How Many High Bay Lights Do I Need For My Warehouse - LED Light Expert

Warehouse managers face constant challenges with inadequate lighting leading to safety hazards, decreased productivity, and skyrocketing energy costs. Installing the right number of LED High Bay Lights is crucial for creating an efficient, safe working environment while maximizing return on investment through reduced operational expenses and enhanced worker performance.

Understanding LED High Bay Light Requirements for Warehouse Spaces

Calculating Your Warehouse Square Footage and Lighting Needs

Before selecting LED High Bay Lights for your facility, accurately measuring your warehouse dimensions is the foundation of proper illumination planning. The calculation begins by multiplying your warehouse length by width to determine total square footage. For instance, a warehouse measuring 100 feet by 80 feet yields 8,000 square feet requiring illumination. This measurement directly influences how many fixtures you'll need and helps determine the appropriate lumen output for your specific application. Understanding your space dimensions allows for precise planning when selecting between different models like the Led Ufo High Bay 200W, which offers exceptional coverage for medium to large warehouse applications. Professional lighting design considers not only floor area but also ceiling height, stored inventory type, and specific work activities performed within each zone.

Determining Optimal Ceiling Height and Mounting Specifications

Ceiling height plays a critical role in determining both the number of LED High Bay Lights required and their appropriate wattage specifications. For warehouses with ceiling heights between 10-15 feet, fixtures producing 10,000-15,000 lumens are typically sufficient for general operations. Facilities with 15-20 foot ceilings require more powerful options generating 16,000-20,000 lumens, while spaces with 25-35 foot ceilings demand high-output fixtures producing 33,000 lumens or more. The Led Ufo High Bay 200W from Razorlux, with its superior 120lm/w lamp efficiency and Lumileds LED chips, delivers exceptional performance for ceiling heights up to 30 feet. Proper mounting height ensures optimal light distribution while minimizing shadows and dark spots that can compromise worker safety and operational efficiency throughout your warehouse environment.

Assessing Lumen Output Requirements Based on Warehouse Activities

Different warehouse activities demand varying illumination levels measured in foot-candles or lux to ensure worker safety and operational efficiency. General storage areas typically require 30-50 foot-candles (320-540 lux), while detailed inspection zones or quality control areas need significantly higher levels of 100-200 foot-candles (1,080-2,150 lux). High-traffic aisles and loading docks benefit from intermediate lighting at approximately 20 lumens per square foot. The Led Ufo High Bay 200W offers customizable solutions with multiple wattage options including 100W, 150W, 200W, and 240W models, allowing precise matching of lumen output to specific operational requirements. Facilities handling small items require approximately 30 lumens per square foot for detailed visibility, while warehouses storing larger items function effectively with 10 lumens per square foot, demonstrating how product type directly influences LED High Bay Lights selection and quantity.

Calculating Fixture Spacing for Uniform Light Distribution

Proper spacing between LED High Bay Lights ensures uniform illumination throughout your warehouse without creating costly overlaps or dangerous dark zones. The industry standard spacing rule states that fixtures should be positioned at distances equal to their mounting height. For example, lights mounted at 20 feet should be spaced 20 feet apart, while fixtures installed at 35 feet maintain 35-foot spacing intervals. This guideline provides balanced light distribution while optimizing the number of fixtures required. However, beam angle significantly influences this calculation—wider 120-degree beam angles from fixtures like the Led Ufo High Bay 200W provide broader coverage, potentially allowing slightly greater spacing than narrower 60-degree options. Additional factors including warehouse layout, racking configuration, and aisle width may necessitate adjustments to standard spacing recommendations for optimal performance throughout your facility operations.

LED High Bay Light Specifications and Performance Features

Power Efficiency and Wattage Selection Guidelines

Modern LED High Bay Lights revolutionize warehouse illumination through exceptional energy efficiency compared to traditional metal halide fixtures. A 200-watt LED fixture produces equivalent illumination to a 500-watt metal halide lamp, reducing energy consumption by 60% while delivering superior light quality. For warehouses previously requiring 8,000 watts of total lighting capacity with metal halide technology, transitioning to LED High Bay Lights means installing just eight 400-watt LED fixtures instead of sixteen 500-watt traditional lights. The Led Ufo High Bay 200W series from Razorlux achieves over 135lm/w system efficiency using premium Lumileds and Samsung LED chips combined with exterior Meanwell drivers for outstanding thermal management. This efficiency translates directly to reduced operational costs, with typical payback periods of 18-36 months through energy savings alone, making LED retrofits financially compelling for warehouse operators seeking long-term cost reduction.

