OEM Crane Light Fixture Solutions: Custom, Durable, Compliant

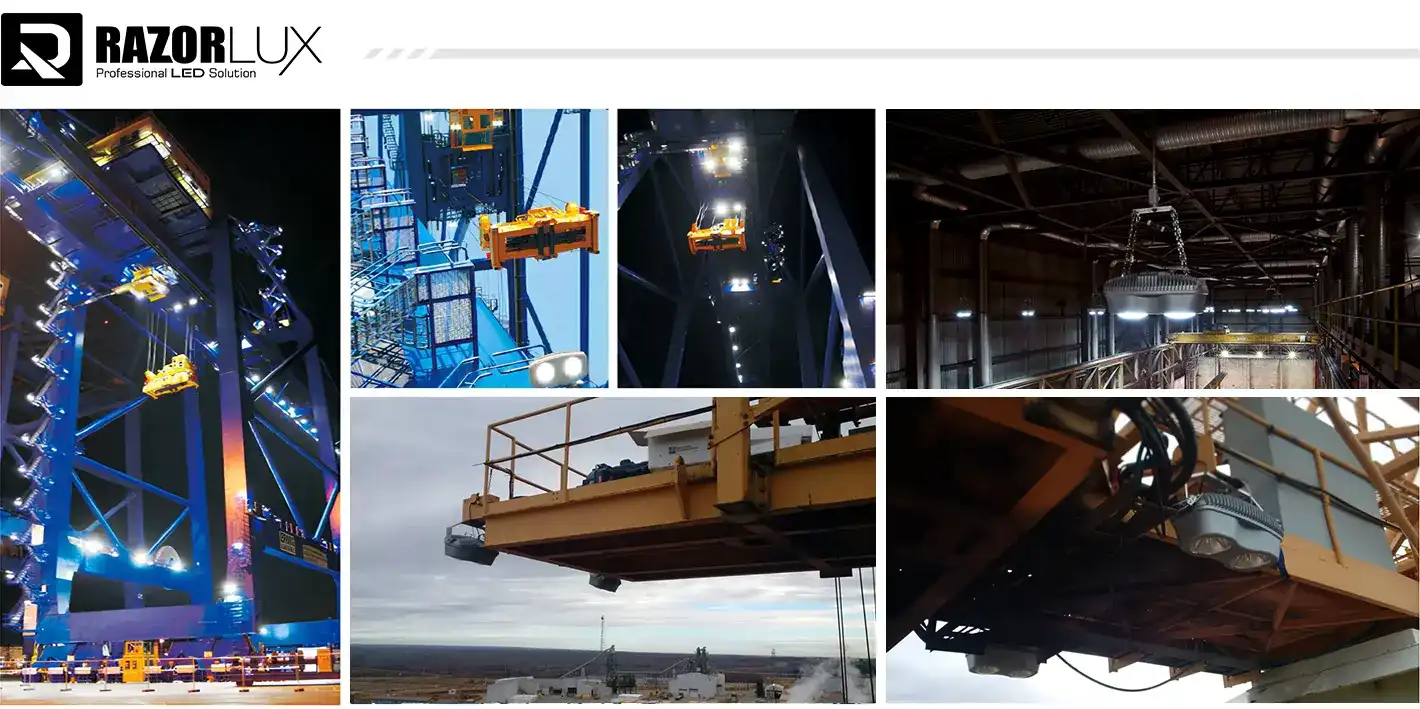

Industrial operations face constant challenges with inadequate lighting that threatens worker safety and productivity. When crane operators struggle with poor visibility in critical work zones, accidents increase and operational efficiency plummets. OEM Crane Light Fixture solutions from Xi'an Razorlux Optoelectronic Technology Co., Ltd. address these pain points directly by delivering customized, durable, and compliant lighting systems engineered specifically for demanding industrial environments. With over 200 patents and 25 years of manufacturing excellence, Razorlux provides high-performance Crane Light Fixture solutions that combine exceptional illumination quality with robust construction designed to withstand the harshest operating conditions while meeting international safety standards.

Why Custom OEM Crane Light Fixtures Are Essential for Industrial Operations?

