How Industrial Flood Lights Led Save Energy and Costs?

Are your facility's energy bills draining profitability while outdated lighting systems demand constant maintenance? Industrial Flood Lights Led technology offers a transformative solution, delivering up to 80% energy savings compared to traditional halogen and metal halide systems. These advanced lighting solutions address the critical challenge faced by warehouse managers, plant operators, and facility directors who struggle with escalating operational costs while maintaining adequate illumination for safety and productivity. Modern Industrial Flood Lights Led combine exceptional luminous efficiency of 130 lumens per watt with extended lifespans exceeding 50,000 hours, eliminating frequent replacements and dramatically reducing total cost of ownership across manufacturing plants, mining operations, ports, and heavy industrial environments worldwide.

Understanding Energy Efficiency in Industrial Flood Lights Led Technology

The Science Behind LED Energy Consumption Reduction

Industrial Flood Lights Led revolutionize energy management through advanced semiconductor technology that converts electrical energy directly into visible light through electroluminescence. Unlike traditional incandescent or halogen systems that waste substantial energy producing heat, Industrial Flood Lights Led achieve remarkable conversion efficiency by generating minimal thermal output. Modern industrial-grade LED systems deliver 120-150 lumens per watt compared to halogen lights producing merely 15-20 lumens per watt, representing a fundamental technological advantage. This efficiency translates directly to reduced electrical demand, with a 1000W Industrial Flood Lights Led system replacing traditional 2200-2500W metal halide installations while maintaining equivalent or superior illumination levels. The patented multi-function design optimizes power management across voltage ranges from AC80-305Vac and DC100-400Vdc, ensuring stable performance across diverse industrial electrical infrastructure. Advanced driver technology maintains power factors exceeding 0.98 while keeping total harmonic distortion below 10%, minimizing electrical losses throughout the distribution system. Industrial facilities implementing Industrial Flood Lights Led technology report immediate reductions in demand charges, contributing to substantial utility bill decreases that accelerate return on investment calculations.

Comparative Power Consumption Analysis

| Lighting Type | Wattage | Lumens Output | Efficacy (lm/W) | Annual Energy Cost* |

|---|---|---|---|---|

| Metal Halide | 2500W | 130,000 lm | 52 | $2,190 |

| High-Pressure Sodium | 2200W | 125,000 lm | 57 | $1,927 |

| Industrial Flood Lights Led | 1000W | 130,000 lm | 130 | $876 |

| Energy Savings vs Metal Halide | -60% | Equal | +150% | -$1,314 |

The comparative analysis demonstrates Industrial Flood Lights Led systems achieve identical illumination using 60% less power than metal halide alternatives. Facilities operating twenty Industrial Flood Lights Led fixtures instead of traditional systems save approximately $26,280 annually in direct electricity costs alone. These calculations exclude additional savings from reduced cooling requirements, as Industrial Flood Lights Led generate significantly less ambient heat that would otherwise burden HVAC systems. The thermal efficiency of Industrial Flood Lights Led becomes particularly valuable in temperature-controlled environments like cold storage warehouses, where minimizing heat emission directly reduces refrigeration costs. Advanced thermal management systems incorporating aluminum housings with powder coating finishes facilitate superior heat dissipation, maintaining optimal LED junction temperatures even in demanding 60°C ambient conditions. Industrial Flood Lights Led systems maintain consistent luminous output throughout their operational lifespan, unlike traditional technologies that experience significant lumen depreciation exceeding 30% within initial operating hours.

