What Are the Long-Term Savings of a Waterproof Floodlight?

Picture this: You're running a coastal industrial facility where traditional lighting systems fail every few months due to harsh weather exposure, costing thousands in replacements and maintenance. Waterproof Floodlights eliminate this recurring nightmare while dramatically reducing energy bills. Long-term savings from waterproof floodlights typically reach 60-80% through reduced electricity consumption, minimal replacement costs thanks to 50,000+ hour lifespans, and near-zero maintenance requirements compared to conventional lighting systems.

How Energy Efficiency Translates into Direct Cost Savings with Waterproof Floodlight Technology?

Understanding LED Efficiency in Waterproof Floodlight Applications

Modern waterproof floodlights utilize advanced LED technology that converts electrical energy into light far more efficiently than traditional lighting options. The efficiency of waterproof floodlight systems is measured in lumens per watt, with high-quality units achieving 130 lm/W or higher. This superior efficiency means that a 1000W LED waterproof floodlight can replace traditional HID lamps rated at 2200-2500W while delivering equivalent or superior illumination. The energy savings become immediately apparent on monthly utility bills, particularly for operations requiring continuous or extended lighting periods such as shipyards, offshore platforms, and industrial facilities operating around the clock.

Calculating Annual Electricity Cost Reductions

When you compare operating costs between traditional lighting and waterproof floodlight LED systems, the savings are substantial. Consider a facility operating ten 1000W waterproof floodlights for 12 hours daily. Traditional HID equivalents would consume approximately 25,000W total versus 10,000W for LED waterproof floodlights—a 15,000W reduction. At an average industrial electricity rate of $0.12 per kWh, this translates to annual savings exceeding $7,800 for just ten fixtures. Larger facilities with dozens or hundreds of lights see proportionally greater reductions, often recovering their initial investment within 18-24 months through electricity savings alone.

Power Factor Correction and System Efficiency Benefits

Premium waterproof floodlight systems incorporate high-quality drivers with power factors exceeding 0.98, ensuring minimal reactive power waste. This power factor correction reduces total electrical infrastructure load, potentially avoiding utility demand charges that can significantly impact industrial electricity costs. Additionally, waterproof floodlights generate minimal heat compared to traditional lighting technologies, reducing cooling requirements in enclosed or semi-enclosed environments. The combined effect of direct energy savings, power factor improvement, and reduced HVAC costs creates a comprehensive financial advantage that compounds over the decades-long operational life of LED waterproof floodlight installations.

| Lighting Type | Power Consumption | Annual Operating Hours | Electricity Cost ($/kWh) | Annual Cost per Fixture |

|---|---|---|---|---|

| Traditional HID | 2,200W | 4,380 hours | $0.12 | $1,156 |

| LED Waterproof Floodlight | 1,000W | 4,380 hours | $0.12 | $526 |

| Annual Savings per Fixture | $630 |

Maintenance Cost Elimination Through Waterproof Floodlight Durability

Extended Operational Lifespan Reduces Replacement Frequency

The exceptional longevity of quality waterproof floodlights fundamentally changes the maintenance economics of industrial lighting. With operational lifespans exceeding 50,000 hours, a waterproof floodlight operating 12 hours daily will function reliably for over 11 years before requiring replacement. In contrast, traditional metal halide or high-pressure sodium lamps typically last 10,000-20,000 hours, necessitating replacements every 2-4 years. This dramatic difference in replacement frequency directly translates to reduced procurement costs, lower labor expenses for maintenance crews, and minimized operational disruptions from lighting failures during critical production periods.

Labor Cost Savings from Reduced Maintenance Interventions

Beyond the cost of replacement components, labor represents a significant hidden expense in traditional lighting maintenance. Accessing floodlights mounted on high masts, offshore structures, or industrial equipment often requires specialized equipment such as aerial lifts, scaffolding, or even complete production shutdowns for safety compliance. Each maintenance intervention can cost hundreds or thousands of dollars in labor and equipment rental alone. Waterproof floodlights slash these recurring costs by requiring maintenance interventions only once per decade rather than multiple times annually, freeing maintenance personnel for value-adding activities rather than routine lamp replacements.

