Are LED Lights Waterproof?

Picture this: You're overseeing a critical offshore operation when sudden torrential rain hits your platform. Your lighting fails, halting work and compromising safety. This nightmare scenario highlights why understanding LED waterproofing isn't just technical knowledge—it's operational necessity. Not all LED lights offer the same protection against water intrusion, and choosing the wrong specification can cost thousands in replacements and downtime. The answer depends on IP ratings, with professional-grade Waterproof LED Flood Light solutions engineered specifically for harsh marine and industrial environments where water exposure is constant and unforgiving.

Understanding IP Ratings and Waterproof Standards for LED Lighting

What IP Ratings Mean for LED Light Protection?

The Ingress Protection rating system serves as the international standard for measuring how well electrical enclosures protect against environmental intrusion. This two-digit classification provides critical information for anyone selecting lighting for demanding applications. The first digit ranges from 0 to 6 and indicates protection against solid particles like dust and debris, while the second digit ranges from 0 to 9 and measures liquid protection levels. For marine and industrial applications, understanding these ratings becomes essential when specifying Waterproof LED Flood Light systems that must withstand continuous exposure to moisture, salt spray, and harsh weather conditions without degradation or failure.

IP65 vs IP67: Which Rating Do You Need

IP65-rated fixtures provide dust-tight protection and resistance against low-pressure water jets from any direction, making them suitable for most outdoor installations exposed to rain and occasional splashing. However, IP67-rated lights offer complete dust protection plus the ability to withstand temporary immersion in water up to one meter deep for 30 minutes. Professional marine-grade Waterproof Led Flood Light 400W systems typically feature IP67 certification, ensuring reliable operation even when waves crash over deck installations or when fixtures are temporarily submerged during storm conditions. The higher rating provides crucial insurance against unexpected water exposure that commonly occurs in shipyard, offshore platform, and coastal infrastructure applications.

Marine-Grade Waterproofing: Beyond Standard IP Ratings

True marine-grade waterproofing extends far beyond basic IP certification to include specialized materials and construction techniques designed for saltwater environments. High-quality Waterproof LED Flood Light fixtures incorporate marine-grade aluminum housings with specialized anti-corrosion coatings that resist the accelerated deterioration caused by salt exposure. Premium models feature stainless steel mounting brackets, sealed cable entries with compression glands, and conformal coating on internal electronics to prevent moisture-related failures. These additional protections explain why professional maritime installations consistently specify certified marine lighting rather than standard outdoor-rated fixtures, as the harsh conditions demand components engineered specifically for constant exposure to corrosive saltwater spray and humidity.

Testing Standards and Certification Requirements

| Certification | Testing Standard | Application Requirement |

|---|---|---|

| IP67 | IEC 60529 | Temporary water immersion testing |

| RMRS | Russian Maritime Register | Mandatory for vessels under Russian classification |

| UL 1598 | Underwriters Laboratories | Required for North American marine installations |

| CE Mark | European Conformity | Essential for European market compliance |

Rigorous testing protocols ensure that certified Waterproof LED Flood Light products genuinely withstand the conditions they claim to handle. Independent testing laboratories subject fixtures to standardized procedures including high-pressure water jet testing, dust chamber exposure, thermal cycling, vibration resistance, and corrosion resistance evaluation. Marine certifications like RMRS require additional specialized testing that simulates years of saltwater exposure in accelerated aging chambers. These comprehensive testing regimens provide the assurance that professional-grade fixtures will deliver reliable performance throughout their rated service life, even in the most demanding maritime and industrial environments where failure isn't merely inconvenient but potentially dangerous.

Critical Features of Professional Waterproof LED Flood Lights

Advanced Sealing Technology and Gasket Systems

Professional-grade waterproof fixtures employ sophisticated multi-layer sealing systems that create redundant barriers against water intrusion. High-performance silicone gaskets with shore hardness ratings specifically engineered for compression sealing provide the primary defense at all opening interfaces. Secondary barriers include conformal coatings on circuit boards, potted driver compartments filled with waterproof compounds, and sealed cable glands that maintain integrity even under pressure differentials. The Waterproof LED Flood Light 400W incorporates these advanced sealing technologies throughout its construction, with particular attention to vulnerable areas like lens-to-housing interfaces and driver compartment access points where water intrusion most commonly occurs in lesser-quality fixtures.

