Mine Site Lighting Benefits: Boost Productivity and Visibility

Picture this: Your mining crew navigates treacherous underground tunnels in dim light, struggling to identify hazards as equipment operators strain to see critical grade markers. Every shadow could hide loose rocks, every poorly lit area risks costly accidents. The mining industry loses millions annually to incidents caused by inadequate visibility. Mine Site Lighting is not just about illumination—it transforms how safely and efficiently your operation performs. This comprehensive guide reveals how advanced LED lighting solutions eliminate these pain points while dramatically boosting productivity, reducing operational costs, and creating safer working environments for your team.

Enhanced Safety Through Superior Mine Site Lighting Systems

Accident Prevention and Hazard Detection with Mine Site Lighting

Mine Site Lighting serves as the first line of defense against workplace accidents in demanding extraction environments. When operations transition from traditional lighting systems to advanced LED solutions, visibility improvements reach transformational levels. Proper illumination eliminates dangerous dark spots where uneven terrain, loose debris, or equipment hazards can hide undetected. Research demonstrates that optimized lighting reduces slip, trip, and fall incidents—which account for approximately 22% of all non-fatal mining injuries—by creating consistent visibility across entire work zones. Modern Mine Site Lighting with high Color Rendering Index values enables workers to accurately identify pipe leaks, dust accumulation, and structural concerns that might otherwise go unnoticed in poor lighting conditions. The impact extends beyond surface-level safety: enhanced visibility allows operators to spot geological instabilities early, preventing catastrophic collapses and equipment damage that could endanger entire crews while halting production.

Operator Visibility and Equipment Collision Reduction

Mobile mining equipment operates in high-traffic environments where collision risks multiply during low-visibility periods. Mine Site Lighting systems engineered specifically for heavy machinery deliver targeted illumination that transforms operator awareness and response capabilities. Task-specific LED fixtures mounted on haul trucks, excavators, and dozers provide focused beam patterns that illuminate danger zones without creating blinding glare for nearby workers or equipment operators. Studies show properly implemented Mine Site Lighting improves operator reaction times by over 112% compared to conventional lighting systems, directly translating to fewer near-miss incidents and equipment collisions. Advanced anti-glare optics in modern mining lights allow operators to aim illumination low enough to avoid blinding smaller vehicle operators while maintaining superior visibility of the work area ahead. Peripheral lighting coverage eliminates blind spots that traditional lighting leaves vulnerable, ensuring operators maintain complete situational awareness when maneuvering multi-million-dollar equipment through confined spaces or navigating busy haul roads during shift changes.

Worker Health and Fatigue Reduction Benefits

The physiological impact of Mine Site Lighting extends far beyond immediate safety concerns, directly affecting miner health and long-term operational performance. Inadequate lighting forces workers to strain their eyes continuously, leading to chronic headaches, blurred vision, and debilitating fatigue that compounds throughout extended shifts. Quality Mine Site Lighting with natural daylight-like color temperatures reduces eye strain significantly, enabling workers to maintain focus and alertness during critical tasks. Proper illumination also supports circadian rhythm regulation—crucial for mining personnel working irregular shifts or overnight rotations. Well-rested miners demonstrate measurably higher alertness levels, make fewer errors, and maintain better decision-making capabilities during emergencies. Mining operations that invest in comprehensive Mine Site Lighting solutions report improved worker morale and reduced absenteeism, as comfortable visual environments combat feelings of isolation and claustrophobia particularly prevalent in underground operations. The connection between lighting quality and mental health cannot be overstated: bright, consistent illumination creates positive work environments that directly support employee retention and job satisfaction.

Productivity Gains from Optimized Mine Site Lighting Solutions

Operational Efficiency and Task Accuracy Improvements

Mine Site Lighting directly correlates with operational throughput and precision across extraction and processing activities. When workers operate in optimally illuminated environments, their ability to perform complex tasks with accuracy increases dramatically, reducing costly errors that delay production schedules. Clear visibility enables geological assessment teams to identify mineral deposits with greater precision, minimizing waste extraction and maximizing valuable resource recovery. Equipment operators working under superior Mine Site Lighting conditions can read grade markers accurately, maintain proper excavation depths, and execute loading procedures with minimal spillage—each improvement contributing measurably to daily output targets. Case studies from Australian iron ore operations demonstrate that upgrading to high-output Led Mine Site Lighting correlates with productivity increases exceeding 25% during night shifts alone. The improvement stems from workers' enhanced ability to assess their work environment accurately, communicate effectively with team members, and execute procedures confidently without constant second-guessing caused by poor visibility conditions.