Long-Term Operational Cost Benefits

Industrial Flood Lights Led technology delivers compounding financial advantages extending far beyond initial energy consumption savings through exceptional operational longevity. Premium Industrial Flood Lights Led systems engineered with Meanwell power supplies and high-grade LED modules achieve rated lifespans exceeding 50,000 operating hours compared to metal halide lamps requiring replacement every 10,000-15,000 hours. This five-fold lifespan advantage eliminates frequent maintenance interventions, reducing labor costs associated with accessing elevated mounting positions, purchasing replacement components, and managing disposal of hazardous waste materials. Industrial facilities with hundreds of lighting fixtures traditionally allocate substantial maintenance budgets for lamp replacement programs, requiring specialized equipment like scissor lifts and trained personnel. Industrial Flood Lights Led installations dramatically reduce these recurring expenses while improving workplace safety by minimizing elevated work requirements. The 5-year comprehensive warranty covering LED modules, drivers, and housing components provides additional financial protection against unexpected replacement costs. Facilities implementing Industrial Flood Lights Led technology typically achieve complete investment payback within 2-3 years through combined energy and maintenance savings, with subsequent years representing pure operational profit improvements.

Cost Savings Through Advanced Industrial Flood Lights Led Features

Intelligent Dimming and Control Systems Integration

Modern Industrial Flood Lights Led systems incorporate sophisticated control capabilities including 0-10V analog dimming and DALI digital protocols, enabling dynamic illumination management that optimizes energy consumption according to actual operational requirements. Intelligent dimming extends Industrial Flood Lights Led efficiency advantages by reducing power consumption during periods requiring lower illumination levels, such as maintenance shifts, overnight security operations, or naturally well-lit daytime periods in facilities with significant fenestration. Advanced motion sensing integration allows Industrial Flood Lights Led systems to automatically adjust output levels based on occupancy detection, delivering full brightness when workers occupy specific zones while reducing illumination to minimal safety levels in unoccupied areas. These intelligent controls can reduce overall lighting energy consumption by additional 30-50% beyond baseline Industrial Flood Lights Led efficiency improvements. Daylight harvesting systems integrate photometric sensors that continuously monitor ambient natural light levels, automatically dimming Industrial Flood Lights Led output to maintain target illumination while minimizing electrical consumption. The instant-on capability of Industrial Flood Lights Led technology eliminates the warm-up delays characteristic of HID systems, allowing facilities to implement aggressive automatic shutoff protocols without productivity impacts from extended restart cycles. Customizable beam angles ranging from 40° to 140° enable precise light distribution targeting specific work areas, minimizing wasted illumination and allowing optimal fixture spacing that reduces total installation quantities required.

Maintenance Cost Reduction Strategies

| Maintenance Factor | Traditional HID | Industrial Flood Lights Led | Annual Savings per 100 Fixtures |

|---|---|---|---|

| Replacement Frequency | Every 1-2 years | Every 8-10 years | - |

| Labor Hours | 200 hours | 25 hours | $8,750* |

| Replacement Parts | $15,000 | $0 | $15,000 |

| Disposal Fees | $2,000 | $250 | $1,750 |

| Equipment Rental | $3,000 | $375 | $2,625 |

| Total Annual Maintenance | $20,000+ | $625 | $28,125 |

The maintenance economics of Industrial Flood Lights Led technology present compelling financial advantages that frequently exceed direct energy savings for large industrial facilities. Traditional high-intensity discharge systems require comprehensive relamping programs every 12-24 months, necessitating coordinated shutdowns, specialized access equipment, and trained electrical personnel to safely execute replacements across extensive installations. Industrial Flood Lights Led systems eliminate these disruptive maintenance cycles through exceptional component longevity achieved via superior thermal management and robust construction standards. The IP65/IP67 environmental protection ratings ensure Industrial Flood Lights Led fixtures withstand harsh industrial conditions including dust, moisture, vibration, and corrosive atmospheres without premature failure or performance degradation. Marine-grade anti-corrosion coatings and stainless steel mounting brackets provide additional durability in particularly aggressive environments like coastal ports, chemical processing facilities, and offshore platforms. The modular design architecture of premium Industrial Flood Lights Led systems facilitates rapid field servicing in rare instances requiring component replacement, with separate LED modules and power supplies enabling targeted repairs without complete fixture replacement. Facilities implementing Industrial Flood Lights Led technology redirect maintenance resources toward higher-value activities, improving overall operational efficiency while reducing unplanned downtime associated with lighting system failures.

