Mine Site Lighting Troubleshooting: Solve Common Failures Fast

When lighting systems fail at your mining operation, production stops, safety risks escalate, and costs mount rapidly. Every minute of downtime in underground tunnels or open-pit operations directly impacts worker safety and operational efficiency. Mine Site Lighting failures can stem from multiple causes including harsh environmental conditions, improper installation, power supply issues, or component degradation. This comprehensive guide addresses the most common Mine Site Lighting failures and provides actionable troubleshooting solutions to restore illumination quickly, minimize downtime, and protect your workforce from preventable accidents in critical mining environments.

Understanding Common Mine Site Lighting System Failures

Mining environments subject lighting systems to extreme conditions that accelerate wear and trigger failures. Understanding root causes enables faster diagnosis and resolution of Mine Site Lighting problems across underground and surface operations.

Power Supply and Voltage Fluctuation Issues

Power supply problems represent the leading cause of Mine Site Lighting failures in mining operations. Industrial mining equipment creates significant electrical noise and voltage fluctuations that can damage LED drivers and control circuits. Modern high-performance LED systems like Razorlux's 1000W models feature wide input voltage ranges from AC80-360Vac and DC100-400Vdc, providing exceptional tolerance against power variations common in mine electrical systems. When Mine Site Lighting fixtures flicker or fail prematurely, the first diagnostic step involves measuring voltage at the fixture with a multimeter under load conditions. Verify that incoming voltage falls within the manufacturer's specified range and check for voltage drops exceeding five percent, which indicate inadequate wire sizing or poor connections. Emergency power backup systems with two-hour runtime capability ensure continuous illumination during power interruptions, maintaining worker safety during evacuation procedures.

Environmental Degradation and Seal Failures

The harsh mining environment exposes lighting fixtures to dust infiltration, moisture ingress, corrosive chemicals, and extreme temperature cycling. IP65 and IP67 protection ratings provide critical defense against these conditions, with IP67 offering superior submersion resistance essential for wet mining applications. Mine Site Lighting seal deterioration often occurs gradually as gaskets compress, fasteners loosen from vibration, or housing materials fatigue from thermal cycling. Regular inspection protocols should include visual examination of gasket condition, testing seal integrity with compressed air, and thermal imaging to detect moisture ingress before catastrophic failure. Stainless steel mounting brackets and marine-grade anti-corrosion coatings extend fixture lifespan in chemically aggressive environments. When condensation appears inside lenses, immediate fixture replacement prevents moisture damage to LED arrays and driver electronics, avoiding complete system failure during critical production shifts.

Mechanical Damage from Vibration and Impact

Mining equipment generates severe vibration and impact forces that exceed typical industrial environments. Underground blasting, heavy vehicle operation, and drilling activities subject Mine Site Lighting fixtures to mechanical stresses reaching 60 Grms vibration levels. IK10 impact resistance ratings ensure fixtures withstand direct impacts from falling rock, equipment collision, and maintenance activities without catastrophic failure. Proper mounting techniques using vibration-dampening hardware and secure attachment to structural members prevent fatigue failures at mounting points. When Mine Site Lighting fixtures exhibit intermittent operation, loose internal connections from vibration often represent the root cause. Inspection should verify that all internal wiring connections remain tight, LED modules seat properly in housings, and driver components show no signs of mechanical displacement. High-quality fixtures incorporating robust aluminum housings with powder coating and 29kg construction mass provide superior vibration resistance compared to lightweight alternatives, reducing failure rates and maintenance interventions.

Systematic Troubleshooting Procedures for Mine Site Lighting

Implementing structured diagnostic procedures enables maintenance teams to identify and resolve Mine Site Lighting failures efficiently, minimizing production disruptions and safety risks.

Initial Visual Inspection and Documentation Methods

Systematic visual inspection forms the foundation of effective Mine Site Lighting troubleshooting protocols. Begin documentation by recording fixture model numbers, installation dates, and previous maintenance history before commencing physical inspection. Examine housings for physical damage including cracks, dents, or corrosion that compromise structural integrity. Check mounting hardware for looseness, missing components, or signs of fatigue failure. Inspect electrical connections at both fixture and junction box locations, verifying proper wire termination and absence of overheating indicators like discoloration or melting. Document any abnormal conditions with photographs and detailed notes, creating maintenance records that identify recurring failure patterns across your Mine Site Lighting installation. The following table summarizes critical inspection checkpoints and corresponding failure indicators for comprehensive troubleshooting procedures:

