Mine Site Lighting: Top LED Solutions for Safer Operations

Picture this: It's 3 AM in an underground tunnel, heavy machinery rumbles through darkness, and a single lighting failure could mean disaster. Poor visibility leads to crushed equipment, worker injuries, and costly production halts. Mine Site Lighting isn't just about seeing—it's about survival, efficiency, and protecting every worker who descends into hazardous environments. This comprehensive guide reveals how advanced LED solutions transform dangerous mining operations into safer, more productive workspaces through superior illumination technology.

Understanding Mine Site Lighting Requirements for Maximum Safety

Critical Illumination Standards in Mining Environments

Mine Site Lighting demands exceed typical industrial applications due to extreme operational hazards. Federal regulations mandate specific lumen levels: underground primary areas require 20-50 footcandles, while precision drilling and blasting zones need 50-100 footcandles for accurate work execution. These standards ensure workers can identify hazards like loose rocks, equipment malfunctions, and ground instability before accidents occur. Proper Mine Site Lighting compliance reduces incident rates by improving hazard recognition and response times across all operational zones.

Durability Requirements for Harsh Mining Conditions

Effective Mine Site Lighting systems must withstand constant vibration from drilling equipment, exposure to corrosive chemicals, extreme temperature fluctuations from -40°C to 60°C, and persistent dust accumulation that clogs inferior fixtures. Traditional lighting technologies fail rapidly under these conditions, requiring frequent dangerous replacements in hazardous locations. Modern Led Mine Site Lighting solutions feature IP65 to IP67 protection ratings ensuring complete dust-tight sealing and water resistance against high-pressure jets. Industrial-grade housings constructed from marine-grade aluminum with powder coating provide exceptional corrosion resistance, while shock-resistant mounting systems maintain performance despite continuous heavy vibration from crushers, haul trucks, and drilling operations.

Energy Efficiency and Operational Cost Considerations

Mine Site Lighting operates continuously across 24/7 operations, making energy consumption a major operational expense. LED technology delivers up to 70% energy reduction compared to metal halide and fluorescent systems, dramatically lowering generator fuel costs in remote sites. A 1000W LED fixture producing 120,000 lumens replaces 2000-3000W HID lamps while consuming significantly less power. This efficiency extends beyond electricity savings—reduced heat generation means lower cooling requirements, extended equipment lifespan, and safer working temperatures. Mine Site Lighting upgrades typically achieve payback within 18-24 months through combined energy savings and reduced maintenance costs.

Advanced LED Technology Transforming Mine Site Lighting Performance

Superior Lumen Output and Color Rendering Quality

| Specification | Traditional HID | Advanced LED Mine Site Lighting |

|---|---|---|

| Lumen Efficiency | 60-80 LM/W | 130+ LM/W |

| Color Rendering Index | Ra 60-70 | Ra 75-90+ |

| Operational Lifespan | 10,000-15,000 hours | 50,000-100,000 hours |

| Warm-up Time | 10-20 minutes | Instant full brightness |

Advanced Mine Site Lighting using LED technology provides exceptional color rendering indices (CRI Ra>75), enabling workers to distinguish safety color codes, identify material differences, and recognize hazards more accurately than older technologies. The 130 LM/W efficiency combined with customizable beam angles (60°, 120°, 140°x60°) ensures optimal light distribution across various mining applications from confined tunnels to expansive open-pit operations. This superior illumination quality directly translates to fewer accidents, improved productivity, and enhanced worker confidence when operating in demanding conditions.

Smart Control Systems and IoT Integration

Contemporary Mine Site Lighting incorporates intelligent control systems featuring motion sensors, occupancy detection, and adaptive brightness adjustment responding to ambient conditions and operational requirements. IoT-enabled fixtures provide real-time monitoring of lighting status, automated failure alerts, and predictive maintenance scheduling through centralized dashboards. These smart capabilities enable remote diagnostics, performance optimization, and seamless integration with mine management systems. Dimming controls including 0-10V and DALI protocols allow precise illumination adjustment, reducing energy consumption during low-activity periods while maintaining safety-critical lighting levels. Emergency backup systems automatically activate during power outages, providing critical visibility for safe evacuation procedures.

