What Makes a Waterproof Floodlight the Best Choice for Outdoors?

Picture this: you're overseeing critical nighttime operations at your industrial facility when suddenly, your lighting system fails due to unexpected rainfall. Equipment sits idle, safety risks multiply, and productivity grinds to a halt. This scenario plays out daily across facilities worldwide that rely on inadequate outdoor lighting solutions. The answer lies in understanding what makes a Waterproof Floodlight not just a good choice, but the best choice for demanding outdoor environments. A Waterproof Floodlight provides reliable, high-intensity illumination that withstands rain, dust, extreme temperatures, and harsh weather conditions, ensuring uninterrupted operations, enhanced safety, and long-term cost savings for industrial, marine, and outdoor applications. This comprehensive guide explores the critical features, technical specifications, and proven benefits that establish waterproof floodlights as the industry standard for outdoor lighting excellence.

Why Waterproof Floodlights Outperform Traditional Outdoor Lighting Solutions?

When selecting lighting for outdoor applications, the decision between standard fixtures and specialized Waterproof Floodlight systems can determine whether your facility operates smoothly or faces costly disruptions. Understanding the fundamental advantages of waterproof technology reveals why industry leaders consistently choose these robust solutions for their most demanding environments.

Superior Weather Resistance Through Advanced IP Rating Standards

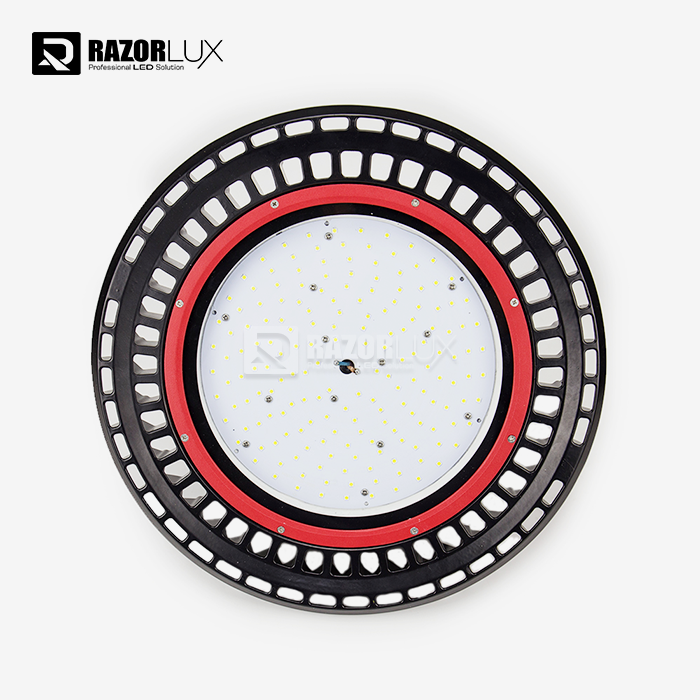

The hallmark of any quality Waterproof Floodlight lies in its Ingress Protection rating, commonly known as IP rating. This international standard measures a fixture's ability to resist solid particles and liquid penetration. Professional-grade waterproof floodlights feature IP65, IP66, or IP67 ratings, with each level offering progressively greater protection. An IP65-rated Waterproof Floodlight provides complete dust protection and withstands low-pressure water jets from any direction, making it suitable for most outdoor applications including parking lots, building facades, and general industrial use. IP67-rated units take protection further by allowing temporary submersion in water up to one meter deep, essential for flood-prone areas, coastal installations, and marine environments. The Razorlux RGL2-1000P model exemplifies this protection standard with its IP67 certification, ensuring reliable operation in shipyards, offshore platforms, and heavy industrial facilities where moisture exposure is constant. The sealed aluminum housing with powder coating creates multiple barriers against water ingress, while specialized gaskets and O-rings at every junction point prevent moisture from reaching sensitive internal components. This engineering approach extends far beyond simple water resistance, it creates a hermetically sealed environment that maintains optimal performance regardless of external weather conditions.

