Why OEM led loading lights Matter for Fleet Reliability?

Fleet managers know the sinking feeling when cargo operations grind to a halt because of inadequate lighting during night shifts or poor weather conditions. Every minute of downtime at the loading dock translates directly into lost revenue and frustrated customers. OEM led loading lights solve this critical challenge by providing consistent, reliable illumination that keeps your fleet operations running smoothly regardless of environmental conditions, ultimately reducing maintenance costs while improving workplace safety and operational efficiency.

How LED Loading Lights Enhance Fleet Operational Efficiency?

Reduced Maintenance Downtime Through Superior Durability

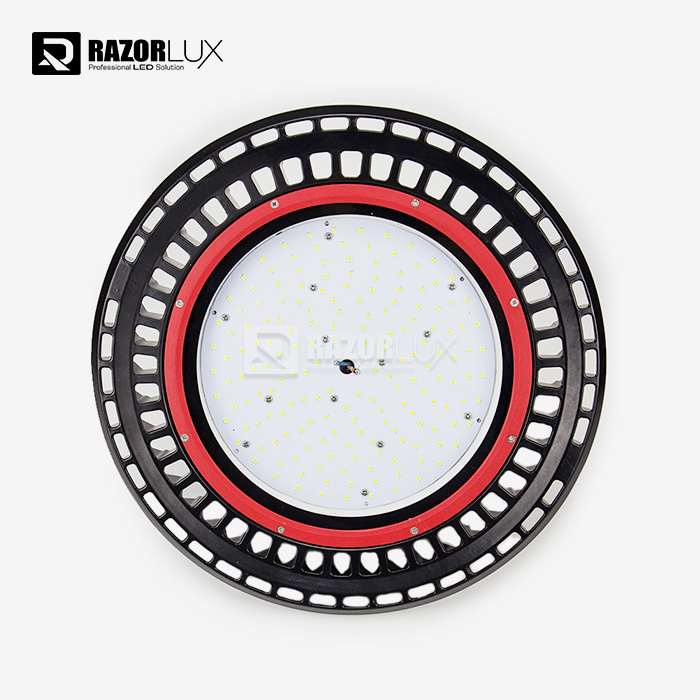

Fleet reliability begins with components that don't fail when you need them most. Traditional incandescent lighting systems create constant maintenance headaches for fleet managers, requiring frequent bulb replacements that pull vehicles out of service and drain maintenance budgets. OEM led loading lights eliminate these costly interruptions through solid-state technology that operates without fragile filaments susceptible to road vibration and shock. The patented multi-function design incorporates Samsung or Phillip LED chips paired with Meanwell drivers, creating a lighting system engineered specifically for the demanding conditions fleet vehicles encounter daily. With an IP67 rating and IK10 impact resistance, these led loading lights withstand extreme temperatures from -40°F to 140°F while maintaining consistent performance through rain, snow, dust, and corrosive environments that would quickly destroy conventional lighting solutions.

Enhanced Energy Efficiency Lowers Operating Costs

The financial impact of switching to OEM led loading lights extends far beyond reduced maintenance expenses. Operating at 130LM/W efficiency, modern LED technology converts electrical energy into usable light with minimal waste heat generation, dramatically reducing the power draw on fleet vehicle electrical systems. This efficiency becomes particularly valuable for fleets operating refrigerated units or vehicles with multiple electrical accessories competing for available power. The 120W rated power of professional-grade led loading lights delivers 21,600 lumens of illumination while consuming significantly less energy than equivalent halogen or HID alternatives. Fleet managers implementing widespread LED adoption report measurable reductions in fuel consumption, as reduced electrical load translates directly into decreased alternator demand and improved overall vehicle efficiency across their entire operation.

Consistent Illumination Improves Loading Safety and Productivity

Workplace safety statistics consistently demonstrate that proper illumination reduces accidents during loading and unloading operations. OEM led loading lights provide uniform, flicker-free illumination across the entire work area, eliminating the shadows and dark spots that create hazardous conditions for dock workers and equipment operators. Multiple beam angle options ranging from 15° to 140°x60° allow precise light distribution tailored to specific dock configurations and operational requirements. The color temperature range of 2700K-6500K ensures optimal visibility for different tasks, from close inspection work requiring warmer tones to broad area coverage benefiting from cooler, daylight-equivalent illumination. This consistent lighting quality enables faster, safer cargo handling operations that directly impact your fleet's productivity metrics and delivery schedules.

| Performance Specification | Value | Operational Benefit |

|---|---|---|

| Lamp Efficiency | 130LM/W | Maximum light output per watt reduces energy costs |

| IP Protection Rating | IP67 | Complete dust protection and water immersion resistance |

| Working Temperature Range | -40°F to 140°F | Reliable operation in extreme climates |

| CRI (Color Rendering Index) | Ra>75 | Accurate color perception improves safety |

| Warranty Period | 5 Years | Long-term reliability reduces replacement costs |

Why OEM LED Loading Lights Outperform Aftermarket Alternatives?

