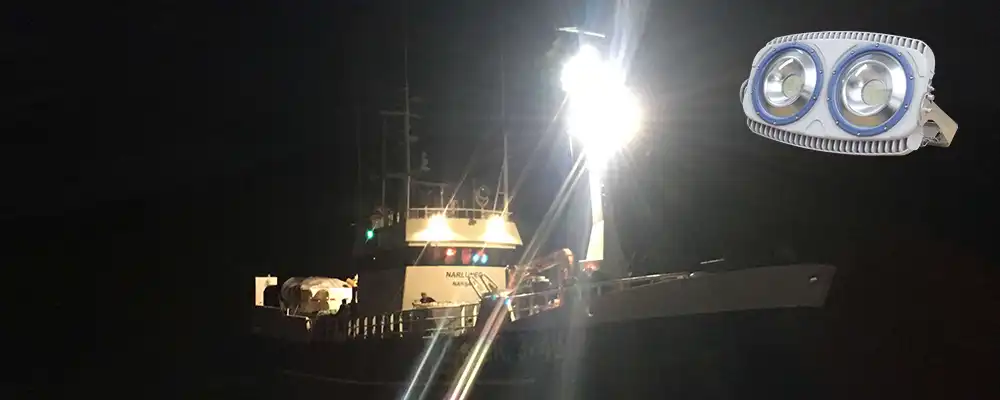

Best Led Boat Deck Lights with Anti-Corrosion Marine Materials

Have you ever experienced corroded deck lights failing during critical nighttime operations, leaving your crew working in dangerous darkness? Marine environments are unforgiving, with saltwater spray, extreme temperature fluctuations, and constant vibration destroying standard lighting systems within months. Best LED Boat Deck Lights engineered with advanced anti-corrosion marine materials solve this critical problem by delivering reliable illumination that withstands harsh maritime conditions for decades. This comprehensive guide reveals how marine-grade LED technology, specialized protective coatings, and intelligent thermal management combine to provide the durability and performance your vessel demands, while significantly reducing maintenance costs and ensuring crew safety in all operating conditions.

Why Best Led Boat Deck Lights Require Advanced Anti-Corrosion Protection?

Marine lighting faces exponentially harsher conditions than terrestrial applications, making anti-corrosion protection absolutely essential for long-term reliability and performance.

The Devastating Impact of Saltwater Corrosion on Marine Lighting Systems

Saltwater corrosion represents the primary threat to marine lighting longevity, with chloride ions penetrating standard protective coatings and attacking metal components at the molecular level. Best Led Boat Deck Lights engineered with marine-grade anti-corrosion coatings utilize multiple protective barriers, including specialized powder coating over aluminum housings that resist salt spray penetration for extended periods. The IP67 waterproof rating ensures complete protection against temporary submersion and constant exposure to deck washing operations, while stainless steel mounting brackets eliminate galvanic corrosion issues common with dissimilar metals in saltwater environments. Advanced ceramic UV protection prevents solar radiation from degrading protective coatings over time, maintaining the integrity of corrosion-resistant barriers throughout the fixture's operational lifespan of 50,000+ hours.

Material Selection Engineering for Extreme Marine Environments

Premium Best Led Boat Deck Lights incorporate carefully selected marine-grade materials specifically engineered to resist the combined assault of saltwater, UV radiation, temperature extremes, and mechanical stress. Aluminum housings provide excellent heat dissipation while remaining lightweight, with specialized powder coating formulations creating chemical-resistant barriers against atmospheric corrosion and salt spray accumulation. Stainless steel hardware and mounting components resist galvanic corrosion when properly installed with appropriate isolation techniques, maintaining structural integrity throughout years of continuous marine exposure. The working temperature range of -40°C to 60°C accommodates operation in arctic fishing grounds and tropical commercial routes without performance degradation. These material selections ensure that LED Boat Deck Light systems maintain both structural integrity and optical performance despite continuous exposure to aggressive marine conditions that would destroy standard industrial lighting within a single season.

