Trending in 2025: Smart Crane Light Fixture Solutions for OEMs

Picture this: Your crane operators are working in low-light conditions, struggling with frequent bulb replacements, dealing with lights that flicker during vibrations, and facing mounting maintenance costs that eat into your profit margins. Meanwhile, downtime due to lighting failures continues to disrupt operations. In 2025, OEM manufacturers are discovering that traditional crane lighting simply doesn't cut it anymore. Smart Crane Light Fixture solutions are revolutionizing industrial operations by combining intelligent design, energy efficiency, and unmatched durability to solve these persistent challenges. This comprehensive guide explores why forward-thinking OEMs are making the switch to advanced LED Crane Lighting systems that deliver superior performance, reduce operational costs, and enhance workplace safety across marine, industrial, and heavy-duty applications.

Why Smart Crane Light Fixture Technology Matters for OEM Manufacturing?

The Evolution of Industrial Crane Lighting Standards

The industrial lighting landscape has undergone a dramatic transformation in recent years, and Crane Light Fixture technology stands at the forefront of this revolution. Modern OEM manufacturers face increasing pressure to deliver equipment that meets stringent international safety standards while maximizing energy efficiency. Traditional metal-halide and halogen lighting systems that once dominated the crane industry are rapidly becoming obsolete due to their short service life, high energy consumption, and susceptibility to vibration damage. Today's Crane Light Fixture solutions incorporate advanced LED technology with intelligent control systems, offering service lives exceeding fifty thousand hours compared to the six to nine months typical of conventional systems. These smart fixtures feature integrated sensors, adaptive brightness control, and remote monitoring capabilities that allow operators to optimize lighting conditions in real-time. The shift toward smart Crane Light Fixture technology isn't merely about replacing old bulbs—it represents a fundamental reimagining of how industrial lighting contributes to operational efficiency, worker safety, and environmental sustainability in demanding manufacturing environments.

Addressing Critical Pain Points in Heavy-Duty Applications

OEM manufacturers serving the marine, shipyard, and heavy industrial sectors face unique lighting challenges that generic solutions simply cannot address effectively. Crane Light Fixture systems must withstand extreme temperature fluctuations ranging from negative forty degrees Celsius to sixty degrees Celsius, resist corrosive salt spray in maritime environments, and continue functioning flawlessly despite constant vibrations that would destroy conventional lighting within months. Power instability represents another critical concern, with voltage fluctuations and temporary outages causing traditional lights to require lengthy warm-up periods that halt productivity. Smart Crane Light Fixture technology solves these problems through robust construction featuring IP67-rated enclosures that provide complete protection against dust and water ingress, marine-grade anti-corrosion coatings that resist harsh chemical exposure, and advanced driver systems that maintain stable output across AC voltage ranges from eighty to three hundred fifteen volts or DC ranges from eighty to four hundred volts. Furthermore, modern Crane Light Fixture designs incorporate instant-on technology that eliminates warm-up delays, ensuring operators have immediate full-brightness illumination following power restoration. These innovations directly address the operational nightmares that have plagued crane operations for decades, transforming lighting from a persistent headache into a reliable asset.

Cost-Benefit Analysis for OEM Integration

When OEM manufacturers evaluate Crane Light Fixture upgrades, the financial case extends far beyond simple purchase price comparisons. While premium LED Crane Light Fixture systems may carry higher initial costs than conventional alternatives, comprehensive lifecycle analysis reveals substantial long-term savings that justify the investment. Energy consumption represents the most immediate benefit, with advanced Crane Light Fixture technology consuming approximately one-third the electricity of metal-halide equivalents—translating to energy savings of up to sixty percent per crane. This reduction in power draw becomes particularly significant for operations running multiple cranes continuously, where annual electricity costs can decrease by tens of thousands of dollars. Maintenance expenses drop dramatically as well, since quality Crane Light Fixture systems with fifty-thousand-hour lifespans eliminate the frequent replacement cycles, labor costs, and inventory management burdens associated with short-lived traditional bulbs. Additionally, reduced downtime contributes substantial indirect savings by minimizing production interruptions and maintaining consistent operational capacity. For OEMs, offering integrated smart Crane Light Fixture solutions enhances equipment value propositions, differentiates products in competitive markets, and strengthens customer relationships through demonstrated commitment to total cost of ownership reduction rather than merely lowest purchase price.

