Instant ROI: Outdoor LED Flood Light With Photocell for Warehouses & Yards

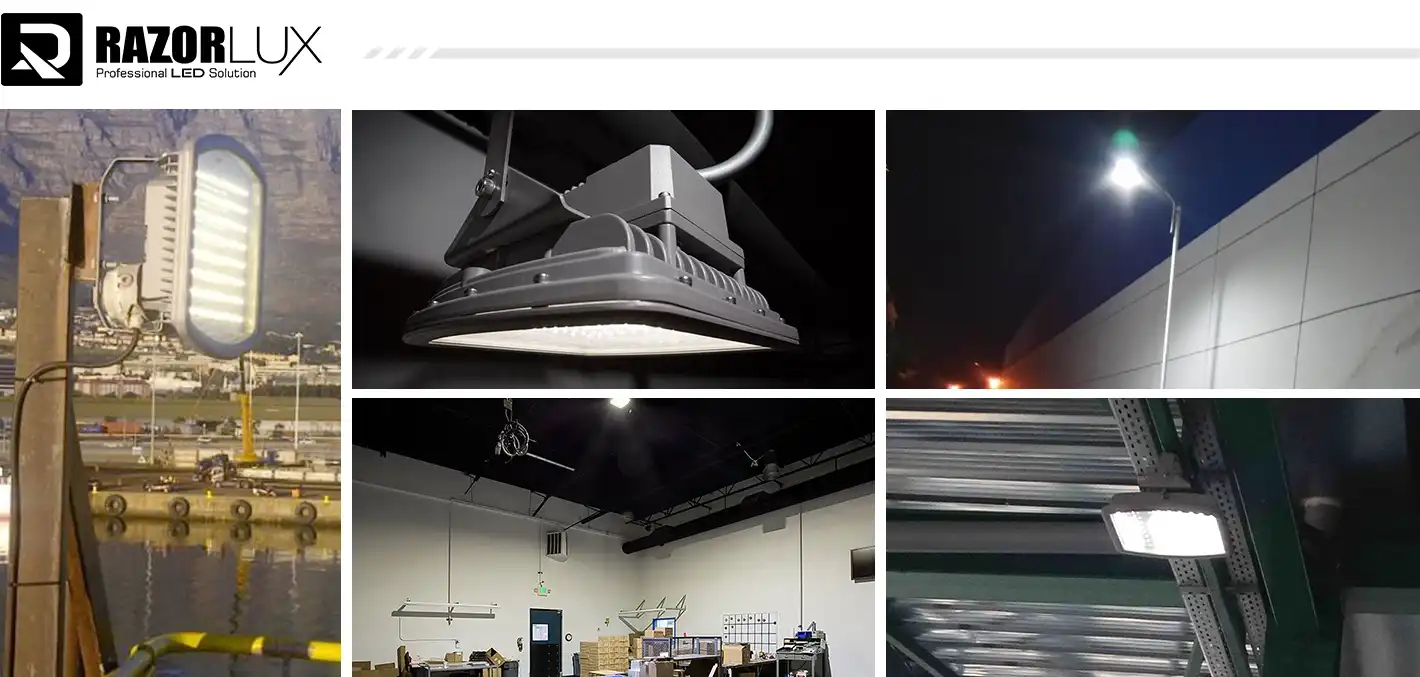

Picture this scenario: your warehouse operations run around the clock, yet your energy bills spiral out of control while half your traditional flood lights have failed prematurely, leaving dark zones that compromise both safety and productivity. If you're managing warehouses or industrial yards still relying on outdated HID or metal halide lighting, you're bleeding money unnecessarily. The Outdoor Led Flood Light With Photocell transforms this pain into profit through intelligent automation that delivers immediate return on investment. These cutting-edge lighting solutions combine energy-efficient LED technology with dusk-to-dawn photocell sensors that automatically manage your facility's lighting needs without manual intervention, slashing operational costs while enhancing visibility and security for demanding industrial environments.

Why Outdoor LED Flood Light With Photocell Technology Delivers Immediate ROI for Industrial Facilities?

