What happens if water touches LED lights?

Picture this: A sudden rainstorm strikes your industrial facility, and you're left wondering whether your expensive lighting system will survive. Water exposure is one of the most critical concerns for outdoor and marine lighting installations. When water infiltrates LED lights, the consequences can range from minor performance issues to complete system failure, potentially costing thousands in replacements and creating dangerous working conditions. Understanding what happens when water touches LED lights—and more importantly, how to prevent it—is essential for facility managers, engineers, and anyone responsible for outdoor or industrial lighting. This guide explores the risks, protective measures, and how advanced Waterproof LED Flood Light technology provides reliable solutions for demanding environments.

Understanding Water Damage to LED Lighting Systems

The Science Behind Water and Electrical Components

When water comes into contact with LED lights, the fundamental issue stems from water's conductivity properties. Electrical current flowing through LED circuits can deviate from its intended path when moisture is introduced, creating multiple hazards. The internal components of LED lights, including circuit boards, drivers, and LED chips themselves, are particularly vulnerable to water infiltration. Modern Waterproof LED Flood Light designs incorporate advanced sealing technologies to prevent this infiltration, but understanding the basic risks helps explain why proper protection is so critical. The interaction between water and electricity in lighting systems creates three primary concerns: short circuits that can instantly disable the fixture, gradual corrosion that undermines long-term reliability, and safety hazards that can endanger personnel working near compromised equipment.

Immediate Effects of Water Contact on LED Fixtures

The moment water penetrates an unprotected LED light fixture, several processes begin simultaneously. Short circuits represent the most immediate danger, occurring when water bridges electrical connections that should remain isolated. This can cause the LED driver to fail instantly, often with visible signs like flickering or complete shutdown. Waterproof LED Flood Light fixtures rated IP67 or higher are specifically engineered to prevent such failures, using multiple layers of protection including sealed housings, gasketed connections, and conformal coatings on circuit boards. Beyond electrical failure, water can also physically interfere with light output by creating condensation on lenses or reflectors, dramatically reducing illumination effectiveness even if the electrical components remain functional.

Long-Term Corrosion and Component Degradation

Even when water exposure doesn't cause immediate failure, the long-term effects can be equally devastating. Moisture trapped inside light fixtures initiates corrosion processes on metal components, including contacts, mounting hardware, and circuit traces. This corrosion gradually increases electrical resistance, causing voltage drops that reduce light output and efficiency. Quality Waterproof LED Flood Light systems combat this through marine-grade materials like stainless steel brackets and aluminum housings with specialized powder coatings. The corrosion process accelerates in environments with salt spray, chemical exposure, or temperature fluctuations—exactly the conditions where industrial and marine lighting must perform. Without proper protection, corroded fixtures typically fail within months rather than years, making initial investment in waterproof technology a critical economic decision.

Color Shifting and Optical Performance Changes

Water infiltration affects not only electrical functionality but also optical performance characteristics. When moisture enters LED packages or accumulates on optical components, it can alter the phosphor coatings that determine color temperature and quality. This manifests as color shifting, where lights gradually drift from their specified color temperature, or as reduced color rendering index (CRI), making it difficult to distinguish colors accurately. Premium Waterproof LED Flood Light fixtures maintain consistent color performance through sealed optical chambers and high-quality LED chips that resist moisture-related degradation. For industrial applications requiring precise color rendering for quality control or safety identification, maintaining optical stability despite environmental challenges is absolutely essential.