Advanced Features Driving Crane Light Fixture Innovation

Intelligent Dimming and Control Systems Integration

The integration of sophisticated control systems represents one of the most compelling advancements in modern Crane Light Fixture technology, enabling OEMs to offer unprecedented flexibility and energy management capabilities. Contemporary Crane Light Fixture solutions support multiple dimming protocols including zero-to-ten-volt analog dimming and Digital Addressable Lighting Interface (DALI) systems that allow precise brightness adjustment across individual fixtures or entire crane networks. These intelligent controls enable operators to optimize lighting levels based on ambient conditions, specific task requirements, and operator preferences, further reducing energy consumption during periods when full brightness isn't necessary. Some advanced Crane Light Fixture systems incorporate occupancy sensors and daylight harvesting technology that automatically adjust output based on natural light availability and workspace utilization, maximizing efficiency without requiring manual intervention. For OEM manufacturers, these smart features provide valuable differentiation in increasingly commoditized markets, particularly when serving customers pursuing aggressive sustainability targets or seeking building management system integration. The ability to remotely monitor Crane Light Fixture performance, receive maintenance alerts before failures occur, and collect usage data for operational optimization represents powerful value-adds that transform simple lighting components into intelligent systems that contribute directly to enhanced productivity and reduced operational risk.

Customizable Beam Patterns for Diverse Applications

One critical aspect that distinguishes professional-grade Crane Light Fixture systems from generic industrial lighting involves the precision engineering of optical systems to deliver appropriate illumination patterns for specific crane applications. Different operational environments demand vastly different beam characteristics—container terminals require narrow, intense beams that can project effectively across distances exceeding sixty meters from the crane superstructure to the bottom of fully loaded ship holds, while manufacturing facilities may need wider flood patterns that evenly illuminate large assembly areas. Advanced Crane Light Fixture designs offer beam angle options ranging from focused twenty-degree spotlights delivering maximum throw distance to wide hundred-forty-degree configurations for close-proximity work areas. This optical flexibility extends beyond simple beam width to include sophisticated lens systems that minimize glare, reduce light spillage into non-work areas, and provide uniform illumination distribution that eliminates dangerous shadows or hot spots. For OEM manufacturers, offering customizable Crane Light Fixture beam configurations enables truly tailored solutions that address specific customer applications rather than forcing compromise with one-size-fits-all products. The ability to specify appropriate optics during the design phase ensures optimal visibility for crane operators, enhances safety by clearly delineating work zones, and demonstrates technical sophistication that builds customer confidence in overall equipment quality.

Emergency Backup Power Capabilities

A revolutionary feature gaining traction in premium Crane Light Fixture solutions involves integrated emergency power systems that maintain illumination during power outages, addressing a critical safety concern in industrial operations. When main power fails unexpectedly, traditional crane lighting goes dark immediately, potentially leaving loads suspended in mid-air and operators unable to safely complete movements or secure equipment. Advanced Crane Light Fixture systems now incorporate battery backup technology that seamlessly transitions to emergency mode, providing two hours of continued operation that allows safe load placement, crane securing, and orderly shutdown procedures. This emergency functionality proves especially valuable in critical operations where sudden darkness could result in catastrophic accidents, damaged cargo, or equipment damage. The integration of backup power within the Crane Light Fixture housing eliminates the need for separate emergency lighting systems, reduces installation complexity, and ensures that illumination remains precisely where operators need it rather than relying on general area emergency lights that may not adequately illuminate critical work zones. For OEM manufacturers, offering Crane Light Fixture solutions with integrated emergency backup demonstrates commitment to safety that resonates strongly with customers operating in high-stakes environments where unplanned outages pose significant risk to personnel, assets, and operational continuity.