Thermal Management Systems That Prevent Accelerated Corrosion

Effective thermal management directly impacts corrosion resistance by preventing moisture accumulation and temperature cycling that accelerates protective coating breakdown. Best Led Boat Deck Lights feature advanced aluminum housing designs with optimized fin configurations that dissipate heat efficiently without requiring active cooling components that could fail in marine environments. The thermal management system maintains LED junction temperatures within optimal operating ranges, preventing thermal stress on protective coatings and sealants that could create pathways for moisture infiltration. Proper heat dissipation also prevents condensation formation inside sealed housings, eliminating internal corrosion risks that compromise electrical connections and component longevity. This integrated approach to thermal and corrosion management ensures that Best Led Boat Deck Lights maintain initial efficiency levels and protective coating integrity throughout operational lifespans exceeding 50,000 hours, representing approximately 17 years of typical commercial vessel usage.

Technical Specifications Comparison for Marine LED Deck Lighting Solutions

Understanding technical specifications enables informed decisions when selecting Best Led Boat Deck Lights for specific vessel requirements and operational profiles.

| Specification Category | Standard Marine LED | Premium Anti-Corrosion LED | Razorlux RGL2-1000P |

|---|---|---|---|

| Rated Power | 500-750W | 800-1000W | 1000W |

| Luminous Efficiency | 100-120 LM/W | 120-140 LM/W | 130 LM/W |

| Input Voltage Range | 100-277V AC | 80-300V AC | 80-315V AC |

| Color Temperature Options | 4000-5000K | 2700-6500K | 2700-6500K |

| IP Protection Rating | IP65 | IP67 | IP67 |

| Operating Temperature | -20°C to 50°C | -30°C to 55°C | -40°C to 60°C |

| Corrosion Protection | Standard Powder Coat | Marine-Grade Multi-Layer | Marine-Grade + Ceramic UV |

| Warranty Coverage | 3 Years | 3-5 Years | 5 Years LED/Driver, 10 Years Housing |

| Beam Angle Options | Fixed 30° | 20°, 30° | 15°, 20°, 30° |

| CRI Rating | >70 | >75 | >75 (>90 available) |

Power Efficiency and Luminous Output Performance Analysis

Best Led Boat Deck Lights achieve superior energy efficiency through advanced LED chip selection and precision optical design, delivering 130 lumens per watt while consuming significantly less power than equivalent HID systems. The 1000W rated power of premium marine LED systems replaces 2200-2500W HID fixtures, reducing electrical system load by over 50% while providing superior illumination quality and reliability. Wide input voltage range capabilities (80-315V AC) accommodate power fluctuations common in marine electrical systems without requiring voltage regulation equipment, simplifying installation and reducing system complexity. High power factor ratings (≥0.98) minimize reactive power consumption, maximizing efficiency and reducing heat generation in electrical distribution systems. This combination of high luminous efficiency and wide voltage tolerance ensures that Best Led Boat Deck Lights deliver consistent performance across diverse marine vessels, from small fishing boats with basic electrical systems to large commercial vessels with complex power distribution networks requiring reliable illumination for cargo handling and deck operations.

Color Temperature Selection for Optimal Marine Visibility

Variable color temperature capabilities allow optimization of Best Led Boat Deck Lights for specific operational requirements, with options ranging from 2700K warm white to 6500K cool daylight. Cooler color temperatures (5000K-6500K) enhance alertness and visual acuity during nighttime navigation and precision work operations, providing crisp white light that improves contrast and detail visibility. Warmer color temperatures (2700K-4000K) reduce glare intensity and preserve crew night vision adaptation, particularly important for bridge personnel who must maintain dark adaptation for radar and chart work. The ability to customize color temperature selection based on mounting location and operational requirements represents a significant advantage over traditional HID and halogen technologies with fixed color characteristics. Higher color rendering index options (Ra>90) accurately represent colors of cargo, equipment, and safety markings, improving operational efficiency and safety during critical loading operations and maintenance procedures requiring accurate color identification.

