How led loading lights Improve Nighttime Loading Safety?

Picture this scenario: It's 2 AM at a busy distribution center. Truck drivers are maneuvering massive vehicles toward loading docks in near-total darkness. Workers are rushing to load cargo, unable to see clearly where trailers end and platforms begin. One misstep, one miscalculation, and serious injuries or costly damage occur. This dangerous reality haunts countless loading facilities every single night. However, professional-grade led loading lights transform these hazardous nighttime operations into safe, efficient workflows by delivering powerful, precision-targeted illumination exactly where it's needed most, protecting both personnel and valuable cargo.

Advanced LED Loading Lights Technology Delivers Superior Nighttime Visibility

Exceptional Brightness Output Eliminates Dangerous Shadows

Modern led loading lights utilize cutting-edge semiconductor technology that produces significantly brighter illumination compared to traditional lighting solutions. Professional loading dock fixtures now deliver 130 lumens per watt efficiency, creating crystal-clear visibility across entire loading platforms. This exceptional brightness eliminates dangerous shadow zones where accidents frequently occur. When workers can clearly see every detail of their environment, from trailer interiors to dock edges, accident rates drop dramatically. The superior light output ensures that even the darkest corners receive adequate illumination, allowing personnel to identify hazards instantly and respond appropriately. High-performance led loading lights maintain consistent brightness throughout their operational lifespan, unlike conventional bulbs that gradually dim over time. This reliability means your facility maintains optimal safety conditions year after year without performance degradation.

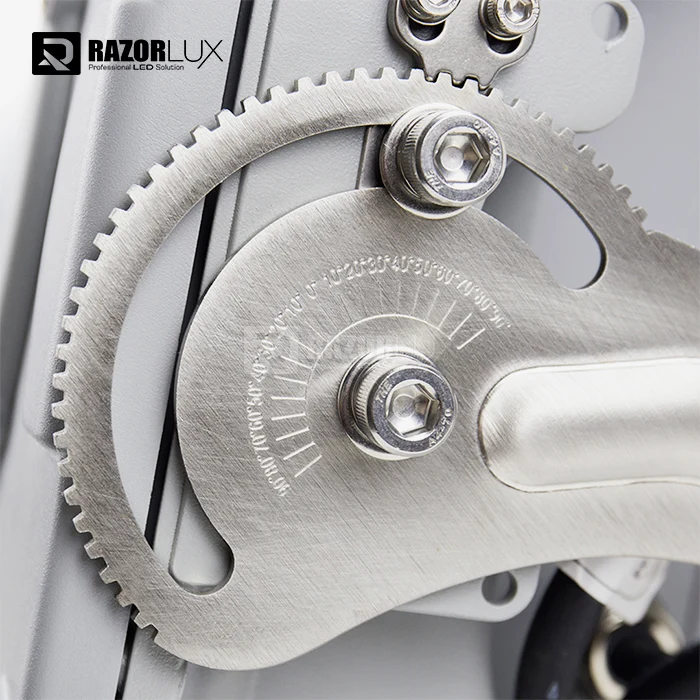

Precision Beam Angles Optimize Task-Specific Illumination

Professional led loading lights offer multiple beam angle configurations ranging from narrow 15-degree spots to wide 140x60-degree floods, enabling precise light distribution for specific operational requirements. Narrow beam patterns concentrate intense illumination deep into trailer interiors, ensuring workers can see cargo positioning clearly even in long-haul trucks. Wide beam configurations flood entire dock areas with uniform light, eliminating blind spots between adjacent loading bays. This versatility allows facilities to customize their lighting strategy based on actual workflow patterns. Mixed beam angle installations create layered illumination that addresses both close-range detail work and broad area coverage simultaneously. Strategic positioning of different beam patterns ensures optimal visibility for various tasks including cargo inspection, equipment operation, and vehicle positioning. The ability to select appropriate beam angles dramatically improves both safety and operational efficiency during nighttime loading activities.