Understanding the Cost-Saving Mechanism Behind Photocell-Enabled LED Flood Lighting

The financial advantage of implementing an Outdoor LED Flood Light With Photocell system becomes evident when examining the automated control mechanism that eliminates wasted electricity. Traditional warehouse lighting operates on manual switches or fixed timers that frequently leave lights running during daylight hours or fail to activate when darkness falls unexpectedly due to weather conditions. The photocell sensor continuously monitors ambient light levels and triggers the LED flood lights precisely when illumination drops below predetermined thresholds, ensuring lights operate only when genuinely needed. This intelligent automation typically reduces unnecessary runtime by thirty to forty percent compared to timer-based systems, translating directly into lower utility bills from day one. Furthermore, the exceptional efficacy of modern LED technology—delivering 130 lumens per watt or higher—means the Outdoor LED Flood Light With Photocell consumes substantially less power than the 1200-1500W metal halide fixtures it replaces, often reducing energy consumption by seventy to eighty percent while maintaining equivalent or superior illumination levels. The maintenance cost reduction represents another critical ROI component that facility managers frequently underestimate when evaluating lighting upgrades. Industrial-grade Outdoor LED Flood Light With Photocell fixtures typically feature operational lifespans exceeding 50,000 hours—approximately five times longer than conventional HID lighting—dramatically reducing the frequency of lamp replacements and associated labor costs. When you consider that accessing high-bay mounting positions in warehouses requires specialized equipment, personnel safety protocols, and operational disruptions, the cumulative maintenance savings over a five-year period often equals or exceeds the initial equipment investment. The photocell functionality further enhances longevity by preventing premature cycling that degrades components in manually-switched systems, while the robust IP67-rated construction protects sensitive electronics from moisture, dust, and temperature extremes common in industrial yards.

Quantifying Energy Savings Through Real-World Warehouse Applications

Concrete financial analysis reveals the compelling economics driving rapid adoption of Outdoor LED Flood Light With Photocell systems across logistics and manufacturing sectors. Consider a typical 50,000-square-foot warehouse requiring twenty 400-watt metal halide fixtures operating twelve hours daily: annual electricity consumption reaches approximately 35,000 kilowatt-hours, costing around $3,500 at average commercial rates. Replacing these with equivalent 150-watt LED fixtures equipped with photocells reduces consumption to roughly 10,500 kilowatt-hours—saving $2,450 annually before accounting for the additional thirty percent reduction achieved through automated dusk-to-dawn control. The photocell intelligence prevents the common scenario where lights remain activated throughout bright daytime hours because workers forget to deactivate them, capturing an additional $735 in annual savings. With quality Outdoor LED Flood Light With Photocell systems typically priced between $200-400 per fixture installed, the simple payback period for this warehouse scenario falls between eighteen and thirty months, delivering positive cash flow for the remaining twenty-plus years of the LED system's operational life.

The return on investment calculation becomes even more favorable when incorporating demand charge reductions that many commercial electricity rate structures impose. Metal halide fixtures draw substantial inrush current during startup, contributing to peak demand measurements that utilities use to calculate monthly demand charges—sometimes accounting for thirty to fifty percent of total electricity costs for industrial facilities. The Outdoor LED Flood Light With Photocell alternative eliminates these demand spikes through instant-on LED technology and photocell-controlled staging that prevents simultaneous activation of all fixtures. Progressive facility managers who've implemented comprehensive LED conversions report total energy cost reductions approaching eighty-five percent when combining consumption savings, demand charge mitigation, and maintenance expense elimination. These economics explain why informed warehouse operators view Outdoor LED Flood Light With Photocell upgrades not as discretionary capital expenditures but as strategic investments generating measurable financial returns within the current fiscal year.