Total Cost of Ownership Analysis

Comprehensive total cost of ownership calculations reveal Industrial Flood Lights Led technology delivers superior financial performance despite higher initial capital investment compared to conventional lighting alternatives. A typical industrial facility replacing 100 traditional 2000W metal halide fixtures with 1000W Industrial Flood Lights Led systems experiences immediate annual energy savings approaching $110,000 based on industrial electricity rates averaging $0.12 per kilowatt-hour. Combined with maintenance cost reductions exceeding $28,000 annually, total first-year operational savings reach $138,000, offsetting the incremental capital investment within 18-24 months for most installations. Industrial Flood Lights Led systems continue delivering these annual savings throughout their 50,000+ hour operational lifespan, representing cumulative financial benefits exceeding $1,380,000 over a ten-year evaluation period. Additional financial advantages include reduced cooling costs from lower heat generation, improved power quality reducing stress on electrical distribution infrastructure, and potential utility rebates or incentive programs supporting energy-efficient technology adoption. Facilities pursuing LEED certification or other sustainability credentials gain additional value from Industrial Flood Lights Led implementations through reduced carbon footprint and demonstration of environmental stewardship commitment. The emergency power functionality available in select Industrial Flood Lights Led models provides critical backup illumination during utility outages, potentially eliminating expensive emergency generator capacity requirements or battery-powered emergency lighting systems. Industrial organizations evaluating Industrial Flood Lights Led technology should conduct comprehensive lifecycle cost analyses incorporating energy savings, maintenance reductions, operational improvements, and risk mitigation benefits to fully capture investment value.

Maximizing ROI with Industrial Flood Lights Led Implementation

Strategic Deployment Planning for Maximum Savings

Successful Industrial Flood Lights Led implementation requires strategic planning that optimizes fixture placement, specification selection, and control system integration to maximize energy efficiency and cost reduction objectives. Facilities should conduct comprehensive lighting audits evaluating existing illumination levels, distribution uniformity, and energy consumption patterns to establish baseline performance metrics and identify improvement opportunities. Professional photometric analysis determines optimal Industrial Flood Lights Led fixture quantities, mounting locations, and beam angle selections to achieve target illumination levels while minimizing total wattage requirements and initial capital investment. Industrial Flood Lights Led technology enables significant fixture count reductions compared to traditional systems due to superior optical efficiency and directional light control, directly reducing both installation costs and ongoing energy consumption. Facilities with diverse operational requirements benefit from specifying multiple Industrial Flood Lights Led configurations customized for specific applications, such as high-output models for precision manufacturing areas and lower-wattage versions for warehouse aisles and storage zones. Color temperature selection impacts visual acuity and worker comfort, with neutral white Industrial Flood Lights Led systems around 5000K providing excellent color rendering for quality inspection tasks while cooler temperatures enhance alertness during overnight operations. Integration with existing building management systems allows centralized Industrial Flood Lights Led control, enabling facilities to implement sophisticated scheduling, occupancy-based dimming, and energy monitoring capabilities that optimize consumption without requiring manual intervention. Phased implementation strategies allow organizations to validate Industrial Flood Lights Led performance in representative applications before committing to facility-wide deployment, building institutional confidence while generating early savings that fund subsequent project phases.

Specification Requirements for Industrial Applications

Industrial environments demand Industrial Flood Lights Led systems engineered to withstand demanding operational conditions while maintaining reliable performance throughout extended service lifetimes. Critical specification parameters include ingress protection ratings of IP65 or IP67 ensuring complete dust sealing and water resistance suitable for both indoor and outdoor industrial installations subjected to cleaning operations, weather exposure, and airborne contaminants. Impact resistance rated IK10 provides protection against physical damage from material handling equipment, falling objects, and vibration common in manufacturing and heavy industrial settings. Wide input voltage acceptance ranging from AC80-305Vac accommodates electrical infrastructure variations and voltage fluctuations typical in industrial facilities while DC input capability supports backup power integration and specialized applications. Industrial Flood Lights Led systems must maintain stable operation across extreme ambient temperature ranges from -40°C to +60°C, requiring robust thermal management solutions and component derating to ensure reliable performance in both outdoor winter conditions and hot process environments. Power quality characteristics including power factor exceeding 0.98 and total harmonic distortion below 10% minimize electrical system stress and ensure compatibility with sensitive electronic equipment. Comprehensive international certification including UL, CE, RoHS, SAA, RMRS, and DLC verification demonstrates Industrial Flood Lights Led compliance with safety standards and qualifies installations for utility rebate programs. Warranty provisions should include minimum 5-year coverage for LED modules and power supplies with extended housing warranties reflecting manufacturer confidence in long-term durability and product quality.