Corrosion-Resistant Materials and Protective Coatings

| Material Component | Standard Grade | Marine Grade | Benefit |

|---|---|---|---|

| Housing | Aluminum | Marine-grade aluminum alloy | 300% longer corrosion resistance |

| Coating | Powder coating | Specialized marine coating | Salt fog test exceeds 1000 hours |

| Fasteners | Stainless steel 304 | Stainless steel 316 | Superior pitting resistance |

| Lens | Tempered glass | Impact-resistant polycarbonate | 10x impact strength |

Material selection fundamentally determines long-term reliability in marine environments where ordinary metals rapidly deteriorate. Premium Waterproof LED Flood Light systems utilize specialized aluminum alloys that resist galvanic corrosion when exposed to saltwater, combined with advanced powder coating processes that create molecular bonds significantly stronger than standard paint finishes. All exposed fasteners employ marine-grade stainless steel rather than ordinary stainless varieties that quickly pit and rust in coastal installations. The lens materials must balance optical clarity with impact resistance and UV stability, as inferior materials yellow and crack within months of continuous sun and salt exposure.

Thermal Management in Sealed Enclosures

Effective heat dissipation presents unique challenges in waterproof fixtures where sealed enclosures trap thermal energy that would normally dissipate through ventilation. Advanced aluminum heat sink designs with optimized fin geometry maximize surface area for passive cooling while maintaining waterproof integrity. High-performance thermal interface materials ensure efficient heat transfer from LED arrays to heat sink structures, preventing hotspot formation that accelerates LED degradation. The Waterproof LED Flood Light 400W achieves 130 lumens per watt efficiency partly through superior thermal engineering that maintains junction temperatures well below damaging thresholds even during continuous high-power operation in ambient temperatures reaching 60°C, ensuring the rated 50,000-hour lifespan translates to actual field performance.

Driver Protection and Power Supply Integration

The LED driver represents the most vulnerable component in waterproof fixtures, as electronic circuitry naturally attracts moisture and suffers rapid degradation when exposed to humidity. Professional designs isolate drivers in separately sealed compartments with additional gaskets and desiccant materials that absorb any trace moisture that penetrates primary seals. Premium Mean Well power supplies specified in quality Waterproof LED Flood Light 400W systems incorporate conformal coating on circuit boards and potted construction that encapsulates components in waterproof compounds. Wide input voltage ranges from AC 90-305V eliminate sensitivity to power quality issues common in remote marine installations, while built-in surge protection guards against lightning-induced voltage spikes that frequently destroy unprotected electronics in coastal environments.

