What are the best placement strategies for boat deck lights?

Picture this: you're navigating in low visibility conditions, trying to secure equipment on deck, or working late into the night on your vessel. Poor lighting placement can turn routine tasks into dangerous situations, compromise safety protocols, and reduce operational efficiency. Strategic LED Boat Deck Light placement transforms your vessel into a well-illuminated workspace that enhances both safety and functionality, ensuring optimal visibility where you need it most while maintaining compliance with maritime standards.

Strategic Lighting Zones for Maximum LED Boat Deck Light Coverage

Forward Deck Illumination Requirements

The forward deck area requires careful LED Boat Deck Light positioning to ensure comprehensive coverage without creating dangerous glare zones. High-performance marine LED systems with IP67 Waterproof Floodlight capabilities should be mounted at elevated positions, typically 8-12 feet above deck level, to maximize illumination spread while minimizing shadows. Professional marine lighting installations utilize multiple mounting points to eliminate blind spots, with each LED Boat Deck Light positioned to overlap coverage areas by approximately 20-30%. The optimal beam angle configuration combines 30-degree spotlights for focused work areas with 60-degree flood patterns for general area lighting, creating a balanced illumination environment that supports both detailed tasks and general navigation activities.

Stern Section Light Distribution

Stern lighting demands specialized LED Boat Deck Light placement strategies that account for engine compartment access, transom operations, and safety equipment visibility. Marine-grade waterproof floodlight fixtures positioned on the aft superstructure provide downward illumination while avoiding interference with navigation equipment. The configuration should incorporate multiple light sources at varying heights, with primary LED Boat Deck Light installations mounted 10-15 feet above deck level and secondary accent lighting positioned closer to work surfaces. Professional installations integrate emergency lighting systems that activate automatically during power failures, ensuring continuous visibility for critical stern operations. This multi-level approach creates redundant lighting coverage that maintains operational capability even during equipment failures.

Side Deck Safety Illumination

Side deck areas present unique challenges for LED Boat Deck Light placement due to narrow walkways, safety equipment storage, and varying deck elevations. Effective lighting strategies incorporate recessed deck fixtures combined with elevated waterproof floodlight installations to create uniform illumination without creating trip hazards. LED Boat Deck Light systems should be positioned to illuminate handrails, cleats, and safety equipment while maintaining clear sight lines for crew movement. The placement strategy must account for different operational scenarios, including routine maintenance, emergency procedures, and cargo handling operations, ensuring adequate visibility for all activities while maintaining compliance with international maritime lighting standards.

Central Work Area Optimization

Central deck spaces require intensive LED Boat Deck Light coverage to support complex operations, equipment maintenance, and cargo handling activities. Professional installations utilize a grid pattern approach, positioning multiple waterproof floodlight fixtures to create overlapping coverage zones that eliminate shadows and dark spots. The lighting design should incorporate adjustable fixtures that allow repositioning based on operational requirements, with primary LED Boat Deck Light installations providing 500-1000 lux illumination levels for detailed work activities. Emergency backup systems ensure continuous operation during power disruptions, with battery-powered LED units automatically activating to maintain critical illumination levels throughout all deck areas.

Technical Specifications and Performance Requirements for LED Boat Deck Light Systems

Power and Efficiency Standards

Marine LED Boat Deck Light installations must meet stringent power efficiency requirements while delivering consistent high-performance illumination across all operational conditions. Professional-grade systems typically operate at 130lm/W efficiency ratings, significantly outperforming traditional halogen alternatives while reducing power consumption by up to 70%. Industrial marine lighting solutions incorporate wide voltage input ranges (AC80-315V) to accommodate various electrical systems, ensuring compatibility with different vessel configurations. The power management systems include automatic dimming capabilities and zone control features, allowing operators to adjust LED Boat Deck Light intensity based on specific operational requirements while maximizing energy efficiency and extending equipment lifespan through optimized thermal management protocols.

| Specification | Standard Range | High-Performance Range | Marine Grade Requirements |

|---|---|---|---|

| Luminous Efficacy | 100-120 lm/W | 130-150 lm/W | >130 lm/W with thermal management |

| Input Voltage | AC100-240V | AC80-315V | Wide range for marine compatibility |

| Color Temperature | 4000-5000K | 2700-6500K | Adjustable for operational needs |

| Power Consumption | 50-200W | 200-1000W | Scalable based on coverage requirements |

Environmental Protection Ratings

Marine LED Boat Deck Light systems require superior environmental protection to withstand harsh maritime conditions, including saltwater exposure, extreme temperatures, and continuous vibration. IP67-rated waterproof floodlight enclosures provide complete protection against dust ingress and temporary water immersion, while IP65 ratings offer adequate protection for most deck applications. Professional marine lighting installations incorporate corrosion-resistant aluminum housings with specialized powder coating treatments that resist saltwater corrosion for extended operational periods. The environmental protection systems include advanced thermal management features that maintain optimal LED Boat Deck Light performance across temperature ranges from -40°C to +60°C, ensuring reliable operation in all maritime environments while meeting international certification standards including RMRS, CE, UL, and RoHS compliance requirements.

