Benefits of LED Crane Light Fixture Upgrades for Warehouses

Picture this: a warehouse operator struggling with dim, flickering lights during critical loading operations while maintenance costs continue climbing from frequent bulb replacements. Traditional metal halide and halogen fixtures drain energy budgets and create safety hazards through inconsistent illumination. Upgrading to LED Crane Light Fixtures transforms warehouse operations by delivering superior visibility, dramatic energy savings, and enhanced worker safety. This comprehensive guide explores how modern LED Crane Lighting solutions revolutionize industrial facilities, reduce operational expenses, and create safer working environments for warehouse teams handling materials under overhead cranes daily.

Energy Efficiency Advantages of Modern Crane Light Fixtures

Reduced Power Consumption Through Advanced LED Technology

Modern crane light fixture installations deliver remarkable energy efficiency compared to traditional lighting systems. LED technology consumes approximately 70-80% less electricity than metal halide equivalents while producing superior illumination quality. A standard 400W metal halide crane light fixture can be replaced with a 150W LED unit that generates equivalent or better light output, resulting in substantial electricity cost reductions. The Razorlux RGL-150P crane light fixture achieves 130 lumens per watt efficiency, replacing 300-400W HID lamps while consuming only 150W total power including driver consumption. This efficiency translates directly into lower utility bills and reduced carbon footprint for warehouse operations running lighting systems continuously across multiple shifts.

Long-Term Cost Savings and ROI Calculations

Investing in LED crane light fixtures generates measurable financial returns through multiple cost-saving mechanisms. The extended lifespan of 50,000+ operating hours means LED fixtures require replacement far less frequently than traditional options, dramatically reducing maintenance labor costs and downtime. Most warehouse crane lighting retrofits achieve complete cost recovery within 12-18 months through combined energy savings and reduced maintenance expenses. Additionally, LED crane light fixtures maintain consistent light output throughout their operational life, unlike metal halide lamps that degrade significantly over time. Facilities can calculate exact payback timelines based on current electricity rates, operating hours, and fixture quantities, with comprehensive energy audits demonstrating projected savings throughout the fixture's decade-long service life.

Environmental Impact and Sustainability Benefits

LED crane light fixture upgrades contribute significantly to corporate sustainability initiatives and environmental responsibility goals. Beyond energy conservation, LED technology eliminates toxic materials like mercury found in fluorescent and metal halide systems, simplifying disposal processes and reducing environmental contamination risks. The extended operational lifespan reduces manufacturing demand and waste generation associated with frequent fixture replacements. Lower energy consumption directly decreases greenhouse gas emissions from power generation, helping warehouses meet environmental compliance requirements and corporate carbon reduction targets. Organizations pursuing LEED certification or other green building standards benefit from LED crane light fixture installations that contribute points toward sustainability ratings while demonstrating commitment to environmental stewardship through tangible operational improvements.

