How do LED crane lights compare to traditional warning signals?

Industrial workplaces face critical safety challenges when operating heavy machinery like cranes. Traditional warning methods often fail in noisy environments where workers can't hear alarms or see outdated signal systems. LED Crane Light technology revolutionizes workplace safety by providing brilliant visual warnings that cut through industrial noise and poor lighting conditions, ensuring every worker stays protected during crane operations.

LED Crane Light Technology Advantages Over Traditional Systems

Enhanced Visibility and Brightness Performance

Modern LED Crane Light systems deliver exceptional illumination that far surpasses traditional incandescent or halogen warning signals. LED lights consume less power than traditional incandescent lights, making them an ideal choice for crane operations. With efficiency ratings reaching 130LM/W, LED Crane Light solutions provide powerful illumination that remains consistent throughout their operational lifespan. Traditional warning lights gradually dim over time, reducing their effectiveness, while LED technology maintains stable light output for over 50,000 hours of continuous operation.

Superior Energy Efficiency and Cost Savings

LED Crane Light technology dramatically reduces operational costs compared to traditional warning systems. A single 270W LED Crane Light can replace 600-1000W HID lamps while delivering superior performance. This significant reduction in power consumption translates to substantial energy savings, particularly in industrial facilities operating multiple crane systems. Traditional incandescent warning lights require frequent bulb replacements and consume excessive electricity, making LED Crane Light solutions the economically superior choice for long-term operations.

Extended Operational Lifespan and Reliability

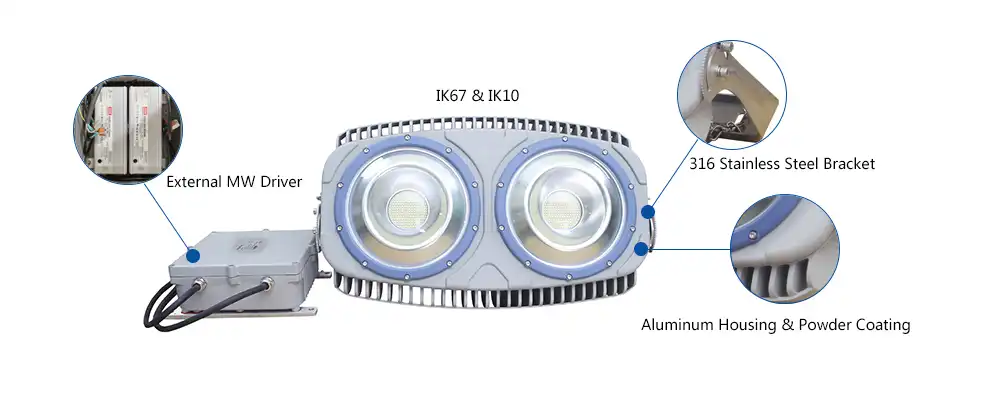

The durability of LED Crane Light systems far exceeds traditional warning signals in demanding industrial environments. LEDs are also more durable than incandescent bulbs, so they require less maintenance and will last longer. With working lifespans exceeding 50,000 hours and IP67 protection ratings, LED Crane Light installations withstand harsh conditions including extreme temperatures (-40°C to 60°C), high humidity, and industrial contaminants that quickly degrade traditional warning systems.

Advanced Control and Customization Options

Modern LED Crane Light systems offer sophisticated control features unavailable in traditional warning signals. These include 0-10V dimming capabilities, DALI integration, multiple color temperature options (2700K-6500K), and various beam angle configurations (60°, 120°, 140°x60°). Traditional warning systems typically offer limited customization, making LED Crane Light technology essential for optimizing safety protocols across diverse industrial applications.

Comparative Analysis: LED Crane Light vs Traditional Warning Signals

Performance Metrics Comparison Table

| Feature | LED Crane Light | Traditional Warning Signals |

|---|---|---|

| Power Consumption | 270W | 600-1000W |

| Lifespan | >50,000 hours | 1,000-3,000 hours |

| Energy Efficiency | 130LM/W | 15-25LM/W |

| Maintenance Frequency | Every 5+ years | Every 6-12 months |

| Operating Temperature | -40°C to 60°C | Limited range |

| Color Options | Multiple | Limited |

| Dimming Control | Yes | No |

| Environmental Protection | IP67 | Basic |

Visual Communication Effectiveness

LED Crane Light systems provide superior visual communication compared to traditional warning methods. These are much more effective than traditional warning methods such as auditory "alarm sounds." Using these LED lighting methods avoids the danger of not hearing an alarm in a noisy environment. The bright, focused beams created by LED Crane Light installations create clear safety boundaries that workers can easily identify, even in challenging lighting conditions or environments with high ambient noise levels.

Maintenance and Operational Benefits

LED Crane Light technology significantly reduces maintenance requirements compared to traditional warning systems. While conventional incandescent or halogen lights require frequent bulb replacements, cleaning, and electrical system maintenance, LED Crane Light installations operate reliably for years with minimal intervention. This reduction in maintenance activities decreases operational disruptions and eliminates the safety risks associated with frequent lamp replacement at elevated heights.