Extended Operational Lifespan in Harsh Environmental Conditions

Durability represents another compelling advantage of Waterproof Floodlight technology over conventional outdoor fixtures. Standard lighting systems exposed to outdoor elements typically fail within 5,000 to 10,000 hours of operation due to moisture infiltration, corrosion, and thermal stress. Professional waterproof floodlights engineered with marine-grade materials and advanced thermal management systems routinely exceed 50,000 operational hours. The RGL2-1000P Waterproof Floodlight achieves this remarkable longevity through several integrated design features including aluminum housing with specialized powder coating that resists corrosion from salt spray and industrial chemicals, advanced heat dissipation architecture that maintains optimal LED junction temperatures below 85 degrees Celsius, premium Samsung LED chips that maintain 90 percent lumen output after 30,000 hours, and Meanwell power supplies rated for 100,000-hour mean time between failures. This extended lifespan translates directly into reduced total cost of ownership. Facilities using Razorlux waterproof floodlights report maintenance intervals five to seven times longer than previous lighting systems, with corresponding reductions in replacement parts inventory, maintenance labor costs, and operational disruptions. The five-year warranty on LED modules and drivers, plus ten-year warranty on housing components, provides additional assurance of long-term reliability. For operations running 24/7, such as port terminals and offshore platforms, this extended operational life becomes absolutely critical for maintaining continuous productivity.

Energy Efficiency That Transforms Operating Economics

The economic case for Waterproof Floodlight adoption becomes undeniable when examining energy consumption patterns. Traditional metal halide and high-pressure sodium fixtures commonly used in outdoor industrial applications consume 2,200 to 2,500 watts to produce illumination levels comparable to modern LED waterproof floodlights. The Razorlux RGL2-1000P Waterproof Floodlight achieves equivalent or superior brightness using only 1,000 watts total power consumption, representing a 55 to 60 percent reduction in energy usage. This efficiency gain stems from LED technology's fundamental advantages in converting electrical energy directly into visible light with minimal heat waste. The 130 lumens per watt efficiency rating of Razorlux waterproof floodlights far exceeds the 60-80 lumens per watt typical of metal halide systems. For a facility operating 100 floodlights 12 hours daily, switching from 2,500-watt metal halide to 1,000-watt LED Waterproof Floodlight units generates annual energy savings exceeding 547,500 kilowatt-hours. At industrial electricity rates averaging 0.12 dollars per kilowatt-hour, this translates to 65,700 dollars in annual savings. The payback period for premium Waterproof Led Floodlights typically ranges from 18 to 30 months, after which all savings flow directly to operational budgets. Beyond direct energy costs, reduced power consumption lowers cooling requirements, extends transformer life, and may qualify facilities for utility rebate programs and green building certifications.

Technical Specifications That Define Waterproof Floodlight Performance

Selecting the optimal Waterproof Floodlight for your application requires understanding key technical specifications and how they impact real-world performance. Professional procurement teams evaluate multiple parameters to ensure lighting systems meet both immediate needs and long-term operational requirements.

Illumination Output and Distribution Characteristics

| Specification | Standard Range | Razorlux RGL2-1000P | Impact on Performance |

|---|---|---|---|

| Luminous Output | 80,000-150,000 lumens | 120,000 lumens | Determines coverage area and visibility levels |

| Luminous Efficacy | 100-140 lm/W | 130 lm/W | Affects energy consumption and operating costs |

| Beam Angle Options | 15°-120° | 15°, 20°, 30° | Controls light distribution pattern |

| Color Temperature | 2700K-6500K | 2700K-6500K adjustable | Influences visibility and color rendering |

| Color Rendering Index | Ra>70 | Ra>75 (Ra>90 available) | Determines color accuracy under illumination |

The lumen output of a Waterproof Floodlight directly determines its effective coverage area and whether it can adequately illuminate your intended space. The 120,000-lumen output of the RGL2-1000P model provides exceptional brightness suitable for large-scale applications including container terminals where cranes operate 24/7, offshore oil platforms requiring clear visibility across extensive deck areas, shipyards conducting precision welding and assembly operations, and mining facilities with large open pit or processing areas. Beam angle selection proves equally critical for optimizing light distribution. Narrow 15-degree beams concentrate illumination over long distances, ideal for tower-mounted fixtures illuminating distant work areas or creating focused spotlighting effects. Medium 20-degree beams balance throw distance with area coverage, suitable for general purpose outdoor lighting at moderate mounting heights. Wide 30-degree beams provide broad area coverage from lower mounting positions, perfect for loading docks, parking areas, and general facility illumination. Color temperature choice impacts both visibility and worker comfort. The 5700K cool white specification common in industrial Waterproof Floodlight applications provides crisp, bright illumination that enhances detail visibility and promotes alertness during night shifts. Warmer 3000K-4000K options create more comfortable environments for public spaces and residential applications. The high color rendering index above Ra75 ensures that colors appear natural and accurate, critical for quality control operations, safety signage visibility, and video surveillance systems.

