Mine Site Lighting Procurement: How to Choose the Best OEM

Every mine manager knows this nightmare scenario: equipment downtime in the middle of a 24/7 operation because inferior Mine Site Lighting failed under harsh conditions. When production stops, costs skyrocket, safety risks multiply, and deadlines evaporate. Choosing the right OEM partner for Mine Site Lighting procurement isn't just about buying lights—it's about securing operational continuity, worker safety, and long-term cost efficiency in one of the world's most demanding industrial environments.

Understanding Critical Requirements for Mine Site Lighting Systems

When procuring Mine Site Lighting solutions, understanding the fundamental technical and environmental requirements separates successful installations from costly failures. Mining operations present unique challenges that demand specialized lighting solutions engineered for extreme durability, consistent performance, and regulatory compliance.

Environmental Durability Standards for Mining Operations

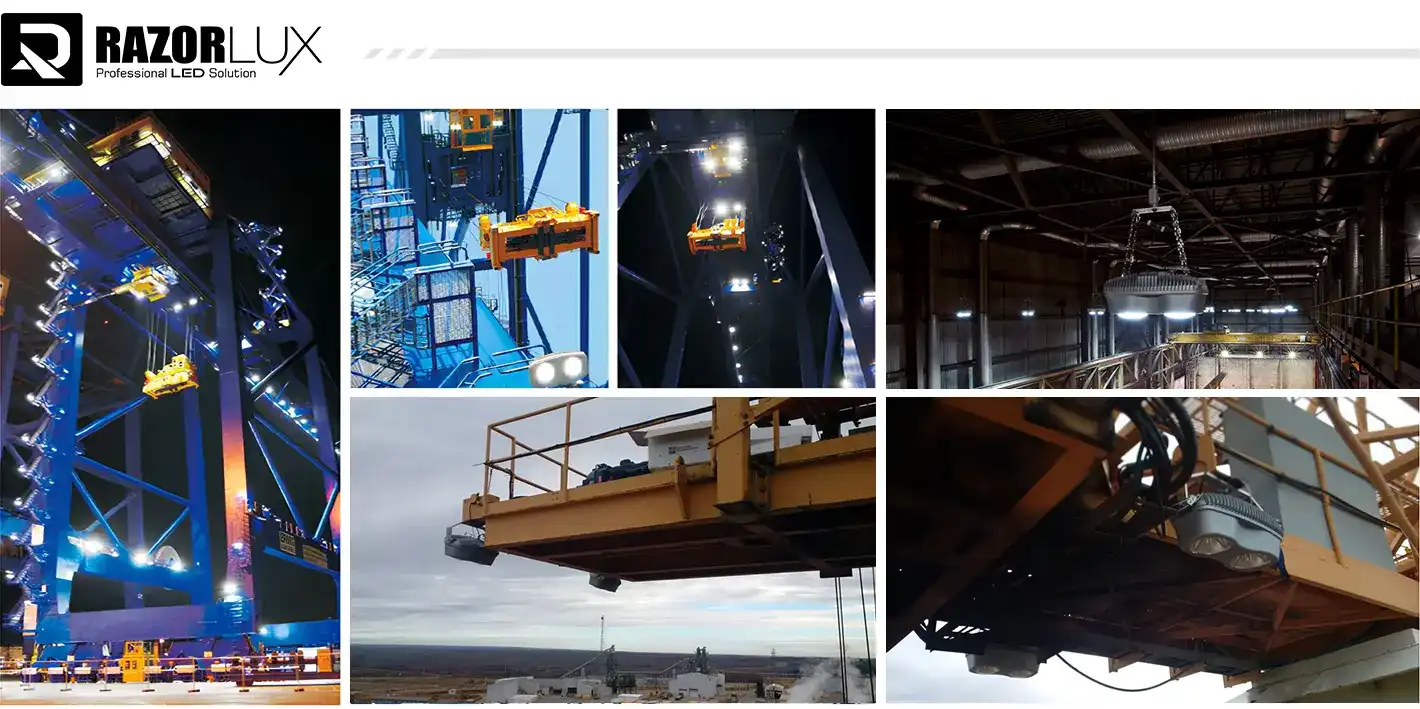

Mine Site Lighting systems must withstand conditions that would destroy conventional industrial fixtures within weeks. Operating temperatures ranging from negative forty degrees Celsius in Arctic operations to sixty degrees Celsius in tropical surface mines create thermal stress that tests every component. Modern Led Mine Site Lighting solutions incorporate advanced thermal management systems, using aluminum alloy housings with powder coating that dissipates heat while protecting against corrosion from salt spray, chemical exposure, and constant moisture. The IP65 and IP67 protection ratings ensure complete dust ingress prevention and water resistance against high-pressure jets during equipment washing, while IK10 impact resistance ratings guarantee survival against falling rocks, equipment collisions, and routine handling abuse. Quality manufacturers like Xi'an Razorlux Optoelectronic Technology implement patented multi-function designs with marine-grade anti-corrosion coatings, stainless steel brackets, and shock-resistant construction specifically engineered for mining environments where fixture replacement creates dangerous downtime and accessibility challenges.

Electrical Performance Requirements