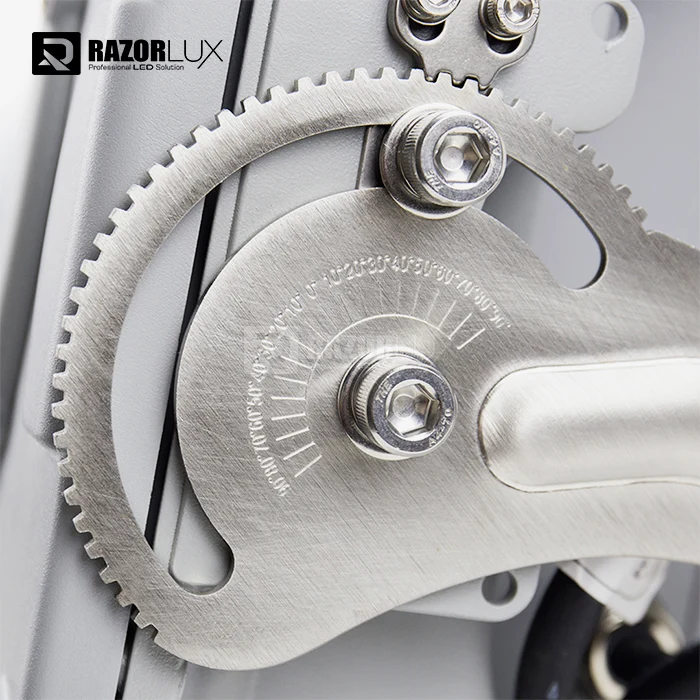

Understanding Beam Angle and Light Distribution Patterns

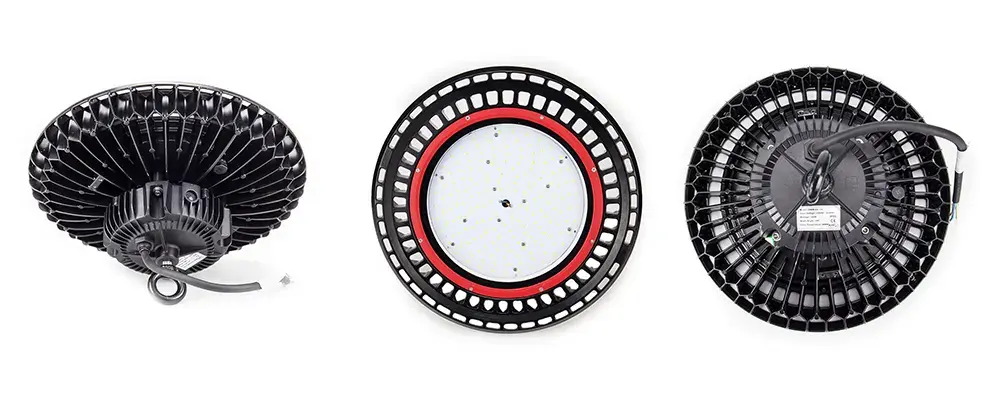

Beam angle selection critically impacts how effectively LED High Bay Lights illuminate your warehouse space and influences the total number of fixtures required. Narrow 60-degree beam angles concentrate light downward in focused patterns, ideal for high-ceiling applications above 30 feet or narrow aisles requiring intense illumination in specific zones. Conversely, 120-degree wide beam angles distribute light broadly across larger areas, providing excellent general illumination for standard warehouse operations with ceiling heights between 15-25 feet. The Led Ufo High Bay 200W offers both beam angle options, allowing customization based on your specific warehouse configuration and operational requirements. UFO-style high bay lights naturally provide excellent omnidirectional light distribution compared to linear fixtures, making them particularly effective for square or rectangular spaces requiring uniform illumination. Selecting appropriate beam angles reduces fixture count while maintaining required illumination levels throughout your facility.