Extended Operating Hours and Continuous Operations Support

Modern mining economics demand maximum equipment utilization through around-the-clock operations, making reliable Mine Site Lighting absolutely essential for maintaining production continuity. Advanced LED lighting systems enable mining companies to extend productive hours beyond daylight limitations without compromising safety or efficiency standards. Unlike traditional lighting technologies that suffer from frequent burnouts and inconsistent output degradation, modern Mine Site Lighting delivers stable, long-lasting illumination that supports uninterrupted 24/7 operations across multiple shift rotations. The ability to maintain daylight-equivalent visibility during nighttime hours eliminates productivity disparities between day and night crews, ensuring consistent extraction rates regardless of natural lighting conditions. Mine Site Lighting systems designed for continuous duty applications feature thermal management technologies that prevent performance degradation even during extended operation periods, maintaining optimal lumen output throughout entire shifts. Operations in remote locations particularly benefit from reliable lighting that minimizes dependence on maintenance crews traveling long distances to replace failed units—every hour of lighting downtime potentially costing operations tens of thousands in lost productivity.

Reduced Downtime Through Reliable Lighting Infrastructure

Equipment downtime represents one of the mining industry's most significant profit drains, with average costs reaching $50,000 per hour for major machinery sitting idle. Mine Site Lighting plays a crucial yet often overlooked role in minimizing these costly interruptions. LED lighting systems with service lives exceeding 50,000 hours dramatically reduce maintenance frequency compared to traditional technologies that require replacement every few thousand hours. This longevity means fewer lighting-related work stoppages, allowing crews to maintain focus on core extraction activities rather than constantly addressing lighting failures. Modern Mine Site Lighting features rugged construction with fewer breakable components—no fragile filaments or glass envelopes that shatter under mining's constant vibrations and impacts. The durability translates directly to operational continuity: when lighting systems reliably perform in harsh conditions, equipment stays productive longer, maintenance teams redirect efforts to higher-priority tasks, and overall site efficiency improves measurably. Mining operations report maintenance cost reductions up to 80% after transitioning to premium Mine Site Lighting solutions, with the savings rapidly offsetting initial investment costs while delivering ongoing operational benefits.

| Performance Metric | Traditional Lighting | Advanced Mine Site Lighting | Improvement |

|---|---|---|---|

| Average Lifespan | 4,000-20,000 hours | 50,000+ hours | 150-1,150% increase |

| Energy Consumption | Baseline (100%) | 40% of baseline | 60% reduction |

| Maintenance Frequency | High (quarterly) | Low (multi-year) | 80% reduction |

| Reaction Time Improvement | Baseline | 112% faster | Significant safety gain |

| Productivity Increase | Baseline | Up to 25% higher | Major output boost |

Cost-Effectiveness and ROI of Modern Mine Site Lighting

Energy Efficiency and Operational Cost Reduction

Mine Site Lighting powered by LED technology delivers transformational energy savings that directly improve mining operations' bottom-line performance. Traditional lighting systems consume enormous amounts of electricity, with energy costs representing a substantial portion of operational budgets—particularly for sites requiring continuous illumination. Advanced Mine Site Lighting reduces energy consumption by up to 60% compared to high-intensity discharge and fluorescent systems, translating to hundreds of thousands in annual savings for large-scale operations. The efficiency gains compound over time: reduced electrical demand lowers generator fuel requirements for remote sites, decreases cooling system loads needed to offset heat from inefficient lighting, and reduces strain on electrical infrastructure extending its service life. For mining companies facing increasing pressure to meet environmental sustainability targets, energy-efficient Mine Site Lighting provides measurable progress toward carbon footprint reduction goals. The superior lumen-per-watt efficiency of modern LED systems means mines achieve better illumination quality while simultaneously reducing energy expenditure—a rare win-win scenario in industrial operations where improved performance typically demands increased resource consumption.