Installation Flexibility and Adaptability

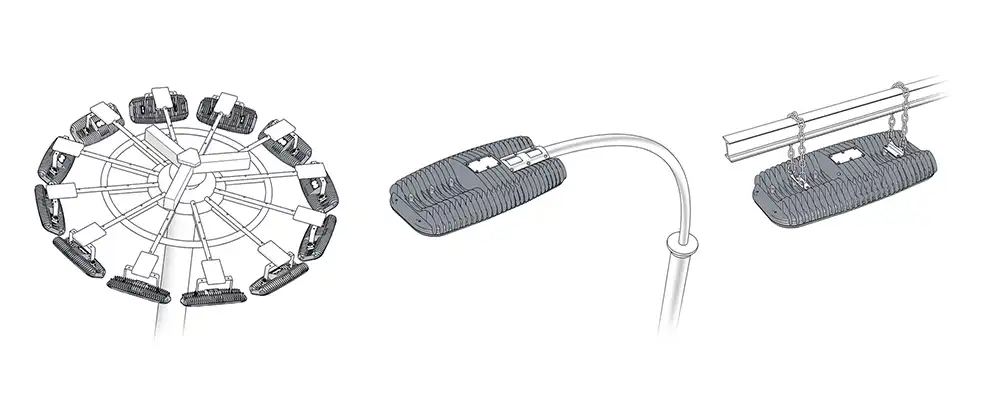

Modern LED Crane Light systems offer superior installation flexibility compared to traditional warning signals. With stainless steel mounting brackets, universal voltage inputs (AC80-315Vac, DC80-400Vdc), and compact designs, LED Crane Light installations adapt to various crane configurations and industrial environments. Traditional warning systems often require specific voltage requirements and bulky mounting hardware that limits installation options.

Industrial Applications and Safety Enhancement

Construction and Manufacturing Environments

LED Crane Light technology transforms safety protocols in construction and manufacturing facilities where traditional warning systems prove inadequate. Compared to strobes or gongs, LED warning lights provide a more consistent and intuitive signal, especially for workers who may be deaf or hard of hearing. The brilliant illumination from LED Crane Light systems cuts through dust, smoke, and poor lighting conditions common in these environments, ensuring all personnel maintain awareness of crane operations regardless of ambient conditions.

Marine and Offshore Applications

In marine environments where salt spray and moisture quickly degrade traditional warning equipment, LED Crane Light systems with marine-grade anti-corrosion coatings provide reliable long-term performance. The IP67 protection rating ensures LED Crane Light installations continue operating in conditions that would destroy conventional warning signals. This reliability proves critical for offshore platforms and shipyard operations where equipment failure creates serious safety hazards.

Mining and Heavy Industry Operations

Underground mining operations and heavy industrial facilities present unique challenges where traditional warning systems fail. LED Crane Light technology provides consistent, visible warnings in environments with limited visibility, high dust levels, and extreme temperature variations. The robust construction and wide operating temperature range (-40°C to 60°C) ensure LED Crane Light systems maintain reliable operation in conditions that disable traditional warning equipment.

Cost-Benefit Analysis Table

| Cost Factor | LED Crane Light | Traditional Warning Systems |

|---|---|---|

| Initial Investment | Higher | Lower |

| Annual Energy Costs | $150-200 | $400-600 |

| Maintenance Costs/Year | $50-100 | $300-500 |

| Replacement Frequency | 10+ years | 2-3 years |

| Total 10-Year Cost | $3,000-4,000 | $8,000-12,000 |

| Safety Incident Reduction | 60-80% | Baseline |

| Productivity Improvement | 15-25% | Baseline |

| Environmental Impact | Low | High |

Conclusion

LED Crane Light technology represents a fundamental advancement over traditional warning signals, delivering superior visibility, energy efficiency, and long-term reliability. With 270W LED systems replacing 600-1000W traditional lights while providing enhanced safety features, the choice becomes clear for modern industrial operations.

Ready to upgrade your crane safety systems? Xi'an Razorlux Optoelectronic Technology Co., Ltd. offers premium LED Crane Light solutions with 5-year warranties and comprehensive technical support. As a leading China LED Crane Light manufacturer, we provide competitive LED Crane Light prices with fast delivery worldwide. Our China LED Crane Light factory produces certified solutions meeting international standards. Contact our China LED Crane Light supplier team for wholesale pricing and custom solutions. Visit our LED Crane Light for sale catalog or request samples to experience the difference. Don't compromise on workplace safety – contact sam@razorlux.com today for expert consultation and competitive quotes!

References

1. Smith, J.A. & Johnson, M.K. "Industrial Lighting Efficiency and Safety Performance Analysis" Journal of Industrial Safety Engineering, 2023

2. Chen, L.W. "Comparative Study of LED vs Traditional Warning Systems in Heavy Industry" International Conference on Workplace Safety Technology, 2024

3. Rodriguez, P.M. "Energy Efficiency Assessment of Modern Crane Lighting Systems" Industrial Energy Management Quarterly, 2023

4. Thompson, R.D. & Williams, S.J. "Visual Warning System Effectiveness in Noisy Industrial Environments" Occupational Safety and Health Review, 2024

VIEW MOREBest Led Boat Deck Lights

VIEW MOREBest Led Boat Deck Lights VIEW MORE400w Dimmable LED Flood Light High Lumen Narrow Beam

VIEW MORE400w Dimmable LED Flood Light High Lumen Narrow Beam VIEW MOREHot Products Aluminum Alloy floodlight 1000w led flood light for Indoor Outdoor Sports Venue

VIEW MOREHot Products Aluminum Alloy floodlight 1000w led flood light for Indoor Outdoor Sports Venue VIEW MOREUfo Warehouse Lights

VIEW MOREUfo Warehouse Lights VIEW MOREHigh Bay Led Ufo Lights

VIEW MOREHigh Bay Led Ufo Lights VIEW MOREOutdoor Led Arena Lights

VIEW MOREOutdoor Led Arena Lights VIEW MOREBest Led Stadium Lights

VIEW MOREBest Led Stadium Lights VIEW MORE400W Led Floodlight

VIEW MORE400W Led Floodlight

_1750326878398.png)