| Inspection Point | Normal Condition | Failure Indicator | Corrective Action |

|---|---|---|---|

| Housing Seals | Gaskets compressed uniformly | Visible gaps, hardened material | Replace gaskets, retorque fasteners |

| Lens Clarity | Clear, no condensation | Fogging, moisture droplets | Inspect seals, dry fixture, reseal |

| Mounting Hardware | Tight, no corrosion | Loose, rust, missing components | Replace hardware, apply anti-seize |

| Electrical Connections | Tight, no discoloration | Loose, burned, corroded | Clean terminals, remake connections |

| LED Array | Uniform illumination | Dark spots, uneven brightness | Replace LED module assembly |

| Thermal Management | Cool to touch when off | Hot spots, discoloration | Check driver output, improve ventilation |

Electrical Testing and Component Diagnosis

Electrical testing requires systematic measurement procedures using calibrated test equipment to isolate Mine Site Lighting component failures. Begin by verifying input power availability at the junction box using a multimeter, confirming voltage presence and measuring actual values against nameplate specifications. For fixtures with AC80-360Vac input ranges, verify voltage stability under load by monitoring for fluctuations exceeding ten percent of nominal values. Test continuity from junction box to fixture, identifying cable damage or connection failures that interrupt power delivery. At the fixture, measure voltage at driver input terminals, comparing readings to junction box measurements to calculate voltage drop. Excessive voltage drop indicates undersized conductors or poor connections requiring immediate correction. Measure driver output voltage and current, verifying values match LED array requirements typically 30-40Vdc for high-power Mine Site Lighting applications. When driver output voltage measures zero despite proper input voltage, driver failure represents the most likely cause requiring component replacement. For fixtures with dimming capability including 0-10V and DALI systems, test control signal presence and voltage levels, ensuring proper communication between controllers and fixtures maintains expected light output levels.

LED Array and Optical System Evaluation

LED array failures in Mine Site Lighting systems manifest as complete fixture darkening, partial illumination loss, or color temperature shifts indicating component degradation. Modern fixtures incorporating 130LM/W efficiency with 120,000 lumen output at 5700K color temperature deliver exceptional performance when operating within design parameters. When evaluating LED arrays, measure light output using calibrated light meters, comparing readings against manufacturer specifications and previous measurements to quantify degradation. Sudden output loss typically indicates driver failure or wiring issues rather than LED degradation, which occurs gradually over the rated 50,000-hour lifespan. Partial array failure where sections of LEDs remain dark points to series connection failures within the LED module, requiring complete module replacement rather than individual LED repair. Color temperature shifts from specified 2700K-6500K range suggest thermal management problems with LED junction temperatures exceeding design limits. Thermal imaging identifies hot spots indicating inadequate heat dissipation from LED arrays to aluminum housings and ultimately to ambient air. The following table presents diagnostic criteria for LED array condition assessment and appropriate corrective measures:

| Symptom | Probable Cause | Diagnostic Test | Repair Solution |

|---|---|---|---|

| Complete darkness | Driver failure, no power | Measure input voltage | Replace driver, check wiring |

| Partial illumination | LED string failure | Visual inspection, thermal scan | Replace LED module assembly |

| Reduced brightness | LED degradation, dirt accumulation | Light meter measurement, lens cleaning | Clean optics or replace if degraded |

| Color shift | Thermal stress, phosphor degradation | Thermal imaging, color meter | Improve cooling, replace module |

| Flickering | Loose connections, driver instability | Connection inspection, voltage monitoring | Tighten connections, replace driver |

| Uneven illumination | Optical damage, LED failure | Visual inspection, beam pattern analysis | Replace lens or LED module |

Preventive Maintenance Strategies for Mine Site Lighting Reliability

Proactive maintenance programs dramatically reduce Mine Site Lighting failure rates while extending fixture lifespans and lowering total cost of ownership across mining operations.

Scheduled Inspection and Cleaning Protocols

Implementing systematic inspection schedules prevents catastrophic Mine Site Lighting failures by identifying and correcting minor issues before they escalate. Establish monthly visual inspections for all critical lighting zones including haul roads, loading areas, and underground production faces where lighting failure creates immediate safety hazards. Quarterly detailed inspections should include photometric measurements documenting light output degradation, thermal imaging to identify heat-related problems, and electrical testing verifying power supply quality and fixture performance parameters. Annual comprehensive inspections involve complete fixture disassembly when appropriate, internal component inspection, seal replacement, and preventive part replacement for wear items approaching service limits. Cleaning protocols significantly impact Mine Site Lighting performance in dusty mining environments where particulate accumulation on lenses and heat sinks reduces light output while increasing operating temperatures. Schedule cleaning frequency based on environmental conditions, ranging from weekly cleaning in extremely dusty locations to monthly cleaning in cleaner areas. Use non-abrasive cleaning solutions and soft cloths to prevent lens scratching that degrades optical performance. High-pressure water cleaning suits IP67-rated fixtures designed for submersion, while IP65 fixtures require careful cleaning avoiding direct high-pressure spray. Document all maintenance activities creating historical records that identify problem fixtures requiring replacement or environmental modifications.