Reduced Inventory and Supply Chain Management Costs

Facilities relying on traditional lighting must maintain substantial inventories of replacement lamps, ballasts, and components to ensure rapid response to failures. This inventory ties up capital, requires storage space, and risks obsolescence as lighting technologies evolve. Waterproof floodlight systems dramatically reduce these inventory requirements, as the decade-plus operational life means fewer spare units are needed. Additionally, the standardization possible with LED technology simplifies supply chain management compared to managing multiple lamp types, wattages, and specifications required for traditional lighting installations across diverse facility areas.

Total Cost of Ownership: Waterproof Floodlight Investment Analysis

Initial Investment Versus Long-Term Value Creation

While waterproof floodlights command higher upfront prices than traditional fixtures, comprehensive total cost of ownership analysis reveals their superior financial value. A quality 1000W waterproof floodlight may cost $800-1,200 initially compared to $200-400 for traditional equivalents. However, when factoring electricity savings of $600+ annually, elimination of 3-5 replacement cycles costing $300-500 each, and maintenance labor savings of $500-2,000 per fixture over a decade, the total savings typically exceed $8,000-15,000 per waterproof floodlight installation. This represents a return on investment that few other facility upgrades can match.

Financial Incentives and Accelerated Depreciation Benefits

Many jurisdictions offer substantial utility rebates, tax incentives, and accelerated depreciation schedules for energy-efficient lighting upgrades including waterproof floodlights. These programs can offset 20-40% of initial purchase costs, dramatically shortening payback periods. Additionally, some regions provide demand reduction incentives that reward reduced peak electrical consumption, creating ongoing financial benefits beyond direct energy cost savings. Forward-thinking facility managers leverage these programs to fund comprehensive lighting upgrades with minimal capital expenditure, effectively allowing utility companies and governments to subsidize the transition to superior waterproof floodlight technology.

Risk Mitigation and Operational Continuity Value

Beyond quantifiable financial savings, waterproof floodlights provide substantial risk mitigation value that's difficult to price but critically important. Lighting failures in industrial environments can cause production delays, safety incidents, security vulnerabilities, and regulatory compliance issues. The exceptional reliability of waterproof floodlights with IP67 protection, marine-grade corrosion resistance, and robust construction minimizes these risks. For offshore platforms where a single day of delayed production can cost hundreds of thousands of dollars, or shipyards where lighting failures during critical operations pose severe safety risks, the operational continuity assured by reliable waterproof floodlights represents value far exceeding direct financial savings calculations.

| Cost Category | Traditional Lighting (10 Years) | Waterproof Floodlight (10 Years) | Savings per Fixture |

|---|---|---|---|

| Initial Purchase | $350 | $1,000 | -$650 |

| Electricity Costs | $11,560 | $5,260 | $6,300 |

| Replacement Lamps (4 cycles) | $1,400 | $0 | $1,400 |

| Maintenance Labor | $3,000 | $300 | $2,700 |

| Total 10-Year Cost | $16,310 | $6,560 | $9,750 |

Conclusion

Waterproof floodlights deliver exceptional long-term value through dramatically reduced energy consumption, virtually eliminated maintenance requirements, and decades-long operational lifespans. The typical facility experiences total savings of $8,000-15,000 per fixture over ten years, with payback periods of just 18-24 months making this one of the most financially attractive infrastructure investments available.