Wide Voltage Range Ensures Stable Performance

Industrial led loading lights engineered with AC100-305V and DC127-431V input ranges maintain consistent performance despite electrical fluctuations common in busy facilities. This wide voltage tolerance protects your lighting investment from power supply variations that would damage conventional fixtures. Facilities operating multiple shifts benefit from uninterrupted illumination regardless of grid conditions during peak demand periods. The robust electrical design incorporates Meanwell drivers that regulate power delivery precisely, preventing flicker or brightness variations that cause eye strain and reduce worker alertness. Stable operation across diverse voltage conditions means your lighting performs reliably whether you're in North America, Europe, Asia, or any global location. This universal compatibility simplifies international facility standardization and reduces spare parts inventory requirements. Reliable electrical performance directly translates to enhanced safety since workers never experience sudden lighting failures during critical loading operations.

Industrial-Grade LED Loading Lights Construction Withstands Harsh Operating Environments

| Performance Feature | Specification | Safety Benefit |

|---|---|---|

| IP Protection Rating | IP67 Waterproof | Reliable operation in rain, snow, and washdown conditions |

| Operating Temperature Range | -40°C to 60°C (-40°F to 140°F) | Consistent performance in extreme climates |

| Impact Resistance | IK10 Rating | Survives accidental impacts from equipment |

| Housing Material | Marine-Grade Aluminum Alloy | Exceptional corrosion resistance and heat dissipation |

| Bracket Construction | 316 Stainless Steel | Long-term structural integrity in corrosive environments |

Military-Grade Housing Protects Critical Components

The aluminum alloy housing utilized in professional led loading lights provides exceptional thermal management that prevents overheating during extended operation periods. Efficient heat dissipation maintains optimal LED chip performance and extends fixture lifespan far beyond traditional lighting solutions. Marine-grade materials resist corrosion from moisture, salt spray, and chemical exposure common in industrial loading environments. This robust construction withstands the physical demands of busy facilities where equipment occasionally contacts lighting fixtures. The sealed housing design prevents dust infiltration that degrades internal components in conventional lights. Professional installations maintain their protective integrity year after year, ensuring consistent safety performance throughout demanding operational lifecycles. Durable construction directly supports workplace safety by eliminating unexpected lighting failures that create hazardous conditions.

IP67 Waterproofing Enables All-Weather Reliability

Professional led loading lights featuring IP67 certification operate flawlessly during rain, snow, and facility washdown procedures without water intrusion compromising electrical components. This weatherproof design proves essential for outdoor loading facilities and covered docks exposed to environmental moisture. The complete seal against dust ingress prevents particle accumulation that reduces light output and creates maintenance headaches. Facilities can maintain rigorous cleaning protocols without concern about damaging expensive lighting equipment. Waterproof construction eliminates corrosion risks that plague conventional fixtures in humid environments. The reliable performance during adverse weather conditions means your safety lighting functions precisely when visibility challenges are greatest. Workers depend on consistent illumination regardless of meteorological conditions, and professional led loading lights deliver that critical reliability.

IK10 Impact Protection Survives Accidental Collisions

Loading environments present constant collision risks from forklifts, pallets, and cargo handling equipment that can damage inadequately protected lighting fixtures. Professional led loading lights engineered to IK10 impact resistance standards survive severe mechanical impacts that would destroy conventional lights. This exceptional durability reduces maintenance costs and prevents dangerous situations caused by broken fixtures. The robust construction maintains structural integrity even when subjected to repeated vibrations from heavy machinery operation. Facilities benefit from reduced downtime since lighting equipment rarely requires emergency replacement. Impact protection directly enhances workplace safety by preventing glass fragments and electrical hazards that result from fixture damage. Investment in properly protected led loading lights pays dividends through improved safety records and reduced maintenance expenses.

Strategic LED Loading Lights Implementation Maximizes Operational Safety

Optimal Positioning Eliminates Dangerous Blind Spots

Proper led loading lights placement requires careful analysis of traffic patterns, vehicle types, and cargo handling procedures specific to each facility. Strategic fixture positioning ensures complete coverage without creating glare zones that impair driver vision during vehicle positioning. Mounting heights must balance between adequate coverage area and concentrated illumination intensity where workers perform detailed tasks. Professional installations position lights to illuminate trailer interiors effectively while simultaneously covering dock platform areas. Eliminating shadows between adjacent loading bays prevents dangerous situations where workers move equipment through poorly lit transitions. Multiple fixture configurations create overlapping coverage zones that maintain visibility even if individual units require maintenance. Thoughtful lighting design considers how illumination patterns change as trailers move into position, ensuring consistent visibility throughout vehicle maneuvering processes.