Component Replacement and Upgrade Planning

Strategic component replacement extends Mine Site Lighting system life while improving performance and reducing energy costs. LED technology advances rapidly with newer generations offering improved efficiency, longer lifespan, and enhanced durability compared to fixtures installed five years ago. Develop replacement strategies prioritizing high-failure-rate fixtures, critical safety areas, and locations where improved illumination enhances productivity. Modern 1000W LED fixtures replacing 2000-3000W HID lamps deliver superior illumination while reducing energy consumption by sixty percent, generating substantial operational savings. Calculate total cost of ownership including purchase price, installation costs, energy consumption, maintenance requirements, and expected lifespan when comparing replacement options. Fixtures offering five-year warranties on LED modules and drivers with ten-year housing warranties provide superior long-term value despite potentially higher initial costs. Standardize on proven fixture models from manufacturers like Xi'an Razorlux Optoelectronic Technology offering comprehensive support, spare parts availability, and technical assistance. Maintain spare parts inventory for critical components including replacement drivers, LED modules, and mounting hardware enabling rapid repairs minimizing downtime. Plan upgrades systematically replacing oldest fixtures first while maintaining adequate illumination throughout transition periods. Consider emergency backup power integration during upgrades, adding two-hour battery backup capability to critical lighting circuits ensuring worker safety during power failures.

Performance Monitoring and Predictive Maintenance

Advanced monitoring systems detect Mine Site Lighting degradation before failures occur, enabling scheduled maintenance during planned downtime rather than emergency repairs during production. Implement periodic photometric measurements at defined locations, recording light levels and comparing trends over time. Light output degradation exceeding twenty percent indicates need for fixture cleaning, component replacement, or complete fixture renewal. Monitor energy consumption at lighting circuit level, identifying increases that signal driver inefficiency or LED degradation. Smart lighting systems with IoT connectivity enable real-time monitoring of individual fixture status, operating hours, energy consumption, and fault conditions. These systems generate maintenance alerts when fixtures approach service life limits or exhibit abnormal behavior patterns. Temperature monitoring using thermal imaging cameras identifies thermal management problems before they cause component failure. LED junction temperatures exceeding design specifications by ten degrees Celsius significantly reduce lifespan, making thermal monitoring essential for maximizing fixture longevity. Track maintenance costs per fixture identifying problem units requiring replacement rather than continued repair. Fixtures requiring multiple repairs within warranty periods indicate manufacturing defects or installation problems requiring root cause analysis and corrective action. Predictive maintenance data combined with manufacturer specifications enables accurate replacement planning, budget forecasting, and inventory management supporting reliable Mine Site Lighting operations across entire mining complexes.

Conclusion

Effective Mine Site Lighting troubleshooting requires systematic diagnostic procedures, proper test equipment, and comprehensive understanding of common failure modes in harsh mining environments. Implementing preventive maintenance programs, selecting robust fixtures with appropriate IP ratings and impact resistance, and training maintenance personnel in proper troubleshooting techniques minimize downtime while maximizing worker safety and operational efficiency.