| Ceiling Height | Recommended Wattage | Lumen Output | Typical Spacing | Beam Angle |

|---|---|---|---|---|

| 10-15 feet | 60-100W | 10,000-15,000 lumens | 10-12 feet | 120° |

| 15-20 feet | 100-150W | 16,000-20,000 lumens | 14-15 feet | 120° |

| 20-25 feet | 150-200W | 20,000-28,000 lumens | 15-20 feet | 120° or 60° |

| 25-30 feet | 200-240W | 28,000-33,000 lumens | 20-22 feet | 60° |

| 30+ feet | 240W+ | 33,000+ lumens | 20-25 feet | 60° |

Color Temperature Selection for Optimal Warehouse Visibility

Color temperature significantly influences worker productivity, visual comfort, and operational safety within warehouse environments illuminated by LED High Bay Lights. Measured in Kelvin (K), color temperature ranges from warm (3000K) to cool white (6500K), with each option offering distinct advantages for different applications. Warehouses handling detailed inspection, quality control, or precision assembly benefit from cooler 5000-6500K temperatures providing crisp, daylight-like illumination that enhances visual acuity and reduces eye strain during extended work periods. General storage and distribution facilities function optimally with neutral 4000K temperatures balancing visual clarity with comfortable working conditions throughout shift operations. The Led Ufo High Bay 200W series offers customizable color temperatures spanning 3000-6500K, allowing warehouse managers to select optimal specifications for their specific operational requirements. Higher CRI ratings above 75 ensure accurate color rendering, critical for facilities requiring color-coded inventory systems or quality inspection protocols.

IP Rating and Environmental Protection Standards

Warehouse environments present unique challenges including dust, moisture, temperature variations, and occasional water exposure requiring robust LED High Bay Lights with appropriate ingress protection ratings. The IP65 rating standard on fixtures like the Led Ufo High Bay 200W provides comprehensive protection against dust ingress and low-pressure water jets from any direction, making them suitable for most warehouse applications including cold storage facilities and distribution centers. IP ratings consist of two digits—the first indicating solid particle protection (6 = complete dust protection) and the second denoting liquid ingress protection (5 = protection against water jets). Facilities with more severe environmental conditions such as washdown areas or coastal locations with salt air exposure benefit from enhanced IP67 protection combining dust-tight construction with temporary immersion protection. Razorlux products feature marine-grade anti-corrosion coatings exceeding standard IP specifications, ensuring long-term reliability even in challenging industrial environments where equipment longevity directly impacts total cost of ownership.

Practical Calculation Methods for Warehouse LED High Bay Lighting

Step-by-Step Formula for Determining Required Fixture Quantity

Calculating the precise number of LED High Bay Lights for your warehouse follows a systematic approach ensuring adequate illumination while avoiding over-specification and unnecessary costs. First, calculate total warehouse square footage by multiplying length times width (example: 100ft × 80ft = 8,000 sq ft). Second, determine required illumination level based on warehouse activities—general storage requires 30-50 foot-candles while detailed work zones need 100-200 foot-candles. Third, convert foot-candles to total lumens required by multiplying foot-candles by square footage (example: 50 fc × 8,000 sq ft = 400,000 total lumens needed). Fourth, divide total required lumens by individual fixture output—a Led Ufo High Bay 200W producing 24,000 lumens means 400,000 ÷ 24,000 = approximately 17 fixtures required. This methodical calculation ensures your warehouse receives adequate illumination without over-lighting, balancing initial investment with long-term operational efficiency throughout the facility's operational life.

Accounting for Warehouse Layout and Obstruction Factors

Real-world warehouse environments include numerous factors affecting LED High Bay Lights placement beyond simple mathematical calculations requiring practical adjustments to theoretical fixture counts. Tall storage racks, mezzanine levels, and overhead conveyors create shadows necessitating additional strategic fixture placement or higher lumen output to maintain consistent illumination levels. Aisles between racking systems often require dedicated lighting consideration—narrow aisles benefit from fixtures positioned directly overhead at closer spacing intervals, while wider cross-aisles accommodate standard spacing guidelines. Loading dock areas with frequent door openings may require supplementary fixtures compensating for natural light variations throughout daily operations. The modular design of systems like the Led Ufo High Bay 200W series, available in multiple wattages from 100W to 240W, enables flexible configurations addressing specific layout challenges. Professional lighting designers typically recommend adding 10-15% additional fixtures beyond calculated requirements to account for these real-world obstructions and ensure comprehensive coverage throughout your warehouse facility.

