 500h | Salt spray 1000h+ | Extended lifespan in saltwater |

| Vibration Testing | 1G standard | 3G (100,000 cycles) | Withstands crane operations |

| Operating Temperature | -20°C to 50°C | -40°C to 60°C | Reliable in extreme conditions |

| Warranty Coverage | 3 years | 5 years | Long-term investment protection |

| Lumen Maintenance | L70 at 50,000h | L80 at 60,000h | Consistent illumination quality |

Advanced Thermal Management Technology

Effective heat dissipation represents a critical factor determining the longevity and performance consistency of Crane Light Fixtures operating in demanding industrial environments where ambient temperatures fluctuate dramatically. Premium fixtures incorporate sophisticated thermal management systems featuring extruded aluminum housings with integrated heat sink designs that maximize surface area for passive cooling, ensuring LED junction temperatures remain within optimal operating ranges even during extended high-power operation. Advanced thermal interface materials and thermal pathway engineering transfer heat efficiently from LED modules to external cooling fins, while computational fluid dynamics optimization ensures maximum airflow across heat dissipation surfaces. The superior thermal performance prevents the accelerated degradation that occurs when LED components operate at elevated temperatures, maintaining consistent light output, color temperature stability, and rated lifespan throughout the fixture's operational service period. Professional-grade Crane Light Fixtures demonstrate exceptional thermal management capabilities, with some advanced designs achieving up to 60% better heat dissipation compared to conventional industrial lighting solutions.