Color Temperature Selection Enhances Visual Acuity

Professional led loading lights offer color temperature options ranging from 2700K warm white to 6500K cool daylight, each providing distinct visual characteristics for specific applications. Neutral white temperatures around 4000K provide excellent color rendering that helps workers accurately identify cargo markings, damage, and safety labels during nighttime operations. The appropriate color temperature reduces eye strain during extended work periods and improves alertness compared to harsh, unbalanced lighting. Facilities can select temperatures that complement existing lighting schemes while optimizing visibility for critical safety inspections. Proper color temperature selection enhances depth perception that proves crucial when operating forklifts and positioning cargo within confined spaces. The right spectral output improves worker comfort and reduces fatigue-related errors that compromise safety. Professional color temperature choices demonstrate commitment to comprehensive workplace safety beyond simple illumination provision.

Emergency Power Integration Maintains Critical Safety Functions

Advanced led loading lights systems incorporate emergency battery backup capabilities that maintain illumination during power outages when conventional lighting fails completely. This critical safety feature ensures workers can safely evacuate loading areas and secure operations during emergency situations. Battery-backed systems provide approximately two hours of operation at reduced output levels sufficient for emergency response activities. The automatic switchover occurs instantaneously without interruption, preventing panic situations caused by sudden darkness. Emergency lighting enables continued operations during brief power interruptions common in industrial settings, minimizing costly downtime. Facilities demonstrate regulatory compliance and duty-of-care obligations through proper emergency lighting provision. Investment in battery-backup led loading lights directly supports comprehensive safety management programs by eliminating one of the most dangerous scenarios in industrial operations.

Comprehensive LED Loading Lights Performance Specifications

| Technical Parameter | Value Range | Application Impact |

|---|---|---|

| Rated Power Options | 90W - 1200W | Scalable solutions for any facility size |

| Luminous Efficacy | 130 LM/W | Maximum energy efficiency with superior output |

| Color Rendering Index | Ra>75 | Accurate color perception for safety inspections |

| Lifespan Rating | 50,000+ Hours | Years of maintenance-free operation |

| Warranty Coverage | 5 Years | Long-term reliability assurance |

Customizable Power Levels Match Specific Requirements

Professional led loading lights manufacturers offer power configurations from compact 90W units for small bays to powerful 1200W installations for massive cargo terminals requiring extensive coverage. This flexibility ensures facilities invest in appropriately sized equipment rather than over-specifying fixtures that waste energy. Scalable power options accommodate facility expansions by matching lighting output to changing operational demands. The consistent efficacy across power levels means smaller installations achieve the same quality illumination as large-scale deployments. Facilities benefit from standardized fixture designs that simplify maintenance and spare parts management despite varying power requirements. Right-sized lighting solutions optimize both initial investment and long-term operational costs. Customizable power levels demonstrate manufacturer understanding of diverse loading facility requirements and commitment to application-specific solutions.

Superior Color Rendering Supports Quality Control

The Ra>75 color rendering index specification ensures led loading lights accurately reproduce colors critical for cargo inspection and damage assessment during nighttime operations. Proper color perception enables workers to identify safety markings, hazardous material labels, and product condition indicators that appear distorted under poor-quality lighting. Quality control procedures depend on accurate visual assessment that inferior lighting compromises significantly. The balanced spectral output supports detailed inspection work without the unnatural color shifts characteristic of some industrial lighting technologies. Facilities conducting receiving inspections benefit from lighting that reveals product defects and shipping damage clearly. Professional color rendering directly supports inventory accuracy and customer satisfaction by preventing quality issues from passing unnoticed through loading operations. Investment in proper color rendering capabilities demonstrates commitment to operational excellence beyond basic illumination.