Understanding the Unique Demands of Industrial Crane Lighting Applications

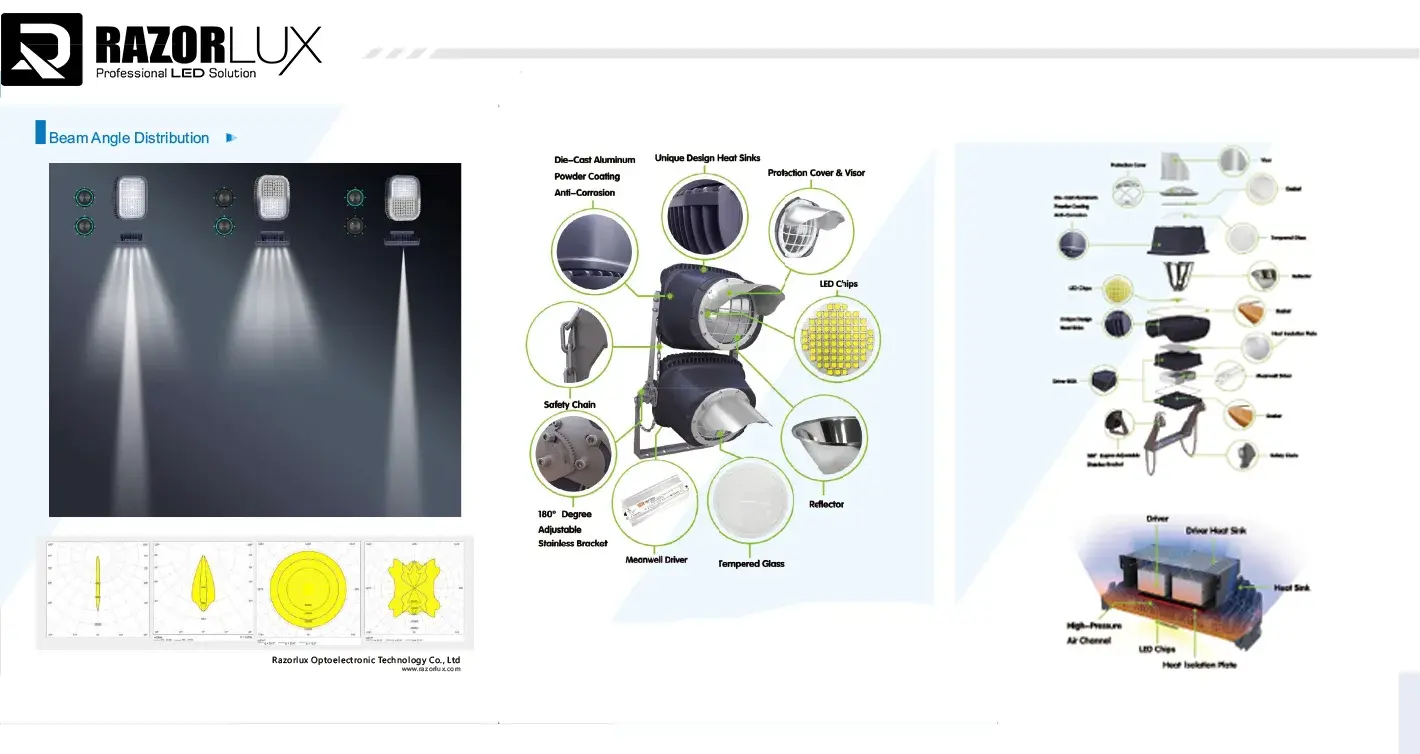

Industrial crane operations present extraordinary lighting challenges that standard fixtures simply cannot address effectively. Crane Light Fixture systems must deliver consistent, powerful illumination across expansive work areas while mounted on equipment subjected to continuous vibration, temperature fluctuations, and potential exposure to moisture, dust, and corrosive elements. The operational environment demands lighting solutions that maintain optimal performance despite being positioned at significant heights, often exceeding forty to one hundred feet above ground level. Razorlux's patented multi-function design addresses these challenges through advanced thermal management systems, vibration-resistant construction using aerospace-grade aluminum alloys, and IP67-rated enclosures that provide complete protection against dust ingress and water immersion. Our Crane Light Fixture products incorporate Meanwell power supplies with universal input capabilities ranging from AC 80-315V and DC 80-400V, ensuring stable operation even during voltage fluctuations common in heavy industrial settings. The 130 lumens per watt efficiency rating delivers superior brightness while minimizing energy consumption, with beam angle options from focused twenty degrees to wide coverage patterns allowing precise light distribution based on specific crane height and coverage requirements.