Enhanced Safety and Visibility With Industrial Crane Lighting

Improved Worker Safety Through Better Illumination

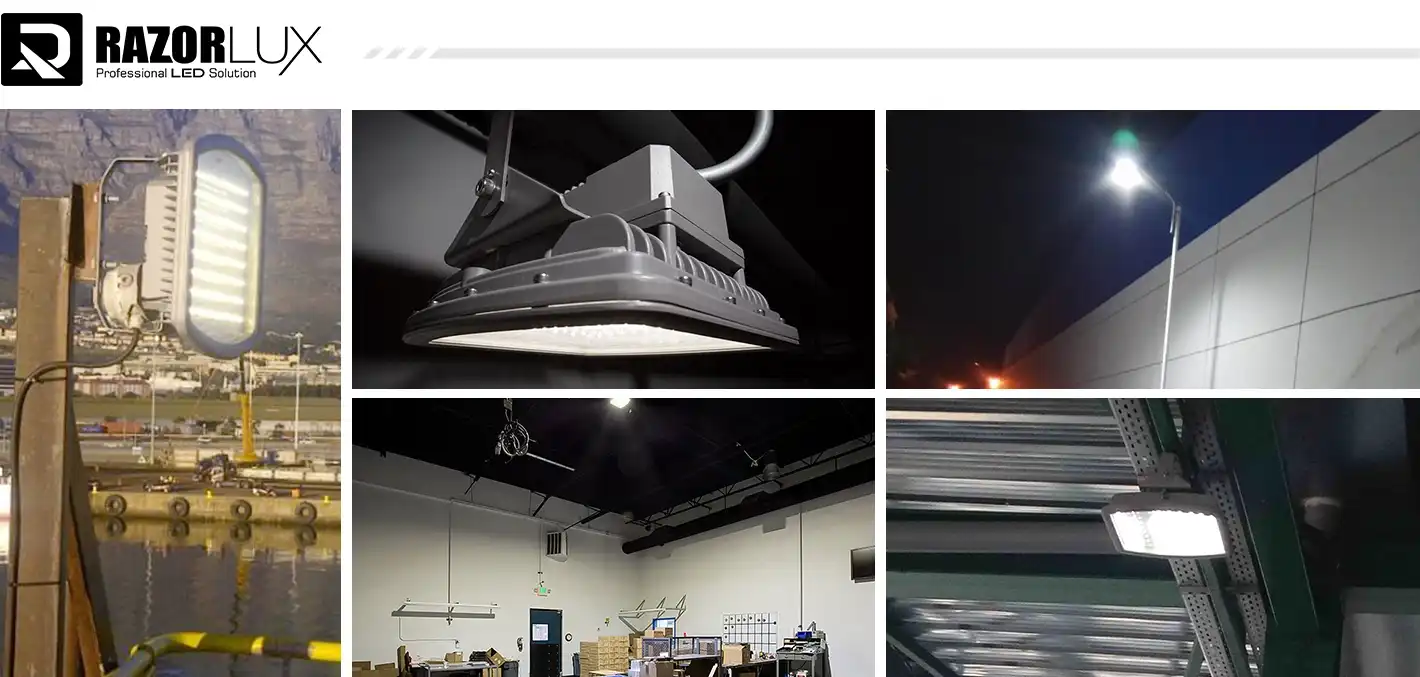

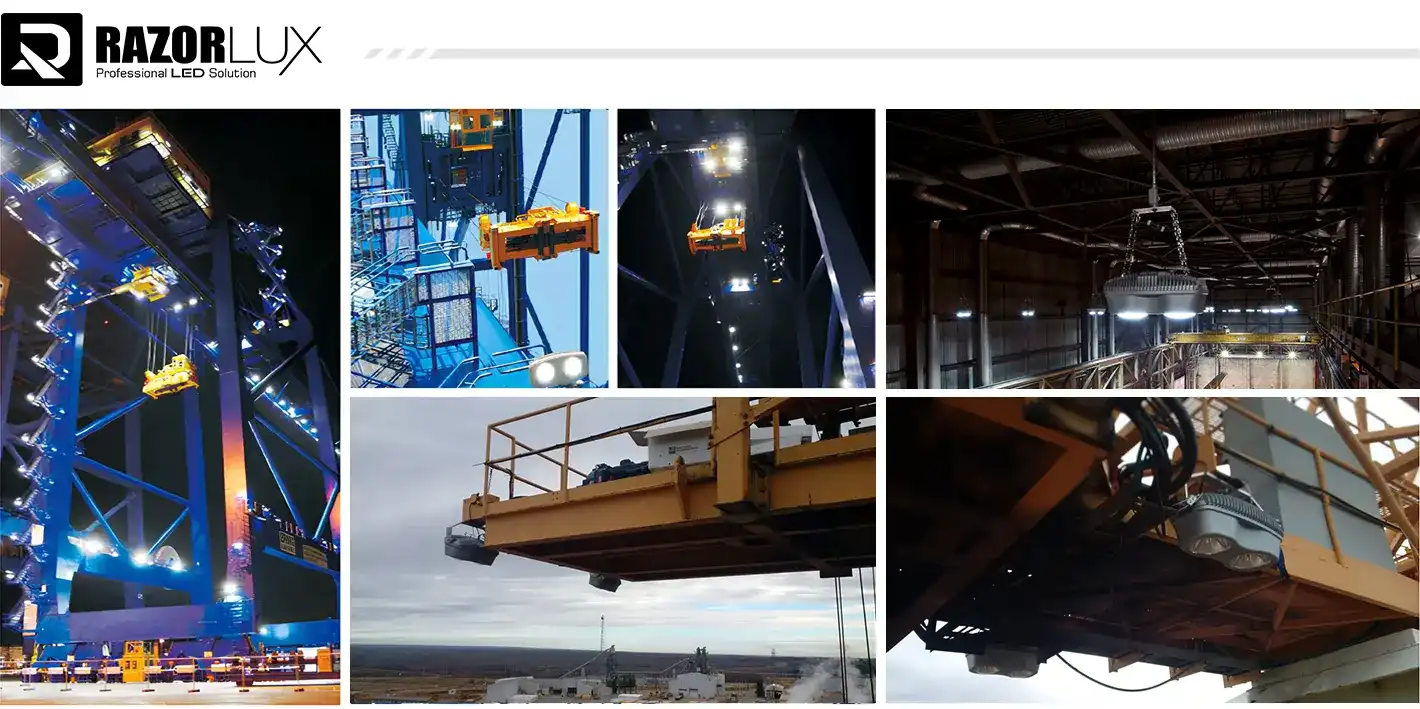

Superior illumination from LED crane light fixtures directly enhances workplace safety by eliminating dangerous shadows and providing consistent visibility throughout crane operating zones. The focused beam patterns of modern crane light fixtures ensure operators maintain clear sight lines to loads, rigging points, and ground personnel during lifting operations. Unlike traditional lighting that disperses light laterally, LED crane light fixtures direct illumination precisely where needed, reducing glare that could blind operators when looking at suspended loads. The IP67-rated construction of industrial-grade fixtures like those from Razorlux ensures reliable performance in harsh warehouse environments with dust, moisture, and temperature fluctuations. Enhanced visibility reduces accident risks, improves material handling precision, and enables workers to identify potential hazards quickly during critical crane movements throughout the facility.

Instant Operation Without Warm-Up Delays

LED crane light fixtures provide immediate full-brightness illumination without the warm-up periods required by metal halide and high-pressure sodium systems. This instant-on capability proves crucial for warehouse safety, allowing lights to operate at full intensity the moment workers activate them. Traditional fixtures often require 10-15 minutes to reach full brightness and cannot be immediately restarted after shutdown, creating visibility gaps during operations. The instant response of LED crane light fixtures supports occupancy sensor integration for additional energy savings without compromising safety when workers enter crane operating zones. This feature particularly benefits facilities with intermittent crane usage patterns, ensuring optimal illumination immediately when equipment becomes active rather than forcing operators to work with inadequate lighting during warm-up cycles that endanger personnel and materials.