IP Rating Standards and Protection Levels

| IP Rating | Protection Against Solids | Protection Against Liquids | Typical Applications |

|---|---|---|---|

| IP65 | Dust-tight | Protected against water jets from any direction | General outdoor lighting |

| IP66 | Dust-tight | Protected against powerful water jets | Heavy industrial environments |

| IP67 | Dust-tight | Protected against temporary immersion up to 1 meter | Marine applications, washdown areas |

| IP68 | Dust-tight | Protected against continuous immersion | Underwater lighting, extreme environments |

Decoding IP Protection Standards for Industrial Use

The International Protection (IP) rating system provides standardized measurement of how well enclosures protect against environmental intrusion. For LED flood lights, the two-digit IP code reveals crucial information about performance expectations. The first digit (0-6) indicates protection against solid particles, while the second digit (0-9) specifies liquid ingress protection. Industrial-grade Waterproof LED Flood Light fixtures typically carry IP67 ratings minimum, ensuring complete dust protection and ability to withstand temporary water immersion. Understanding these ratings allows facility managers to match lighting specifications to actual environmental conditions. A fixture rated IP65 might suffice for covered outdoor areas, but IP67 protection becomes essential for marine environments where wave action or pressure washing occurs regularly. Xi'an Razorlux Optoelectronic Technology Co., Ltd. manufactures Waterproof LED Flood Light systems meeting IP67 standards, tested rigorously to ensure performance under extreme conditions.

Why IP67 Matters for Marine and Industrial Applications?

Marine and heavy industrial environments present unique challenges that demand IP67-rated protection. Unlike general outdoor lighting, these applications involve direct water exposure through rain, waves, spray, or cleaning processes. IP67 certification means fixtures can withstand immersion in water up to one meter deep for 30 minutes without allowing any harmful ingress. This protection level is particularly critical for shipyards, offshore platforms, and port facilities where Waterproof LED Flood Light installations face constant moisture exposure. The robust sealing required for IP67 ratings involves precision-engineered gaskets, threaded cable glands, and carefully designed housing joints that maintain integrity despite temperature cycling and mechanical stress. Facilities operating in corrosive environments—such as chemical plants or seaside installations—benefit tremendously from this protection level, as it prevents both immediate water damage and long-term corrosion that would compromise lesser-rated fixtures.

Testing and Certification Processes for Waterproof Ratings

Achieving and maintaining IP67 certification requires rigorous testing protocols that simulate real-world environmental conditions. Manufacturers submit Waterproof LED Flood Light samples to independent testing laboratories where they undergo immersion testing, jet spray evaluation, and dust ingress assessment. These tests verify that design specifications translate into actual protection performance. Temperature cycling tests ensure that gaskets and seals maintain effectiveness across operating temperature ranges from -40°C to +60°C, typical for industrial applications. Razorlux products undergo additional validation through certifications from RMRS, CE, RoHS, UL, and other international standards bodies, demonstrating compliance across multiple regulatory frameworks. This multi-layered certification approach provides assurance that waterproof ratings represent genuine protection rather than marketing claims, giving facility managers confidence in long-term performance.

Comparing Protection Levels for Different Environments

Different operational environments require different protection levels, making proper specification critical for system longevity and cost-effectiveness. Indoor warehouses might function adequately with IP54-rated fixtures offering basic splash protection, but outdoor loading docks require IP65 minimum to handle rain exposure. Marine installations demand IP67 rating due to direct wave action and pressure washing requirements. The Waterproof LED Flood Light selection process should consider not only current conditions but also worst-case scenarios and maintenance procedures. Facilities that perform regular high-pressure washing need fixtures rated for powerful jet spray (IP66 or IP67), even if daily conditions seem less demanding. Economic analysis consistently shows that specifying appropriate protection upfront costs less than premature replacement of under-specified fixtures, particularly when considering labor costs for installation and disposal expenses for failed equipment.

Advanced Waterproof LED Flood Light Technology

Marine-Grade Construction Materials and Design

Modern Waterproof LED Flood Light technology employs sophisticated material engineering to achieve reliable performance in hostile environments. Housing construction typically utilizes die-cast aluminum with specialized surface treatments that resist corrosion far better than standard aluminum finishes. These housings feature precision-machined sealing surfaces that mate with silicone or EPDM gaskets, creating watertight barriers without relying solely on sealants that can degrade over time. Stainless steel mounting brackets (SS304 or SS316 grade) provide structural support while resisting rust formation even in salt spray environments. The optical chamber design incorporates tempered glass lenses with sealed perimeters, preventing condensation while allowing thermal expansion without compromising integrity. Razorlux Waterproof LED Flood Light models exemplify this engineering approach, combining robust mechanical design with advanced materials to deliver decades of reliable service in demanding applications including shipyards, offshore platforms, and coastal industrial facilities.