Customization Capabilities That Meet Specific Application Requirements

Every industrial facility operates under unique conditions requiring tailored lighting solutions rather than one-size-fits-all products. Razorlux's OEM and ODM services enable comprehensive customization of Crane Light Fixture specifications including wattage selection from 100W to 400W, color temperature adjustment between 2700K and 6500K to match operational preferences, housing material modifications for enhanced corrosion resistance in marine environments, and integration of advanced control systems such as 0-10V dimming and DALI protocols. Our engineering team collaborates directly with clients to develop custom mounting brackets fabricated from marine-grade stainless steel that accommodate various crane structures including overhead gantry systems, tower cranes, and mobile harbor cranes. The customization process extends to optical performance with adjustable beam angles and specialized lens configurations that eliminate dangerous shadow zones while providing uniform illumination across critical work areas. With dedicated R&D capabilities supported by over two decades of field experience, Razorlux delivers Crane Light Fixture solutions optimized for specific applications including shipyard operations, steel manufacturing facilities, container terminals, mining operations, and heavy construction sites where lighting performance directly impacts both safety outcomes and operational productivity.

Compliance Standards and Certification Requirements for Global Markets

International regulatory compliance represents a critical consideration when specifying Crane Light Fixture systems for industrial applications. Razorlux maintains comprehensive certification portfolios including UL listing for North American markets, CE marking for European Union conformity, SAA approval for Australian and New Zealand installations, TUV certification for international safety standards, RMRS approval for marine applications, and RoHS compliance ensuring restriction of hazardous substances. These certifications validate that our Crane Light Fixture products meet stringent safety requirements regarding electrical safety, electromagnetic compatibility, environmental impact, and operational reliability. Beyond basic safety certifications, Razorlux fixtures comply with industry-specific standards such as OSHA illumination requirements for crane work zones typically mandating thirty to fifty foot-candles at ground level in manufacturing facilities, IEC standards for ingress protection ratings, and IK10 impact resistance classification ensuring fixtures withstand mechanical impact from tools or equipment. Our ISO 9001 certified manufacturing processes guarantee consistent quality control throughout production with comprehensive testing protocols including photometric verification using integrating sphere equipment, extended aging tests simulating years of operational conditions, and vibration testing exceeding 3G standards to ensure reliability in harsh industrial environments where equipment failure could compromise worker safety or cause costly operational downtime.

Technical Specifications and Performance Features of Professional Crane Light Fixtures

| Feature Category | Specification Details | Performance Benefits |

|---|---|---|

| Power Systems | AC 80-315V / DC 80-400V Input | Universal compatibility eliminates need for additional transformers |

| Optical Performance | 130 LM/W with 13,200 lumen output | Superior brightness with exceptional energy efficiency |

| Environmental Protection | IP67 rated with IK10 impact resistance | Complete dust and water protection for harsh conditions |

| Thermal Management | Advanced aluminum heat sink design | Maintains optimal LED junction temperature for 50,000+ hour lifespan |

| Control Options | 0-10V dimming, DALI integration available | Flexible lighting control for varying operational needs |

| Warranty Coverage | 5-year comprehensive warranty on LED modules and drivers | Long-term reliability assurance and investment protection |

Advanced LED Technology and Optical Engineering in Modern Crane Fixtures

The technological foundation of Razorlux Crane Light Fixture systems centers on advanced LED Packaging technology protected by proprietary patents covering chip-on-board configurations, thermal interface materials, and precision optical systems. Our fixtures utilize high-efficacy LED arrays achieving 130 lumens per watt efficiency while maintaining color rendering index values exceeding Ra75, with Ra80 and Ra90 options available for applications requiring superior color discrimination such as quality inspection zones or precision assembly operations. The optical engineering incorporates precision-molded polycarbonate lenses or tempered glass optics depending on application requirements, with computer-optimized reflector geometries that maximize light extraction efficiency while controlling beam distribution patterns. Twenty-degree narrow beam configurations concentrate intense illumination for high-mounting applications where fixtures may be positioned fifty to one hundred feet above work surfaces, while wider sixty to one hundred twenty degree flood patterns provide expansive coverage for general area lighting in warehouses and distribution centers. The Crane Light Fixture thermal management system employs die-cast aluminum heat sinks with optimized fin geometry facilitating passive convective cooling that eliminates mechanical fan requirements and associated maintenance concerns, ensuring LED junction temperatures remain within optimal operating ranges even during continuous operation in ambient temperatures reaching sixty degrees Celsius.