Engineering Integration With Fleet Vehicle Systems

Genuine OEM led loading lights represent more than just replacement components—they embody engineering integration specifically designed for fleet vehicle electrical architectures. Aftermarket lighting solutions often create compatibility issues that manifest as electrical interference, premature component failure, or inadequate performance under real-world operating conditions. Professional OEM solutions feature advanced input voltage ranges from AC100-305V and DC127-431V, ensuring stable operation across varying electrical conditions encountered in diverse fleet applications. The stainless steel bracket construction provides corrosion-resistant mounting solutions that maintain secure installation through years of vibration and environmental exposure. This engineering approach eliminates the trial-and-error experimentation that consumes valuable maintenance time when installing generic aftermarket products that weren't designed specifically for heavy-duty fleet applications.

Certification Compliance Protects Against Operational Disruptions

Fleet vehicles operate under stringent regulatory oversight, and lighting system compliance directly impacts your ability to maintain operational schedules without interruption. OEM led loading lights carry comprehensive certifications including RMRS, CE, RoHS, SAA, C-Tick, UL, DLC, CB, and ISO:9001 approval, demonstrating compliance with international safety and performance standards. These certifications aren't merely bureaucratic paperwork—they represent rigorous testing protocols validating electromagnetic compatibility, environmental resilience, and photometric performance under standardized conditions. When roadside inspections scrutinize your fleet vehicles, certified OEM lighting systems provide documentation that protects against citations and out-of-service orders. The alternative of installing uncertified aftermarket products exposes your fleet to legal liabilities and potential insurance complications that far exceed any initial cost savings.

Warranty Coverage Ensures Long-Term Investment Protection

The financial calculus of fleet lighting decisions extends beyond initial purchase price to encompass total cost of ownership over the product lifecycle. Premium OEM led loading lights back their quality claims with comprehensive 5-year warranty coverage protecting against manufacturing defects and premature failure. This warranty represents manufacturer confidence in their engineering processes and component selection, providing fleet managers with predictable budgeting for lighting system maintenance. The warranty terms typically cover not just component replacement but technical support for installation guidance and troubleshooting assistance, resources that prove invaluable when integrating new lighting systems across diverse fleet vehicle types. Aftermarket alternatives offering minimal or no warranty protection shift financial risk entirely onto fleet operators, creating exposure to unexpected replacement costs that can quickly exceed any perceived initial savings.

| OEM Features | Aftermarket Limitations | Fleet Impact |

|---|---|---|

| Designed for specific vehicle integration | Generic one-size-fits-all approach | Reduced installation complications |

| Comprehensive international certifications | Limited or absent regulatory compliance | Avoids inspection failures and citations |

| 5-year manufacturer warranty | Short warranty periods or none | Predictable long-term costs |

| Technical support and documentation | Minimal customer service | Faster problem resolution |

Maximizing Fleet Reliability Through Strategic LED Loading Light Selection

Assessing Your Fleet's Specific Lighting Requirements

Strategic selection of led loading lights begins with comprehensive assessment of your fleet's operational characteristics and environmental challenges. Different fleet applications demand different lighting solutions—refrigerated transport requires fixtures that maintain performance in sub-zero temperatures, while construction fleets need impact-resistant housings that survive harsh jobsite conditions. The available power range from 90W through 1200W enables matching lighting intensity to specific work area requirements without oversizing systems that waste energy or undersizing installations that compromise visibility. Beam angle selection proves equally critical, with focused 15° and 20° options providing long-distance illumination for large loading areas, while wider 120° and 140°x60° patterns deliver broad coverage for confined spaces. Fleet managers should conduct lighting audits evaluating current fixture performance, identifying failure patterns, and measuring actual illumination levels against industry safety standards before specifying replacement systems.