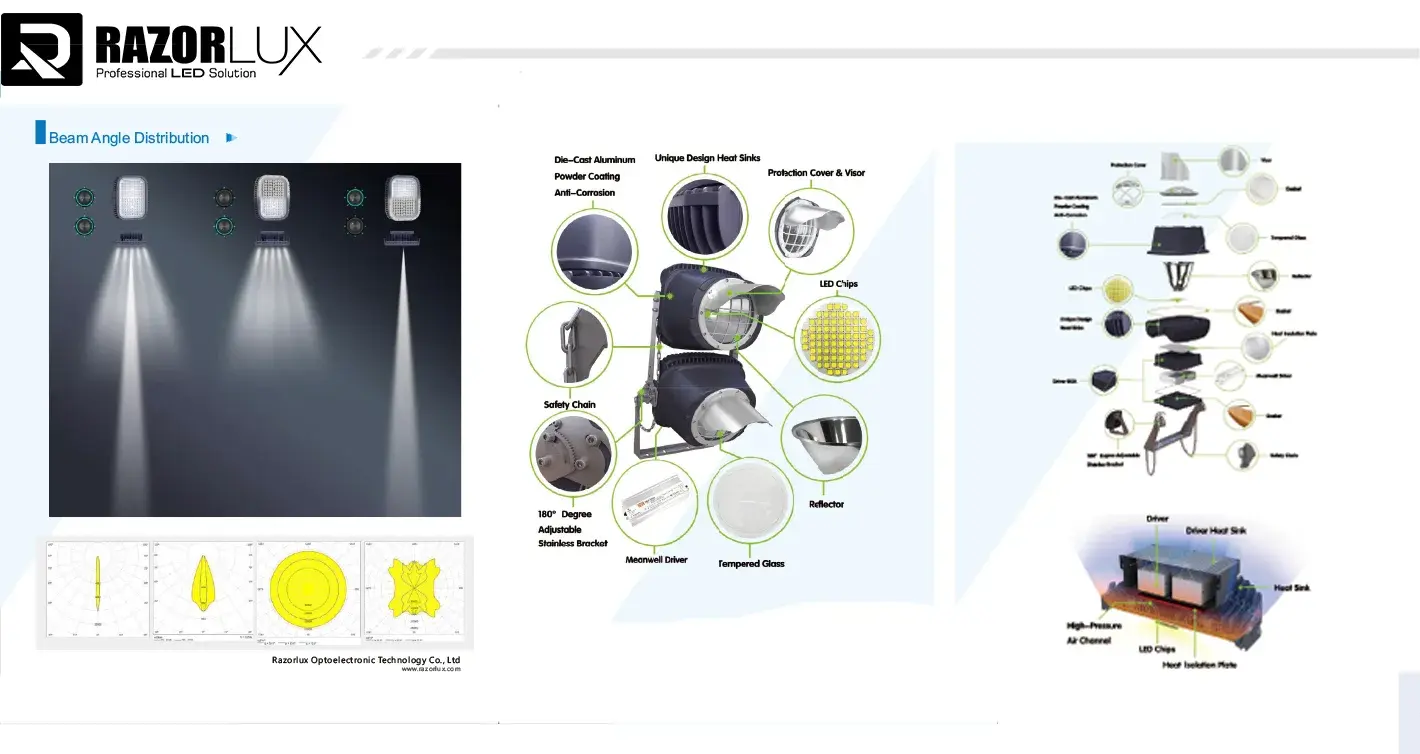

Optical Performance and Beam Control

Precision illumination patterns represent essential requirements for Crane Light Fixtures serving maritime operations, where operator visibility directly impacts safety and operational efficiency during critical cargo handling procedures. Advanced optical systems provide carefully engineered beam angles ranging from narrow 20-degree focused distributions for high-mounted applications to wide 140x60-degree asymmetric patterns for lower mounting heights, ensuring optimal ground coverage while minimizing glare that could interfere with vessel navigation systems or adjacent operations. High-quality fixtures utilize precision-molded optical lenses or reflector systems that maximize light utilization efficiency while maintaining excellent beam control characteristics, eliminating the wasted spill light and hot spots common with inferior lighting designs. The optical components feature anti-reflective coatings and UV-stable materials that maintain their performance characteristics throughout extended outdoor exposure, while advanced designs incorporate adjustable mounting brackets enabling precise aiming adjustments to accommodate specific operational requirements and mounting configurations found in diverse maritime crane installations.

Energy Efficiency and Power Management

Modern LED Crane Light Fixtures deliver exceptional energy efficiency that dramatically reduces operational costs compared to legacy HID or halogen lighting systems while providing superior illumination quality and reliability. Premium fixtures achieve luminous efficacy ratings of 130 lumens per watt or higher, enabling a 150W LED fixture to deliver illumination equivalent to 300-400W metal halide systems while consuming less than half the electrical power. Advanced electronic drivers incorporate power factor correction technology achieving PF values of 0.98 or better, minimizing reactive power consumption and reducing total electrical system loading in port crane installations. The wide input voltage range capability spanning AC 80-315V and DC 80-400V without additional adapters provides exceptional installation flexibility while eliminating the ballast failures common with gas discharge lighting systems. Instant-on performance delivers full brightness immediately upon energization without warm-up delays, ensuring operators have immediate illumination when switching on crane lighting systems, particularly critical during emergency situations or unexpected power restoration scenarios.

Certification Requirements and Compliance Standards

| Certification | Standard Coverage | Marine Application Importance |

|---|---|---|

| CE | European product safety | Required for EU port operations |

| UL / DLC | North American safety & energy | US maritime facility compliance |

| RoHS | Hazardous substance restrictions | Environmental responsibility |

| ISO 9001 | Quality management systems | Manufacturing consistency |

| ATEX (optional) | Explosive atmosphere safety | Hazardous location installations |