Thermal Management in Sealed Environments

One of the greatest challenges in Waterproof LED Flood Light design involves managing heat dissipation within sealed enclosures. LED efficiency translates most input power into light, but remaining energy becomes heat that must be removed to prevent premature LED degradation. Sealed waterproof housings complicate this thermal management by eliminating natural convection cooling. Advanced designs employ substantial aluminum heat sinks with optimized fin geometry that conducts heat from LED modules to external housing surfaces. Some high-power fixtures incorporate thermal interface materials with superior conductivity, ensuring efficient heat transfer from LED chips to heat dissipation structures. The 400W Waterproof LED Flood Light from Razorlux demonstrates sophisticated thermal design, maintaining LED junction temperatures within safe operating ranges despite 400W power consumption and IP67 sealing. This thermal performance directly impacts longevity, with properly managed fixtures delivering over 50,000 hours of operation while maintaining light output and color consistency.

Driver Electronics Protection and Reliability

LED driver circuits represent particularly vulnerable components in waterproof lighting systems, as electronic controllers contain sensitive components susceptible to moisture damage. Quality Waterproof LED Flood Light designs protect drivers through multiple strategies: physical separation from the LED light engine, conformal coating application to circuit boards, and housing within sealed compartments with their own gasket protection. Premium drivers like Meanwell power supplies feature inherent environmental protection through potted construction where electronic components are encapsulated in protective resin. This potting provides electrical insulation, moisture barrier, and mechanical stability simultaneously. Wide input voltage capability (110-480VAC in Razorlux products) ensures reliable operation despite voltage fluctuations common in industrial power systems. The driver also incorporates surge protection, power factor correction (≥0.98), and low total harmonic distortion (<10%), delivering clean power to LED arrays while minimizing electrical stress that could compromise waterproof sealing over time.

Emergency Backup Power Integration

Critical applications require lighting that continues functioning during power outages, driving development of Waterproof LED Flood Light systems with integrated emergency backup capabilities. These systems incorporate rechargeable battery packs within the waterproof housing or in separate sealed enclosures, maintaining the same environmental protection standards as the primary lighting components. Advanced emergency systems provide two hours of operation after AC power loss, sufficient for safe shutdown procedures or emergency response activities. The battery management circuitry monitors charge state, provides automatic switchover during outages, and protects batteries from overcharge or deep discharge conditions that reduce lifespan. This emergency backup functionality proves especially valuable in marine applications, offshore platforms, and industrial facilities where lighting failure during power outages creates immediate safety hazards. Integrating emergency power within waterproof fixtures eliminates separate emergency lighting requirements, reducing overall system complexity and installation costs.

Protective Measures and Installation Best Practices

| Protection Method | Application Type | Effectiveness | Maintenance Requirements |

|---|---|---|---|

| Silicone Sealant | Cable entries, housing joints | High when properly applied | Re-seal every 2-3 years |

| Cable Glands | Electrical connections | Excellent with quality products | Inspect annually, tighten as needed |

| Mounting Position | Installation angle selection | Very high for drainage | Verify during installation only |

| Protective Enclosures | Fixtures in harsh environments | Excellent for specific threats | Clean and inspect quarterly |

Proper Installation Techniques for Maximum Protection

Even the best-designed Waterproof LED Flood Light can fail if improperly installed, making correct installation techniques absolutely critical. Cable entry represents the most common failure point, requiring careful attention to manufacturer specifications for cable gland selection and installation torque. Quality cable glands with compression seals provide reliable long-term protection, but only when appropriately sized for cable diameter and properly tightened to specification. Installation orientation significantly impacts water drainage and accumulation—fixtures should be mounted to allow water runoff rather than pooling on horizontal surfaces. Avoiding water traps in mounting configurations prevents long-term moisture exposure to seals and gaskets. All threaded connections require appropriate torque to compress gaskets without overtightening that could damage sealing surfaces or strip threads. Following manufacturer specifications for installation procedures ensures that waterproof ratings translate from laboratory testing to field performance.