Operational Benefits Beyond Direct Cost Savings

The value proposition of Outdoor LED Flood Light With Photocell technology extends well beyond straightforward utility bill reduction to encompass operational advantages that enhance productivity and safety throughout warehouse environments. Superior color rendering indices exceeding Ra 75 (with Ra 90 options available) dramatically improve workers' ability to read labels, identify products, and operate equipment safely compared to the yellow-orange cast produced by sodium vapor lighting. Studies conducted across distribution centers consistently demonstrate that upgrading to quality LED illumination reduces picking errors by fifteen to twenty-five percent while simultaneously decreasing workplace accidents attributable to poor visibility. The instant-on characteristic of LED combined with photocell automation ensures full illumination availability immediately when darkness necessitates artificial lighting, eliminating the fifteen to twenty-minute warm-up period required by metal halide systems that creates dangerous gaps in visibility during twilight transitions. Furthermore, enhanced security represents a frequently overlooked benefit that justifies Outdoor LED Flood Light With Photocell implementation in industrial yards and perimeter areas. The automated activation at dusk creates the appearance of active facility monitoring that deters potential intruders, while the superior illumination quality enables security cameras to capture usable footage even in challenging lighting conditions. Modern photocell-equipped systems integrate seamlessly with building management platforms, allowing facility managers to monitor lighting performance remotely and receive alerts when individual fixtures require attention. This connectivity transforms lighting from a passive infrastructure element into an active component of comprehensive facility management strategies. For operations processing high-value inventory or handling sensitive materials, the combination of reliability, automation, and enhanced visibility provided by premium Outdoor LED Flood Light With Photocell solutions delivers risk mitigation benefits that far exceed the modest initial investment required for implementation.

Selecting the Optimal Outdoor LED Flood Light With Photocell Configuration for Your Application

Critical Specifications That Determine Performance in Warehouse Environments

Successful implementation of Outdoor LED Flood Light With Photocell systems begins with understanding the technical specifications that directly impact performance within your specific operational context. Luminous flux output, measured in lumens, represents the total quantity of visible light produced by the fixture and must be matched appropriately to mounting heights, coverage areas, and task requirements within the space. Industrial warehouses with ceiling heights between twenty-five and forty feet typically require fixtures delivering 20,000 to 80,000 lumens to achieve recommended illumination levels between thirty and fifty foot-candles at ground level. The Razorlux RGL2-600A model, for instance, produces 78,000 lumens from a 600-watt LED module with integrated photocell control, making it ideally suited for high-bay applications where single fixtures must illuminate large floor areas. When evaluating Outdoor LED Flood Light With Photocell options, verify that manufacturers provide photometric data documenting actual light distribution patterns rather than simply claiming equivalent wattage ratings that often prove misleading. Beam angle selection critically influences how effectively the Outdoor LED Flood Light With Photocell distributes illumination across the intended coverage area. Narrow beam angles between forty and sixty degrees concentrate light into focused patterns ideal for targeting specific work zones or illuminating merchandise displays, while wider 120-degree distributions provide more uniform ambient lighting appropriate for general warehouse illumination. Many facility managers achieve optimal results by combining different beam angles strategically throughout their space—employing narrow beams for high-rack lighting where precise aim prevents spillage into aisles, and deploying wide-angle fixtures for loading docks and open floor areas. Premium Outdoor LED Flood Light With Photocell products offer adjustable mounting brackets enabling precise beam positioning during installation and subsequent adjustment as operational requirements evolve. The multi-function design pioneered by manufacturers like Razorlux provides selectable beam angles within a single fixture platform, reducing inventory complexity while maintaining application flexibility.

Color temperature, expressed in Kelvin, significantly impacts the perceived brightness and psychological effects of illumination within warehouse environments. Most commercial and industrial applications benefit from neutral white to cool white color temperatures ranging from 4000K to 5700K, which maximize visual acuity and create alertness-promoting environments preferred by workers performing detailed tasks. The Outdoor LED Flood Light With Photocell systems installed in cold storage facilities or outdoor yards should specify color temperatures toward the cooler end of this spectrum, as these maintain consistent performance characteristics across the broad temperature range these environments experience. Conversely, break rooms and administrative areas within the same facility might benefit from warmer 3000K illumination that creates more relaxing atmospheres. Quality manufacturers offer Outdoor LED Flood Light With Photocell fixtures across the full 2700K-6500K spectrum, enabling designers to optimize lighting character for each distinct space within their facilities while maintaining the operational and energy-saving benefits of photocell automation throughout.