The electrical characteristics of Mine Site Lighting directly impact both operational safety and energy costs across mining operations. Premium OEM solutions offer ultra-wide input voltage ranges, with AC inputs from 80-360Vac and 400-600Vac, plus DC inputs from 100-400Vdc and 500-800Vdc, ensuring compatibility with inconsistent power supplies common in remote mining locations and compatibility with backup generator systems. High-efficiency LED technology achieving 130 lumens per watt reduces energy consumption by up to sixty percent compared to traditional metal halide systems, translating to substantial savings on fuel costs for off-grid operations and reduced electrical infrastructure requirements. Power factor correction above 0.98 minimizes reactive power losses, while total harmonic distortion below ten percent protects sensitive electrical equipment throughout the mine site. Advanced Mine Site Lighting systems incorporate Meanwell power supplies with overcharge, overdischarge, and short circuit protection, plus optional emergency power functionality allowing two hours of operation during power failures—a critical safety feature when electrical systems fail during underground operations or nighttime surface mining activities.

Compliance Certifications and Safety Standards

Regulatory compliance represents a non-negotiable requirement when selecting Mine Site Lighting OEM partners, as mining operations face strict oversight from safety authorities worldwide. Comprehensive certification portfolios demonstrate manufacturer commitment to international safety standards and provide legal protection for mine operators. Essential certifications include UL listing for North American markets, CE marking for European compliance, SAA and C-Tick for Australian operations, plus RoHS and REACH directives for environmental standards. For underground operations and areas with explosive atmosphere risks, ATEX and IECEx certifications prove fixtures meet intrinsically safe or explosion-proof requirements for Group I (methane atmospheres) or Group II (other combustible gases and dusts) classifications. Leading manufacturers maintain ISO 9001 certified quality management systems ensuring consistent production standards, while specialized mining lighting certifications from authorities like MSHA in the United States provide additional assurance. Xi'an Razorlux Optoelectronic Technology holds over 200 patents covering LED Packaging, power control, and structural design, with products complying with UL, RMRS, TUV, CE, SAA, RoHS, DLC, and CB standards—demonstrating the comprehensive certification approach necessary for global mining operations.