Emergency Power Capabilities for Continuous Operation

Modern Mine Site Lighting solutions integrate emergency power functionality ensuring uninterrupted illumination during electrical failures. Advanced systems incorporate battery backup providing two hours of full-brightness operation, critical for safe equipment shutdown and personnel evacuation during power disruptions. This emergency capability proves essential in underground operations where sudden darkness creates immediate life-threatening situations. Automatic switchover occurs instantaneously, preventing the dangerous gap experienced with traditional emergency lighting requiring manual activation. Mine Site Lighting with integrated emergency power eliminates separate emergency fixture installations, reducing infrastructure complexity while enhancing overall safety reliability.

Selecting Optimal Mine Site Lighting Solutions for Different Applications

Underground Tunnel and Shaft Illumination Requirements

Underground Mine Site Lighting faces unique challenges including limited natural light, confined spaces with restricted mounting options, high dust concentrations reducing visibility, and moisture accumulation from groundwater seepage. Fixtures must provide uniform illumination eliminating dangerous shadows where hazards hide, while mounting systems accommodate irregular rock surfaces and ceiling heights. Portable Mine Site Lighting solutions on mobile towers support tunneling operations, maintenance activities, and emergency response scenarios. Explosion-proof fixtures rated for hazardous atmospheres prevent ignition of combustible gases and dust particles, meeting ATEX and IECEx certification requirements for underground coal and mineral extraction operations.