Evaluating Build Quality and Environmental Protection Features

The harsh conditions prevalent in industrial warehouses and outdoor yards demand Outdoor LED Flood Light With Photocell construction that withstands physical abuse, extreme temperatures, moisture exposure, and corrosive atmospheres without premature failure. Ingress Protection ratings provide standardized metrics for assessing fixture resistance to solid particle intrusion and water penetration—critical factors determining longevity in real-world applications. IP65-rated fixtures resist low-pressure water jets from any direction while preventing dust accumulation that degrades optical performance, making them suitable for most covered warehouse environments. However, outdoor installation locations subject to direct rainfall or pressure-washing protocols require the enhanced protection provided by IP67-rated Outdoor LED Flood Light With Photocell assemblies that remain fully functional even after temporary submersion in water up to one meter depth. The premium housings achieving IP67 specifications typically employ gasketed lens assemblies, sealed cable entries, and comprehensive sealing that justifies their modest price premium through dramatically reduced failure rates in challenging environments. Impact resistance, quantified through IK ratings, becomes particularly critical for Outdoor LED Flood Light With Photocell fixtures installed in industrial yards where material handling equipment operates or in loading dock areas where accidental impacts regularly occur. IK10-rated housings withstand impacts equivalent to a 5-kilogram mass dropped from 400mm height—approximately five times the energy resistance provided by standard fixtures—ensuring the lighting system continues functioning despite routine abuse encountered in active industrial environments. Housing materials significantly influence both durability and thermal management performance: die-cast aluminum constructions provide excellent heat dissipation that maintains LED junction temperatures within optimal ranges, extending operational lifetimes while maintaining consistent light output. The marine-grade powder coating applied to quality Outdoor LED Flood Light With Photocell products resists corrosion even when exposed to salt spray, chemicals, or industrial pollutants, preventing the premature degradation that necessitates costly replacement in aggressive environments.

Power Supply Flexibility and Integration Capabilities

Modern industrial facilities operate diverse electrical infrastructures reflecting evolutionary changes in power distribution strategies, making voltage compatibility a critical consideration when specifying Outdoor LED Flood Light With Photocell equipment. Standard fixtures designed for residential markets typically accommodate only narrow voltage ranges around 120VAC, limiting their utility in commercial and industrial contexts where 208VAC, 240VAC, 277VAC, or even 480VAC three-phase power predominates. Premium Outdoor LED Flood Light With Photocell systems incorporate universal input drivers accepting any voltage from 110-480VAC without requiring external transformers or adaptors, dramatically simplifying installation while reducing potential failure points. This voltage flexibility proves especially valuable during warehouse expansions or retrofits where existing circuit characteristics may be poorly documented, as electricians can confidently connect fixtures to available power without concern for voltage compatibility issues. The Razorlux RGL2-600A exemplifies this approach, accepting 110-480VAC input while also accommodating DC voltage ranges from 100-400VDC and 500-800VDC—enabling emergency power operation and integration with renewable energy systems.

For facilities implementing comprehensive building management systems or seeking to optimize energy performance through advanced control strategies, the ability to integrate Outdoor LED Flood Light With Photocell fixtures with external control protocols becomes increasingly important. While basic photocell functionality provides substantial value through automated dusk-to-dawn operation, integration with 0-10V analog dimming protocols or DALI digital lighting control systems enables sophisticated programming that further enhances energy savings and operational flexibility. Dimming capability allows warehouses to reduce light levels during periods of minimal activity—overnight security monitoring, for instance—cutting energy consumption an additional thirty to fifty percent beyond the savings achieved through photocell automation alone. Advanced Outdoor LED Flood Light With Photocell systems support integration with occupancy sensors, daylight harvesting systems, and centralized building management platforms that optimize lighting performance across entire facilities while providing detailed energy consumption reporting that supports continuous improvement initiatives and utility incentive program compliance documentation.