Real-World Applications and Performance Considerations

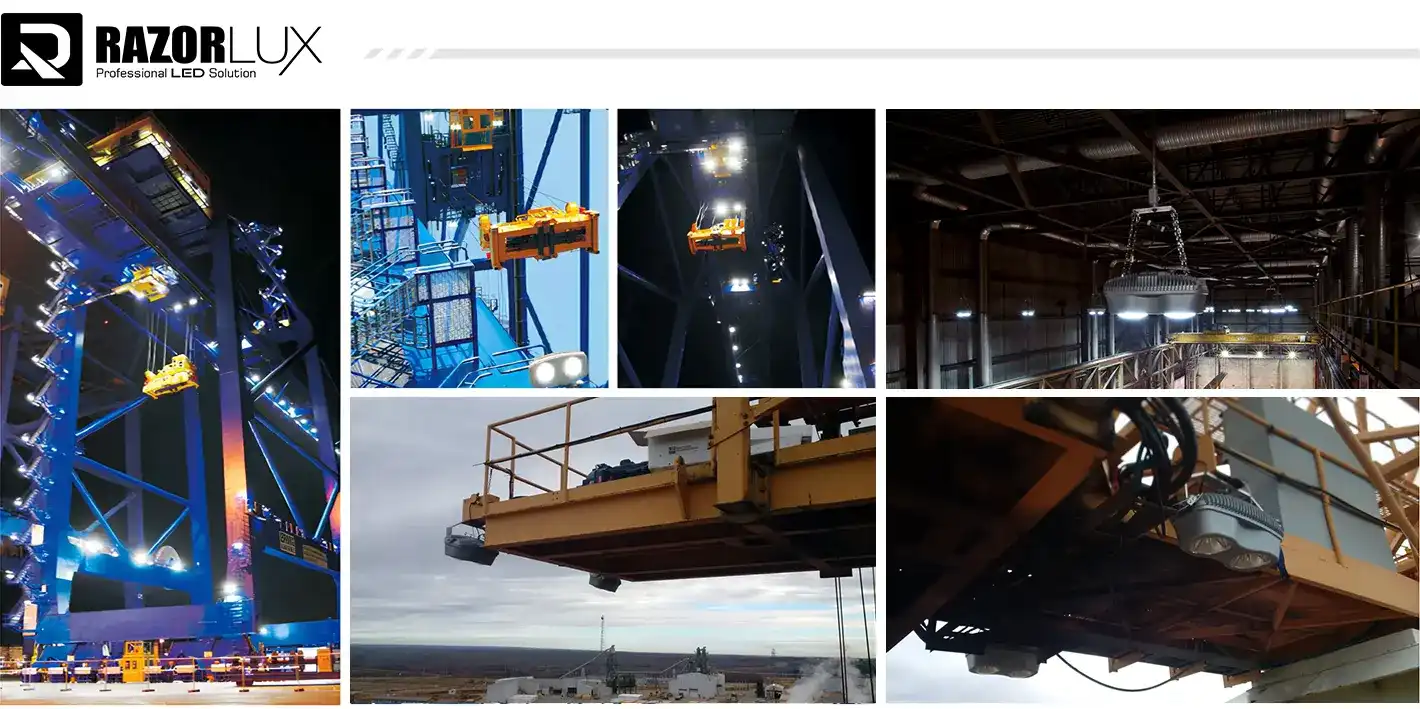

Shipyard and Dry Dock Lighting Requirements

Shipyard environments present extreme lighting challenges combining heavy machinery operation, continuous water exposure from pressure washing and rainfall, and safety-critical visibility requirements during vessel construction and repair operations. Waterproof LED Flood Light installations must provide uniform illumination across vast work areas while withstanding direct water impact from cleaning operations, falling debris from overhead work, and corrosive paint overspray. The 400W output delivers sufficient intensity for detailed inspection work even at mounting heights of 15-20 meters typical in large dry dock facilities, while the 15° to 140° beam angle options enable precise lighting design that eliminates dangerous shadows where accidents commonly occur during critical lifting and welding operations.

Offshore Platform and Marine Vessel Applications

Offshore oil and gas platforms operate in arguably the harshest environment for electrical equipment, facing constant salt spray, high winds, temperature extremes, and complete submersion during severe weather events. Marine-certified Waterproof LED Flood Light systems must maintain operational integrity despite these conditions while providing reliable illumination for safety-critical operations that continue regardless of weather. The stainless steel mounting brackets and IP67-rated construction ensure fixtures remain securely attached and fully functional even when waves wash completely over platform decks. Emergency power integration capabilities enable lights to continue operating for two hours during power failures, a crucial safety feature when evacuations or emergency procedures require reliable visibility during the most dangerous conditions.

Port Terminal and Container Yard Installations

Modern container terminals operate 24/7 with efficiency demands requiring precise visibility for crane operators, terminal workers, and security personnel across expansive yards often spanning hundreds of acres. High-mast Waterproof LED Flood Light 400W installations provide the intense, uniform illumination necessary for accurate container positioning and safe equipment operation while withstanding constant exposure to coastal weather, salt air, and occasional direct water contact from rain and sea spray. The 130-lumen-per-watt efficiency dramatically reduces energy costs compared to traditional metal halide systems, with typical payback periods under three years when factoring in energy savings plus virtually eliminated maintenance costs from the 50,000-hour rated life that translates to over 11 years of continuous operation before replacement becomes necessary.

Industrial Facility and Heavy Manufacturing Environments

Heavy industrial facilities including steel mills, chemical processing plants, and manufacturing operations require lighting solutions that withstand not just weather but also harsh industrial conditions including vibration, chemical exposure, and extreme temperature variations. The Waterproof LED Flood Light 400W construction withstands operating temperatures from -40°C to +60°C while maintaining full light output, unlike metal halide and high-pressure sodium fixtures that lose significant output in cold conditions and require extended warm-up periods. The instant-on capability eliminates dangerous dark periods when power interruptions occur, immediately restoring full visibility crucial for worker safety around moving machinery and hazardous materials. Multiple mounting configurations and beam angle options enable customized solutions for specific industrial applications from overhead crane illumination to loading dock work areas.

Selecting the Right Waterproof LED Solution for Your Application

Power Output and Lumen Requirements Analysis

Determining appropriate lighting levels requires careful analysis of mounting heights, work area dimensions, task requirements, and ambient light conditions that affect visibility. General industrial and marine applications typically require maintained illuminance levels between 150-300 lux for safe operations, with critical inspection and precision work areas needing 500-1000 lux. A single Waterproof LED Flood Light 400W fixture producing 48,000 lumens can effectively illuminate approximately 400-600 square meters when mounted at heights of 10-15 meters, though precise coverage depends on beam angle selection and whether uniform illumination or targeted highlighting is required. Professional lighting designers utilize photometric software that models exact light distribution patterns based on fixture specifications, mounting configurations, and reflectance characteristics of work surfaces.