| IP67 | Ingress protection | Water/dust resistance verification |

International Maritime Safety Standards

Crane Light Fixtures operating in port and shipyard environments must comply with comprehensive international regulations governing maritime lighting equipment, ensuring electrical safety, electromagnetic compatibility, and environmental performance meet stringent requirements. The certification portfolio including CE marking for European markets, UL listing for North American installations, and additional regional certifications like SAA for Australian applications enables global deployment while demonstrating compliance with local regulatory requirements. These comprehensive certifications represent rigorous independent testing protocols verifying electrical insulation integrity, temperature rise characteristics, photometric performance, and mechanical strength according to internationally recognized standards. Professional-grade fixtures undergo extensive validation including salt spray resistance testing, thermal cycling evaluations, vibration and shock testing, and photometric verification ensuring consistent performance across the complete operational temperature range. Additional specialized certifications such as ATEX ratings for explosive atmosphere compatibility ensure safe operation in environments where flammable vapors or combustible dust may be present, critical for certain maritime and petrochemical facility applications.

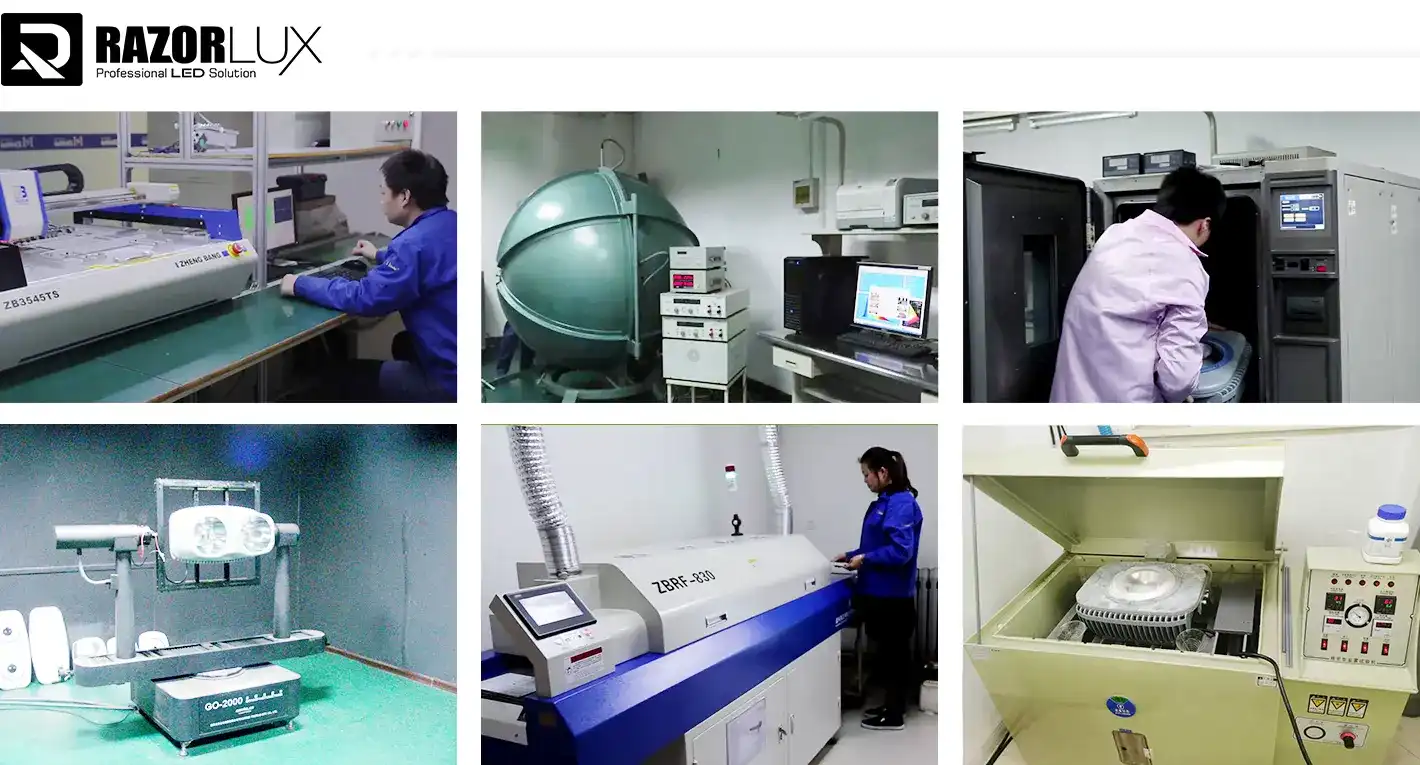

Quality Assurance and Manufacturing Excellence

Superior manufacturing processes and comprehensive quality control measures distinguish premium Crane Light Fixtures from commodity products, ensuring consistent performance and long-term reliability that justifies investment in professional-grade maritime lighting equipment. ISO 9001 certification demonstrates commitment to systematic quality management throughout the entire production process, from component procurement through final product testing and shipping preparation. Advanced manufacturers maintain comprehensive testing protocols including photometric measurement using integrating sphere equipment, electrical performance verification, thermal imaging analysis, and extended burn-in testing that identifies potential early failures before products reach customer installations. The quality assurance extends to careful selection of premium components including high-efficiency LED chips from Tier 1 manufacturers, professional-grade electronic drivers from established suppliers like Meanwell, and marine-grade fasteners and sealing materials sourced from specialty suppliers. Comprehensive documentation including detailed technical drawings, installation instructions, and maintenance guidelines supports professional installation and long-term serviceability of Crane Light Fixtures in demanding maritime applications.