Evaluating OEM Manufacturing Capabilities and Technical Support

Selecting a Mine Site Lighting OEM partner requires thorough evaluation of manufacturing infrastructure, research and development capabilities, and post-installation support systems. The distinction between suppliers who merely assemble components and true manufacturers with vertically integrated production capabilities determines long-term partnership success.

| Evaluation Criteria | What to Look For | Why It Matters |

|---|---|---|

| Manufacturing Facilities | GMP-certified factories with in-house assembly lines, photometric testing labs, and aging test equipment | Ensures consistent quality control and ability to customize products |

| R&D Investment | Dedicated engineering teams, patent portfolios, and ongoing product development | Indicates innovation capability and technical problem-solving capacity |

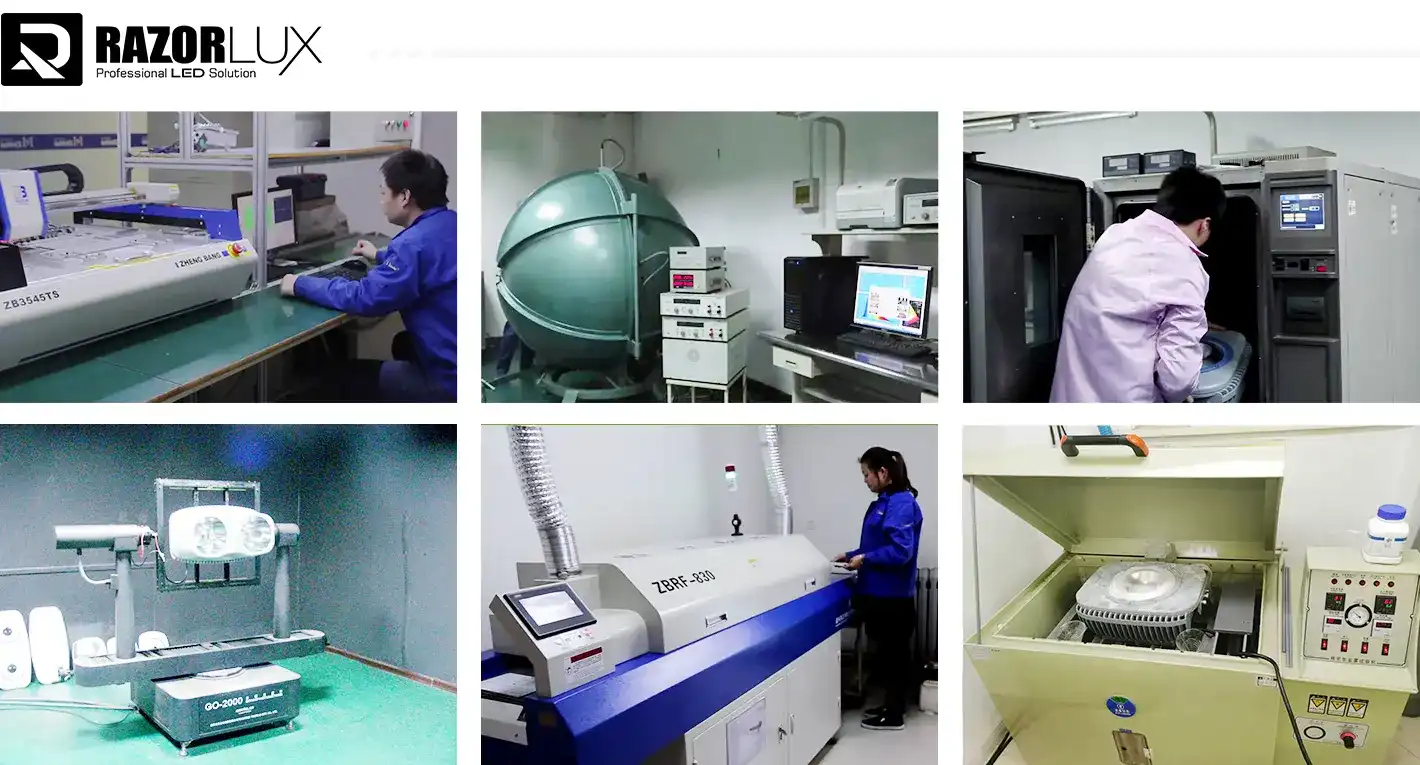

| Quality Testing | Integrating sphere photometric testing, DFMEA analysis, simulated harsh environment testing | Validates performance claims and identifies potential failure modes |

| Production Capacity | Large inventory, multiple production lines, scalable manufacturing | Ensures timely delivery for large projects and replacement part availability |