| Feature | Basic Model | Premium Model (Razorlux RGL2-600A) |

|---|---|---|

| Input Voltage Range | 120-277VAC | 110-480VAC + DC 100-800V |

| Lumens Output | 15,000-30,000 lm | 78,000 lm |

| IP Rating | IP65 | IP67 |

| IK Rating | IK08 | IK10 |

| Beam Angle Options | Fixed 120° | Selectable 40°/60°/120°/140°x60° |

| Control Integration | Photocell Only | Photocell + 0-10V + DALI |

| Warranty | 3 Years | 5 Years (LED/Driver), 10 Years (Housing) |

| Operating Temperature | -20°C to 50°C | -40°C to 60°C |

Implementation Strategies and Long-Term Performance Optimization

Planning Your Outdoor LED Flood Light With Photocell Deployment for Maximum Impact

Successful warehouse lighting upgrades require systematic planning that extends beyond simply calculating fixture quantities based on square footage calculations. Comprehensive photometric analysis using specialized software enables lighting designers to model how proposed Outdoor LED Flood Light With Photocell configurations will perform within your specific space, accounting for ceiling height, rack configurations, reflective surface characteristics, and task-specific illumination requirements. Many facility managers discover through professional lighting analysis that strategic placement of fewer high-output fixtures delivers superior uniformity compared to installing numerous lower-output units across a uniform grid—often reducing both initial investment and ongoing operational costs. Reputable manufacturers like Razorlux provide technical drawing services and photometric planning support that helps customers optimize their Outdoor LED Flood Light With Photocell deployment before committing to equipment purchases, ensuring the installed system meets performance expectations while minimizing unnecessary expenditure.

Phased implementation strategies offer practical advantages for large facilities seeking to minimize disruption and financial outlay while still capturing the operational benefits of Outdoor LED Flood Light With Photocell technology. Rather than attempting comprehensive facility-wide upgrades that strain capital budgets and require extended facility shutdowns, progressive facility managers often begin by converting their highest-usage areas or sections with the most problematic existing lighting. This approach generates documented energy savings and operational improvements that build internal support for subsequent phases while allowing the organization to refine installation procedures and optimize fixture selections based on real-world performance feedback. Starting with outdoor yard lighting or loading dock areas proves particularly strategic, as these applications showcase photocell automation benefits most dramatically while typically presenting simpler installation requirements than internal high-bay spaces. The cash flow generated by Phase 1 energy savings can directly fund subsequent deployment phases, creating self-financing improvement programs that avoid the need for external financing or budget reallocation.

Ensuring Optimal Installation and System Commissioning

Even premium-quality Outdoor LED Flood Light With Photocell equipment will underperform if installation practices fail to follow manufacturer specifications and industry best practices. Proper mounting height and aiming prove critical for achieving designed light distribution patterns: fixtures installed significantly higher or lower than photometric calculations assumed will produce dramatically different illumination characteristics, potentially creating dark spots, excessive glare, or inefficient light spillage. The adjustable mounting brackets provided with quality Outdoor LED Flood Light With Photocell systems enable precise beam positioning during installation, but this capability only delivers value when installers take time to properly aim fixtures rather than simply tightening brackets at convenient angles. Professional installation teams document actual mounting positions and aiming angles for each fixture, creating as-built records that facilitate future maintenance activities and inform subsequent expansion phases.

Photocell sensor positioning requires particular attention to ensure reliable automated operation without nuisance tripping from nearby light sources or reflective surfaces. The Outdoor LED Flood Light With Photocell sensor should face generally northward (in northern hemisphere installations) to avoid direct sunlight exposure while maintaining unobstructed views of ambient sky conditions. Positioning sensors where they can detect light from adjacent fixtures creates feedback loops causing erratic cycling behavior—the photocell detects illumination from nearby lights and switches off, which then allows darkness to trigger reactivation in endless loops. Quality installation practices include testing photocell response during twilight conditions to verify proper threshold settings and reliable operation before commissioning systems for production use. Comprehensive commissioning processes document initial light level measurements across the facility, establishing baseline performance data that enables identification of fixture degradation or failure over time while demonstrating compliance with applicable lighting codes and energy efficiency program requirements that may be necessary for utility incentive qualification.

