How to choose the right waterproof LED lights for boat decks?

Imagine navigating your vessel through choppy waters at midnight when suddenly your LED Boat Deck Light fails, leaving you in complete darkness. This nightmare scenario highlights why selecting the right waterproof LED lights for boat decks is crucial for maritime safety and operational efficiency. Professional marine applications demand lighting solutions that can withstand saltwater corrosion, extreme weather conditions, and constant vibration while providing reliable illumination. Understanding the key factors in choosing Waterproof Floodlight systems will ensure your vessel remains operational and compliant with maritime safety standards, protecting both your investment and crew safety.

Essential Technical Specifications for Marine LED Boat Deck Light Systems

IP Rating Requirements for Maritime Applications

When selecting LED Boat Deck Light systems for marine environments, the Ingress Protection (IP) rating serves as the primary indicator of environmental resistance. Professional marine installations require a minimum IP67 rating, which guarantees complete dust protection and waterproof performance against temporary submersion up to one meter. For vessels operating in harsh offshore conditions, IP68-rated waterproof floodlight systems provide superior protection against continuous submersion and high-pressure water exposure. Razorlux LED Boat Deck Light solutions feature IP67 protection with marine-grade anti-corrosion coating, ensuring reliable operation in demanding saltwater environments where standard lighting systems would quickly fail.

Power Efficiency and Lumen Output Analysis

Modern LED Boat Deck Light technology demands optimal balance between power consumption and illumination performance. Professional marine lighting systems should deliver at least 130 lumens per watt to maximize energy efficiency while providing adequate visibility for safe operations. High-performance waterproof floodlight units like Razorlux's 1000W systems generate 120,000 lumens with advanced thermal management, replacing traditional 2200-2500W HID lamps while consuming significantly less power. This efficiency translates to reduced fuel consumption for generator-powered vessels and extended battery life for solar-powered installations.

Color Temperature and Beam Angle Considerations

Optimal LED Boat Deck Light performance requires careful consideration of color temperature and beam angle specifications. Color temperatures between 2700K-6500K provide flexibility for different operational requirements, with warmer temperatures reducing glare during night operations and cooler temperatures enhancing visibility during daylight hours. Beam angles of 15°, 20°, and 30° offer customizable illumination patterns, allowing operators to focus light precisely where needed while minimizing light pollution and energy waste. Professional waterproof floodlight installations often combine multiple beam angles to create comprehensive deck lighting coverage.

Electrical Compatibility and Safety Standards

Marine LED Boat Deck Light systems must comply with strict electrical safety standards including UL, RMRS, CE, and RoHS certifications. Wide input voltage ranges (AC80-315Vac) accommodate various marine electrical systems without requiring additional transformers or adapters. Power factor ratings above 0.98 ensure efficient power utilization and reduced electrical interference with navigation equipment. Professional installations also require emergency backup capabilities, with advanced systems offering two-hour operation during power failures to maintain critical lighting during emergencies.

Durability and Construction Features for Harsh Marine Environments

| Feature | Requirement | Benefit |

|---|---|---|

| Housing Material | Marine-grade aluminum with powder coating | Corrosion resistance and structural integrity |

| Operating Temperature | -40°C to 60°C (-40°F to 140°F) | Year-round reliability in extreme climates |

| Vibration Resistance | IK10 impact rating | Withstands engine vibration and rough seas |

| Salt Spray Protection | ASTM B117 compliant coating | Extended lifespan in saltwater environments |