Research and Development Strength

A robust R&D infrastructure distinguishes industry-leading Mine Site Lighting manufacturers from commodity suppliers who lack innovation capabilities. Established OEMs invest heavily in engineering talent, maintaining teams of specialists in optical design, thermal management, power electronics, and materials science who continuously refine product performance. Patent portfolios provide tangible evidence of innovation, with leading manufacturers holding dozens or hundreds of patents covering critical technologies like LED chip packaging methods, intelligent power supply circuits, and structural designs optimized for extreme environments. Xi'an Razorlux Optoelectronic Technology exemplifies this commitment with over 200 patents developed since the company's founding in 1998, when it operated as Xi'an Zhihai Power Technology. This long operational history combined with continuous R&D investment enables manufacturers to anticipate industry needs, develop next-generation solutions before competitors, and provide technical consultation based on deep domain expertise. When evaluating potential OEM partners, request detailed information about their engineering team structure, recent product innovations, and technical documentation quality—manufacturers with strong R&D capabilities produce comprehensive technical drawings, installation guides, and specification sheets that facilitate project planning and troubleshooting.

Customization and OEM/ODM Services

Mining operations vary dramatically in their specific Mine Site Lighting requirements, making customization capabilities essential when selecting OEM partners. Premium manufacturers offer flexible design modification services covering wattage adjustments, color temperature selection from 2700K to 6500K for different task requirements, housing material options, and specialized mounting solutions for unique equipment configurations. Beam angle customization allows optimization for specific applications—60-degree spots for targeted illumination of work areas, 120-degree floods for general area lighting, or asymmetric 140x60-degree patterns for roadway and haul route lighting where horizontal spread maximizes coverage while minimizing light pollution. Control system integration including 0-10V analog dimming and DALI digital protocols enables smart lighting management responsive to occupancy, daylight contribution, and operational schedules. Full OEM and ODM services allow mining companies and equipment manufacturers to develop proprietary Mine Site Lighting solutions with custom branding, unique specifications, and exclusive features that differentiate their operations or product offerings. Xi'an Razorlux Optoelectronic Technology's comprehensive service portfolio includes pre-sales consultation, custom sampling and prototyping, technical drawing provision, and complete product customization—ensuring clients receive precisely specified solutions rather than compromising with off-the-shelf products that inadequately address their requirements.

Quality Control and Testing Procedures

Rigorous quality control throughout the manufacturing process separates reliable Mine Site Lighting systems from products prone to premature failure. Leading OEMs implement multi-stage testing protocols beginning with incoming component inspection, continuing through assembly verification, and culminating in comprehensive final product testing before shipment. Assembly line quality control includes skilled worker training, standardized procedures, and in-process inspection checkpoints that identify defects before components become integrated into finished products. Photometric testing using integrating sphere equipment validates luminous flux output, color temperature accuracy, and color rendering index performance against specifications—ensuring customers receive the advertised light output rather than discovering shortfalls after installation. Aging tests subject completed Mine Site Lighting fixtures to extended operation at rated power and elevated temperatures, identifying infant mortality failures and confirming long-term reliability before products reach job sites. Environmental simulation testing exposes fixtures to temperature cycling, vibration, moisture ingress, and impact scenarios that replicate years of harsh mining conditions compressed into accelerated test protocols. Xi'an Razorlux Optoelectronic Technology maintains ISO 9001 certified quality management systems and conducts DFMEA failure mode analysis for enhanced reliability, ensuring their Mine Site Lighting products undergo the comprehensive testing necessary to achieve fifty-thousand-hour operational lifespans with minimal maintenance requirements.