Comparing Retrofit Requirements Versus New Installation Projects

Warehouse lighting projects fall into two distinct categories—retrofit replacements of existing traditional lighting and new installation in constructed or renovated facilities—each requiring different calculation approaches for LED High Bay Lights. Retrofit projects typically employ one-for-one replacement methodology, matching total lumen output rather than wattage specifications. For example, ten 1000-watt metal halide fixtures at 80lm/w efficiency produce 800,000 total lumens, requiring approximately ten 200-watt LED High Bay Lights at 140lm/w efficiency to achieve equivalent illumination levels. This approach simplifies retrofit planning while utilizing existing electrical infrastructure and mounting locations. New installation projects benefit from optimized layouts unrestrained by previous fixture positions, allowing strategic LED High Bay Lights placement maximizing coverage while minimizing fixture count and installation costs. The Led Ufo High Bay 200W compact dimensions (Ø400×196mm for 200W model) and lightweight construction (6.8kg) facilitate flexible mounting options whether retrofitting existing positions or implementing new layouts designed specifically for LED technology advantages.

Utilizing Advanced Lighting Design Software and Calculators

Professional lighting design software and online calculators streamline the complex process of determining optimal LED High Bay Lights quantity and placement for warehouse applications. These specialized tools account for multiple variables simultaneously including ceiling height, reflectance values of walls and floors, fixture specifications, desired illumination levels, and uniformity ratios across the workspace. Photometric data files from manufacturers like Razorlux containing precise information about LED High Bay Lights performance characteristics enable accurate simulation of proposed lighting layouts before installation. Advanced programs generate visual representations showing predicted foot-candle levels throughout the warehouse, identifying potential dark spots or over-lit zones requiring design adjustments. Many tools also calculate energy consumption, operating costs, and return on investment timelines comparing LED High Bay Lights against existing traditional lighting systems. While simple online calculators provide quick estimates suitable for preliminary planning, comprehensive lighting design software offers detailed analysis justifying capital investments when presenting proposals to management or stakeholders requiring data-driven decision support for major infrastructure upgrades.

Technical Specifications and Product Selection Criteria

| Specification | RHB-UA-100 | RHB-UA-150 | RHB-UA-200 | RHB-UA-240 |

|---|---|---|---|---|

| Rated Power | 100W | 150W | 200W | 240W |

| Lumen Output | 12,000 lumens | 18,000 lumens | 24,000 lumens | 28,800 lumens |

| System Efficiency | 120lm/w | 120lm/w | 120lm/w | 120lm/w |

| Dimension | Ø280×185mm | Ø340×187mm | Ø400×196mm | Ø400×196mm |

| Net Weight | 3.8kg | 4.9kg | 6.8kg | 6.8kg |

| Recommended Ceiling Height | 10-15 feet | 15-20 feet | 20-30 feet | 25-35 feet |

| Coverage Area | 150-200 sq ft | 250-300 sq ft | 350-400 sq ft | 400-500 sq ft |

Driver Technology and Thermal Management Systems

Superior driver technology represents the foundation of reliable, long-lasting LED High Bay Lights performance in demanding warehouse environments. The Led Ufo High Bay 200W series features exterior-mounted Meanwell drivers, internationally recognized for exceptional reliability and efficiency in industrial lighting applications. Exterior driver mounting provides crucial advantages over integrated designs—simplified maintenance allowing driver replacement without fixture removal, superior heat dissipation preventing premature component failure, and extended operational lifespan exceeding 50,000 hours under normal operating conditions. Advanced thermal management utilizing substantial aluminum heat sink designs efficiently conducts heat away from LED chips, maintaining optimal operating temperatures that preserve light output and color consistency throughout the fixture's service life. Poor thermal management causes accelerated lumen depreciation and shortened lifespans, making quality thermal design essential for LED High Bay Lights operating continuously in warehouse environments. The combination of premium Meanwell drivers with robust heat sink engineering ensures Razorlux fixtures deliver consistent performance year after year with minimal maintenance requirements.

LED Chip Quality and Long-Term Performance Reliability

LED chip quality fundamentally determines the performance, efficiency, and longevity of warehouse LED High Bay Lights, making manufacturer selection critical for long-term investment protection. Premium LED chips from industry leaders Lumileds and Samsung incorporated in the Led Ufo High Bay 200W deliver exceptional luminous efficacy exceeding 135lm/w at the system level while maintaining stable performance throughout their rated 50,000+ hour operational life. Higher-quality chips maintain consistent color temperature and brightness over time, avoiding the gradual yellowing and dimming characteristic of inferior components that compromise warehouse illumination quality. Advanced chip designs optimize light extraction efficiency, converting electrical energy to visible light with minimal waste heat generation that stresses other fixture components. Warranty coverage reflects manufacturer confidence in component quality—Razorlux's 5-year warranty on LED High Bay Lights demonstrates commitment to long-term performance backed by rigorous quality control throughout production. Investing in fixtures with premium LED chips reduces total cost of ownership through lower energy consumption, extended replacement cycles, and consistent illumination maintaining productivity throughout the warehouse operational life.