Gasket Maintenance and Replacement Schedules

Gaskets and seals provide the primary barrier against water ingress in Waterproof LED Flood Light systems, but these components don't last indefinitely. Environmental exposure causes gradual degradation through ultraviolet radiation, temperature cycling, and chemical attack, eventually compromising sealing effectiveness. Proactive maintenance programs include periodic gasket inspection and replacement according to manufacturer recommendations or observed condition. Warning signs of gasket deterioration include visible cracking, permanent compression set, or loss of elasticity. High-quality gaskets fabricated from silicone or fluoroelastomers withstand environmental degradation better than cheaper alternatives, justifying their higher initial cost through extended service intervals. Replacement procedures must follow manufacturer specifications precisely, including proper gasket positioning, surface cleaning, and torque sequences that ensure even compression. Organizations operating large Waterproof LED Flood Light installations benefit from establishing standardized gasket replacement intervals based on operating environment severity, preventing premature failures while avoiding unnecessary maintenance activities.

Environmental Monitoring and Preventive Inspection

Systematic inspection programs identify potential waterproofing issues before they cause lighting failures, substantially reducing downtime and replacement costs. Inspection protocols should examine cable entries for seal integrity, housing joints for gap development, and lenses for crack formation. Thermal imaging can reveal water intrusion through temperature anomalies caused by moisture accumulation inside fixtures. Many organizations schedule quarterly inspections in harsh environments, with inspection frequency adjusted based on failure history and criticality of the lighting application. Inspection findings guide maintenance prioritization, focusing resources on fixtures showing early warning signs rather than waiting for complete failure. Documentation of inspection results over time reveals patterns that inform specification improvements for future procurement. For Waterproof LED Flood Light installations in mission-critical applications like offshore platforms or shipyards, the modest cost of regular inspections provides enormous value through avoided failures that would compromise operations or safety.

Selecting Appropriate Fixtures for Specific Environments

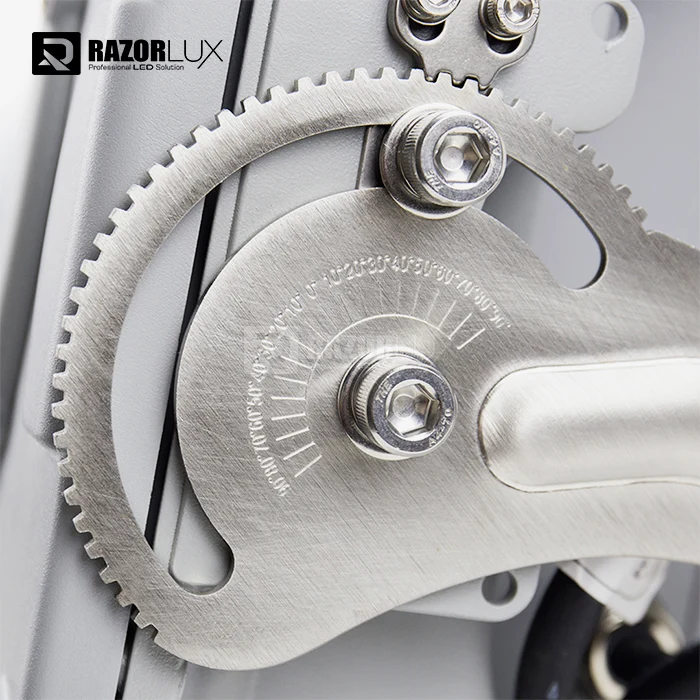

Matching Waterproof LED Flood Light specifications to actual operating conditions represents the foundation of reliable system performance. This selection process considers multiple environmental factors: maximum and minimum temperatures, humidity levels, presence of corrosive substances, physical impacts, and cleaning procedures. Marine environments require fixtures with marine-grade corrosion protection beyond standard IP67 sealing. Chemical processing plants need fixtures resistant to specific chemical exposures. Mining operations require fixtures with high-impact resistance (IK10 rating). The wide input voltage capability (110-480VAC) available in industrial-grade fixtures like those from Razorlux eliminates concerns about voltage compatibility in diverse installations. Beam angle selection (40°, 60°, 120°, or 140°x60°) optimizes illumination patterns for specific applications—narrow beams for long-throw requirements, wide beams for area lighting. Color temperature choices (2700K-6500K) affect visibility and ambiance, with cooler temperatures generally preferred for industrial applications requiring high visual acuity.