Comparing Total Cost of Ownership and Long-Term Value

Purchase price represents only a fraction of true Mine Site Lighting system costs over operational lifetimes. Sophisticated procurement decisions evaluate total cost of ownership, incorporating energy consumption, maintenance requirements, replacement frequency, and operational disruption costs to identify solutions delivering maximum long-term value.

Energy Efficiency and Operational Cost Analysis

Energy consumption constitutes a major ongoing expense for Mine Site Lighting systems operating continuously in 24/7 mining environments. Premium LED technology achieving 130 lumens per watt luminous efficacy delivers the same illumination as traditional high-intensity discharge lamps while consuming less than half the electrical power. A single 1000W Mine Site Lighting fixture replacing a 2000-3000W metal halide lamp saves 1000-2000 watts per fixture—multiplied across dozens or hundreds of lights throughout large mining operations, these savings translate to hundreds of thousands of dollars annually in reduced fuel costs for diesel generators or utility electrical charges. Beyond direct energy costs, reduced power consumption enables smaller electrical infrastructure, with lower-capacity transformers, circuit breakers, and wiring sufficient to support LED Mine Site Lighting installations. Heat reduction from efficient LED technology decreases cooling requirements in enclosed spaces and improves worker comfort in already hot mining environments. The Razorlux RGL-1000A model exemplifies efficiency optimization, consuming only 1000W total power (900W LEDs plus 100W driver) while delivering 120,000 lumens stable flux output—a luminous efficacy that maximizes visibility per dollar spent on electricity throughout the fixture's fifty-thousand-hour operational life.

| Cost Category | Traditional HID | LED Mine Site Lighting | Annual Savings per Fixture |

|---|---|---|---|

| Energy Consumption (24/7) | 2500W x 8760h = 21,900 kWh | 1000W x 8760h = 8,760 kWh | 13,140 kWh |

| Electricity Cost ($0.15/kWh) | $3,285 | $1,314 | $1,971 |

| Lamp Replacement | 2-3 times annually | Once per 6+ years | $500+ |

| Maintenance Labor | 10+ hours annually | 2 hours per 6 years | $800+ |

| Total Annual Savings | $3,200+ |

Warranty Coverage and Lifecycle Costs

Comprehensive warranty programs demonstrate manufacturer confidence in product reliability while protecting buyers from defect-related replacement costs. Industry-leading Mine Site Lighting OEMs offer five-year warranty coverage on LED modules, drivers, and complete fixtures—compared to one or two-year warranties common among budget suppliers. Extended warranty periods reduce total cost of ownership by eliminating premature replacement expenses and associated labor costs for accessing difficult mounting locations in mining environments. Careful warranty evaluation should examine coverage scope, claim procedures, and geographical service availability—warranties that require international shipping for claims processing or lack local service centers create extended downtime during replacement processing. Premium manufacturers structure warranties with separate coverage periods for different components, recognizing that LED modules, electronic drivers, and mechanical housings have different failure modes and operational lifespans. Xi'an Razorlux Optoelectronic Technology provides five-year warranties on LED modules and drivers, with ten-year coverage on housings, ensuring long-term protection aligned with component reliability characteristics. When comparing Mine Site Lighting proposals, calculate total lifecycle costs including purchase price, installation labor, energy consumption over expected lifespan, maintenance and lamp replacement expenses, and probability-adjusted warranty claim costs to identify solutions offering superior long-term value rather than simply choosing lowest initial purchase prices.