Durability Features Ensuring Long-Term Reliability in Harsh Environments

Industrial crane environments subject lighting equipment to extraordinary mechanical and environmental stresses requiring exceptional durability engineering. Razorlux Crane Light Fixture construction begins with precision die-cast aluminum alloy housings providing superior strength-to-weight ratios compared to stamped steel alternatives, with powder-coated finishes offering enhanced corrosion resistance essential for marine applications or facilities with corrosive atmospheric conditions. The IP67 ingress protection rating ensures complete dust-tight sealing preventing particulate contamination of internal components while providing protection against temporary water immersion up to one meter depth for thirty minutes, critical for outdoor installations or facilities with regular washdown procedures. Vibration resistance represents a paramount concern for crane-mounted fixtures, addressed through reinforced mounting points, shock-absorbing gasket materials, and LED driver mounting systems that isolate sensitive electronic components from mechanical stress. Safety cable attachment points provide secondary retention preventing fixtures from falling if primary mounting hardware fails. The marine-grade stainless steel mounting brackets resist corrosion in saltwater environments while accommodating various crane structural configurations. Extended temperature range capabilities from negative forty degrees Celsius to positive sixty degrees Celsius ensure reliable operation across diverse geographic locations and seasonal variations, with specialized conformal coating protecting electronic assemblies from moisture condensation in high-humidity environments.

Energy Efficiency and Operational Cost Advantages Over Traditional Lighting

The transition from legacy metal halide or high-pressure sodium Crane Light Fixture systems to LED technology delivers substantial operational cost reductions beyond simple energy savings. A typical 150W LED fixture replaces 300-400W metal halide units while providing equivalent or superior illumination levels, reducing electrical consumption by sixty to seventy percent. In facilities operating cranes twenty-four hours daily, this efficiency translates to significant utility cost reductions with typical payback periods of eighteen to thirty-six months depending on local electricity rates. Beyond direct energy savings, LED Crane Light Fixture systems eliminate the frequent relamping cycles required by traditional discharge lamps that typically fail after six to twelve months in vibration-intensive crane applications. The extended fifty thousand hour LED operational life spans five to ten years under continuous operation, dramatically reducing maintenance labor costs and eliminating crane downtime associated with lighting replacement. The instant-on capability of LED technology provides immediate full brightness without the several-minute warm-up period required by metal halide systems, improving operational readiness when cranes are activated. Power factor correction exceeding 0.98 and total harmonic distortion below ten percent minimize electrical distribution system losses while reducing utility demand charges. The emergency power function available as a custom option enables two hours of continued operation during power outages, maintaining critical safety lighting and allowing safe completion of in-progress lifting operations.

Comprehensive OEM Services and Manufacturing Capabilities

Complete Product Development from Concept Through Production

Razorlux's comprehensive OEM services transform customer specifications into production-ready Crane Light Fixture products through structured development processes beginning with detailed application analysis and lighting design. Our engineering team conducts thorough consultations to understand specific operational requirements including crane types and configurations, mounting height parameters, coverage area dimensions, environmental conditions, electrical infrastructure characteristics, and any special regulatory requirements applicable to the facility or industry sector. This information feeds computer-aided photometric modeling generating detailed lighting plans that predict illumination levels, uniformity ratios, and potential shadow zones before physical prototyping begins. The custom sampling and prototyping phase produces functional units for client evaluation under actual operating conditions, allowing performance verification and design refinement prior to committing to full production tooling investments. Technical documentation packages include detailed mechanical drawings with complete dimensional specifications, electrical schematics, installation instructions with mounting templates, and comprehensive specification sheets suitable for incorporation into facility design documentation or bid packages. Throughout development, Razorlux maintains transparent communication regarding production timelines, tooling requirements, and cost structures ensuring clients maintain complete project visibility and control.

Quality Control Processes Ensuring Consistent Manufacturing Excellence

Manufacturing excellence at Razorlux's ISO 9001 certified facilities ensures every Crane Light Fixture meets rigorous quality standards through comprehensive testing protocols at multiple production stages. Incoming material inspection verifies LED chip bin consistency, driver component specifications, housing casting integrity, and optical component clarity before materials enter production. Assembly operations follow documented work instructions with in-process inspection checkpoints validating proper component installation, fastener torque specifications, and seal integrity. Every completed fixture undergoes photometric testing in calibrated integrating sphere equipment measuring total luminous flux output, color temperature consistency, and beam angle distribution verifying conformance to specification targets with documented test reports. Electrical safety testing validates insulation resistance, ground continuity, power factor, and surge protection operation. Extended burn-in aging tests operate fixtures at elevated temperatures for extended periods revealing infant mortality failures and validating thermal management effectiveness before shipment. Vibration testing simulates years of crane operation ensuring mechanical integrity and LED driver resilience. Environmental chamber testing validates performance across specified temperature and humidity ranges. This comprehensive quality control approach combined with traceability systems tracking component lots through finished goods ensures Razorlux Crane Light Fixture products deliver consistent performance and reliability throughout extended service lives.