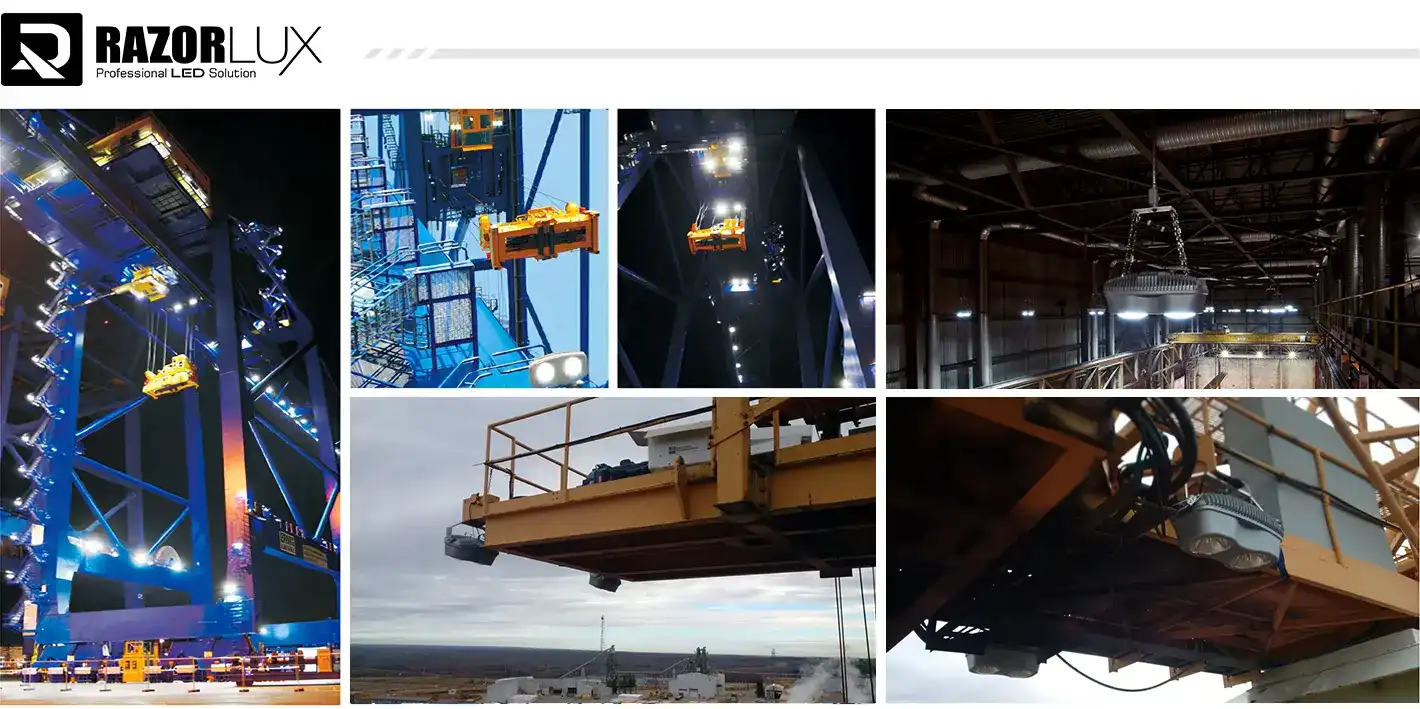

Open-Pit Mining and Surface Operation Lighting

Surface Mine Site Lighting illuminates vast areas requiring high-output fixtures with wide beam distribution covering haul roads, loading zones, and equipment staging areas. Open-pit operations demand robust weatherproofing protecting against rain, snow, extreme temperatures, and intense solar exposure degrading inferior housings. High-mast lighting towers with multiple LED arrays provide comprehensive area coverage, while vehicle-mounted Mine Site Lighting ensures mobile equipment operators maintain clear visibility during nighttime operations. Perimeter security lighting deters unauthorized access while enabling surveillance systems to monitor expansive mining properties effectively.

Specialized Applications in Processing and Maintenance Facilities

| Application Area | Recommended Specifications | Key Features |

|---|---|---|

| Mineral Processing Plants | 400-1000W, IP67, Vibration-Resistant | Withstands crusher vibration, chemical exposure |

| Equipment Maintenance Bays | 200-600W, High CRI (Ra>80), Adjustable Mounting | Precise color rendering for inspection work |

| Storage Warehouses | 100-300W, Wide Beam (120°), Dimming Capability | Energy-efficient coverage for large spaces |

| Haul Roads | 600-1000W, Narrow Beam (60°), High Mounting | Long-distance illumination for transportation routes |

Processing facilities require Mine Site Lighting withstanding constant heavy vibration from crushing equipment, conveyors, and material handling systems. Maintenance workshops demand high color rendering enabling accurate inspection of equipment conditions, weld quality, and component wear. Warehouse storage areas benefit from dimming capabilities and zoned controls reducing energy consumption while maintaining adequate visibility for material handling operations. Each application demands tailored Mine Site Lighting specifications optimizing performance, safety, and operational efficiency.

Implementation Best Practices for Mine Site Lighting Systems

Professional Installation and Compliance Standards

Successful Mine Site Lighting implementation requires professional assessment of site-specific illumination requirements, electrical infrastructure capacity, and regulatory compliance obligations. Qualified electricians familiar with hazardous area classifications ensure proper fixture selection and installation meeting MSHA, OSHA, and international mining safety standards. Comprehensive lighting plans optimize fixture placement, mounting heights, and beam angles achieving uniform illumination while minimizing energy consumption and equipment costs. Documentation including technical drawings, electrical schematics, and compliance certifications facilitates regulatory inspections and future maintenance planning.

Maintenance Strategies for Extended System Lifespan

Despite superior LED durability, Mine Site Lighting requires periodic maintenance preserving optimal performance throughout 50,000+ hour operational lifespans. Regular cleaning removes dust accumulation degrading light output by up to 30% in high-particulate environments. Inspection protocols identify mounting hardware loosening from vibration, seal degradation compromising weatherproofing, and early signs of component failure enabling proactive replacements before critical failures occur. Systematic maintenance scheduling coordinated with production downtime minimizes operational disruptions while extending fixture longevity and maintaining consistent illumination quality.