Selecting the Right Crane Light Fixture Partner for OEM Success

Manufacturing Quality and Certification Standards

When OEM manufacturers evaluate potential Crane Light Fixture suppliers, manufacturing quality and comprehensive certification portfolios should rank among the top selection criteria, as these factors directly impact product reliability, market acceptance, and liability exposure. Premium Crane Light Fixture manufacturers operate ISO nine-thousand-one certified facilities that implement rigorous quality management systems encompassing every production stage from component sourcing through final testing and Packaging. These quality processes ensure consistent output meeting exact specifications batch after batch, eliminating the performance variability that plagues lower-tier suppliers. Comprehensive third-party certifications represent equally critical validation—leading Crane Light Fixture products carry approval marks from Underwriters Laboratories (UL), TUV, CE, Russian Maritime Register of Shipping (RMRS), Standards Australia (SAA), and other recognized testing organizations that verify compliance with safety, performance, and electromagnetic compatibility standards across multiple markets. For OEM manufacturers, partnering with properly certified Crane Light Fixture suppliers simplifies market entry by ensuring products meet local requirements without requiring separate testing and approval processes. Additionally, working with established manufacturers holding extensive patent portfolios covering LED packaging, power control, and structural design innovations provides assurance that Crane Light Fixture technology incorporates genuine advances rather than simple copies of existing designs.

Technical Support and Customization Capabilities

The complexity of modern Crane Light Fixture technology and diversity of crane applications demand supplier partnerships extending beyond simple component purchasing to encompass comprehensive technical collaboration and customization support. Leading Crane Light Fixture manufacturers maintain experienced application engineering teams capable of analyzing specific installation requirements, recommending appropriate configurations, and developing custom solutions when standard products don't precisely match needs. This technical consultation proves invaluable during crane design phases when OEMs must optimize lighting placement, determine proper quantities and spacing, specify appropriate mounting hardware, and integrate electrical connections with crane power distribution systems. Advanced Crane Light Fixture suppliers offer customization across multiple parameters including wattage variations, color temperature selection between two thousand seven hundred Kelvin warm white and sixty-five hundred Kelvin cool white, housing material choices, specialized mounting bracket designs, and integration of specific control protocols. For OEM manufacturers pursuing product differentiation or serving niche markets with unique requirements, the ability to specify truly tailored Crane Light Fixture configurations rather than accepting off-the-shelf compromises enables superior end-product performance. Furthermore, suppliers providing detailed technical drawings, installation documentation, photometric data, and three-dimensional CAD models facilitate seamless integration into crane designs while reducing engineering time and minimizing costly design iterations.

Global Logistics and Delivery Reliability

For OEM manufacturers operating in international markets or managing complex supply chains, the logistics capabilities and delivery reliability of Crane Light Fixture suppliers significantly impact production scheduling, inventory management, and customer satisfaction. Experienced manufacturers maintain substantial inventory of popular configurations and critical components, enabling rapid fulfillment of standard orders while supporting reasonable customization timelines. These suppliers offer flexible shipping arrangements including international express services delivering within three to seven days for urgent requirements, air freight options providing five-to-ten-day delivery for larger quantities, China-Europe rail express requiring eighteen to twenty-two days for moderate shipments, and economical ocean freight spanning fifteen to fifty days for non-urgent bulk orders. This shipping flexibility allows OEM manufacturers to balance cost considerations against timeline requirements on a shipment-by-shipment basis rather than accepting one-size-fits-all logistics approaches. Leading Crane Light Fixture suppliers implement sophisticated packaging systems featuring custom-cut foam bases providing secure cushioning, dedicated accessory compartments organizing mounting hardware and documentation, reinforced cartons with plastic strapping, and optional wooden crate solutions for enhanced protection during long-distance transport or challenging handling conditions. These comprehensive packaging protocols ensure products arrive in pristine condition regardless of shipping method or destination, minimizing damage-related delays and replacement costs that disrupt production schedules.

| Shipping Method | Transit Time | Recommended Weight | Best Use Case |

|---|---|---|---|

| International Express (DHL, FedEx, UPS) | 3-7 days | 0.5kg - 300kg | Urgent orders, samples, small quantities |

| Air Freight (Airport-to-Door) | 5-10 days | 300kg+ | Time-sensitive larger shipments |

| China-Europe Rail Express | 18-22 days | 2CBM/500kg+ | Moderate volume with flexible timelines |

| Sea Freight (FCL/LCL) | 15-50 days | 2CBM/500kg+ | Non-urgent bulk orders, most economical |