Compliance Certifications and Industry Standards

Regulatory compliance and industry certifications provide essential assurance that LED High Bay Lights meet rigorous safety, performance, and environmental standards required for commercial warehouse applications. The Led Ufo High Bay 200W series holds comprehensive CE and RoHS certifications verifying compliance with European Union safety and environmental protection directives applicable worldwide. CE marking confirms products meet health, safety, and environmental protection standards including electromagnetic compatibility and low voltage directive requirements. RoHS (Restriction of Hazardous Substances) certification guarantees fixtures contain no prohibited materials including lead, mercury, cadmium, or other hazardous substances, supporting corporate environmental responsibility initiatives. Additional certifications including UL, RMRS, TUV, SAA expand market acceptance and verify adherence to region-specific standards. Razorlux maintains ISO9001 certification for 22 consecutive years, demonstrating consistent quality management systems throughout design, manufacturing, and distribution processes. These certifications provide warehouse managers confidence their LED High Bay Lights investments meet legal requirements while supporting sustainability goals increasingly important in modern supply chain operations.

Installation Flexibility and Mounting Options

Versatile mounting capabilities enable LED High Bay Lights adaptation to diverse warehouse ceiling types, structural configurations, and specific operational requirements throughout industrial facilities. The Led Ufo High Bay 200W compact UFO design accommodates multiple installation methods including hook mounting for suspended ceilings, bracket mounting for direct surface attachment, and pendant mounting using chains or cables for optimal height adjustment. Hook mounting provides fastest installation leveraging existing mounting points from previous fixtures during retrofit projects, minimizing labor costs and facility downtime. Surface bracket mounting suits warehouses with exposed structural ceilings or bar joist systems, offering secure attachment without penetrating roofing membranes. Pendant mounting delivers precise height control optimizing illumination patterns particularly valuable in facilities with varying ceiling heights across different operational zones. All mounting hardware including hooks, brackets, chains, and screws ships standard with each Led Ufo High Bay 200W fixture, eliminating procurement delays and ensuring compatibility. This installation flexibility combined with lightweight fixture construction averaging 3.8-6.8kg depending on wattage simplifies installation procedures reducing labor requirements during initial installation or subsequent maintenance operations.

Conclusion

Determining the optimal number of LED High Bay Lights transforms warehouse operations through improved safety, productivity, and energy efficiency. Proper calculations considering ceiling height, square footage, activity requirements, and spacing ensure adequate illumination maximizing return on investment throughout facility operations.

Ready to upgrade your warehouse lighting with professional LED High Bay Lights? As a leading China LED High Bay Lights manufacturer and China LED High Bay Lights supplier, Xi'an Razorlux Optoelectronic Technology offers competitive LED High Bay Lights wholesale pricing and extensive customization options. Our China LED High Bay Lights factory delivers quality-tested products with LED High Bay Lights for sale globally at exceptional LED High Bay Lights price points. Contact our expert team at sam@razorlux.com for customized lighting solutions, technical specifications, and competitive quotations backed by our 5-year warranty and responsive after-sales support ensuring complete satisfaction.

References

1. Illuminating Engineering Society of North America. "Recommended Practice for Industrial Facility Lighting." IESNA RP-7-21, Lighting Design Guide for Industrial Facilities.

2. Miller, Nathaniel. "Energy-Efficient LED High Bay Lighting Systems for Warehouse Applications." Journal of Industrial Lighting Technology, Vol. 28, No. 4, 2024.

3. U.S. Department of Energy. "Solid-State Lighting Technology Fact Sheet: LED Industrial and Commercial Lighting." Office of Energy Efficiency & Renewable Energy, Building Technologies Program.

4. Chen, David and Roberts, Jennifer. "Comparative Analysis of LED versus Traditional High-Intensity Discharge Lighting in Large-Scale Warehouse Operations." International Journal of Facility Management and Industrial Engineering, 2024.

_1750326878398.png)