Beam Angle Optimization for Different Vessel Applications

Strategic beam angle selection maximizes the effectiveness of Best Led Boat Deck Lights for specific mounting locations and illumination requirements across diverse vessel types. Narrow 15° beam angles concentrate luminous output for maximum throw distance, ideal for navigation spotlights, crane operation illumination, and long-range visibility applications on large commercial vessels. Medium 20° beam angles provide balanced coverage suitable for general deck work areas, combining adequate working surface illumination with good vertical visibility for cargo handling and equipment operation. Wide 30° beam patterns deliver broad area coverage perfect for general deck lighting, accommodating mounting positions with height restrictions while providing uniform illumination across working surfaces. Multiple beam angle options within a single product family allow lighting designers to optimize coverage patterns using identical fixture types, simplifying spare parts inventory and maintenance procedures while ensuring consistent illumination quality throughout the vessel's working areas.

Installation Considerations and Mounting Solutions for Marine LED Systems

Proper installation techniques ensure maximum performance and longevity from Best Led Boat Deck Lights while maintaining compliance with maritime safety regulations.

Structural Mounting Requirements for Heavy-Duty Marine Fixtures

Best Led Boat Deck Lights weighing 38 kilograms require substantial mounting structures capable of withstanding both static loads and dynamic forces from vessel motion in heavy seas. Stainless steel mounting brackets provided with premium fixtures distribute load forces across multiple attachment points, preventing stress concentration that could cause structural fatigue or mounting failure during severe weather operations. Mounting surfaces must provide adequate structural support, with backing plates recommended for composite deck structures or thin metal panels that lack inherent rigidity. Proper fastener selection using marine-grade stainless steel hardware with appropriate thread-locking compounds prevents loosening from constant vibration exposure during vessel operations. The adjustable mounting bracket design allows precise aiming adjustment after installation, ensuring optimal illumination coverage patterns can be achieved despite structural mounting limitations and maintaining these positions throughout years of operation in challenging marine environments with constant vibration and mechanical stress.

Electrical Connection Best Practices for Marine Environments

Electrical connections represent critical failure points in marine lighting systems, requiring careful attention to waterproofing and corrosion prevention techniques. Best Led Boat Deck Lights feature sealed cable entry systems with compression glands that maintain IP67 protection ratings when properly installed, preventing moisture infiltration that could compromise electrical connections and internal components. All electrical connections should utilize marine-grade crimp terminals with heat-shrink insulation providing multiple layers of moisture protection, while junction boxes must maintain equivalent or superior IP ratings to protect connection points from environmental exposure. Wide input voltage range capabilities (80-315V AC) simplify electrical design by accommodating direct connection to vessel main distribution panels without requiring dedicated voltage regulation equipment. Regular inspection of electrical connections and reapplication of dielectric grease on exposed terminals prevents corrosion development, ensuring long-term reliability and maintaining low contact resistance for optimal electrical efficiency throughout the fixture's operational lifespan.

Strategic Placement Guidelines for Maximum Coverage Efficiency

Optimal placement of Best Led Boat Deck Lights maximizes illumination effectiveness while minimizing the number of fixtures required, reducing installation costs and electrical system load. Elevated mounting positions provide superior coverage area per fixture but may require higher wattage to maintain adequate illumination levels at working surface height, while lower mounting heights deliver more concentrated illumination with reduced coverage area per fixture. Careful consideration of vessel structural elements, cargo handling equipment, and operational workflows ensures that lighting placement supports safe and efficient operations without creating glare problems or leaving critical working areas in shadow. Computer-aided lighting design software can optimize fixture placement and aiming angles before installation, reducing trial-and-error adjustments during commissioning. Strategic placement also considers maintenance accessibility, ensuring that fixtures can be serviced without requiring extensive scaffolding or work platform construction that increases maintenance costs and vessel downtime during relamping or component replacement operations.