Maintenance Cost Savings and Labor Optimization

The financial benefits of advanced Mine Site Lighting extend well beyond energy savings into substantial maintenance cost reductions. Traditional lighting technologies require frequent lamp replacements, ballast servicing, and fixture repairs that consume both materials budgets and skilled labor hours. Mine Site Lighting systems featuring LEDs with 50,000+ hour lifespans eliminate most recurring replacement costs while freeing maintenance personnel to address higher-priority equipment needs. The impact becomes particularly significant in underground operations where lamp replacement requires extensive safety procedures, production shutdowns, and elevated labor costs due to hazardous working conditions. Durable Mine Site Lighting constructed specifically for mining environments withstands extreme vibrations, temperature fluctuations, moisture exposure, and physical impacts that destroy conventional fixtures—further reducing unexpected failure rates and emergency maintenance calls. Mining operations report that comprehensive transitions to LED-based Mine Site Lighting yield maintenance cost reductions approaching 80%, with many sites achieving full return on investment within 18-24 months through combined energy and maintenance savings alone.

Long-Term Investment Value and Equipment Compatibility

Evaluating Mine Site Lighting as a long-term capital investment rather than consumable expense reveals its true financial value to mining operations. While initial acquisition costs for premium LED lighting systems exceed traditional options, the total cost of ownership calculation strongly favors modern technology. Mine Site Lighting systems deliver consistent performance throughout their extended service lives without the gradual degradation characteristic of older technologies, maintaining return on investment over many years of reliable operation. Advanced systems integrate seamlessly with modern mining equipment, supporting retrofit installations on existing mobile machinery while providing scalability for fleet expansions. The compatibility with digital control systems and IoT platforms means Mine Site Lighting infrastructure remains relevant as mining operations adopt Industry 4.0 technologies, protecting capital investments against premature obsolescence. Mining companies increasingly recognize that premium Mine Site Lighting solutions represent infrastructure investments similar to excavation equipment or processing facilities—foundational assets that support production capabilities, enhance safety culture, and contribute to operational excellence for decades rather than merely years.

Advanced Features of Professional Mine Site Lighting Technology

Durability and Environmental Protection Standards

Professional-grade Mine Site Lighting must withstand environmental conditions that would quickly destroy consumer or commercial-grade fixtures. Mining environments subject lighting equipment to constant vibrations from heavy machinery, exposure to corrosive dust and moisture, extreme temperature swings, and frequent physical impacts. Quality Mine Site Lighting systems feature IP65 or IP67 ingress protection ratings, ensuring complete dust intrusion prevention and protection against powerful water jets or temporary submersion—critical capabilities for washdown areas and wet underground operations. Robust aluminum housings with powder coating provide superior corrosion resistance against chemical exposure from mining processes, extending fixture lifespan in harsh atmospheric conditions. Impact resistance rated to IK10 standards means Mine Site Lighting can withstand forces equivalent to 20 joules—approximately the impact of a 5kg mass dropped from 40cm height—without damage to critical components. Advanced thermal management systems dissipate LED heat effectively across temperature ranges from -40°C to +60°C, ensuring consistent performance whether installed in frigid surface operations or sweltering underground environments. These durability features aren't merely specifications on datasheets: they represent the difference between lighting systems that reliably support operations for decades versus equipment that fails repeatedly, disrupting production and endangering workers.