Razorlux Waterproof LED Flood Light Solutions

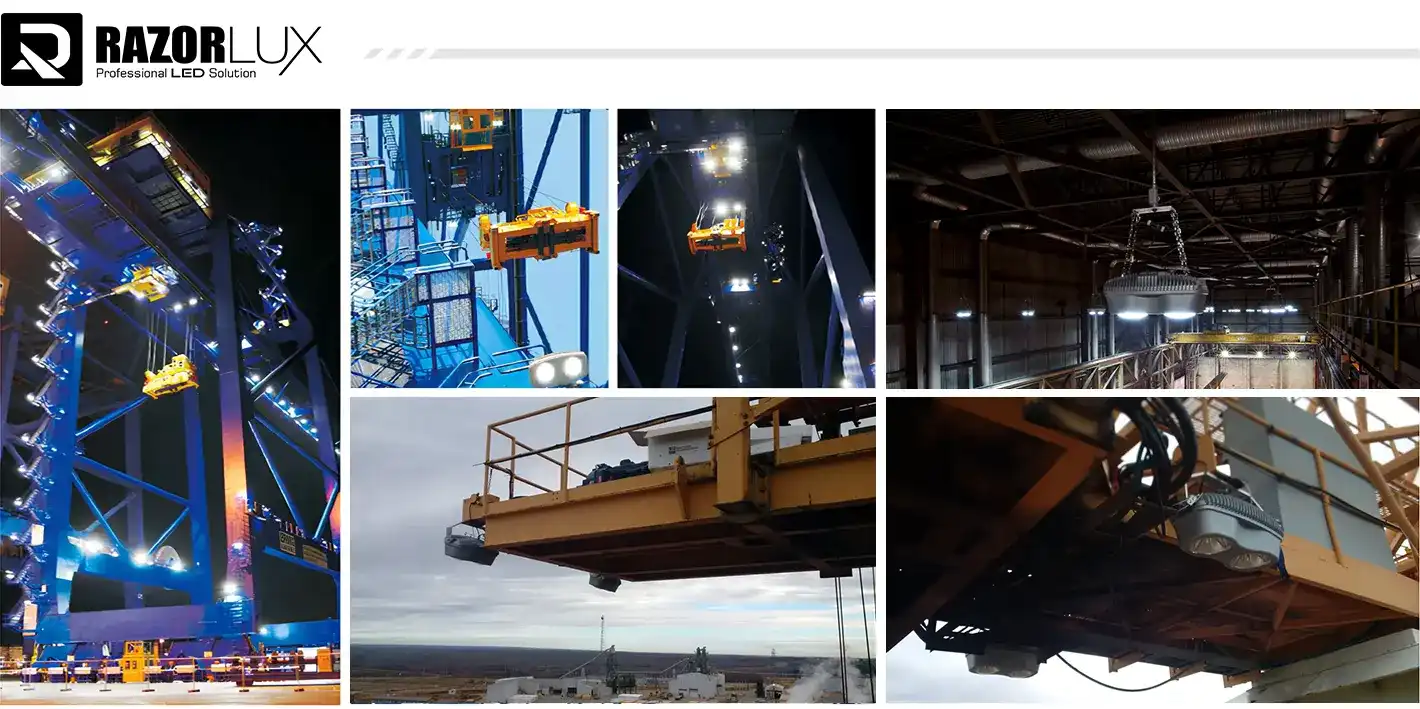

Engineering Excellence in Marine-Grade Lighting

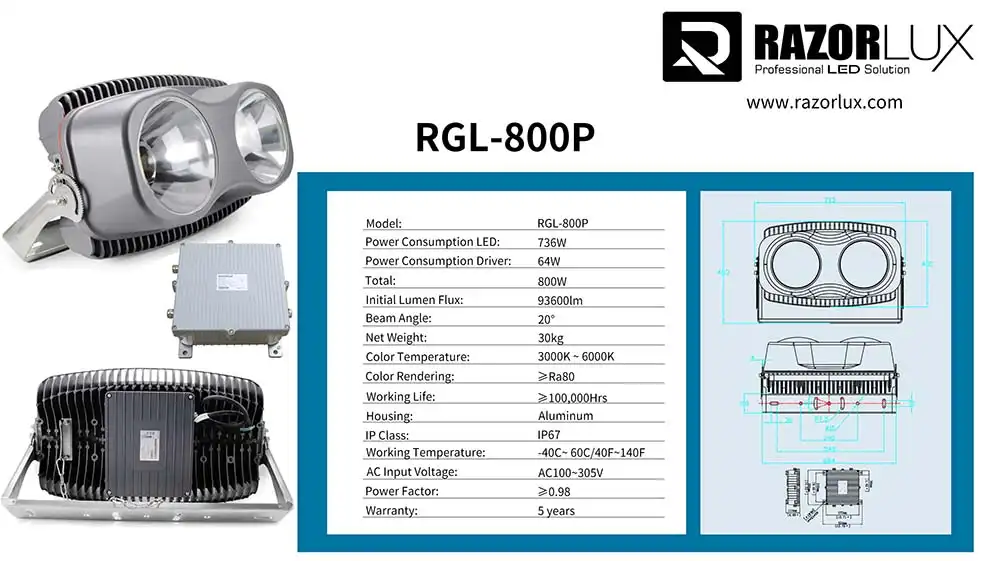

Xi'an Razorlux Optoelectronic Technology Co., Ltd. brings over two decades of LED lighting expertise to developing Waterproof LED Flood Light solutions that exceed industry standards for reliability and performance. Founded in 1998, the company combines extensive research and development capabilities with precision manufacturing to produce fixtures specifically engineered for the harshest operating environments. The RGL2-400A model exemplifies this engineering philosophy, delivering 52,000 lumens of stable output through 360W of LED power plus 40W driver consumption for 400W total system power. This high-efficiency design (130lm/W) provides illumination equivalent to 800-1000W HID lamps while consuming substantially less energy. The IP67 rating ensures complete protection against dust and temporary water immersion, while IK10 impact resistance protects against mechanical damage. Comprehensive certifications including RMRS, CE, RoHS, UL, and ISO:9001 validate the design and manufacturing quality that makes Razorlux fixtures preferred choices for demanding applications worldwide.

Comprehensive Specifications and Performance Capabilities

The technical specifications of Razorlux Waterproof LED Flood Light products demonstrate the sophisticated engineering behind their exceptional performance. The 400W model operates across an extraordinarily wide input voltage range (AC 110-480V or DC 100-800V), accommodating diverse power systems without requiring additional transformers or adapters. This voltage flexibility proves especially valuable in marine and international applications where power standards vary. Multiple beam angle options (40°, 60°, 120°, 140°x60°) enable precise light distribution control, matching illumination patterns to specific application requirements. Color temperature availability spans 2700K to 6500K, supporting applications from warm accent lighting to cool industrial task lighting. Color rendering index exceeds Ra75 standard, with Ra80 and Ra90 options available for applications requiring superior color discrimination. The fixtures operate reliably across temperature extremes from -40°C to +60°C and humidity from 10% to 95%, specifications that encompass virtually any terrestrial environment. Five-year warranties on LED modules and drivers plus ten-year housing warranties demonstrate manufacturer confidence in long-term durability.