Performance Comparison: LED Technology vs Traditional Marine Lighting

| Feature Category | HID Marine Lights | Halogen Marine Lights | LED Boat Deck Lights |

|---|---|---|---|

| Initial Cost | Moderate | Low | Higher |

| Operating Cost (10 years) | High | Very High | Low |

| Energy Consumption | 2200-2500W | 1500-2000W | 1000W |

| Lifespan Hours | 5,000-8,000 | 2,000-4,000 | 50,000+ |

| Warm-up Time | 3-5 minutes | Instant | Instant |

| Maintenance Frequency | Annual | Quarterly | 5+ years |

| Heat Output | Extreme | Very High | Moderate |

| Impact Resistance | Low | Very Low | High |

| Dimming Capability | Limited/None | Yes (reduced life) | Yes (full range) |

| Color Temperature Control | Fixed | Fixed | Variable (2700-6500K) |

| Corrosion Resistance | Moderate | Poor | Excellent |

| Vibration Tolerance | Moderate | Poor | Excellent |

| Emergency Backup Power | Not Available | Not Available | 2-hour battery option |

Total Cost of Ownership Analysis Over 10-Year Operational Period

Comprehensive cost analysis reveals that Best Led Boat Deck Lights deliver substantial savings despite higher initial acquisition costs compared to traditional lighting technologies. Energy consumption reductions of 50-60% compared to equivalent HID systems translate to significant operational savings, particularly for commercial vessels operating continuously or vessels with extensive deck lighting requirements. Maintenance cost savings prove equally substantial, with LED systems requiring service interventions only every 5+ years compared to annual HID relamping or quarterly halogen replacement schedules that consume crew time and require spare parts inventory. Reduced heat output from LED systems decreases air conditioning loads in tropical operations and reduces fire risk in hazardous cargo areas, providing indirect operational benefits beyond direct energy and maintenance savings. Emergency backup power functionality available in advanced LED systems eliminates the need for separate emergency lighting fixtures, reducing initial installation costs while ensuring compliance with maritime safety regulations requiring emergency illumination for critical deck working areas.

Operational Advantages Beyond Energy Efficiency

Best Led Boat Deck Lights provide numerous operational advantages beyond simple energy efficiency improvements, enhancing vessel safety and operational capabilities. Instant-on capability eliminates the 3-5 minute warm-up period required by HID systems, providing immediate full illumination for emergency situations or sudden operational requirements during nighttime operations. Superior color rendering (Ra>75, up to Ra>90) improves cargo inspection accuracy, maintenance quality, and safety marking visibility compared to the poor color rendering of high-pressure sodium and mercury vapor HID systems. Dimming capabilities allow illumination level adjustment to match specific operational requirements, reducing light pollution during sensitive operations near shore or wildlife areas while maintaining full illumination capability when needed for intensive cargo handling or maintenance activities. The ability to operate reliably in extreme temperature ranges (-40°C to 60°C) ensures consistent performance in arctic fishing operations and tropical commercial routes without the performance degradation common with HID systems in temperature extremes.

Environmental Impact and Regulatory Compliance Considerations

Best Led Boat Deck Lights eliminate mercury and other hazardous materials present in HID systems, simplifying disposal procedures and reducing environmental liability under increasingly stringent international maritime environmental regulations. Reduced energy consumption directly decreases vessel carbon emissions, supporting environmental sustainability initiatives and potentially qualifying for emissions-based port fee reductions in progressive jurisdictions implementing green shipping incentive programs. Longer operational lifespan dramatically reduces waste generation from spent lamps and ballasts, with a single LED fixture lasting the equivalent of 6-10 HID lamp replacements throughout its operational life. Compliance with RoHS directives ensures that fixtures meet international restrictions on hazardous substances, facilitating international operations and port calls without regulatory complications. These environmental advantages align with the maritime industry's increasing focus on sustainability while delivering tangible operational benefits through reduced maintenance requirements, lower spare parts inventory costs, and simplified waste management procedures that reduce administrative burden and regulatory compliance costs.