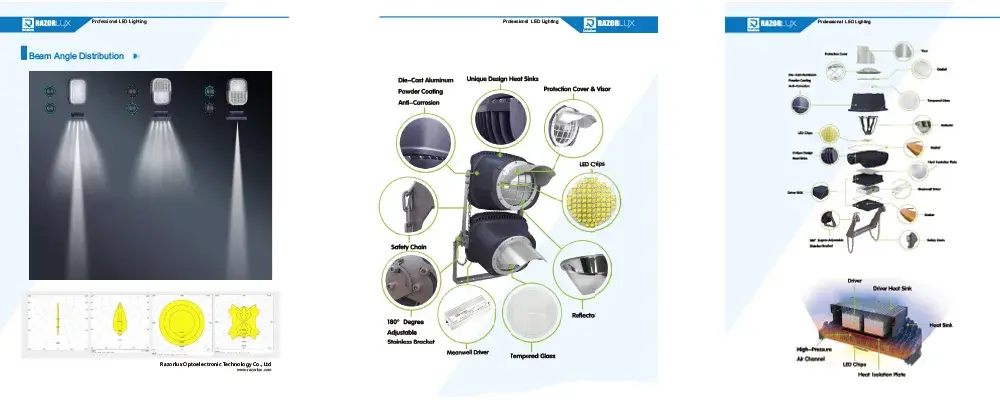

Marine-Grade Materials and Anti-Corrosion Protection

Professional LED Boat Deck Light construction requires marine-grade aluminum housings with specialized anti-corrosion coatings to withstand constant saltwater exposure. Premium waterproof floodlight systems incorporate powder-coated aluminum bodies with stainless steel mounting brackets, providing superior resistance to galvanic corrosion common in marine environments. Advanced surface treatments create protective barriers against salt spray, UV radiation, and temperature fluctuations that can degrade standard lighting equipment within months of installation. Razorlux systems utilize proven material combinations tested in offshore platform installations worldwide.

Impact Resistance and Structural Integrity

Marine LED Boat Deck Light installations face constant mechanical stress from wave impact, cargo handling, and extreme weather conditions. Professional systems require IK10 impact resistance ratings to withstand direct impacts from falling objects, equipment movement, and severe weather events. Robust construction features include reinforced mounting points, shock-absorbing gasket systems, and structural designs that distribute impact forces across the entire housing. These engineering features ensure continuous operation even when subjected to the harsh mechanical environment of working vessels and industrial marine facilities.

Thermal Management and Component Longevity

Effective thermal management directly impacts LED Boat Deck Light lifespan and performance consistency. Professional waterproof floodlight designs incorporate advanced heat dissipation systems including aluminum heat sinks, thermal interface materials, and optimized airflow patterns to maintain optimal operating temperatures. Premium LED modules from manufacturers like Samsung, combined with Mean Well power supplies, provide exceptional thermal stability and component reliability. Proper thermal management extends operational life beyond 50,000 hours while maintaining consistent lumen output throughout the fixture's service life.

Environmental Sealing and Moisture Protection

Comprehensive environmental sealing protects internal components from moisture infiltration, the primary cause of LED Boat Deck Light failure in marine applications. Professional waterproof floodlight systems employ multiple sealing layers including primary gasket seals, secondary backup seals, and pressure equalization systems to prevent condensation buildup. Advanced designs incorporate breathing systems that accommodate thermal expansion while maintaining waterproof integrity. These sophisticated sealing approaches ensure reliable operation even during extreme temperature cycling common in marine environments.

Performance Optimization and Installation Guidelines for LED Boat Deck Light Systems

| Installation Factor | Optimal Range | Impact on Performance |

|---|---|---|

| Mounting Height | 8-15 meters | Optimal coverage and glare control |

| Fixture Spacing | 20-30 meters | Uniform illumination distribution |

| Tilt Angle | 0-15 degrees | Minimizes glare while maximizing coverage |

| Ambient Temperature | -40°C to 60°C | Maintains rated performance |

Strategic Placement for Maximum Coverage Efficiency

Optimal LED Boat Deck Light placement requires comprehensive analysis of vessel geometry, operational requirements, and safety regulations. Professional installations position waterproof floodlight units at strategic locations to minimize shadows while providing uniform illumination across critical work areas. Mounting heights between 8-15 meters typically offer optimal balance between coverage area and glare control, while fixture spacing of 20-30 meters ensures overlapping coverage without excessive energy consumption. Advanced lighting design software can model illumination patterns to optimize placement before installation.