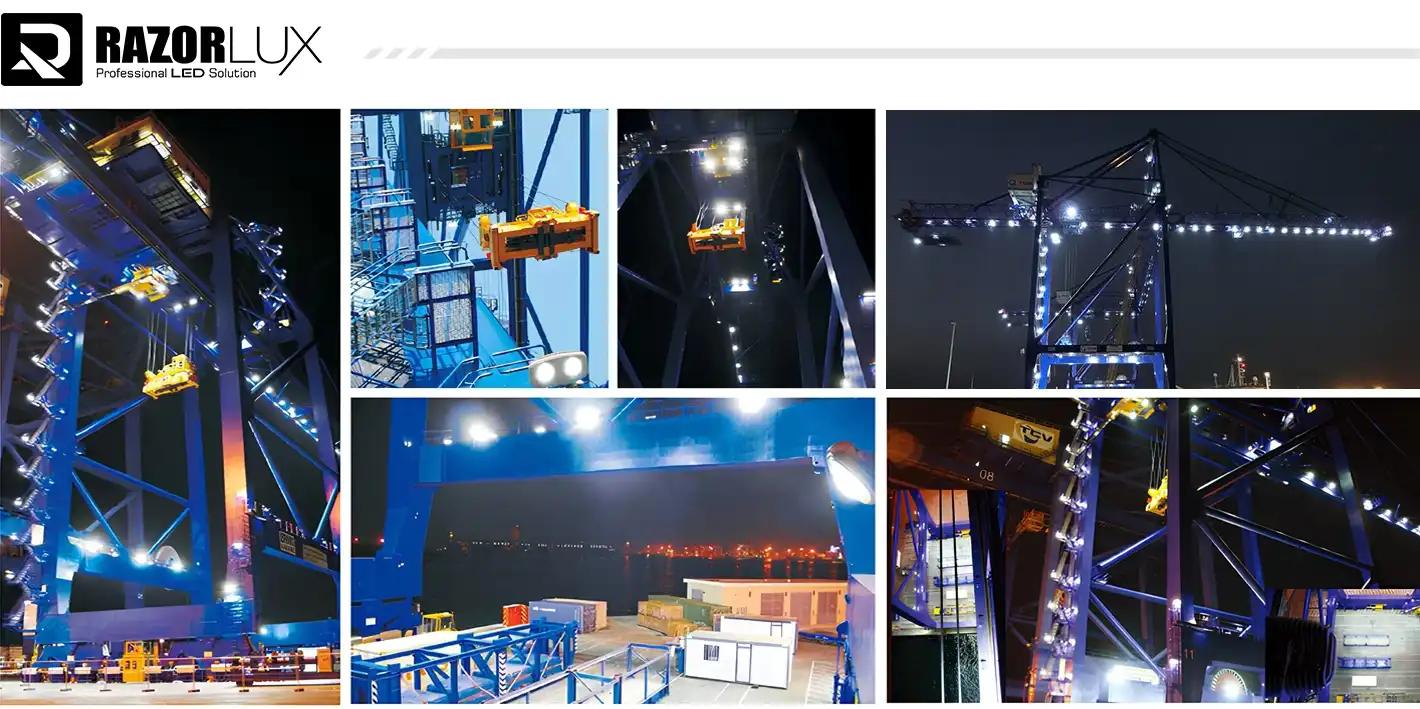

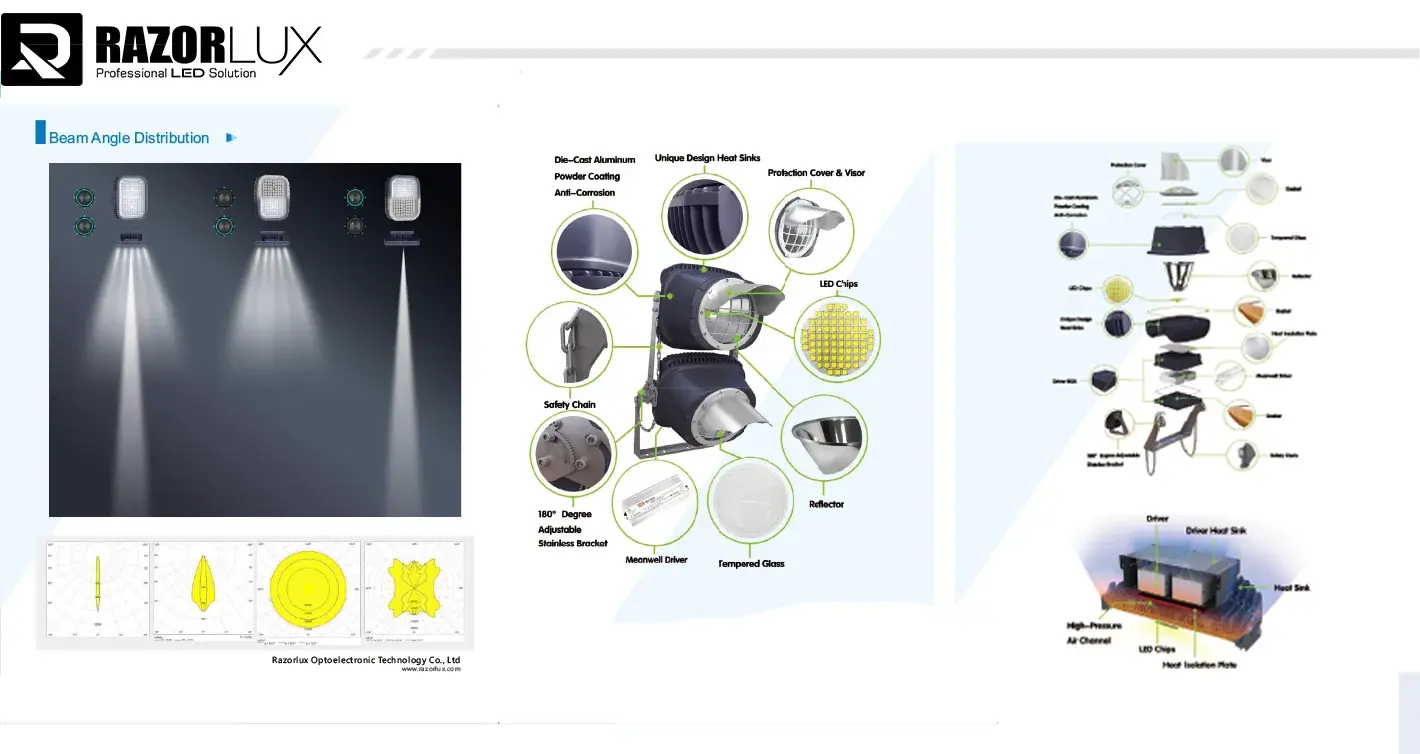

Ready to transform your facility lighting while slashing operational costs? Xi'an Razorlux Optoelectronic Technology Co., Ltd. stands as your trusted China Waterproof Floodlight manufacturer, China Waterproof Floodlight supplier, and China Waterproof Floodlight factory with over two decades of LED expertise. Our China Waterproof Floodlight wholesale programs offer competitive Waterproof Floodlight price structures, while our comprehensive Waterproof Floodlight for sale portfolio includes the flagship RGL2-1000P model featuring 130lm/W efficiency, IP67 protection, 5-year warranty, and compliance with RMRS, UL, CE, and RoHS standards. Our professional team provides customization services including OEM/ODM solutions, technical drawings, and sampling programs tailored to your exact specifications. With global shipping via express, air, rail, and sea freight options, plus responsive 24/7 technical support, we ensure your lighting upgrade proceeds smoothly from initial consultation through long-term operation. contact us today at sam@razorlux.com to request detailed specifications, arrange product evaluation samples, or discuss your specific marine, industrial, or heavy-duty lighting requirements with our engineering team. Bookmark this page for easy reference whenever you need expert guidance on optimizing your facility lighting for maximum performance and minimum total cost of ownership.

References