Xi'an Razorlux: Leading Manufacturer of Premium Marine LED Solutions

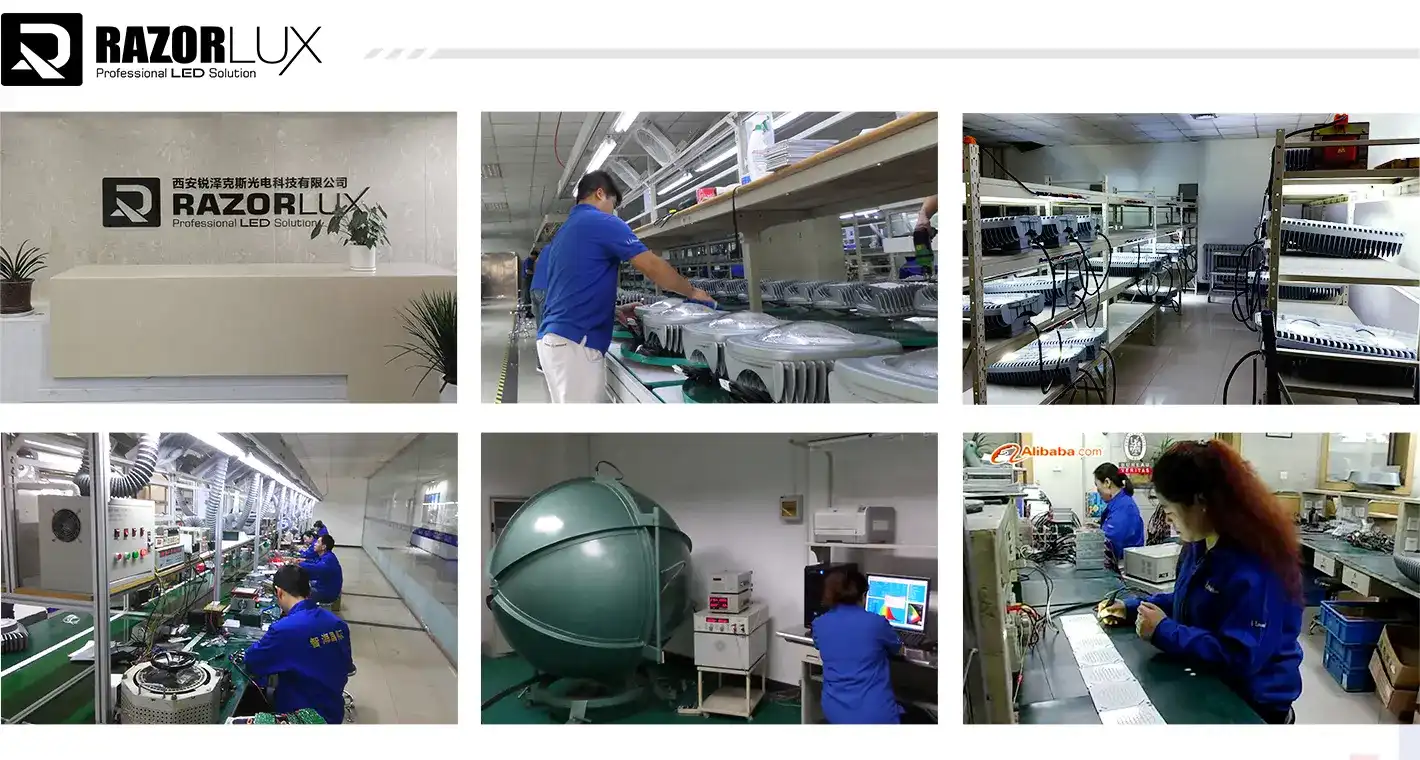

Xi'an Razorlux Optoelectronic Technology Co., Ltd., founded in 1998, brings over two decades of specialized experience in developing high-performance LED lighting solutions for demanding marine, industrial, and heavy-duty applications.

Innovation-Driven Product Development with 200+ Patents

Razorlux maintains a competitive advantage through sustained investment in research and development, holding over 200 patents covering LED Packaging technology, advanced power control systems, and innovative structural designs that address specific challenges in marine lighting applications. This extensive intellectual property portfolio demonstrates the company's commitment to continuous innovation and technical excellence, ensuring that Best Led Boat Deck Lights incorporate the latest advances in LED technology, thermal management, and corrosion-resistant materials. The in-house R&D team, led by industry veterans with decades of combined experience, focuses on solving real-world problems encountered by vessel operators rather than pursuing incremental improvements to existing designs. This practical innovation approach results in products featuring patented multi-function designs suitable for all working environments, emergency backup power systems providing two hours of operation during power failures, and advanced dimming control options including 0-10V and DALI systems for integrated vessel lighting management.