Partnership with Reliable Industrial Flood Lights Led Manufacturers

Selecting the appropriate China Industrial Flood Lights Led supplier represents a critical success factor for organizations implementing advanced lighting technology across industrial facilities. Established China Industrial Flood Lights Led manufacturers like Xi'an Razorlux Optoelectronic Technology Co., Ltd. bring over two decades of specialized experience developing high-performance lighting solutions for demanding marine, industrial, and heavy-duty applications worldwide. China Industrial Flood Lights Led factory operations must demonstrate comprehensive quality management systems including ISO 9001 certification, rigorous testing protocols encompassing photometric verification and accelerated aging studies, and documented failure mode analysis ensuring product reliability. Reputable China Industrial Flood Lights Led wholesale partners provide extensive customization capabilities allowing specification of exact wattage, color temperature, beam angles, mounting configurations, and control system integration to meet specific application requirements. OEM and ODM services enable organizations to develop proprietary Industrial Flood Lights Led solutions incorporating unique features or branding elements that differentiate their facilities or product offerings. Responsive technical support throughout project lifecycle from initial consultation through installation commissioning and ongoing maintenance ensures successful Industrial Flood Lights Led deployment and maximizes long-term value realization. Transparent Industrial Flood Lights Led pricing structures and flexible ordering options accommodate both large-scale facility conversions and pilot program implementations, reducing financial barriers to technology adoption. Global logistics capabilities including air, rail, and sea transportation options with reliable delivery timelines ensure project schedules remain on track regardless of procurement quantities or destination locations. Organizations evaluating China Industrial Flood Lights Led manufacturers should request detailed product specifications, certification documentation, case study references, and sample evaluation opportunities to verify capability and establish confidence before committing to significant investments.

Conclusion

Industrial Flood Lights Led technology represents a transformative opportunity for industrial facilities seeking substantial energy cost reduction while enhancing operational efficiency, workplace safety, and environmental sustainability. The compelling combination of 60-80% energy consumption reduction, minimal maintenance requirements, and extended operational lifespans delivers rapid investment payback typically within 24-36 months, with ongoing annual savings continuing throughout the system's 50,000+ hour lifespan. As organizations face increasing pressure to reduce operational costs and carbon emissions, Industrial Flood Lights Led implementation provides a proven solution that simultaneously addresses financial and environmental objectives while improving workplace illumination quality.