| Manufacturing Phase | Quality Control Activities | Performance Verification |

|---|---|---|

| Material Receiving | LED bin sorting, component testing, housing inspection | Ensures premium component quality and consistency |

| Assembly Operations | Work instruction compliance, torque verification, seal integrity | Maintains manufacturing consistency and reliability |

| Electrical Testing | Safety compliance, power quality, surge protection | Validates electrical safety and performance standards |

| Photometric Verification | Integrating sphere measurement, beam angle analysis | Confirms optical performance meets specifications |

| Environmental Testing | Temperature cycling, humidity exposure, vibration simulation | Ensures reliability across operational conditions |

| Final Inspection | Visual examination, documentation review, packaging verification | Validates complete product quality before shipment |

Flexible Production Capabilities Supporting Various Order Volumes

Razorlux's manufacturing infrastructure accommodates diverse production requirements from small prototype runs through high-volume production campaigns. Small batch capabilities support initial market testing or specialized applications requiring limited quantities, with flexible production scheduling minimizing lead times for urgent projects. Medium volume orders benefit from established production processes delivering consistent quality while maintaining cost efficiency through optimized material procurement and production planning. Large volume contracts leverage Razorlux's significant manufacturing capacity with dedicated production lines ensuring schedule reliability and volume pricing advantages. The vertically integrated manufacturing model controlling LED packaging, driver assembly, housing fabrication, and final assembly operations provides supply chain security and quality control throughout production. Strategic raw material inventory management ensures availability of critical components minimizing lead time extensions from supply disruptions. Production planning systems coordinate manufacturing activities with global logistics networks providing streamlined delivery to project sites worldwide through air freight for expedited requirements, China-Europe railway express for balanced speed and economy to European destinations, or ocean freight providing maximum cost efficiency for non-urgent bulk shipments with comprehensive packaging protecting products during extended transit.

Strategic Partnership Benefits and Customer Support Services

Pre-Sales Engineering Support and Application Consulting

Razorlux's technical sales team provides comprehensive pre-sales engineering support helping customers navigate Crane Light Fixture selection and application design considerations. Initial consultations assess operational requirements, environmental conditions, regulatory compliance needs, and budget parameters establishing project feasibility and identifying optimal product configurations. Photometric analysis services utilize industry-standard lighting design software generating detailed illumination predictions showing expected light levels, uniformity patterns, and coverage areas based on proposed fixture locations and specifications. This analytical approach eliminates guesswork from lighting system design while providing documentation supporting facility planning approvals or regulatory submissions. Our engineers provide guidance on electrical infrastructure requirements including circuit loading calculations, dimming control integration options, and emergency power system compatibility. Mounting hardware recommendations consider structural loading limits, vibration isolation requirements, and maintenance accessibility ensuring installations meet safety standards while facilitating future servicing. The pre-sales support extends to competitive analysis comparing Razorlux Crane Light Fixture specifications against alternative products, providing objective performance and value assessments supporting informed procurement decisions. Technical documentation packages assembled during pre-sales support streamline project implementation by providing contractors and facility engineers complete specification and installation information.

Comprehensive After-Sales Support and Technical Assistance

Customer satisfaction extends beyond initial product delivery through Razorlux's comprehensive after-sales support services ensuring successful installation commissioning and long-term operational satisfaction. Technical support specialists remain available addressing installation questions, troubleshooting operational issues, and providing application guidance throughout product service life. The five-year comprehensive warranty covers LED modules, electronic drivers, and fixture housing against manufacturing defects providing long-term investment protection and performance assurance. Warranty administration processes expedite claims resolution with rapid replacement part shipment minimizing operational disruption from unexpected failures. Field service support coordinates with local partners providing on-site technical assistance for complex installations or troubleshooting activities requiring physical inspection. Spare parts availability ensures maintenance teams access replacement drivers, optical components, or mounting hardware supporting proactive maintenance programs extending equipment service life. Technical training programs educate facility maintenance personnel on proper fixture installation, routine maintenance procedures, and basic troubleshooting methodologies empowering customers to maintain lighting system performance independently. Customer feedback systems continuously capture operational experiences and improvement suggestions feeding product development activities ensuring future Crane Light Fixture generations address evolving market requirements and incorporate lessons learned from field applications.