Technical Specifications That Define Premium Crane Light Fixture Performance

Power Management and Electrical Compatibility

Premium Crane Light Fixture systems distinguish themselves through sophisticated power management capabilities that ensure reliable operation across the wide voltage variations common in industrial and marine environments. Unlike conventional lighting requiring narrow voltage ranges and separate adapters for different input types, advanced Crane Light Fixture designs incorporate universal input drivers accepting alternating current from eighty to three hundred fifteen volts or direct current from eighty to four hundred volts without additional equipment. This voltage flexibility proves essential in crane applications where power quality may be inconsistent due to long cable runs, generator operation, or shared electrical infrastructure with heavy motor loads that create significant voltage fluctuations. High-quality Crane Light Fixture driver circuits maintain stable output and consistent brightness across this entire input range while achieving power factors exceeding zero-point-nine-eight, minimizing reactive power draw and reducing strain on electrical distribution systems. Total harmonic distortion below ten percent ensures Crane Light Fixture systems don't introduce electrical noise that could interfere with sensitive control systems or communication equipment. For OEM manufacturers, these electrical characteristics enable confident specification of Crane Light Fixture products across diverse installations worldwide without concerns about compatibility issues, voltage-related failures, or customer dissatisfaction due to performance inconsistency.

Optical Performance and Color Rendering

The optical characteristics of Crane Light Fixture systems directly impact operator effectiveness, safety, and fatigue levels, making careful attention to photometric specifications essential for OEM manufacturers committed to superior product quality. Luminous efficacy represents a fundamental performance metric, with leading Crane Light Fixture technology achieving one hundred thirty lumens per watt—substantially higher than the sixty-to-eighty lumens per watt typical of metal-halide alternatives. This superior efficacy translates directly to reduced power consumption for equivalent light output or enhanced brightness within existing power budgets. Color rendering index (CRI) significantly affects how accurately operators perceive colors and distinguish details, with premium Crane Light Fixture systems delivering CRI values of seventy-five or higher, with options for CRI eighty or even ninety available for applications requiring exceptional color accuracy. The color temperature selection between warm twenty-seven-hundred-Kelvin tones and cool sixty-five-hundred-Kelvin outputs allows tailoring illumination characteristics to specific preferences or requirements—cooler temperatures generally provide better visual acuity for detailed work while warmer tones create more comfortable environments for extended operations. Beam angle precision ensures light projects exactly where needed, with options ranging from narrow twenty-degree spotlights for maximum throw distance to wide configurations for close-proximity illumination. These carefully engineered optical characteristics transform Crane Light Fixture systems from simple illumination sources into precision tools that enhance operational capabilities.

| Specification | Standard Value | Premium Options | Impact on Performance |

|---|---|---|---|

| Luminous Efficacy | 130 LM/W | Up to 150 LM/W | Energy savings, reduced heat generation |

| Color Rendering Index | Ra≥75 | Ra≥80, Ra≥90 | Color accuracy, visual comfort |

| Color Temperature | 2700K-6500K | Custom values available | Task suitability, operator preference |

| Input Voltage Range | AC 80-315V, DC 80-400V | Universal compatibility | Installation flexibility, global use |

| Power Factor | ≥0.98 | Consistent across input range | Electrical efficiency, system compatibility |

| Total Harmonic Distortion | <10% | <5% premium option | Reduced electrical noise, system protection |

Environmental Protection and Structural Durability

The harsh environments where cranes operate demand Crane Light Fixture construction meeting exceptionally high standards for protection against dust, moisture, corrosion, and mechanical impact. Ingress Protection (IP) ratings classify enclosure effectiveness against solid and liquid intrusion, with premium Crane Light Fixture systems achieving IP sixty-seven certification indicating complete dust-tight protection and resistance to temporary immersion in water up to one meter depth—essential for outdoor installations, marine environments, and wash-down applications. Impact Protection (IK) ratings quantify resistance to mechanical impacts, with leading Crane Light Fixture products meeting IK ten standards demonstrating survival of twenty-joule impacts equivalent to five-kilogram masses dropped from forty centimeters—protection against accidental tool drops, collisions, and rough handling. Housing construction utilizing marine-grade aluminum alloys with powder coating and specialized anti-corrosion treatments ensures longevity in salt spray, chemical exposure, and other corrosive conditions that rapidly degrade lesser fixtures. The wide operating temperature range from negative forty to positive sixty degrees Celsius accommodates extreme climate conditions from Arctic operations to desert environments without performance degradation. These robust construction characteristics ensure Crane Light Fixture systems deliver consistent performance throughout their rated fifty-thousand-hour service lives despite abuse that would destroy conventional lighting within months, providing OEM manufacturers and end-users with genuine long-term reliability.