Comparison of Lighting Technologies for Warehouse Cranes

| Technology | Power Draw | Lifespan | Warm-Up Time | Maintenance | Safety Features |

|---|---|---|---|---|---|

| LED Crane Light Fixture | 150W | 50,000+ hours | Instant | Minimal | High CRI, No glare, Vibration resistant |

| Metal Halide | 400W | 10,000 hours | 10-15 minutes | High | Color shift, Glare issues |

| High-Pressure Sodium | 400W | 24,000 hours | 3-5 minutes | Moderate | Poor color rendering |

| Halogen | 500W | 2,000 hours | Instant | Very High | Heat generation, Frequent failure |

Durability and Performance in Demanding Environments

Vibration Resistance for Crane Applications

Industrial crane light fixtures must withstand constant mechanical stress from crane movements, load handling, and structural vibrations that destroy conventional lighting within months. LED crane light fixtures engineered specifically for crane applications feature robust construction with shock-resistant components rated for 3G, 4G, or 5G vibration levels. The solid-state LED technology contains no fragile filaments or delicate gas-filled tubes vulnerable to vibration damage, ensuring consistent performance throughout the fixture's operational life. Razorlux crane light fixtures incorporate aluminum housing with powder coating and stainless steel mounting brackets that maintain structural integrity under continuous mechanical stress. The IK10 impact resistance rating protects against accidental collisions with loads or equipment during warehouse operations, while specialized crane mounting systems with fall protection ensure secure installation that prevents fixture displacement during crane movements.