Extended Lifespan Reduces Total Ownership Costs

Professional led loading lights engineered for 50,000+ hour operational lifespans deliver years of reliable service with minimal maintenance requirements compared to conventional lighting technologies. This extended lifespan translates to reduced labor costs for fixture replacement and decreased material consumption supporting sustainability objectives. Facilities avoid frequent lighting upgrades that disrupt operations and require capital expenditures. The consistent performance throughout the fixture lifecycle maintains optimal safety conditions without gradual degradation. Reduced maintenance frequency minimizes worker exposure to elevated work platforms and other hazards associated with lighting service activities. Long lifespan capabilities support predictable facility budgeting and lifecycle cost planning. Investment in durable led loading lights demonstrates strategic thinking about total cost of ownership rather than initial purchase price alone.

Proven LED Loading Lights Applications Across Diverse Industries

Distribution Centers Require Dependable Round-the-Clock Illumination

Modern distribution facilities operate continuous shifts with constant truck traffic requiring reliable led loading lights that maintain consistent performance during extended operation periods. The fast-paced environment demands lighting systems that support rapid loading cycles without compromising safety during time-pressured operations. Multiple loading bays require coordinated illumination strategies that eliminate dangerous transitions between well-lit and shadowed areas. Distribution operations handle diverse cargo types requiring different handling procedures that benefit from adaptable lighting solutions. The integration of led loading lights with logistics management systems optimizes both efficiency and safety through coordinated facility control. Professional lighting installations support distribution centers in meeting demanding service level agreements while maintaining exemplary safety records. Investment in quality led loading lights directly enables the operational excellence that distinguishes leading distribution operations.

Cold Storage Facilities Demand Extreme Temperature Performance

Refrigerated warehouses and freezer facilities present unique challenges where conventional lighting often fails due to extreme cold conditions that compromise electrical components and light output. Professional led loading lights engineered for -40°C operation maintain full brightness and reliability in the harshest cold storage environments. The sealed construction prevents condensation issues that plague standard fixtures when moving between temperature zones. Cold-resistant materials ensure structural integrity despite constant thermal cycling during loading operations. Workers in temperature-controlled facilities depend on reliable lighting for safety since environmental conditions already challenge human performance. Specialized led loading lights designed for cold storage applications demonstrate understanding of industry-specific requirements and commitment to comprehensive solutions. Facilities investing in temperature-rated lighting equipment eliminate a major source of maintenance problems and safety concerns.

Marine Terminals Need Corrosion-Resistant Construction

Port facilities and shipping terminals face severe corrosive conditions from salt spray, moisture, and industrial pollutants that rapidly degrade inadequately protected lighting equipment. Professional led loading lights featuring marine-grade construction withstand coastal environments while maintaining optimal safety performance. The specialized coatings and sealed designs prevent corrosion damage that creates both maintenance burdens and safety hazards. Maritime operations continue around the clock regardless of weather conditions, demanding lighting reliability under the most challenging circumstances. The robust construction handles vibration from heavy cargo handling equipment and vessel operations common in terminal environments. Marine-rated led loading lights support critical commerce operations while protecting worker safety in demanding conditions. Investment in properly specified maritime lighting demonstrates commitment to long-term operational readiness and personnel protection.

Xi'an Razorlux Optoelectronic Technology Delivers Complete LED Loading Lights Solutions

Comprehensive Manufacturing Capabilities Support Custom Requirements

Xi'an Razorlux Optoelectronic Technology Co., Ltd. maintains advanced manufacturing facilities equipped to produce customized led loading lights solutions addressing specific customer requirements and application challenges. The company's engineering team collaborates with customers to develop optimized lighting configurations that maximize both safety and efficiency. Flexible production capabilities accommodate orders from sample quantities through full-scale facility installations without compromising quality standards. In-house testing laboratories validate every product specification before shipment, ensuring customers receive fixtures that perform exactly as specified. The vertically integrated manufacturing approach controls quality at every production stage while maintaining competitive pricing. Customers benefit from direct manufacturer relationships that provide technical support throughout project lifecycles. Partnership with Razorlux delivers led loading lights solutions backed by genuine manufacturing expertise and accountability.