Power Supply and Electrical Integration Features

Modern Waterproof Floodlight systems incorporate sophisticated power management technologies that simplify installation and enhance reliability. The wide input voltage range of 80-315VAC eliminates the need for additional voltage adaptation equipment, allowing direct connection to diverse electrical systems worldwide. This flexibility proves invaluable for international projects and facilities with non-standard voltage specifications. The power factor greater than 0.98 ensures efficient energy utilization while minimizing harmonic distortion on electrical distribution systems. High power factor reduces current draw for a given wattage, lowering conductor heating and allowing more fixtures per circuit. Facilities with power quality sensitive equipment particularly benefit from this characteristic. Advanced Waterproof Floodlight designs also incorporate active power factor correction and electromagnetic interference suppression to meet strict electrical codes. The Meanwell driver technology used in Razorlux systems provides multiple layers of electrical protection including surge protection up to 10 kilovolts, over-voltage lockout preventing damage from electrical spikes, short-circuit protection ensuring safe fault handling, and thermal protection preventing driver damage from excessive heat. These protective features extend equipment life while ensuring personnel safety during installation and maintenance. The emergency power function available in select Razorlux Waterproof Floodlight models adds another dimension of reliability by providing two hours of battery-backed operation during power outages. This capability proves essential for maintaining safety lighting in critical areas, enabling controlled shutdown procedures during power failures, and supporting emergency response operations when grid power is unavailable.

Structural Durability and Installation Versatility

| Component | Material/Specification | Benefit |

|---|---|---|

| Housing | Marine-grade aluminum with powder coating | Corrosion resistance, heat dissipation, structural integrity |

| Mounting Bracket | 316 stainless steel | Salt water resistance, long-term stability |

| Optical Lens | Tempered glass with UV stabilization | Impact resistance, optical clarity retention |

| Sealing System | Silicone gaskets with multiple redundancy | Moisture barrier, pressure equalization |

| Net Weight | 38 kg complete with bracket | Indicates robust construction quality |

The structural design of a Waterproof Floodlight determines its ability to withstand both environmental stresses and mechanical impacts common in industrial settings. The 38-kilogram weight of the RGL2-1000P reflects its robust construction using thick-gauge aluminum housings and substantial mounting hardware. This mass provides stability against wind loading and vibration while indicating the substantial heat sink capacity necessary for passively cooling high-power LED arrays. The marine-grade aluminum housing with specialized powder coating creates a corrosion barrier capable of withstanding continuous salt spray exposure, chemical mist from industrial processes, and UV radiation degradation. This protection extends the fixture's cosmetic appearance while maintaining the structural integrity of heat dissipation fins and mounting points. The tempered glass lens provides impact resistance rated to IK10, the highest level on the International Electrotechnical Commission scale, capable of withstanding 20 joules impact energy equivalent to dropping a five-kilogram mass from 400 millimeters. This durability proves essential in environments where falling tools, flying debris, or accidental contact could damage standard fixtures. Stainless steel mounting brackets manufactured from 316-grade material provide superior corrosion resistance compared to standard 304-grade stainless steel, particularly important in coastal environments where chloride exposure rapidly degrades lesser materials. The adjustable mounting system allows precise aiming of the Waterproof Floodlight beam while maintaining secure positioning against wind loads and structural vibration.

Applications Where Waterproof Floodlights Deliver Maximum Value

The versatility of professional-grade Waterproof Floodlight systems extends across diverse industries and applications, each benefiting from the unique combination of weatherproofing, high output, and reliability that these specialized fixtures provide.