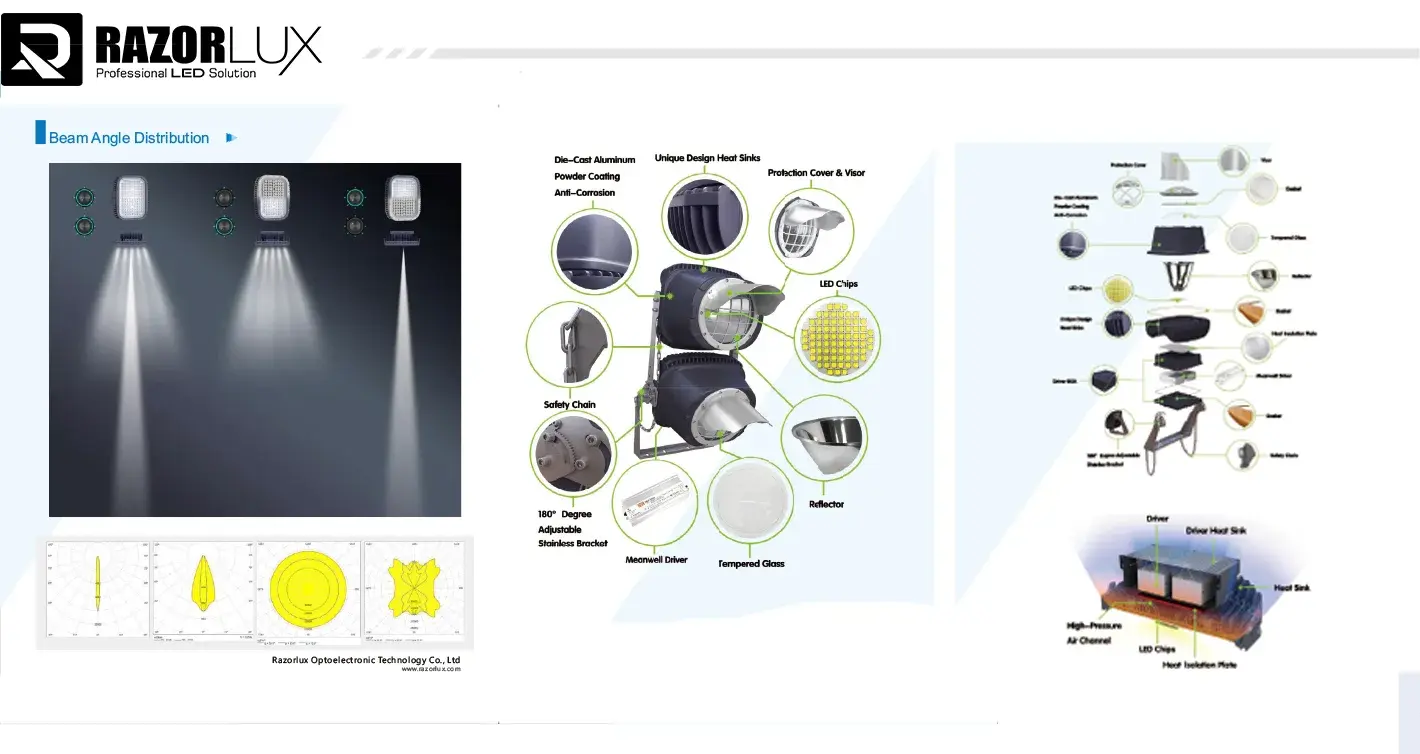

Customization Options for Diverse Mining Applications

No two mining operations face identical lighting challenges, making customization capabilities essential in professional Mine Site Lighting solutions. Advanced manufacturers offer extensive configuration options allowing mining companies to specify exact parameters matching their unique operational requirements. Power output customization enables precise illumination levels optimized for specific tasks—from high-intensity floodlighting for large-scale excavation areas to focused beam patterns for detailed inspection work. Color temperature selection between 2700K and 6500K allows operations to optimize for specific conditions: warmer temperatures reducing glare in foggy conditions while cooler temperatures maximizing visibility and alertness during precision tasks. Beam angle options including 60°, 120°, and asymmetric patterns like 140°x60° enable targeted illumination coverage without wasting light or creating problematic glare zones. Voltage flexibility accommodates diverse power systems, with Mine Site Lighting available in configurations supporting AC input from 80-360Vac or 400-600Vac, plus DC options spanning 100-400Vdc or even 500-800Vdc for specialized equipment. Mounting hardware customization ensures secure installation on any equipment type or structural configuration, while control system integration supports 0-10V dimming, DALI protocols, and emergency backup power functions. This customization capability means mining operations receive precisely engineered Mine Site Lighting solutions rather than compromising with off-the-shelf products inadequate for their specific needs.

Smart Control and Integration Capabilities

The future of Mine Site Lighting lies in intelligent systems that respond dynamically to operational conditions rather than providing static illumination. Modern lighting solutions integrate with IoT platforms and mining management systems, enabling centralized monitoring and control across entire sites. Smart Mine Site Lighting systems utilize occupancy sensors and ambient light detection to optimize energy consumption automatically, dimming or activating fixtures based on actual work area utilization rather than fixed schedules. Centralized control panels allow supervisors to manage lighting infrastructure remotely, implementing zone-based activation during shift transitions or emergency protocols that activate full-intensity illumination site-wide within seconds. Predictive maintenance capabilities represent particularly valuable innovations: Mine Site Lighting systems with integrated diagnostics monitor operating parameters continuously, flagging potential failures before they occur and scheduling maintenance during planned downtime rather than reacting to unexpected outages. Advanced systems support data logging and performance analytics, providing mining operations with detailed insights into lighting utilization patterns, energy consumption trends, and equipment reliability metrics that inform long-term infrastructure planning. The integration capability extends to emergency response systems, with Mine Site Lighting automatically activating backup power modes during power failures or switching to emergency protocols that guide evacuation routes—potentially life-saving features in underground operations where visibility becomes critical during crisis situations.