Weather Resistance and Environmental Protection

Modern LED crane light fixtures provide comprehensive environmental protection essential for demanding warehouse conditions. IP67 ingress protection ratings ensure complete dust-tightness and protection against water immersion, allowing fixtures to operate reliably in facilities with high humidity, condensation, or occasional water exposure from cleaning operations. The wide operating temperature range of -40°C to 60°C (-40°F to 140°F) accommodates both refrigerated warehouses and high-temperature industrial environments without performance degradation. Marine-grade anti-corrosion coatings protect crane light fixtures in coastal facilities or environments with corrosive atmospheres from chemicals or salt spray. These environmental protections extend fixture lifespan dramatically compared to traditional lighting vulnerable to moisture infiltration, corrosion, and temperature-related component failures that compromise both performance and safety.

Maintenance Requirements Comparison Table

| Maintenance Factor | LED Crane Light Fixture | Traditional Metal Halide | Halogen Fixture |

|---|---|---|---|

| Replacement Frequency | Every 10+ years | Every 2-3 years | Every 6-12 months |

| Cleaning Requirements | Annual inspection | Quarterly cleaning | Monthly maintenance |

| Component Failures | Rare | Moderate | Frequent |

| Emergency Replacements | Minimal | Common | Very Common |

| Labor Hours/Year | 2-4 hours | 20-30 hours | 40-60 hours |

Advanced Control Integration Capabilities

Contemporary LED crane light fixtures support sophisticated control systems that optimize warehouse lighting operations. Universal input drivers automatically detect and adjust to facility voltage supplies ranging from AC 80-315V or DC 80-400V without additional adapters, simplifying installation across diverse electrical infrastructures. Advanced dimming capabilities including 0-10V and DALI protocols enable crane light fixtures to integrate with building management systems for centralized control and monitoring. Power factor correction exceeding 0.98 and total harmonic distortion below 10% ensure LED crane light fixtures operate efficiently without introducing electrical noise into facility power systems. Optional emergency backup power functionality allows fixtures to operate for two hours during power failures, maintaining critical illumination for safe crane operations and worker evacuation during electrical outages, a feature particularly valuable for facilities requiring uninterrupted operations.

Conclusion

Upgrading to LED crane light fixtures delivers transformative benefits for warehouse operations through superior energy efficiency, enhanced safety, and exceptional durability. These advanced lighting solutions reduce operational costs while improving visibility and worker protection in demanding industrial environments.