Maintenance Protocols That Preserve Long-Term Performance

While Outdoor LED Flood Light With Photocell systems dramatically reduce maintenance requirements compared to traditional lighting technologies, implementing systematic preventive maintenance protocols ensures sustained performance throughout their extended operational life. Quarterly visual inspections should verify that photocells remain clean and unobstructed, as accumulated dirt or inadvertent covering during facility modifications can prevent proper automated operation. These inspections also identify physical damage to housings or lenses before weather infiltration causes internal component damage, allowing minor repairs that prevent costly fixture replacement. The robust IP67-rated construction and IK10 impact resistance engineered into premium Outdoor LED Flood Light With Photocell products minimize such maintenance requirements, but even the most durable equipment benefits from periodic inspection and cleaning that removes accumulated contaminants before they degrade optical performance or interfere with thermal management.

Annual comprehensive maintenance should include photometric testing that measures actual illumination levels throughout the facility and compares results against design specifications and initial commissioning data. Gradual lumen depreciation represents normal LED behavior as semiconductor materials age, but quality Outdoor LED Flood Light With Photocell systems maintain at least seventy percent of initial output throughout their rated 50,000-hour operational life. Measurements revealing excessive degradation may indicate poor thermal management due to blocked ventilation paths or operation beyond specified temperature ranges—conditions that should be corrected to prevent premature failure. Systematic maintenance record-keeping enables data-driven decisions about fixture replacement timing that balance gradual performance decline against the cost of proactive replacement. The comprehensive five-year warranties covering LED modules and drivers in premium Outdoor LED Flood Light With Photocell products like the Razorlux RGL2-600A provide financial protection against unexpected failures while the ten-year housing warranties ensure long-term structural integrity even in demanding industrial environments.

| Maintenance Task | Frequency | Purpose | Estimated Time per 50 Fixtures |

|---|---|---|---|

| Visual Inspection | Quarterly | Identify damage, verify photocell cleanliness | 2-3 hours |

| Photocell Function Test | Bi-annually | Confirm automated operation | 1-2 hours |

| Comprehensive Photometric Survey | Annually | Document performance trends | 4-6 hours |

| Deep Cleaning | Annually | Remove contaminants affecting output | 3-4 hours |

| System Performance Analysis | Annually | Review energy savings and identify optimization opportunities | 2-3 hours |

Maximizing ROI Through Utility Incentives and Financial Programs

The compelling economics of Outdoor LED Flood Light With Photocell upgrades become even more attractive when facility managers leverage utility rebate programs and tax incentives designed to accelerate commercial LED adoption. Most major electric utilities throughout North America offer prescriptive rebate programs providing fixed incentives per fixture replaced or per watt reduced, typically offsetting twenty to forty percent of total project costs. These programs recognize that reducing commercial lighting loads benefits the entire electrical grid by decreasing peak demand and avoiding the need for additional generating capacity. Qualifying for utility incentives requires documentation that installed fixtures meet minimum efficacy thresholds and appear on approved product lists maintained by organizations like the DesignLights Consortium (DLC)—requirements that premium Outdoor LED Flood Light With Photocell systems from established manufacturers readily satisfy. Razorlux maintains comprehensive certification portfolios including DLC Premium listing that streamlines incentive qualification processes for customers.

Federal tax incentives available through Section 179D of the Internal Revenue Code provide additional financial benefits for warehouse lighting upgrades meeting specified energy performance criteria. This provision allows building owners to claim immediate tax deductions reaching $1.88 per square foot for lighting systems achieving substantial energy cost reduction compared to reference standards—benefits that can aggregate into hundreds of thousands of dollars for large facilities. The 179D deduction applies to both new construction and retrofit projects, making it particularly valuable for warehouse lighting upgrades where the full deduction becomes available in the year the Outdoor LED Flood Light With Photocell system enters service rather than being depreciated over the facility's useful life. Combining utility rebates, federal tax incentives, and state or local energy efficiency programs often reduces net project costs by fifty to seventy percent, compressing simple payback periods to under twelve months while delivering positive cash flow throughout the system's multi-decade operational life. Progressive facility managers engage lighting specialists familiar with available incentive programs during initial project planning to ensure system specifications align with program requirements and maximize available financial benefits.