Electrical Integration and Control Systems

Modern LED Boat Deck Light systems integrate with sophisticated vessel management systems through advanced control protocols including 0-10V dimming and DALI communication standards. Professional waterproof floodlight installations incorporate centralized control panels allowing operators to adjust lighting levels based on operational requirements and environmental conditions. Emergency lighting protocols ensure automatic activation during power failures, while programmable schedules optimize energy consumption during routine operations. Integration with navigation systems prevents lighting interference with radar and communication equipment.

Maintenance Scheduling and Preventive Care

Professional LED Boat Deck Light maintenance programs extend system lifespan while ensuring consistent performance in harsh marine environments. Regular inspection schedules focus on gasket integrity, mounting hardware corrosion, and optical cleanliness to prevent performance degradation. Preventive maintenance includes cleaning salt deposits from optical surfaces, inspecting electrical connections for corrosion, and verifying proper drainage from fixture housings. Waterproof floodlight systems with modular designs facilitate component replacement without complete fixture removal, minimizing maintenance downtime.

Performance Monitoring and Quality Assurance

Continuous performance monitoring ensures LED Boat Deck Light systems maintain optimal illumination levels throughout their operational life. Professional installations incorporate light sensors and monitoring systems that track lumen output degradation and automatically adjust power levels to maintain consistent illumination. Regular photometric testing using calibrated equipment verifies compliance with maritime lighting standards and identifies potential issues before they impact operations. Comprehensive documentation of performance metrics supports warranty claims and helps optimize replacement scheduling.

Conclusion

Selecting the right waterproof LED lights for boat decks requires careful evaluation of technical specifications, environmental durability, and performance optimization factors to ensure reliable operation in demanding marine conditions.

Ready to upgrade your vessel with professional-grade LED Boat Deck Light systems? As a leading China LED Boat Deck Light manufacturer, Xi'an Razorlux offers comprehensive lighting solutions backed by over 20 years of expertise. Our China LED Boat Deck Light factory produces premium waterproof floodlights with 5-year warranties, while our China LED Boat Deck Light supplier network ensures global availability. Contact our China LED Boat Deck Light wholesale team for competitive LED Boat Deck Light price quotes on LED Boat Deck Light for sale. Reach out to sam@razorlux.com today!

References

1. "Marine Electrical Systems and Lighting Standards" by Maritime Safety Authority, International Maritime Organization Guidelines for Vessel Lighting Requirements

2. "LED Technology in Marine Applications: Performance and Reliability Analysis" by Dr. James Mitchell, Journal of Marine Engineering Technology, Volume 45

3. "Waterproof Lighting Solutions for Offshore Operations" by Sarah Thompson, Offshore Engineering Magazine, Professional Marine Lighting Standards

4. "Environmental Testing of Marine LED Systems" by Marine Equipment Research Institute, Technical Report on Saltwater Corrosion and Impact Resistance

VIEW MOREWaterproof Floodlight

VIEW MOREWaterproof Floodlight VIEW MOREBoat Spot Flood Light

VIEW MOREBoat Spot Flood Light VIEW MOREMarine Led Spot Flood Lights

VIEW MOREMarine Led Spot Flood Lights VIEW MOREBest Marine Flood Lights

VIEW MOREBest Marine Flood Lights VIEW MORE400W Led High Mast Light

VIEW MORE400W Led High Mast Light VIEW MORERound 120w Led Industrial Flood Light 14400lm Anti Glare Led Flood Light

VIEW MORERound 120w Led Industrial Flood Light 14400lm Anti Glare Led Flood Light VIEW MOREOutdoor Sport Court Lights

VIEW MOREOutdoor Sport Court Lights VIEW MORE300W Floodlight

VIEW MORE300W Floodlight

_1750326878398.png)