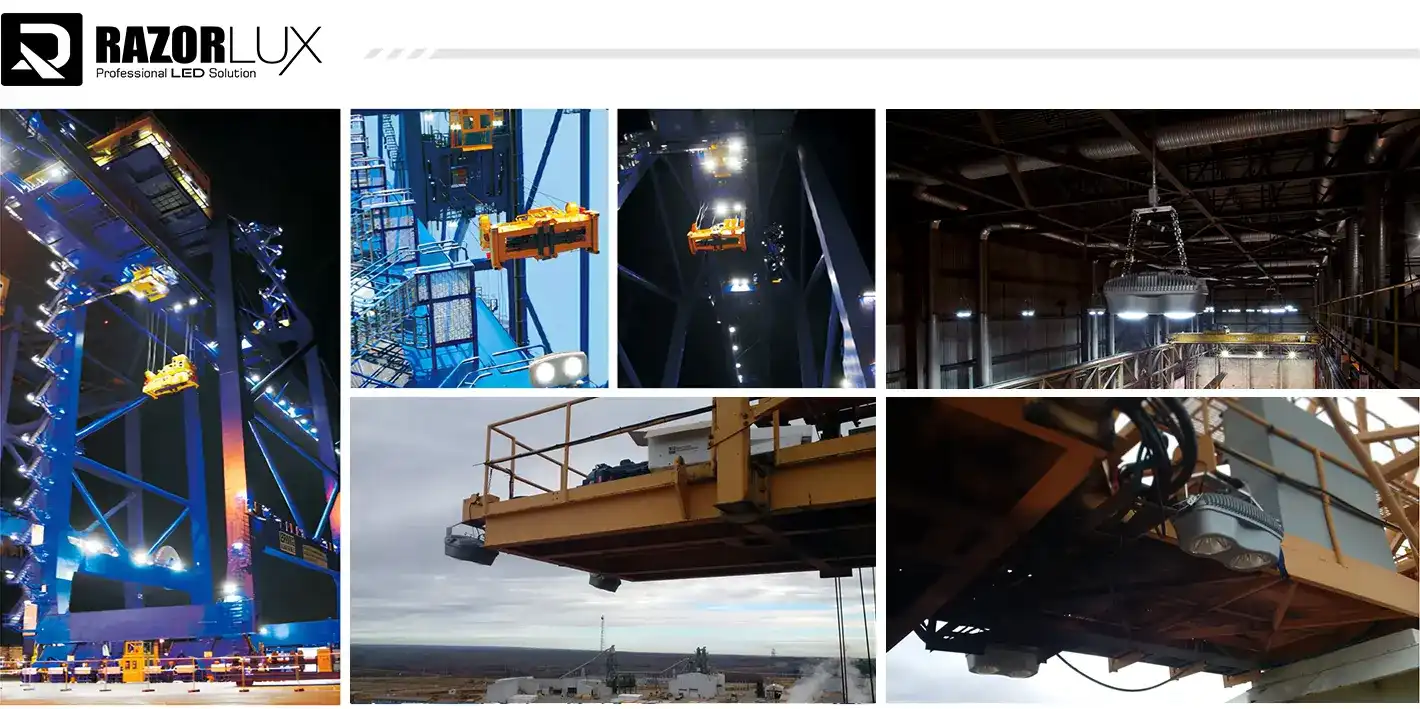

Ready to slash your facility's energy costs and enhance lighting performance? Xi'an Razorlux Optoelectronic Technology Co., Ltd., your trusted China Industrial Flood Lights Led supplier and China Industrial Flood Lights Led manufacturer, delivers premium Industrial Flood Lights Led for sale with comprehensive customization, competitive Industrial Flood Lights Led price structures, and full lifecycle support from our experienced team. Our China Industrial Flood Lights Led factory produces certified solutions backed by 5-year warranties, 200+ patents, and over 20 years of proven expertise. Whether you're outfitting a manufacturing plant, mining operation, or port facility, our Industrial Flood Lights Led wholesale programs provide the reliability and performance your operation demands. contact us today at sam@razorlux.com to discuss your specific requirements, request detailed specifications, or arrange sample evaluation. Transform your facility lighting while capturing immediate cost savings—reach out now and discover why leading industrial operations worldwide choose Razorlux for their critical lighting applications.

References

1. U.S. Department of Energy, "LED Lighting in Industrial Applications: Energy Savings and Performance Benefits," Office of Energy Efficiency and Renewable Energy, 2023.

2. International Association of Lighting Designers, "Best Practices for Industrial LED Lighting Systems: Efficiency, Safety, and Cost Optimization," Technical Standards Committee Report, 2024.

3. National Electrical Manufacturers Association, "High-Performance LED Systems for Demanding Environments: Technical Guidelines and Specification Standards," Industrial Lighting Division, 2023.

4. Illuminating Engineering Society, "Industrial and Manufacturing Facility Lighting: Energy Management Strategies and Technology Selection," Technical Memorandum Series, 2024.

_1750326878398.png)