Global Logistics Network and Reliable Delivery Solutions

Razorlux's established logistics partnerships ensure reliable product delivery to customers worldwide regardless of project location or timeline requirements. International express services through established carriers including DHL, FedEx, and UPS provide three to seven day delivery for urgent requirements or sample shipments, with optimized weight brackets maximizing cost efficiency under contracted shipping rates. Air freight services offer five to ten day delivery windows for medium-weight shipments where express costs become prohibitive but rapid delivery remains important, utilizing both airport-to-port and airport-to-door service options depending on destination infrastructure and customer preferences. China-Europe railway express provides eighteen to twenty-two day transit for European destinations offering significant cost advantages compared to air freight while maintaining schedule reliability superior to ocean transportation, ideal for projects with moderate timeline flexibility. Ocean freight via full container load or less-than-container load consolidation delivers maximum cost efficiency for bulk shipments or projects without urgent timeline pressures, with fifteen to fifty day transit windows depending on destination port and routing. Comprehensive packaging protocols protect Crane Light Fixture products throughout international transit using custom-cut foam bases providing secure cushioning, dedicated accessory compartments organizing mounting hardware and documentation, reinforced cartons with strapping providing structural integrity, and optional wooden crate solutions for shipments requiring additional protection during handling or extended storage.

Conclusion

OEM Crane Light Fixture solutions from Razorlux represent the optimal convergence of customization capabilities, engineering excellence, and manufacturing quality delivering lighting systems precisely matched to demanding industrial applications. Through comprehensive services spanning pre-sales consultation and custom prototyping through flexible production capabilities and dedicated after-sales support, Razorlux empowers customers to specify and implement lighting solutions optimized for their unique operational requirements while maintaining full compliance with international safety standards and regulatory frameworks.

Ready to illuminate your industrial operations with superior crane lighting solutions? Whether you're a China Crane Light Fixture manufacturer seeking OEM partnerships, a China Crane Light Fixture supplier expanding product portfolios, or a facility manager evaluating China Crane Light Fixture wholesale options, Razorlux delivers the customization capabilities, technical expertise, and manufacturing excellence your projects demand. Our comprehensive product lines offer competitive Crane Light Fixture price points without compromising quality or performance, with extensive Crane Light Fixture for sale inventory supporting immediate project requirements. As a leading China Crane Light Fixture factory with global reach and proven reliability, we invite you to experience the Razorlux difference. Contact our technical sales team today at sam@razorlux.com to discuss your specific application requirements, request customized samples for evaluation, or receive detailed quotations for your upcoming projects. Save this resource for future reference and reach out whenever lighting challenges arise in your industrial operations.

References

1. International Electrotechnical Commission (IEC). "Ingress Protection Rating Standards for Industrial Lighting Equipment." IEC Standard 60529.

2. Occupational Safety and Health Administration (OSHA). "Overhead and Gantry Cranes: Safety Standards for Material Handling Equipment." OSHA Standard 1910.179.

3. Illuminating Engineering Society (IES). "Recommended Practice for Industrial Lighting Design." IES RP-7-21.

4. American National Standards Institute (ANSI). "LED Light Fixtures for Hazardous Industrial Locations." ANSI/UL 844 Standard.

5. International Organization for Standardization (ISO). "Quality Management Systems Requirements for Manufacturing Organizations." ISO 9001:2015.

VIEW MOREled tennis court lights

VIEW MOREled tennis court lights VIEW MOREmarine led flood light

VIEW MOREmarine led flood light VIEW MORE1000 Watt Led Stadium Light

VIEW MORE1000 Watt Led Stadium Light VIEW MOREPortable 400w 347V Led Crane Light Badminton Court Cool White

VIEW MOREPortable 400w 347V Led Crane Light Badminton Court Cool White VIEW MORERoHS Waterproof Garden Led Light 48000lm Solar Powered Security Lights

VIEW MORERoHS Waterproof Garden Led Light 48000lm Solar Powered Security Lights VIEW MORECricket Stadium Led Lights

VIEW MORECricket Stadium Led Lights VIEW MORE1000 Watt Stadium Light

VIEW MORE1000 Watt Stadium Light VIEW MOREMost Powerful Flood Light

VIEW MOREMost Powerful Flood Light

_1750326878398.png)