Implementation Planning for Minimal Fleet Disruption

Converting your fleet to modern OEM led loading lights requires careful planning to minimize operational disruption while maximizing the benefits of upgraded lighting technology. Phased implementation strategies allow gradual conversion that spreads capital investment across budget cycles while building internal expertise with installation and maintenance procedures. Many fleet managers begin with vehicles scheduled for routine maintenance, integrating lighting upgrades into existing service appointments to eliminate dedicated downtime. The availability of customized samples enables thorough evaluation before bulk orders, allowing testing under actual operating conditions to verify performance characteristics and confirm compatibility with existing vehicle electrical systems. Technical drawings and installation guides provided with OEM products streamline the installation process, reducing labor hours and ensuring proper mounting that prevents premature failure from improper installation techniques.

Establishing Preventive Maintenance Protocols

Even the most reliable led loading lights benefit from systematic preventive maintenance that extends service life and maintains optimal performance throughout their operational lifespan. Fleet maintenance programs should incorporate regular inspection schedules examining fixture housing for damage, verifying mounting security, and confirming electrical connections remain clean and corrosion-free. The tempered glass lenses protecting LED arrays require periodic cleaning to remove accumulated road film, salt deposits, and organic debris that gradually reduces light output. While LED technology eliminates bulb replacement schedules, proactive monitoring identifies potential issues before they progress to complete failure that compromises fleet operations. Advanced fleet management systems can integrate lighting performance monitoring, tracking individual fixture hours and establishing predictive replacement schedules that prevent unexpected failures during critical operations.

Conclusion

OEM led loading lights deliver measurable improvements in fleet reliability through superior durability, energy efficiency, and consistent performance that traditional lighting solutions simply cannot match. Strategic investment in certified lighting systems reduces maintenance costs, improves workplace safety, and ensures regulatory compliance that protects your fleet operations from costly disruptions. The comprehensive warranty coverage and technical support provided by established manufacturers like Xi'an Razorlux Optoelectronic Technology Co., Ltd. creates long-term partnerships that extend beyond simple component supply to encompass ongoing consultation supporting your fleet's evolving operational requirements.

Ready to transform your fleet's lighting performance? Whether you're seeking reliable China led loading lights factory solutions, evaluating China led loading lights supplier options, or researching qualified China led loading lights manufacturer partnerships, our experienced team provides the expertise you need. Discover competitive led loading lights for sale with transparent led loading lights price structures that fit your budget. As a leading China led loading lights wholesale provider, we deliver customized solutions backed by over 200 patents and 22 years of ISO9001-certified manufacturing excellence. Contact our professional sales team today at sam@razorlux.com to discuss your specific requirements and request detailed product specifications. Bookmark this resource to reference whenever lighting challenges arise in your fleet operations—we're here to illuminate your path to operational excellence.

References

1. Gilbert, Tim. "Identifying Root Causes of Fleet Lighting Maintenance Issues." Peterson Manufacturing Heavy-Duty Fleet OEM Sales Division.

2. Hoover, John. "LED Technology Durability and Fleet Uptime Management." Truck-Lite Aftermarket and Fleet Sales Research.

3. Smith, Dustin. "Impact Resistance and Thermal Management in Commercial Vehicle LED Systems." Optronics Vice Presidential Sales Analysis.

4. Van Riper, Brad. "Solid-State LED Technology Development for Fleet Applications." Truck-Lite Chief Technology Officer Technical Report.

5. Hopkey, Travis. "Energy Efficiency and Safety Benefits of LED Lighting in Commercial Fleets." Phillips Industries Marketing Research Division.

VIEW MOREwarehouse flood lights

VIEW MOREwarehouse flood lights VIEW MOREfootball pitch floodlights

VIEW MOREfootball pitch floodlights VIEW MOREbadminton court flood lights

VIEW MOREbadminton court flood lights VIEW MOREWaterproof Marine High Intensity Led Flood Light

VIEW MOREWaterproof Marine High Intensity Led Flood Light VIEW MORECrane Light Fixture

VIEW MORECrane Light Fixture VIEW MOREEMC 6500K Led Outdoor Sports Lighting Ip67 1200w Led Baseball Field Lights

VIEW MOREEMC 6500K Led Outdoor Sports Lighting Ip67 1200w Led Baseball Field Lights VIEW MOREExternal Led Flood Lights

VIEW MOREExternal Led Flood Lights VIEW MOREOutdoor Landscape Flood Lights

VIEW MOREOutdoor Landscape Flood Lights

_1750326878398.png)