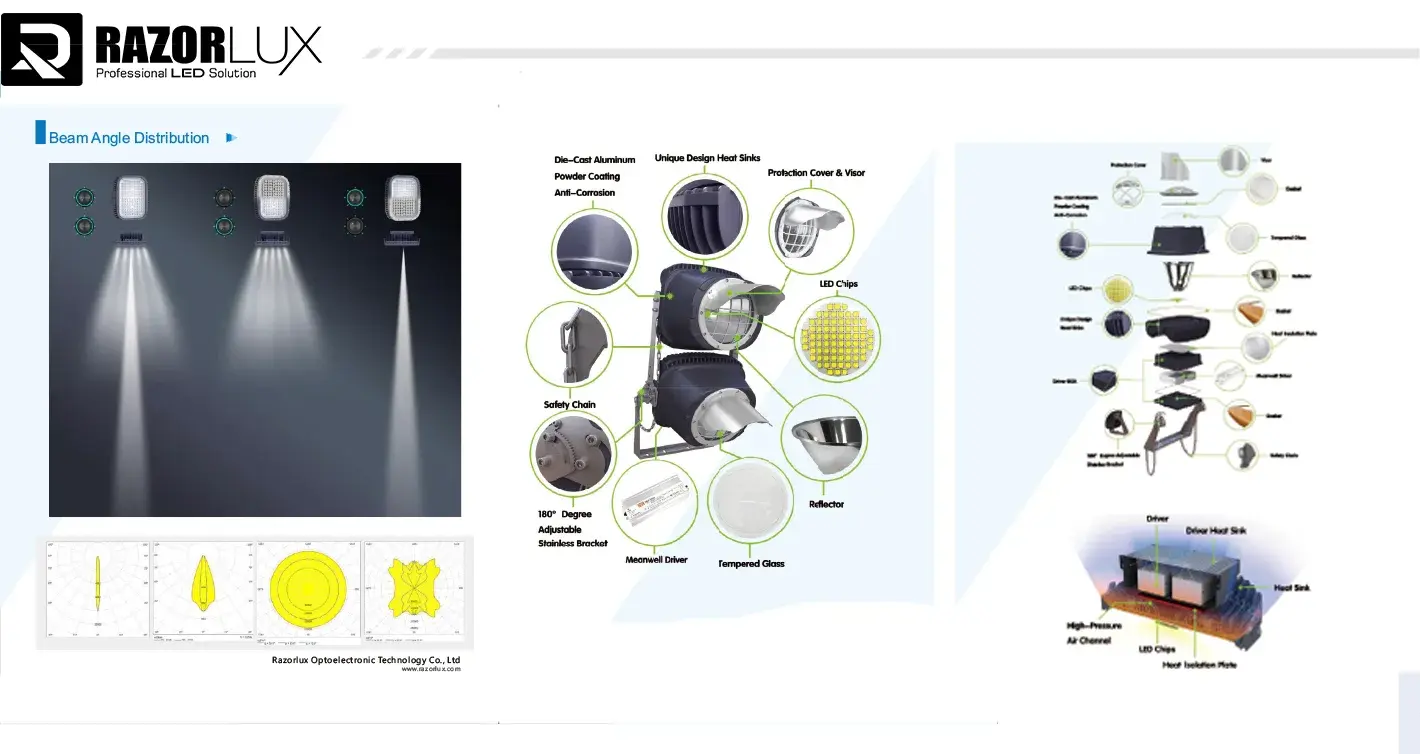

Beam Angle Selection for Optimal Coverage

| Beam Angle | Coverage Pattern | Best Applications | Mounting Height |

|---|---|---|---|

| 15°-20° | Narrow spot | Long-distance illumination, security | 20-30 meters |

| 30°-40° | Medium flood | General area lighting, platforms | 15-20 meters |

| 60°-120° | Wide flood | Large area coverage, warehouses | 8-15 meters |

| 140°x60° | Asymmetric | Building facades, dock lighting | Variable |

Beam angle dramatically affects both coverage area and light intensity at working surfaces, making appropriate selection critical for achieving required illuminance levels. Narrow beam Waterproof LED Flood Light configurations concentrate luminous output into smaller areas, delivering high-intensity illumination ideal for security applications or illuminating specific work zones from considerable distances. Wide-angle beams distribute light more broadly, requiring more fixtures but providing uniform illumination preferred for general area lighting. Professional marine and industrial installations often combine multiple beam angles strategically positioned to eliminate shadows while minimizing fixture counts, balancing initial installation costs against long-term energy consumption and maintenance considerations.