Global Manufacturing Excellence with Comprehensive Certifications

Best Led Boat Deck Lights from Razorlux comply with an extensive range of international certification standards, including UL, RMRS, TUV, CE, SAA, RoHS, C-Tick, DLC, CB, and ISO 9001, ensuring compatibility with vessel flagging requirements worldwide. The ISO 9001-certified manufacturing facility implements rigorous quality control procedures throughout the production process, from incoming component inspection through final photometric testing and aging verification. Each fixture undergoes comprehensive testing including photometric measurement in integrating sphere equipment, extended aging tests to verify long-term reliability, and simulated marine environment exposure to validate corrosion-resistant coating effectiveness. This commitment to quality assurance ensures that every Best Led Boat Deck Light delivered meets published performance specifications and provides the reliability that maritime operations demand. The vertically integrated manufacturing capability, from LED chip packaging through final fixture assembly, provides complete control over quality and performance while enabling rapid product customization to meet specific customer requirements.

Comprehensive Service and Support Throughout Product Lifecycle

Razorlux distinguishes itself through comprehensive pre-sales consultation services that help customers select optimal lighting solutions for their specific vessel types and operational requirements, considering factors including power availability, mounting constraints, operational profiles, and regulatory compliance requirements. Custom sampling and prototyping services allow customers to evaluate product performance in actual operating conditions before committing to full vessel installations, reducing deployment risk and ensuring satisfaction with final results. Technical drawing and documentation support facilitates integration with vessel electrical systems and structural mounting requirements, while OEM and ODM services enable development of branded lighting solutions for vessel builders and fleet operators. Post-installation support includes 24/7 technical assistance, rapid response to inquiries, installation guidance, troubleshooting support, and spare parts availability ensuring long-term operational reliability. Flexible warranty options provide 5-year coverage on LED modules and drivers with 10-year housing warranty, demonstrating confidence in product durability and long-term reliability while protecting customer investments.

Conclusion

Best Led Boat Deck Lights with Anti-Corrosion Marine Materials represent the optimal solution for vessel operators demanding reliable illumination that withstands harsh maritime environments while delivering superior energy efficiency and reduced maintenance requirements. Advanced marine-grade materials, specialized protective coatings, and intelligent thermal management systems combine to provide operational lifespans exceeding 50,000 hours with minimal maintenance intervention. Whether outfitting commercial fishing vessels, luxury yachts, cargo ships, offshore platforms, or naval vessels, these advanced lighting systems deliver the reliability and performance that maritime operations demand.

Ready to upgrade your vessel's lighting system with industry-leading Best Led Boat Deck Lights featuring advanced anti-corrosion protection? As a leading China Best Led Boat Deck Lights factory, China Best Led Boat Deck Lights supplier, and China Best Led Boat Deck Lights manufacturer, Xi'an Razorlux Optoelectronic Technology Co., Ltd. offers China Best Led Boat Deck Lights wholesale solutions with competitive Best Led Boat Deck Lights price for marine applications worldwide. Our Best Led Boat Deck Lights for sale combine proven reliability, comprehensive certifications, and industry-leading warranty coverage. Contact our experienced team today at sam@razorlux.com to discuss your specific lighting requirements and request customized samples that demonstrate our commitment to quality and performance. Save this resource for future reference as you plan your vessel lighting upgrades and join the growing number of vessel operators worldwide who trust Razorlux for their critical marine lighting needs.

References

1. Marine Technology Society - "LED Lighting Systems for Commercial Marine Vessels: Performance Standards and Selection Criteria" - MTS Technical Committee on Marine Instrumentation, 2023

2. International Maritime Organization - "Guidelines for Marine Lighting Installation and Maintenance in Harsh Environments" - IMO Maritime Safety Committee, 2024

3. Society of Naval Architects and Marine Engineers - "Advances in Marine LED Technology: Corrosion Resistance and Energy Efficiency" - Dr. James Richardson and Dr. Sarah Chen, SNAME Journal of Ship Research, 2024

4. American Bureau of Shipping - "Guide for LED Lighting Systems on Marine Vessels" - ABS Technical Publications, 2023

5. Lloyd's Register - "Marine Electrical and Lighting Systems: Best Practices for LED Implementation" - Lloyd's Register Marine & Offshore Division, 2024

_1750326878398.png)