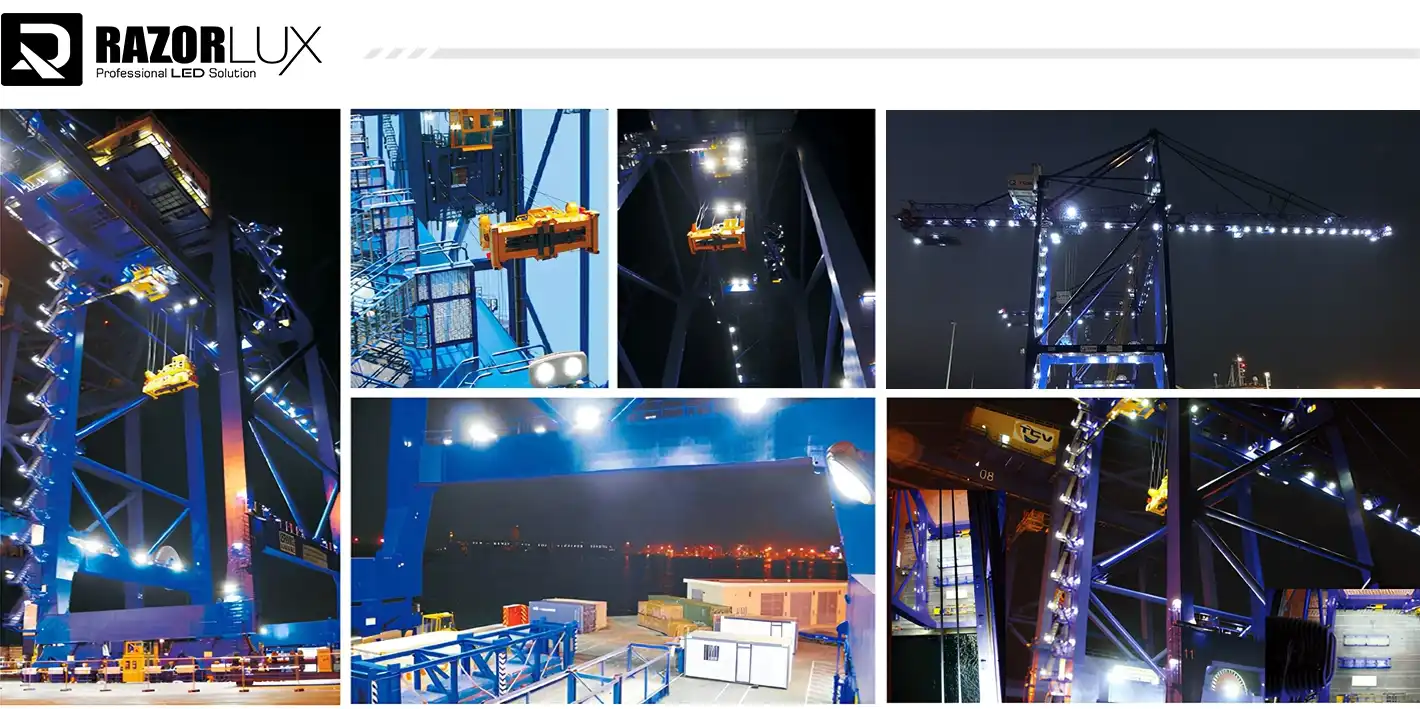

Maritime and Offshore Industrial Installations

Maritime environments present the most demanding conditions for outdoor lighting equipment, with constant salt spray exposure, high humidity, temperature fluctuations, and mechanical vibration creating a perfect storm of destructive forces. Waterproof Floodlight systems designed specifically for these applications incorporate enhanced corrosion protection and structural reinforcement. Shipyards and dry dock facilities utilize high-power Waterproof Floodlight arrays to maintain continuous operations during night shifts. The RGL2-1000P units mounted on gantry cranes, building structures, and temporary towers provide uniform illumination across work areas where welding, cutting, painting, and assembly operations proceed around the clock. The 120,000-lumen output ensures adequate task lighting at distances up to 50 meters, while the IP67 rating protects electronics from deck washing operations and weather exposure. Offshore oil and gas platforms depend on reliable Waterproof Floodlight systems for operational safety in environments where equipment failure could have catastrophic consequences. These facilities typically deploy hundreds of fixtures across drilling decks, heliports, loading areas, and accommodation modules. The wide input voltage range and surge protection features of professional waterproof floodlights accommodate the variable power quality common on platforms with multiple generator sources, while the extended operational life minimizes the logistical complexity and expense of offshore maintenance operations. Container ports and terminal facilities present unique lighting challenges combining large area coverage requirements with critical safety needs. Modern Waterproof Floodlight installations at major ports utilize computer-controlled aiming systems with narrow beam fixtures mounted on tall masts to illuminate specific crane operating zones, reducing light spillage and energy consumption. The instant-on capability of LED technology eliminates the warm-up time required by traditional high-intensity discharge lamps, enabling responsive control systems that activate lighting only where and when needed.