Color Temperature and Color Rendering Considerations

Color temperature selection influences both visibility and worker comfort, with cooler temperatures around 5000-6500K providing crisp, daylight-like visibility preferred for detailed inspection work and precision operations. Warmer temperatures near 3000-4000K create more comfortable environments for general work areas while reducing light pollution in environmentally sensitive coastal locations. The Waterproof LED Flood Light 400W offers adjustable color temperature options from 2700K to 6500K, enabling customization for specific applications without requiring different fixture models. Color rendering index (CRI) above 75 ensures accurate color perception critical for quality control, equipment maintenance, and safety applications where color-coded systems identify hazards, though CRI 80+ or 90+ options are available when color accuracy becomes paramount for specialized industrial processes or marine vessel navigation lighting applications.

Long-Term Total Cost of Ownership Evaluation

While professional-grade Waterproof LED Flood Light systems command higher initial purchase prices than consumer-grade alternatives, comprehensive lifecycle cost analysis consistently demonstrates superior value through dramatically reduced operating expenses. Energy consumption represents the largest operational cost component, with 130-lumen-per-watt LED efficiency delivering identical illumination for approximately 60% less energy than metal halide fixtures and 75% less than high-pressure sodium systems. Maintenance costs essentially disappear over the 50,000-hour rated life, eliminating dangerous and expensive fixture relamping operations that require scaffolding, confined space entry, or aerial lifts in marine and industrial installations. The combination of energy savings, eliminated maintenance labor, and avoided production disruptions typically generates return on investment within 24-36 months, after which installations realize pure savings for the remaining 8+ years of the system's operational life.

Conclusion

Waterproof LED lighting technology has fundamentally transformed marine and industrial illumination, delivering unprecedented reliability in harsh environments where traditional lighting consistently failed. Understanding IP ratings, marine-grade construction, and application-specific requirements enables informed decisions that protect operations and personnel while optimizing long-term value through reduced energy consumption and virtually eliminated maintenance.

Ready to upgrade your facility with professional-grade waterproof lighting solutions? Xi'an Razorlux Optoelectronic Technology Co., Ltd. brings over 25 years of LED innovation to your most demanding applications, backed by 200+ patents and certifications including RMRS, UL, and CE compliance. As a leading China Waterproof LED Flood Light manufacturer, China Waterproof LED Flood Light supplier, and trusted China Waterproof LED Flood Light factory, we offer comprehensive China Waterproof LED Flood Light wholesale programs with competitive Waterproof LED Flood Light price structures. Explore our complete Waterproof LED Flood Light for sale catalog featuring the proven 400W model with IP67 protection, 5-year warranty, and global shipping options. Contact our technical team today at sam@razorlux.com for customized lighting solutions, free consultation, and sample availability—let's illuminate your success together!

References

1. International Electrotechnical Commission. "IEC 60529: Degrees of Protection Provided by Enclosures (IP Code)." IEC Standards Publication, 2013.

2. Marine Equipment Trade Association. "Design and Performance Standards for Marine Electrical Equipment in Harsh Environments." Maritime Safety Guidelines, 2022.

3. U.S. Department of Energy. "LED Lighting Performance in Extreme Environments: Testing Protocols and Long-Term Reliability Assessment." Energy Efficiency Research Report, 2023.

4. International Maritime Organization. "Guidelines on Marine Lighting Systems and Waterproof Certification Requirements for Commercial Vessels." IMO Maritime Safety Committee, 2021.

VIEW MOREindustrial workshop led lights

VIEW MOREindustrial workshop led lights VIEW MORElarge warehouse lights

VIEW MORElarge warehouse lights VIEW MOREcricket stadium flood light

VIEW MOREcricket stadium flood light VIEW MOREflood light for basketball court

VIEW MOREflood light for basketball court VIEW MOREtennis court flood lights

VIEW MOREtennis court flood lights VIEW MOREOutdoor Ground Flood Lights

VIEW MOREOutdoor Ground Flood Lights VIEW MORESports Venue 120000lm Led Sports Light 347 Vac Basketball Court Lights

VIEW MORESports Venue 120000lm Led Sports Light 347 Vac Basketball Court Lights VIEW MORELed High Mast Luminaire

VIEW MORELed High Mast Luminaire

_1750326878398.png)