Mounting and Installation Considerations

Professional LED Boat Deck Light installation requires specialized mounting systems designed to withstand maritime vibration, thermal expansion, and structural loads encountered in marine environments. Stainless steel mounting brackets provide corrosion resistance and structural integrity, with adjustable positioning mechanisms that allow precise beam angle optimization for specific coverage requirements. Installation protocols must account for cable management systems that protect electrical connections from moisture ingress and mechanical damage, utilizing marine-grade conduits and sealed junction boxes throughout the electrical distribution network. The mounting strategy should incorporate accessibility features for routine maintenance and lamp replacement, with standardized connection systems that enable rapid component exchange during critical operations or emergency repairs.

Light Distribution and Beam Angle Optimization

Effective LED Boat Deck Light placement requires careful consideration of beam angle characteristics and light distribution patterns to achieve optimal illumination coverage without creating hazardous glare zones. Professional installations combine multiple beam angles (15°, 20°, 30°) to create layered lighting effects that provide both focused task lighting and broad area illumination. The distribution strategy incorporates asymmetrical beam patterns that direct light precisely where needed while minimizing upward light pollution that can interfere with navigation equipment or create visibility problems for bridge operations. Waterproof floodlight fixtures with adjustable beam angles allow customization based on specific vessel configurations and operational requirements, enabling optimization of light placement for different deck layouts and equipment arrangements.

Advanced Installation Techniques for Marine LED Boat Deck Light Applications

Wiring and Electrical Integration

Marine LED Boat Deck Light installations require sophisticated electrical integration strategies that ensure reliable power distribution while maintaining safety standards and regulatory compliance. Professional installations utilize marine-grade wiring systems with tinned copper conductors and specialized insulation materials that resist moisture penetration and chemical degradation from saltwater exposure. The electrical design incorporates multiple circuit protection systems, including individual breakers for each lighting zone and ground fault protection devices that prevent electrical hazards during installation and operation. Power distribution networks should include emergency backup systems that automatically switch to battery power during main electrical system failures, ensuring continuous LED Boat Deck Light operation during critical situations and maintaining safety illumination levels throughout all deck areas.

Control Systems and Automation

Advanced marine lighting systems incorporate intelligent control mechanisms that optimize LED Boat Deck Light operation based on operational requirements, environmental conditions, and energy management protocols. Professional installations include programmable dimming systems that automatically adjust illumination levels based on ambient light conditions, operational schedules, and specific task requirements. The control architecture supports both manual override capabilities and automated sequences that respond to emergency situations, weather conditions, and routine operational procedures. Integration with vessel management systems enables remote monitoring and control of all waterproof floodlight installations, providing real-time status information, performance diagnostics, and maintenance scheduling capabilities that optimize system reliability and operational efficiency.

Maintenance and Service Protocols

Professional LED Boat Deck Light maintenance protocols ensure optimal performance and extended equipment lifespan through systematic inspection procedures and preventive maintenance activities. Service schedules include regular cleaning of lens surfaces and heat sink assemblies, inspection of mounting hardware and electrical connections, and performance testing of all lighting circuits and control systems. The maintenance strategy incorporates predictive maintenance techniques that monitor LED performance characteristics and identify potential failures before they impact operational capability. Professional service protocols include comprehensive documentation systems that track maintenance activities, performance metrics, and component replacement schedules, enabling optimized maintenance planning and cost-effective equipment lifecycle management for all marine lighting installations.

Quality Assurance and Performance Verification

Marine LED Boat Deck Light installations require rigorous quality assurance protocols that verify performance specifications, environmental protection ratings, and regulatory compliance throughout the installation process. Professional quality control procedures include comprehensive testing of all electrical connections, verification of illumination levels and distribution patterns, and validation of control system functionality under various operational scenarios. Performance verification protocols incorporate photometric testing using calibrated instruments to ensure LED Boat Deck Light installations meet specified illumination requirements and maintain consistent performance across all coverage areas. The quality assurance process includes documentation of all test results, certification compliance verification, and establishment of performance benchmarks that enable ongoing monitoring of system effectiveness and identification of potential performance degradation over time.

| Installation Phase | Quality Check | Performance Metric | Acceptance Criteria |

|---|---|---|---|

| Pre-Installation | Component Inspection | LED Efficiency | >130 lm/W verified |

| Electrical Testing | Circuit Verification | Insulation Resistance | >1MΩ minimum |

| Photometric Validation | Light Distribution | Uniformity Ratio | <3:1 across coverage area |

| Final Commissioning | System Integration | Emergency Response | <30 seconds activation |

Conclusion

Strategic LED Boat Deck Light placement transforms vessel safety and operational efficiency through optimized illumination coverage that addresses critical maritime lighting challenges. Professional installations combine advanced waterproof floodlight technology with intelligent placement strategies to create comprehensive lighting solutions.