Upgrading Existing Systems to Modern LED Technology

Legacy Mine Site Lighting systems using metal halide, high-pressure sodium, or fluorescent technologies present significant upgrade opportunities. Retrofit strategies include direct LED replacement maintaining existing mounting infrastructure, complete fixture replacement when housings lack adequate sealing or structural integrity, and phased implementation prioritizing highest-risk areas where lighting failures pose greatest safety consequences. Upgrade planning considers voltage compatibility (AC 80-360V, 400-600V or DC 100-400V, 500-800V options), emergency power integration, and smart control system implementation. Financial analysis comparing energy savings, maintenance reduction, and safety improvements demonstrates rapid return on investment justifying capital expenditure for Mine Site Lighting modernization.

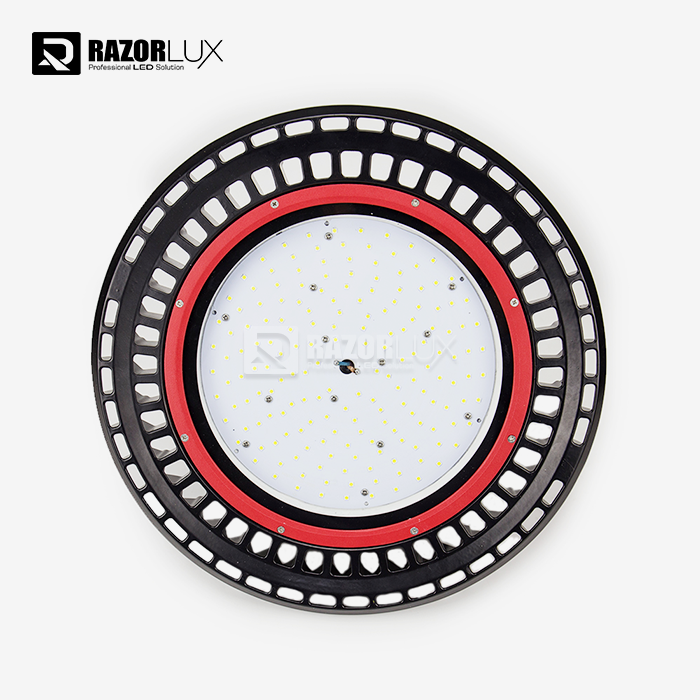

Razorlux Mine Site Lighting: Industry-Leading Solutions

Technical Excellence and Innovation Leadership

Xi'an Razorlux Optoelectronic Technology Co., Ltd., established in 1998, has evolved into a global China Mine Site Lighting manufacturer pioneering advanced LED solutions for harsh industrial environments. With over 200 patents covering LED Packaging innovation, intelligent power control systems, and structural design optimization, Razorlux combines extensive research capabilities with comprehensive manufacturing excellence. The company's Mine Site Lighting products comply with rigorous international standards including UL, RMRS, TUV, CE, SAA, RoHS, DLC, and CB certifications, ensuring global market acceptance and regulatory compliance across diverse jurisdictions.

Comprehensive Service Ecosystem Supporting Client Success

As a premier China Mine Site Lighting supplier, Razorlux provides end-to-end professional services beyond product sales. Pre-sales consultation guides clients selecting optimal specifications matching operational requirements, while custom sampling and prototyping enable performance validation before bulk orders. Technical documentation including detailed drawings and installation guides supports engineering integration and project planning. Product customization capabilities accommodate specific wattage requirements, color temperatures (2700K-6500K), housing materials, mounting configurations, and control system integration. OEM and ODM services enable partners creating branded Mine Site Lighting solutions tailored to regional market demands.

Global Distribution and Reliable Delivery Capabilities

Razorlux operates through strategic subsidiaries in the USA and Hong Kong, with products distributed across Europe, North America, Southeast Asia, and emerging mining markets worldwide. As a trusted China Mine Site Lighting factory, the company offers flexible shipping options including international express (3-7 days for 0.5-300kg shipments), air freight (5-10 days for 300kg+ orders), China-Europe railway express (18-22 days for 500kg+ bulk shipments), and sea transport (15-50 days representing the most economical option for large-volume projects). Robust packaging using custom-cut foam protection, reinforced cartons, and optional wooden crates ensures safe transit protecting precision optical components during international transportation.