Installation Flexibility and Maintenance Requirements

Practical installation and maintenance considerations significantly impact true Mine Site Lighting system costs beyond purchase prices and operational expenses. Fixture weight affects mounting structure requirements—lightweight designs reduce structural reinforcement needs and simplify handling during installation and maintenance activities, while excessive weight increases rigging equipment requirements and worker fatigue during overhead installations. The Razorlux RGL-1000A model achieves 29 kilogram weight despite its 1000W power rating through advanced materials engineering, enabling easier installation compared to heavier fixtures requiring additional mounting support and handling equipment. Modular design philosophies that separate LED modules, drivers, and housings facilitate component-level replacement without complete fixture removal, dramatically reducing maintenance downtime when repairs become necessary. Comprehensive technical documentation including detailed installation guides, wiring diagrams, and dimensional drawings accelerates installation and reduces errors that create safety risks or performance problems. Manufacturers offering pre-sales consultation and technical support help buyers optimize fixture selection, mounting locations, and electrical configurations before procurement—avoiding costly field modifications when inadequately specified Mine Site Lighting systems reach job sites. Post-installation support including troubleshooting assistance, spare parts availability, and on-site service for large installations ensures operational continuity when issues arise during the equipment's operational life.

Conclusion

Successful Mine Site Lighting procurement demands comprehensive evaluation of OEM technical capabilities, product specifications, certification compliance, and long-term support infrastructure. Rather than focusing solely on initial purchase prices, sophisticated buyers calculate total cost of ownership incorporating energy efficiency, maintenance requirements, and warranty protection. Partnering with established manufacturers demonstrating deep R&D investment, rigorous quality control, and proven track records in demanding mining environments ensures procurement decisions that enhance safety, maximize operational efficiency, and deliver superior long-term value.

Ready to upgrade your mining operation with industry-leading Mine Site Lighting solutions? As a trusted China Mine Site Lighting factory and China Mine Site Lighting supplier, Xi'an Razorlux Optoelectronic Technology combines over two decades of manufacturing excellence with comprehensive customization services. Our China Mine Site Lighting manufacturer credentials include 200+ patents, certifications for global markets, and competitive China Mine Site Lighting wholesale pricing. Explore our Mine Site Lighting for sale at competitive Mine Site Lighting price points backed by five-year warranties and responsive technical support. Contact our professional sales team at sam@razorlux.com to request custom samples, technical specifications, and project quotations tailored to your specific operational requirements. Bookmark this guide for future reference when evaluating procurement decisions or troubleshooting lighting system challenges.

References

1. "Mine Safety and Health Administration Lighting Standards for Underground Mines" - U.S. Department of Labor, Mine Safety and Health Administration (MSHA), Technical Compliance Division

2. "LED Technology Application in Hazardous Mining Environments: Performance and Safety Considerations" - International Society for Mining, Metallurgy & Exploration (SME), Mining Engineering Journal

3. "Energy Efficiency in Industrial Lighting: Comparative Analysis of LED vs. Traditional Technologies" - U.S. Department of Energy, Office of Energy Efficiency & Renewable Energy, Industrial Technologies Program

4. "Lighting Design for Open Pit and Underground Mining Operations: Best Practices and Safety Standards" - International Council on Mining and Metals (ICMM), Health and Safety Research Committee

5. "Total Cost of Ownership Models for Industrial Lighting Procurement" - Institute of Electrical and Electronics Engineers (IEEE), Industrial Applications Society, Industrial Lighting Systems Technical Committee

VIEW MOREled baseball field lights

VIEW MOREled baseball field lights VIEW MOREled athletic field lighting

VIEW MOREled athletic field lighting VIEW MOREled court lights

VIEW MOREled court lights VIEW MORESuper Bright Outdoor Flood Light

VIEW MORESuper Bright Outdoor Flood Light VIEW MORE400w Dimmable LED Flood Light High Lumen Narrow Beam

VIEW MORE400w Dimmable LED Flood Light High Lumen Narrow Beam VIEW MORE5700K Outdoor Garden Led Light Ip67 100000lm Flood Lights For Volleyball Court

VIEW MORE5700K Outdoor Garden Led Light Ip67 100000lm Flood Lights For Volleyball Court VIEW MORE120 Volt Outdoor Spotlight

VIEW MORE120 Volt Outdoor Spotlight VIEW MOREStylish Outdoor Flood Lights

VIEW MOREStylish Outdoor Flood Lights

_1750326878398.png)