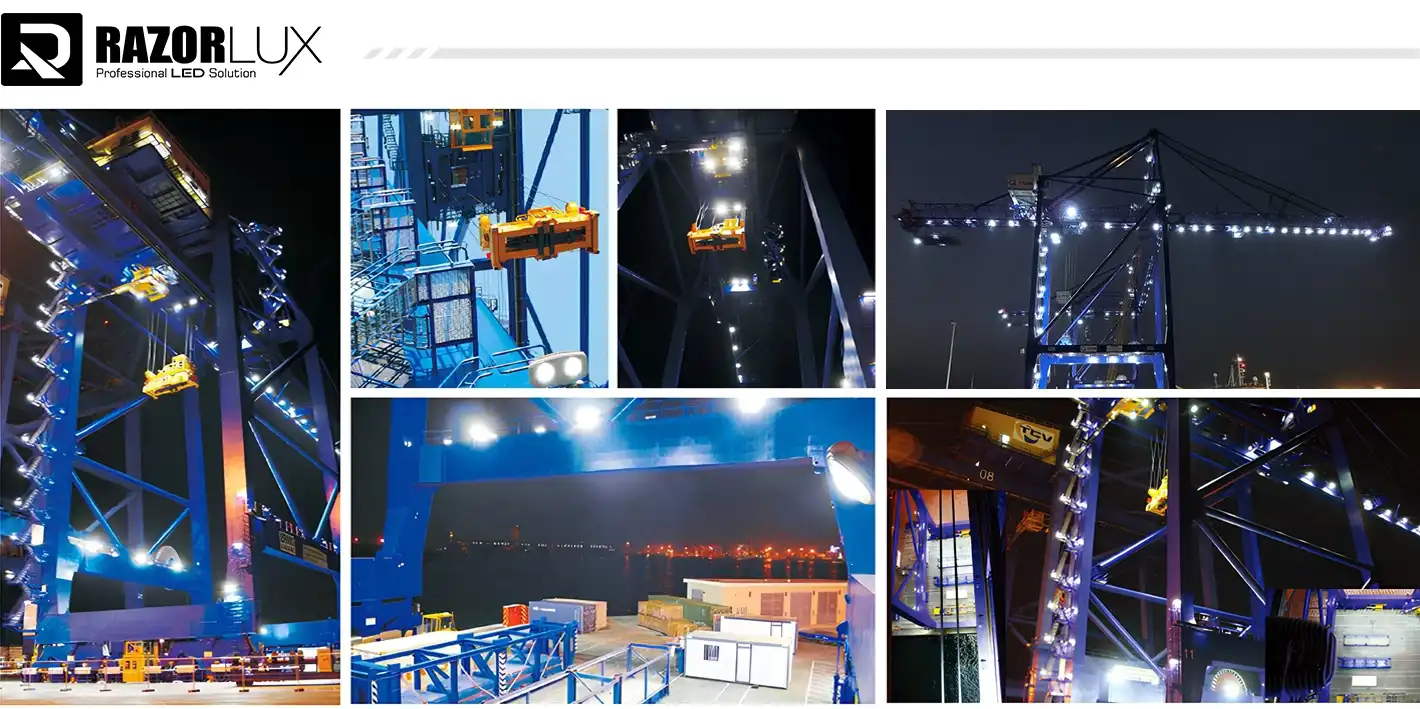

Real-World Application Performance

The true measure of marine-grade Crane Light Fixture quality emerges through extended operational experience in actual port, shipyard, and offshore platform installations where equipment faces relentless environmental challenges. Professional-grade fixtures demonstrate exceptional reliability with documented installations maintaining full operational performance throughout 5-year warranty periods and beyond, delivering the consistent illumination quality that maritime operations require for safe and efficient crane operations. The superior construction quality and component selection enables these fixtures to withstand direct exposure to tropical storms, freeze-thaw cycling in northern climates, and continuous operation in high-temperature desert port environments without premature failure or performance degradation. Customer feedback consistently highlights the dramatic reduction in maintenance requirements compared to legacy lighting systems, with installations reporting zero failures throughout extended operational periods where conventional fixtures required multiple replacements. The operational cost savings from reduced energy consumption, eliminated lamp replacement expenses, and minimized maintenance interventions typically achieve complete payback of the initial investment within 2-3 years, with subsequent years delivering pure cost savings while maintaining superior illumination quality for crane operators and ground personnel.

Technical Advantages of Razorlux Marine Crane Light Fixtures

Patented Multi-Function Design Innovation

The RGL-150P model from Xi'an Razorlux Optoelectronic Technology represents the culmination of over two decades of specialized development in demanding industrial and marine lighting applications. This Crane Light Fixture incorporates patented multi-function design elements that enable adaptability across diverse working conditions while maintaining exceptional performance specifications. The 150W rated