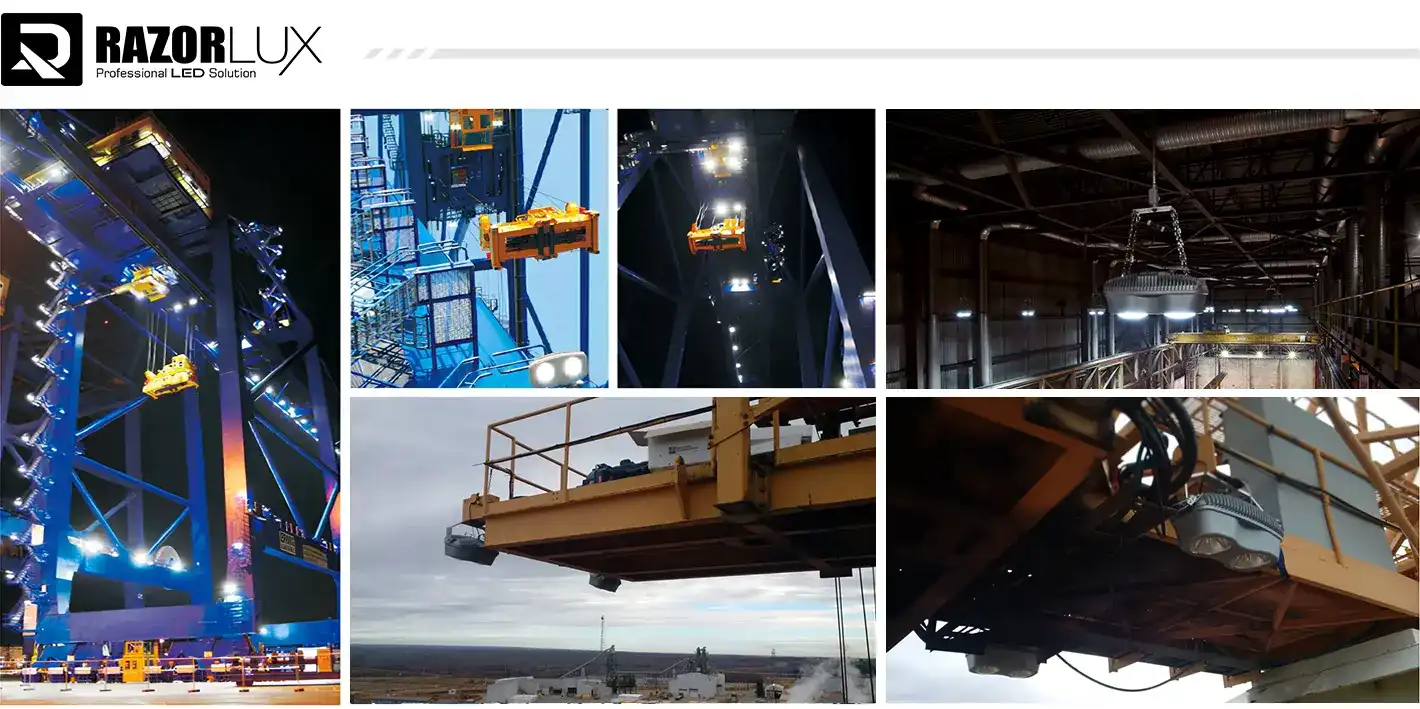

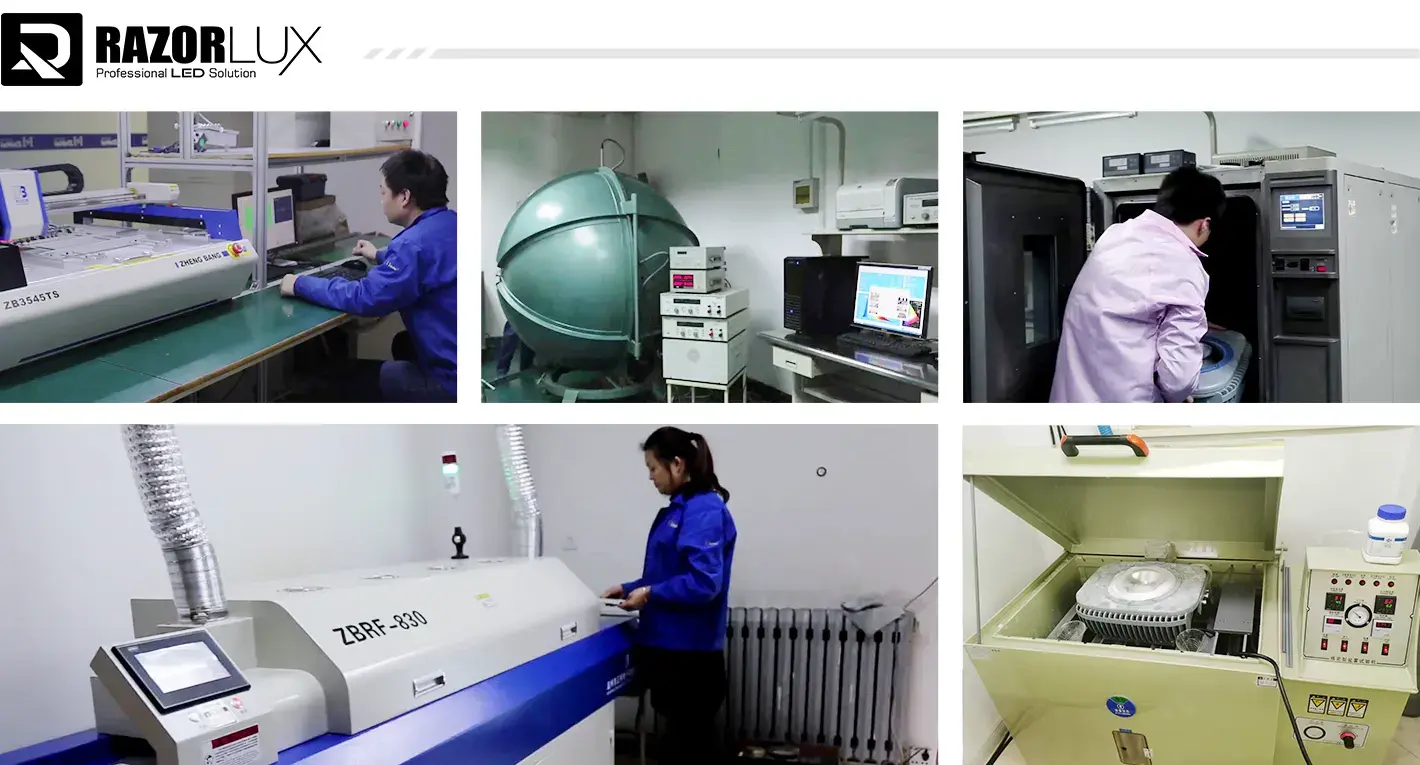

Ready to upgrade your Mine Site Lighting system with industry-leading solutions? Xi'an Razorlux Optoelectronic Technology Co., Ltd. delivers proven LED lighting designed specifically for demanding mining applications worldwide. Our 1000W high-performance fixtures combine IP67 protection, 130LM/W efficiency, wide voltage input compatibility, and five-year comprehensive warranties ensuring reliable illumination in the harshest conditions. Whether you need solutions as a China Mine Site Lighting factory partner, sourcing from a trusted China Mine Site Lighting supplier, or purchasing from an established China Mine Site Lighting manufacturer, Razorlux provides complete support from pre-sales consultation through after-sales service. Explore competitive Mine Site Lighting wholesale pricing, check current Mine Site Lighting for sale inventory, or request detaiLed Mine Site Lighting price quotations tailored to your specific requirements. Contact our technical team at sam@razorlux.com today for custom lighting solutions, photometric analysis, and comprehensive project support transforming your mining illumination challenges into operational advantages.

References

1. National Institute for Occupational Safety and Health (NIOSH). "Human Factors and Lighting for Underground Mining." Mining Program Research Division, U.S. Department of Energy.