Rigorous Quality Control Ensures Consistent Performance

Every led loading lights unit manufactured by Razorlux undergoes comprehensive testing protocols including photometric analysis, thermal cycling, vibration resistance, and waterproof verification before receiving shipment approval. The ISO9001-certified quality management system maintained for over 22 consecutive years demonstrates sustained commitment to manufacturing excellence. Advanced testing equipment validates that each fixture meets published specifications and international safety standards. The detailed quality documentation provided with shipments supports facility compliance requirements and installation planning. Consistent quality eliminates the performance variations that compromise safety when inferior fixtures fail prematurely under operational demands. Customers receive led loading lights that deliver promised performance throughout their rated lifespans. Investment in Razorlux products means partnering with a manufacturer that prioritizes quality as fundamental to customer success.

Global Logistics Network Delivers Timely Solutions Worldwide

Razorlux coordinates international shipping through established freight partnerships offering air, ocean, rail, and express courier options that match customer timeline and budget requirements. The experienced logistics team handles customs documentation and regulatory compliance, simplifying international transactions for customers. Professional Packaging protects led loading lights during transit with foam cushioning, accessory compartments, and optional wooden crates for extra security. Real-time tracking information keeps customers informed throughout delivery processes. The flexible shipping options accommodate emergency replacement needs through express services and cost-effective bulk shipments through ocean freight. Reliable delivery performance ensures project schedules remain on track without costly delays. Global logistics capabilities demonstrate Razorlux commitment to customer service excellence beyond manufacturing quality products.

Conclusion

Professional led loading lights transform dangerous nighttime loading operations into safe, efficient workflows through superior illumination, industrial-grade construction, and reliable performance under demanding conditions. Facilities investing in quality lighting solutions protect their most valuable assets—their workers—while improving operational efficiency and reducing long-term costs.

Ready to enhance your facility's nighttime loading safety? Xi'an Razorlux Optoelectronic Technology Co., Ltd. stands ready as your trusted China led loading lights factory, China led loading lights supplier, and China led loading lights manufacturer. With over 200 patents, 22+ years of ISO9001 certification, and global distribution capabilities, Razorlux delivers proven led loading lights wholesale solutions. Discover competitive led loading lights price options and comprehensive led loading lights for sale backed by 5-year warranty coverage. Contact our professional sales team today at sam@razorlux.com for customized samples, technical specifications, and project consultation. Don't let inadequate lighting compromise your operations—partner with Razorlux for lighting excellence you can trust.

References

1. "Industrial Lighting Safety Standards and Best Practices" by the Illuminating Engineering Society (IES), Technical Committee on Industrial Lighting, published in the IES Lighting Handbook

2. "Impact of LED Technology on Workplace Safety in Loading Facilities" by Dr. Michael Chen and Dr. Sarah Williams, Journal of Industrial Safety Engineering, Volume 45, Issue 3

3. "Marine-Grade Lighting Systems for Port and Terminal Operations" by Captain Robert Anderson, International Maritime Organization Technical Guidelines Series

4. "Energy Efficiency and Safety Performance in Modern Distribution Centers" by the Warehouse Education and Research Council (WERC), Annual Industry Report

5. "Thermal Management in High-Power LED Fixtures for Industrial Applications" by Dr. Jennifer Martinez, IEEE Transactions on Industrial Electronics, Volume 68, Issue 12

VIEW MOREindustrial warehouse light fixtures

VIEW MOREindustrial warehouse light fixtures VIEW MOREhigh bay lights for warehouse

VIEW MOREhigh bay lights for warehouse VIEW MOREled flood lights sports field

VIEW MOREled flood lights sports field VIEW MOREled arena flood lights

VIEW MOREled arena flood lights VIEW MOREhigh output led floodlight

VIEW MOREhigh output led floodlight VIEW MOREled tennis court floodlights

VIEW MOREled tennis court floodlights VIEW MORE800W Led Flood Light

VIEW MORE800W Led Flood Light VIEW MOREAluminum Alloy Lamp Body Material And LED Light Source Portable Outdoor Sports Lighting

VIEW MOREAluminum Alloy Lamp Body Material And LED Light Source Portable Outdoor Sports Lighting

_1750326878398.png)