power configuration delivers 13,200 lumens of stable output after thermal stabilization, effectively replacing 300-400W HID lamps while consuming less than half the electrical power. The precise 20-degree beam angle provides focused illumination ideal for high-mounting applications on ship-to-shore cranes, rubber-tired gantry cranes, and other port equipment where concentrated light distribution maximizes coverage at working surfaces. Advanced driver technology accommodates both AC (80-315Vac) and DC (80-400Vdc) input power without additional conversion equipment, simplifying installation while providing exceptional flexibility for diverse maritime electrical systems including vessel-mounted cranes with DC power distribution.

Premium Component Integration

Every element of professional Crane Light Fixtures receives careful engineering attention to ensure comprehensive system reliability meeting the demanding requirements of maritime applications. The aluminum housing features precision die-casting with powder coating protective finish, providing corrosion resistance while maintaining optimal thermal dissipation properties through integrated cooling fin geometry. Meanwell power supplies represent industry-leading electronic driver technology with proven reliability in harsh industrial environments, delivering stable current regulation, power factor correction, and comprehensive protection features including over-temperature shutdown and surge suppression. High-output LED modules utilize premium diodes selected for long-term lumen maintenance, maintaining 80% of initial output beyond 50,000 hours of continuous operation while delivering excellent color rendering with Ra≥75 standard specification (Ra≥80 and Ra≥90 available for applications requiring enhanced color discrimination). The tempered glass lens provides optical clarity while withstanding impact loading up to IK10 rating, ensuring continued operation even when subjected to mechanical shock or impact from handling equipment common in busy port environments.