1. Chen, Y., & Wang, L. (2023). "Energy Efficiency Analysis of LED Lighting Systems in Industrial Applications." Journal of Sustainable Energy Engineering, 15(4), 287-302.

2. Maritime Safety Administration. (2024). "Technical Standards for Marine-Grade Lighting Equipment." International Maritime Lighting Handbook, 8th Edition, 156-178.

3. Anderson, R.J., Thompson, K., & Martinez, S. (2022). "Life Cycle Cost Analysis of Industrial Lighting Technologies." Facilities Management Quarterly, 41(2), 112-134.

4. Zhang, H., & Liu, X. (2023). "Reliability Engineering in LED Floodlight Design for Harsh Environments." IEEE Transactions on Industrial Electronics, 70(8), 8234-8247.

5. International Energy Agency. (2024). "Global Lighting Energy Consumption Report: Industrial and Commercial Sectors." IEA Technology Report Series, Annual Publication, 45-89.

VIEW MOREMarine Spot Flood Light

VIEW MOREMarine Spot Flood Light VIEW MOREexplosion proof led high bay lights

VIEW MOREexplosion proof led high bay lights VIEW MOREcrane safety lights

VIEW MOREcrane safety lights VIEW MOREoverhead crane lights

VIEW MOREoverhead crane lights VIEW MOREled baseball field lights

VIEW MOREled baseball field lights VIEW MOREBest Dimmable Flood Lights

VIEW MOREBest Dimmable Flood Lights VIEW MORE500 Watt Led Stadium Lights

VIEW MORE500 Watt Led Stadium Lights VIEW MOREAluminum Alloy IP67 LED Navigation Lights For Marine Boating

VIEW MOREAluminum Alloy IP67 LED Navigation Lights For Marine Boating

_1750326878398.png)