| Technical Specification | Standard Range | Xi'an Razorlux RGL-1000A |

|---|---|---|

| Rated Power | 200W-1000W | 1000W (LEDs: 900W, Driver: 100W) |

| Input Voltage (AC) | 100-277Vac | 80-360Vac, 400-600Vac |

| Input Voltage (DC) | 100-300Vdc | 100-400Vdc, 500-800Vdc |

| Luminous Efficiency | 100-130 LM/W | 130 LM/W |

| Color Temperature | 3000K-5000K | 2700K-6500K |

| IP Protection Rating | IP65 | IP65/IP67 (upgradeable) |

| Operating Temperature | -20°C to +50°C | -40°C to +60°C |

| Lifespan | 30,000-50,000 hours | ≥50,000 hours |

| Warranty Coverage | 3 years standard | 5 years (LED & Driver) |

Conclusion

Mine Site Lighting represents far more than basic illumination—it functions as critical infrastructure that determines safety outcomes, productivity levels, and long-term profitability for modern mining operations. The evidence overwhelmingly demonstrates that advanced LED lighting solutions deliver measurable improvements across every operational metric: accident rates decline, worker satisfaction increases, equipment uptime extends, energy costs decrease, and production throughput rises. Mining companies that continue relying on outdated lighting technologies essentially accept preventable losses while competitors gain competitive advantages through superior infrastructure. The transition to professional-grade Mine Site Lighting should be viewed not as discretionary spending but as strategic investment in operational excellence.

Ready to transform your mining operation with superior illumination? Xi'an Razorlux Optoelectronic Technology Co., Ltd. brings over 25 years of LED lighting expertise directly to your site. As a leading China Mine Site Lighting manufacturer, we engineer solutions specifically for demanding extraction environments. Our China Mine Site Lighting factory produces lighting systems with IP67 protection, marine-grade construction, and certifications including UL, CE, SAA, and RoHS—ensuring compliance across global markets. Whether you're seeking a reliable China Mine Site Lighting supplier for large fleet outfits or exploring competitive Mine Site Lighting wholesale pricing for ongoing operations, Razorlux delivers comprehensive solutions. Browse our complete Mine Site Lighting for sale catalog featuring customizable power outputs, voltage ranges, and beam configurations. Request detailed Mine Site Lighting price quotations and discuss your specific requirements with our technical team. We offer 3-5 year warranty coverage, OEM/ODM services, and responsive after-sales support. Contact our professional sales team today at sam@razorlux.com to receive customized samples, technical drawings, and project consultation. Save this resource for future reference as you plan lighting infrastructure upgrades that will boost your operation's safety and productivity for decades to come.

References

1 ."Mine Safety and Health Administration Injury Data Analysis: Slip, Trip, and Fall Incidents in Mining Operations 2014-2018" - National Institute for Occupational Safety and Health (NIOSH), Centers for Disease Control and Prevention

2. "LED Lighting Technology Implementation in Underground Mining: Safety and Efficiency Outcomes" - International Journal of Mining Science and Technology, Research Department of Mining Engineering

3. "Energy Efficiency and Cost-Benefit Analysis of LED Adoption in Mining Operations" - Society for Mining, Metallurgy & Exploration (SME), Industrial Efficiency Division

4. "Illumination Standards for Mining Environments: International Safety Regulations and Best Practices" - Mine Safety and Health Administration (MSHA), United States Department of Labor

5. "Ergonomics and Worker Health: The Impact of Lighting Quality on Mining Personnel Performance" - International Labour Organization (ILO), Occupational Safety and Health Branch

VIEW MOREMarine Flood Lights 1000W

VIEW MOREMarine Flood Lights 1000W VIEW MORELed Flood Lights For Football Field

VIEW MORELed Flood Lights For Football Field VIEW MOREMarine Led Spotlights For Boats

VIEW MOREMarine Led Spotlights For Boats VIEW MOREExplosion Proof Luminaire

VIEW MOREExplosion Proof Luminaire VIEW MORE800w Powerful Marine LED Flood Light Wireless Control Boat Bow Lights

VIEW MORE800w Powerful Marine LED Flood Light Wireless Control Boat Bow Lights VIEW MOREMast Led Lighting

VIEW MOREMast Led Lighting VIEW MOREBest Light For Outdoor Basketball Court

VIEW MOREBest Light For Outdoor Basketball Court VIEW MOREStadium Light Fixtures

VIEW MOREStadium Light Fixtures

_1750326878398.png)