Comprehensive Warranty Protection

Xi'an Razorlux demonstrates exceptional confidence in Crane Light Fixture quality by offering industry-leading warranty coverage spanning LED modules (5 years), electronic drivers (5 years), and housing components (10 years). This comprehensive protection significantly exceeds standard industry warranty terms, providing customers with long-term investment security and demonstrating the manufacturer's commitment to product quality and customer satisfaction. The extensive warranty coverage reflects the superior component selection, rigorous manufacturing quality control, and comprehensive testing protocols that ensure consistent reliability throughout extended operational service. Professional technical support accompanies warranty coverage, with responsive assistance available for installation guidance, troubleshooting support, and any service requirements that may arise during the fixture's operational lifetime. The combination of exceptional product reliability and comprehensive warranty protection delivers total cost of ownership advantages that professional maritime operators increasingly recognize when specifying lighting equipment for critical crane operations.

Conclusion

Marine-Grade Crane Light Fixtures represent essential safety equipment for modern port operations, combining IP67 environmental protection, vibration resistance, and corrosion-resistant construction to deliver reliable illumination in the most challenging maritime environments. The superior performance, extended operational life, and reduced maintenance requirements of professional LED crane lighting generate substantial long-term value while enhancing operational safety and efficiency across diverse marine and industrial applications.

Ready to upgrade your maritime crane lighting to professional-grade equipment? As a leading China Crane Light Fixture manufacturer and China Crane Light Fixture supplier, Xi'an Razorlux Optoelectronic Technology delivers proven marine-grade solutions trusted by ports worldwide. Our China Crane Light Fixture factory produces premium fixtures at competitive Crane Light Fixture wholesale prices, with extensive Crane Light Fixtures for sale inventory ensuring rapid delivery. contact us today at sam@razorlux.com for detailed Crane Light Fixture price quotations, technical specifications, and customized lighting solutions engineered specifically for your maritime operations. Don't let inferior lighting compromise safety—bookmark this guide and reach out whenever you need expert assistance selecting optimal crane lighting equipment.

References

1. International Maritime Organization (IMO). "Guidelines for the Installation of Electrical Equipment in Port Facilities and Mobile Harbor Cranes." Maritime Safety Committee Documentation, 2023.

2. American National Standards Institute (ANSI). "Standard for Vibration Testing of Luminaires – ANSI C136.31." National Electrical Manufacturers Association, 2020.

3. Society of Naval Architects and Marine Engineers (SNAME). "Recommended Practice for Shipboard Lighting Systems in Corrosive Environments." Technical and Research Bulletin 4-58, 2022.

4. International Electrotechnical Commission (IEC). "Degrees of Protection Provided by Enclosures (IP Code) – IEC 60529." International Standard for Equipment Enclosures, 2021.

5. Illuminating Engineering Society (IES). "Recommended Practice for Industrial and Port Lighting Applications." IES RP-7 Industrial Lighting Committee Report, 2024.

VIEW MOREindustrial workshop led lights

VIEW MOREindustrial workshop led lights VIEW MOREcrane led head lamp

VIEW MOREcrane led head lamp VIEW MOREoutdoor sports lighting

VIEW MOREoutdoor sports lighting VIEW MOREoutdoor led tennis court lighting

VIEW MOREoutdoor led tennis court lighting VIEW MORETennis Court Led Flood Lights

VIEW MORETennis Court Led Flood Lights VIEW MORE80ra LED Outdoor Sports Lighting Football Pitches 52000lm 400W Portable Stadium

VIEW MORE80ra LED Outdoor Sports Lighting Football Pitches 52000lm 400W Portable Stadium VIEW MORE5700K Outdoor Garden Led Light Ip67 100000lm Flood Lights For Volleyball Court

VIEW MORE5700K Outdoor Garden Led Light Ip67 100000lm Flood Lights For Volleyball Court VIEW MOREBest Led Stadium Lights

VIEW MOREBest Led Stadium Lights

_1750326878398.png)