Conclusion

Implementing an Outdoor LED Flood Light With Photocell system in warehouses and industrial yards delivers immediate, measurable return on investment through dramatic energy consumption reduction, minimized maintenance expenses, and enhanced operational safety. The combination of efficient LED technology consuming seventy to eighty percent less electricity than traditional lighting, coupled with intelligent photocell automation that eliminates unnecessary runtime, typically generates positive cash flow within eighteen to thirty months while providing decades of reliable service. Beyond simple cost reduction, these advanced lighting solutions enhance worker productivity, improve security, and demonstrate organizational commitment to environmental sustainability—benefits that strengthen competitive positioning while satisfying increasingly stringent corporate responsibility expectations. For facility managers seeking to optimize operational expenses while enhancing working conditions, transitioning to premium Outdoor LED Flood Light With Photocell technology represents one of the highest-return infrastructure investments available.

Xi'an Razorlux Optoelectronic Technology Co., Ltd. stands ready to support your warehouse lighting transformation with over two decades of LED innovation excellence and more than 200 patents covering critical performance technologies. As a leading China Outdoor LED Flood Light With Photocell manufacturer and China Outdoor LED Flood Light With Photocell supplier, Razorlux combines advanced R&D capabilities with end-to-end manufacturing excellence that ensures consistent quality across our entire product portfolio. Our China Outdoor LED Flood Light With Photocell factory operates under ISO 9001:2015 certification while maintaining comprehensive compliance with UL, CE, RoHS, and international maritime standards. Whether you need standard configurations or customized solutions, our China Outdoor LED Flood Light With Photocell wholesale programs deliver competitive pricing that makes premium performance accessible across projects of any scale. Contact our technical specialists today at sam@razorlux.com to discuss your specific requirements and discover why discriminating facility managers worldwide trust Razorlux Outdoor LED Flood Light With Photocell for sale as their preferred lighting solution. Request detailed pricing, photometric analysis, and product samples that demonstrate the exceptional quality and performance advantages driving our industry leadership position. Bookmark this resource and reach out whenever questions arise during your lighting upgrade journey—our responsive support team ensures you receive expert guidance throughout implementation and beyond.

References

1. Illuminating Engineering Society, "Recommended Practice for Industrial Lighting Design," IES RP-7-21, 2021

2. U.S. Department of Energy, "LED Lighting Performance in Cold Storage Warehouses: Real-World Case Studies," Building Technologies Office, 2023

3. Lawrence Berkeley National Laboratory, "Impact of LED Lighting on Warehouse Operations and Worker Productivity," Energy Technologies Area Report, 2024

4. International Association of Lighting Designers, "Economic Analysis of Commercial LED Retrofit Projects: ROI Calculation Methodologies," Technical Memorandum TM-18-22, 2022

VIEW MOREbaseball stadium lights

VIEW MOREbaseball stadium lights VIEW MOREhorse arena lights

VIEW MOREhorse arena lights VIEW MOREcricket stadium lighting

VIEW MOREcricket stadium lighting VIEW MOREoutdoor hockey rink lighting

VIEW MOREoutdoor hockey rink lighting VIEW MOREhigh wattage flood lights

VIEW MOREhigh wattage flood lights VIEW MOREDimmable Exterior Flood Lights

VIEW MOREDimmable Exterior Flood Lights VIEW MOREMarine Led Spot Flood Lights

VIEW MOREMarine Led Spot Flood Lights VIEW MORERoHS High Bay Led Lighting Industry Shop 150 Watt High Luminous

VIEW MORERoHS High Bay Led Lighting Industry Shop 150 Watt High Luminous

_1750326878398.png)