2. Industrial Illuminating Engineering Society. "Recommended Lighting Practices for Mining Operations." Technical Guidelines for Underground and Surface Mine Illumination Standards.

3. International Electrotechnical Commission. "IEC 60079 Series: Explosive Atmospheres - Equipment Protection Standards." Certification Requirements for Hazardous Location Lighting Equipment.

4. American National Standards Institute. "ANSI/IES RP-12: Recommended Practice for Industrial Lighting." Illumination Engineering Society Guidelines for Mining Facilities.

5. Mine Safety and Health Administration. "Safety Standards for Underground Metal and Nonmetal Mines." Federal Regulations for Mine Illumination and Electrical Safety Requirements.

VIEW MOREoutdoor field lighting

VIEW MOREoutdoor field lighting VIEW MOREOutdoor Pole Mounted Flood Lights

VIEW MOREOutdoor Pole Mounted Flood Lights VIEW MOREOutdoor Flood Light Fixtures Waterproof

VIEW MOREOutdoor Flood Light Fixtures Waterproof VIEW MORECrane Boom Lights

VIEW MORECrane Boom Lights VIEW MOREAluminum Alloy 120000lm Sports Light Fixture 1000w Led Stadium Lights 5000K

VIEW MOREAluminum Alloy 120000lm Sports Light Fixture 1000w Led Stadium Lights 5000K VIEW MORE500W Robust Heavy Duty LED Stadium Lights Arena LED Lighting

VIEW MORE500W Robust Heavy Duty LED Stadium Lights Arena LED Lighting VIEW MOREUfo Warehouse Lights

VIEW MOREUfo Warehouse Lights VIEW MORELed Ufo High Bay 200W

VIEW MORELed Ufo High Bay 200W

_1750326878398.png)