Heavy Industrial Manufacturing and Processing Facilities

Steel mills, foundries, cement plants, chemical processing facilities, and other heavy industries share common requirements for robust, reliable, high-output lighting capable of operating in harsh environmental conditions. Temperature extremes pose particular challenges in these settings. The -40°C to +60°C operating temperature range of the RGL2-1000P Waterproof Floodlight enables reliable performance in facilities where extreme cold from outdoor winter conditions contrasts with radiant heat from furnaces, kilns, and other thermal processes. The aluminum housing's thermal management capacity maintains LED junction temperatures within optimal ranges across this wide ambient temperature spectrum. Dust and particulate exposure in cement plants, mining operations, and material handling facilities necessitates the complete dust protection provided by IP6X-rated Waterproof Floodlight enclosures. The sealed housing prevents fine particulates from infiltrating and coating internal optical surfaces, which would progressively reduce light output and eventually cause premature failure. Regular external cleaning maintains optimal performance without requiring fixture disassembly. Chemical resistance becomes critical in processing facilities where airborne vapors and occasional splashing expose lighting equipment to corrosive substances. The specialized powder coating on Razorlux waterproof floodlights provides chemical resistance beyond standard anodizing or painting, maintaining both cosmetic appearance and structural integrity in aggressive atmospheres. Facilities processing acids, caustics, solvents, and other reactive chemicals report five to ten-year service life from properly specified Waterproof Floodlight installations. The high color rendering index specification proves particularly valuable in manufacturing environments requiring accurate color perception for quality control, process monitoring, and safety compliance. Operators inspecting painted surfaces, monitoring chemical reactions indicated by color changes, or identifying components by color coding all benefit from the Ra>75 color rendering provided by quality waterproof floodlights.

Infrastructure Projects and Public Utility Applications

Bridge construction and maintenance operations frequently occur during nighttime hours to minimize traffic disruption, requiring temporary Waterproof Floodlight installations capable of illuminating work zones while withstanding exposure to vehicle traffic, weather, and mechanical abuse. The robust construction and flexible mounting options of professional waterproof floodlights make them ideal for these demanding temporary installations. Utility companies maintain extensive outdoor switchyard and substation facilities requiring reliable lighting for routine operations, emergency response, and security monitoring. The surge protection features of quality Waterproof Floodlight systems become particularly important in these high-voltage environments where electrical transients are common. The extended maintenance intervals reduce the frequency of work in potentially dangerous areas, improving personnel safety while reducing operational costs. Municipal water and wastewater treatment facilities combine outdoor exposure with corrosive atmospheres from chemical treatment processes and biological activity. Waterproof Floodlight systems specified with enhanced chemical resistance provide reliable illumination across tank farms, clarifier basins, pump stations, and control buildings. The emergency backup power capability allows critical area lighting to remain operational during grid outages, supporting continued operations and ensuring personnel safety during facility evacuation. Transportation infrastructure including rail yards, bus depots, and logistics centers require extensive outdoor lighting to support 24/7 operations while meeting strict light trespass and glare control requirements. Modern Waterproof Floodlight installations utilize computer-controlled aiming and intensity management to provide adequate task lighting while minimizing environmental impact. The precise beam control available with narrow-angle optics concentrates light exactly where needed, reducing wasted illumination and associated energy costs.

Conclusion

Selecting the right outdoor lighting solution determines whether your facility operates efficiently or struggles with frequent failures and safety concerns. Waterproof Floodlight technology offers superior weather resistance through IP67 protection, extended 50,000-hour operational life, and 55-60 percent energy savings compared to traditional systems, making it the definitive choice for demanding industrial, marine, and infrastructure applications.

Ready to transform your outdoor lighting with industrial-grade reliability? As a leading China Waterproof Floodlight manufacturer, Xi'an Razorlux Optoelectronic Technology delivers proven solutions backed by 20+ years of LED expertise and over 200 patents. Our China Waterproof Floodlight factory produces certified fixtures meeting UL, RMRS, CE, and RoHS standards, with comprehensive 5-year warranties ensuring long-term performance. Whether you need a trusted China Waterproof Floodlight supplier for maritime projects or a China Waterproof Floodlight wholesale partner for large-scale installations, Razorlux provides customized solutions, rapid global delivery, and responsive technical support. Explore our complete Waterproof Floodlight for sale range at competitive Waterproof Floodlight price points. Contact our team today at sam@razorlux.com to discuss your specific requirements and receive detailed specifications tailored to your application.

References

1. Illuminating Engineering Society, "Recommended Practice for Outdoor Environment Lighting," IES RP-33-14, Lighting Design and Application Journal, 2014.

2. International Electrotechnical Commission, "Degrees of Protection Provided by Enclosures (IP Code)," IEC 60529 Standard, Technical Documentation Series, 2013.

3. U.S. Department of Energy, "LED Lighting for Industrial Facilities: Assessment and Recommendations," Energy Efficiency and Renewable Energy Office, Industrial Technologies Program, 2015.

4. Society of Naval Architects and Marine Engineers, "Marine Electrical Systems and Lighting Standards for Commercial Vessels," SNAME Technical Research Bulletin, Maritime Engineering Division, 2016.

5. National Institute of Standards and Technology, "Life-Cycle Assessment of Energy and Environmental Impacts of LED Lighting Products," NIST Technical Note 1887, Building and Fire Research Laboratory, 2015.

_1750326878398.png)