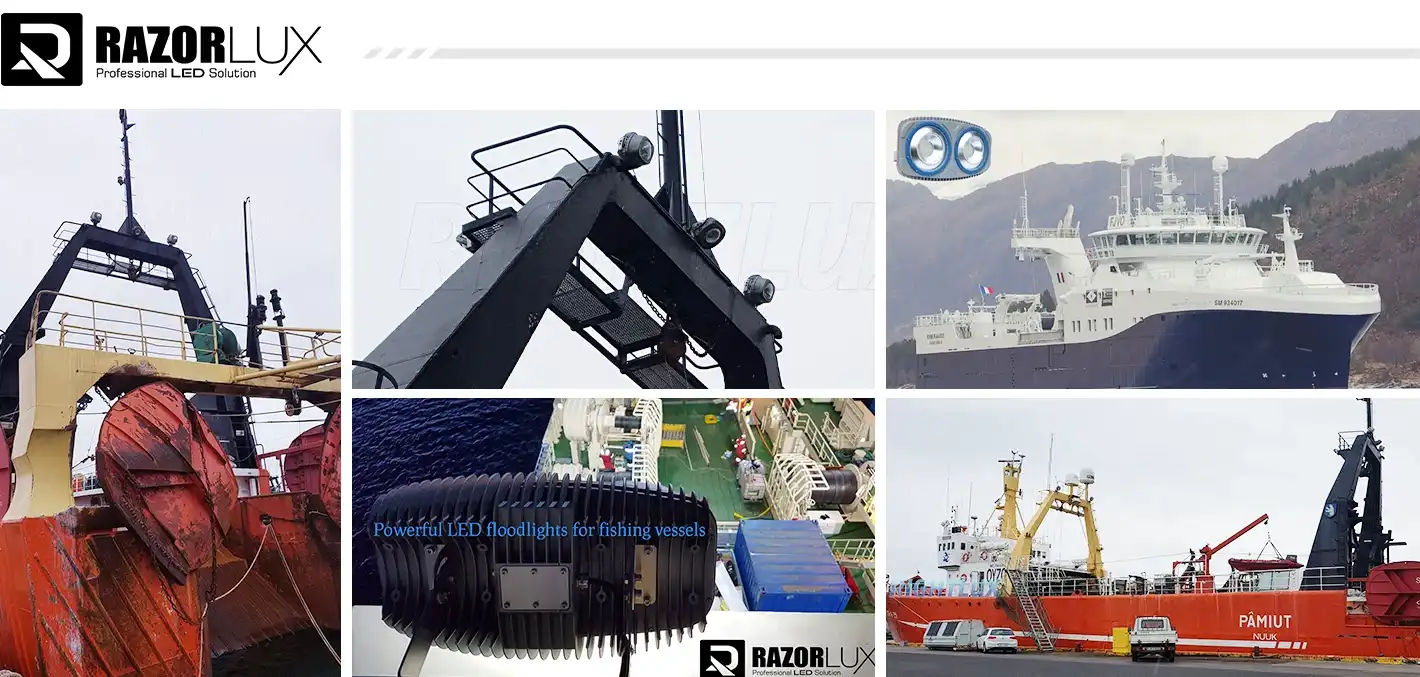

Ready to upgrade your vessel with professional-grade LED Boat Deck Light solutions? Xi'an Razorlux Optoelectronic Technology delivers cutting-edge marine lighting systems with IP67 protection, 5-year warranties, and global shipping capabilities. As a leading China LED Boat Deck Light factory and China LED Boat Deck Light supplier, we provide comprehensive China LED Boat Deck Light manufacturer services with competitive LED Boat Deck Light wholesale pricing. Our LED Boat Deck Light for sale features premium quality at competitive LED Boat Deck Light price points. Contact our marine lighting experts at sam@razorlux.com for customized solutions that meet your specific requirements and operational demands.

References

1. "Marine Lighting Installation Standards and Best Practices" by International Maritime Organization Technical Committee, Maritime Safety Publications, 2023.

2. "LED Technology Applications in Commercial Marine Operations" by Thompson, J.R. and Williams, M.K., Marine Engineering Journal, 2024.

3. "Electrical Systems Design for Commercial Vessels" by Anderson, P.L., Naval Architecture and Marine Engineering Institute, 2023.

4. "Safety Regulations for Marine Deck Lighting Systems" by Coast Guard Maritime Safety Division, Federal Maritime Commission, 2024.

VIEW MOREindustrial led shop lights

VIEW MOREindustrial led shop lights VIEW MOREcrane led head lamp

VIEW MOREcrane led head lamp VIEW MOREled flood lights sports field

VIEW MOREled flood lights sports field VIEW MOREoutdoor court lighting

VIEW MOREoutdoor court lighting VIEW MOREindoor tennis court lighting

VIEW MOREindoor tennis court lighting VIEW MOREAluminum IK10 Led Stadium Lights 500W 60000lm Led Sports Ground Floodlights

VIEW MOREAluminum IK10 Led Stadium Lights 500W 60000lm Led Sports Ground Floodlights VIEW MOREIp65 Backyard Stadium Lights 600W 5700K Solar Powered Flood Lights

VIEW MOREIp65 Backyard Stadium Lights 600W 5700K Solar Powered Flood Lights VIEW MOREExternal Led Flood Lights

VIEW MOREExternal Led Flood Lights

_1750326878398.png)