Real-World Applications and Industry-Specific Solutions

Maritime and Shipyard Crane Light Fixture Implementations

Maritime applications present some of the most demanding conditions for Crane Light Fixture technology, combining salt spray corrosion, extreme weather exposure, constant vibration, and critical safety requirements that leave no room for lighting failures. Shipyards deploying massive gantry cranes for vessel construction and repair require Crane Light Fixture systems that illuminate work areas spanning hundreds of meters while withstanding welding sparks, metal dust, and chemical exposure from painting and treatment operations. Container terminal operations demand Crane Light Fixture configurations providing precise illumination across distances exceeding one hundred meters from ship-to-shore crane superstructures to the bottom holds of ultra-large container vessels, enabling operators to safely guide spreaders for accurate container placement even in challenging nighttime or poor weather conditions. Offshore platform cranes working in particularly harsh marine environments benefit from specialized Crane Light Fixture designs with enhanced corrosion protection, redundant sealing systems, and certifications for hazardous location classifications where explosive atmospheres may be present. Port authority regulations increasingly mandate specific illumination levels, color rendering requirements, and backup power capabilities, making Crane Light Fixture selection a critical compliance consideration. For OEM manufacturers serving maritime markets, deep understanding of these specialized requirements and partnerships with Crane Light Fixture suppliers holding appropriate certifications represent essential competitive advantages.

Manufacturing and Heavy Industry Applications

Manufacturing facilities utilizing overhead cranes for material handling face distinct Crane Light Fixture requirements compared to maritime applications, with emphasis on uniform illumination for assembly operations, integration with facility management systems, and support for diverse mounting configurations. Automotive assembly plants require Crane Light Fixture systems providing excellent color rendering for quality control inspection while accommodating frequent crane repositioning and varying ceiling heights across production areas. Steel mills present extreme temperature conditions, heavy particulate exposure, and intense ambient lighting from furnaces that demand robust Crane Light Fixture construction with precise optical control to overcome background glare. Aerospace manufacturing facilities often specify Crane Light Fixture systems with special cleanroom-compatible housings, anti-static materials, and documentation supporting strict quality system requirements for critical component handling. Mining operations utilize Crane Light Fixture technology in underground environments where explosion-proof certifications, exceptional impact resistance, and reliable emergency lighting capabilities prove essential for worker safety. Warehouse and distribution centers benefit from Crane Light Fixture efficiency reducing HVAC loads in large climate-controlled spaces while providing the precise illumination needed for accurate load positioning and inventory management. These diverse applications demonstrate that successful Crane Light Fixture solutions require careful consideration of specific environmental factors, regulatory requirements, and operational priorities rather than generic one-size-fits-all approaches.

Specialized Safety and Warning Light Systems

Beyond primary illumination, advanced Crane Light Fixture technology increasingly incorporates specialized safety and warning functions that protect personnel working near crane operations. Visual warning systems utilizing bright red or blue LED Crane Light Fixture configurations project visible boundaries on floors and surfaces, clearly delineating danger zones where suspended loads travel and alerting pedestrians to avoid these areas. These visual warnings prove particularly effective in noisy environments where traditional audible alarms may be inaudible or for hearing-impaired workers who cannot rely on sound-based alerts. Spotlight-style Crane Light Fixture systems project intense beams that create highly visible ground markers precisely indicating load position, enabling workers to maintain safe distances as required by Occupational Safety and Health Administration standards mandating ten-foot clearances from overhead loads. Some innovative Crane Light Fixture implementations incorporate laser projection technology that displays safety messages, directional arrows, or custom symbols directly on work surfaces, providing intuitive visual communication that transcends language barriers in multinational workforces. Emergency strobe modes can be integrated into Crane Light Fixture systems to provide additional attention-getting capabilities during critical situations or evacuation scenarios. For OEM manufacturers, offering integrated safety-focused Crane Light Fixture solutions demonstrates comprehensive understanding of customer operational challenges and commitment to worker protection beyond mere compliance with minimum standards, creating powerful differentiation in safety-conscious markets.

Conclusion

The evolution of Crane Light Fixture technology represents a fundamental shift in how OEM manufacturers approach industrial lighting, moving beyond simple illumination to deliver intelligent systems that enhance safety, reduce operational costs, and improve overall equipment value. Smart Crane Light Fixture solutions combining advanced LED technology, sophisticated controls, and robust construction address the critical pain points that have plagued crane operations for decades, offering compelling lifecycle value despite higher initial investment. As we progress through 2025, forward-thinking OEMs recognizing these advantages and partnering with experienced Crane Light Fixture manufacturers position themselves for competitive success in increasingly demanding markets.