Cost Analysis and Return on Investment for Mine Site Lighting Upgrades

Total Cost of Ownership Comparison

Evaluating Mine Site Lighting investments requires comprehensive total cost of ownership analysis extending beyond initial purchase prices. LED systems command higher upfront costs compared to traditional technologies, yet deliver substantially lower operational expenses through reduced energy consumption (saving thousands annually per fixture), dramatically extended maintenance intervals (eliminating dangerous lamp replacements in hazardous locations), and enhanced reliability minimizing production disruptions from lighting failures. A 1000W LED Mine Site Lighting fixture consuming 1000W total power replaces 2000-3000W HID lamps, generating immediate 50-66% energy savings while providing superior illumination quality and twice the effective brightness.

Safety Improvements Delivering Measurable Value

Enhanced Mine Site Lighting directly reduces workplace accidents, injury claims, production stoppages, and regulatory compliance costs. Improved visibility enables faster hazard identification, reduces equipment damage from collisions and operational errors, and supports safer emergency evacuations during critical incidents. Quantifying safety value includes reduced workers' compensation premiums, avoided MSHA penalties, decreased equipment repair costs, and improved workforce morale contributing to better retention rates. Mining operations report 30-50% accident reduction following comprehensive LED Mine Site Lighting upgrades, translating to millions in avoided costs for large-scale operations.

Financing Options and Government Incentives

Many jurisdictions offer utility rebates, tax credits, and accelerated depreciation for energy-efficient Mine Site Lighting installations. Manufacturers like Razorlux, a leading China Mine Site Lighting wholesale provider, facilitate financing arrangements enabling cash-flow-positive implementations where monthly energy savings exceed financing payments. Government mine safety improvement grants and low-interest equipment loans support LED adoption, particularly for smaller operators lacking capital for comprehensive upgrades. Engaging energy consultants and utility representatives during planning phases maximizes available incentives, potentially covering 20-40% of total project costs through combined programs.

Conclusion

Mine Site Lighting represents a critical investment in operational safety, worker protection, and long-term profitability for mining enterprises worldwide. Advanced LED technology delivers superior illumination quality, exceptional durability in harsh conditions, dramatic energy efficiency improvements, and intelligent control capabilities transforming mining operations. Selecting the right Mine Site Lighting solution requires careful assessment of site-specific requirements, regulatory compliance obligations, and total cost of ownership considerations balancing upfront investment against operational savings and safety improvements.

Ready to transform your mining operation with industry-leading illumination solutions? Xi'an Razorlux Optoelectronic Technology Co., Ltd. stands ready to support your Mine Site Lighting needs with proven expertise, comprehensive customization capabilities, and global support infrastructure. As a trusted China Mine Site Lighting factory, China Mine Site Lighting supplier, and China Mine Site Lighting manufacturer, we offer competitive Mine Site Lighting wholesale pricing with Mine Site Lighting for sale backed by 5-year warranties and responsive technical support. Contact our expert team today at sam@razorlux.com to discuss your specific requirements, request custom samples, and receive detailed Mine Site Lighting price quotations tailored to your project specifications.

References

1. National Institute for Occupational Safety and Health (NIOSH). "Illumination and Color Perception in Underground Mining." Pittsburgh Research Laboratory, Mining Safety Research Division.

2. Mine Safety and Health Administration (MSHA). "Lighting Standards and Luminance Measurement for Mine Operations." U.S. Department of Labor, Safety Standards Division.

3. International Electrotechnical Commission (IEC). "Explosive Atmospheres - Part 10: Classification of Areas - Explosive Gas Atmospheres." IEC 60079-10-1 Technical Standard.

4. Illuminating Engineering Society (IES). "Recommended Practice for Lighting Industrial Facilities." IES RP-7-21 Standards Publication.

5. Society for Mining, Metallurgy & Exploration (SME). "LED Lighting Technology Applications in Modern Mining Operations." SME Annual Conference Technical Proceedings.

_1750326878398.png)