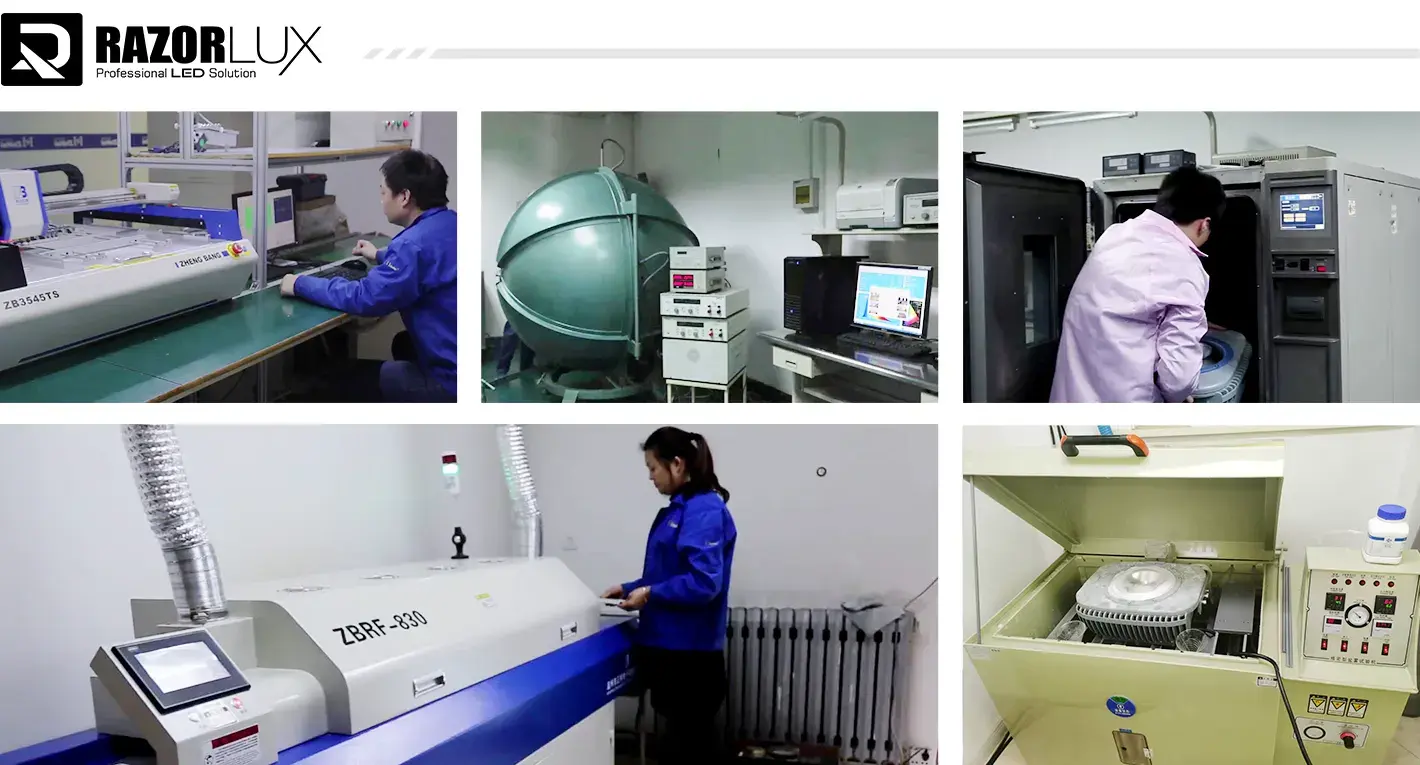

Ready to transform your warehouse lighting? As a trusted China crane light fixture manufacturer, supplier, and factory, Xi'an Razorlux Optoelectronic Technology Co., Ltd. offers competitive crane light fixture prices and wholesale options with 5-year warranties. Our crane light fixtures for sale feature patented designs, IP67 protection, and comprehensive certifications including UL, CE, and RoHS compliance. Contact our professional sales team at sam@razorlux.com for customized solutions, technical specifications, and fast delivery with complete after-sales support. Discover why leading facilities worldwide choose Razorlux for reliable, high-performance industrial lighting.

References

1. U.S. Department of Energy. "LED Lighting for Industrial Applications: Energy Savings and Performance Standards." Industrial Technologies Program, Office of Energy Efficiency and Renewable Energy.

2. Illuminating Engineering Society. "Recommended Practice for Industrial Lighting Including Overhead Cranes and Material Handling Equipment." IES RP-7-21.

3. Occupational Safety and Health Administration. "Workplace Safety Standards for Overhead Crane Operations and Lighting Requirements." OSHA Technical Manual Section V.

4. International Association of Lighting Designers. "Energy Efficiency and Safety Optimization in Warehouse and Distribution Center Lighting." IALD Research Report.

5. National Electrical Manufacturers Association. "LED Systems Reliability for Industrial Environments: Performance Testing and Certification Standards." NEMA Publication.

_1750326878398.png)