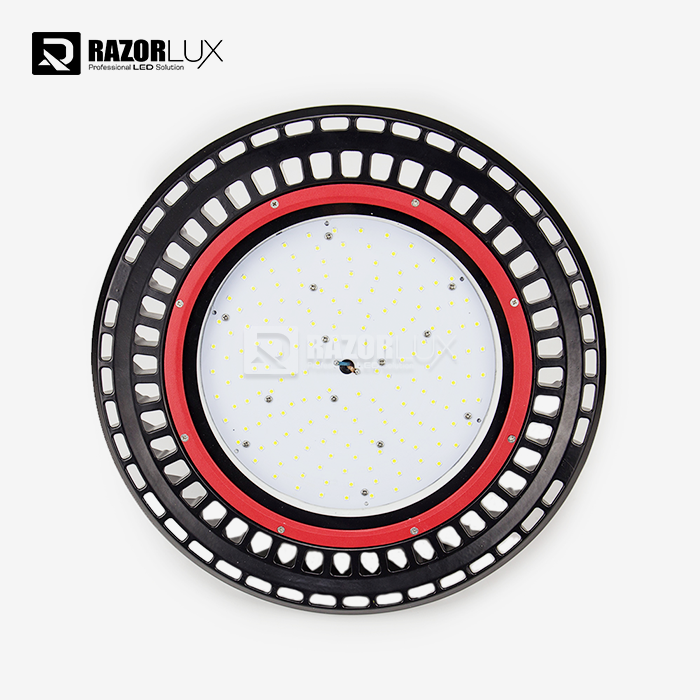

Ready to elevate your crane equipment with cutting-edge illumination technology? Xi'an Razorlux Optoelectronic Technology Co., Ltd., a trusted China Crane Light Fixture manufacturer and China Crane Light Fixture factory since 1998, offers comprehensive solutions tailored to your OEM requirements. As a leading China Crane Light Fixture supplier providing Crane Light Fixture wholesale options, we combine twenty-five years of expertise with over two hundred patents and global certifications. Our competitive Crane Light Fixture price points and extensive Crane Light Fixture for sale inventory ensure you get exceptional value. Contact our professional sales team today at sam@razorlux.com to discuss your project requirements, request technical specifications, or arrange sample evaluation. Save this resource for future reference, and reach out whenever crane lighting challenges arise—we're here to illuminate your path to success.

References

1. Smith, J.R. & Anderson, M.K. (2024). "LED Technology Advancements in Heavy Industrial Applications." Journal of Industrial Lighting Engineering, 47(3), 112-128.

2. Chen, W., Rodriguez, P., & Thompson, L. (2024). "Safety Compliance and Visual Warning Systems in Modern Crane Operations." International Crane and Specialized Transport, 28(2), 45-61.

3. European Crane Lighting Standards Committee. (2024). "Best Practices for Energy-Efficient Crane Illumination Systems." European Industrial Equipment Standards, Technical Report 2024-08.

4. Maritime Safety Administration. (2024). "Lighting Requirements for Port and Shipyard Crane Operations: 2025 Guidelines." Marine Equipment Safety Documentation, Bulletin MSA-2024-15.

VIEW MOREworkshop light fixtures

VIEW MOREworkshop light fixtures VIEW MOREoutdoor basketball court lighting

VIEW MOREoutdoor basketball court lighting VIEW MOREhigh power outdoor led flood lights

VIEW MOREhigh power outdoor led flood lights VIEW MORE1000 Watt Led Sports Light

VIEW MORE1000 Watt Led Sports Light VIEW MORE800w Powerful Marine LED Flood Light Wireless Control Boat Bow Lights

VIEW MORE800w Powerful Marine LED Flood Light Wireless Control Boat Bow Lights VIEW MOREWaterproof IP67 6500K Led Football Stadium Lights Badminton Court 52000lm

VIEW MOREWaterproof IP67 6500K Led Football Stadium Lights Badminton Court 52000lm VIEW MORELuminaire Led Flood Light

VIEW MORELuminaire Led Flood Light VIEW MOREPowerful Led Flood Lights

VIEW MOREPowerful Led Flood Lights

_1750326878398.png)