Global Manufacturing Excellence and Quality Assurance

Razorlux manufacturing operations embody the integration of advanced technology with rigorous quality control that characterizes world-class production facilities. The company holds over 200 patents covering LED Packaging, power control systems, and structural design innovations, intellectual property that provides competitive advantages in performance and reliability. ISO 9001 certification validates systematic quality management throughout the manufacturing process, from incoming component inspection through final product testing. Every Waterproof LED Flood Light undergoes comprehensive testing including photometric evaluation in integrating spheres, extended aging tests that verify long-term stability, and waterproof validation confirming IP67 performance. This testing rigor ensures that catalog specifications represent actual delivered performance rather than theoretical capabilities. Manufacturing facilities in Xi'an, China, combined with subsidiaries in the USA and Hong Kong, provide global reach with local support capabilities. This geographic distribution enables responsive customer service and efficient logistics while maintaining consistent manufacturing standards across all production locations.

Customization Capabilities and OEM Services

Beyond standard product offerings, Razorlux provides extensive customization capabilities that address unique application requirements. The flexible manufacturing infrastructure supports modifications in wattage, color temperature, housing materials, mounting configurations, and control systems including 0-10V and DALI dimming protocols. This customization extends to OEM and ODM services where Razorlux collaborates with partners to develop unique branded Waterproof LED Flood Light solutions tailored to specific market segments. The customization process begins with technical consultation where Razorlux engineers work directly with customers to understand application requirements, environmental conditions, and performance objectives. This collaborative approach often identifies opportunities for performance optimization or cost reduction that wouldn't emerge from standard product selection. Sample production and prototyping capabilities allow customers to evaluate customized designs before committing to volume production. For organizations requiring specialized marine or industrial lighting solutions that standard products don't adequately address, Razorlux customization services provide pathways to optimized solutions without the risks and investments associated with independent development programs.

Conclusion

Water exposure represents one of the most significant threats to LED lighting systems in industrial and marine environments, causing immediate electrical failures through short circuits and long-term degradation through corrosion and component damage. Understanding the mechanisms of water-related damage and the protective technologies that prevent it enables informed specification decisions that optimize both performance and lifecycle costs. IP67-rated Waterproof LED Flood Light fixtures provide robust protection against moisture intrusion, maintaining reliable operation despite direct water exposure from rain, waves, pressure washing, or temporary immersion. Advanced designs incorporate marine-grade materials, sophisticated thermal management, protected driver electronics, and optional emergency backup power to address the complete spectrum of industrial lighting challenges.

Selecting appropriate Waterproof LED Flood Light solutions requires careful consideration of operating environments, installation practices, and maintenance capabilities. Razorlux combines decades of LED engineering expertise with world-class manufacturing to deliver fixtures that exceed industry standards for performance and durability. Whether outfitting shipyards, offshore platforms, chemical plants, or other demanding facilities, Razorlux provides comprehensive solutions backed by extensive certifications and responsive global support. As a leading China Waterproof LED Flood Light manufacturer and China Waterproof LED Flood Light supplier, we offer competitive Waterproof LED Flood Light pricing with flexible OEM services. Our China Waterproof LED Flood Light factory produces industrial-grade fixtures with Waterproof LED Flood Light for sale globally through our network, supported by comprehensive technical resources.

Ready to upgrade your facility lighting with proven waterproof technology? Contact our team at sam@razorlux.com to discuss your specific requirements and receive customized recommendations. Visit our product pages, bookmark this resource for future reference, or request samples to evaluate performance firsthand. Don't let water damage compromise your lighting investment—choose Razorlux Waterproof LED Flood Light solutions engineered for the harshest environments and backed by comprehensive warranties and expert support.

References

1. National Electrical Manufacturers Association (NEMA). Standards Publication on Enclosures for Electrical Equipment. NEMA Standards Publication 250.

2. Illuminating Engineering Society (IES). The Lighting Handbook: Reference and Application. IES Technical Committee.

3. International Electrotechnical Commission (IEC). Degrees of Protection Provided by Enclosures (IP Code). IEC Standard 60529.

4. Institute of Electrical and Electronics Engineers (IEEE). Recommended Practice for Protection of Wire-Line Communication Facilities Serving Electric Power Stations. IEEE Standard 487.

_1750326878398.png)