Top-Rated Waterproof Floodlight for Harsh Weather Conditions

When coastal facilities face relentless storms, offshore platforms battle corrosive salt spray, and industrial sites operate through extreme temperature swings, inadequate lighting becomes a critical safety hazard and operational nightmare. Choosing a top-rated Waterproof Floodlight designed specifically for harsh weather conditions isn't just about illumination—it's about ensuring worker safety, maintaining productivity during adverse weather, and avoiding costly equipment failures. This comprehensive guide explores how industrial-grade waterproof floodlights deliver reliable performance when conventional lighting systems fail, helping facility managers and project engineers make informed decisions for their most demanding applications.

Essential Features of Industrial Waterproof Floodlights

Advanced IP Rating Protection Standards

Industrial waterproof floodlights must meet rigorous ingress protection standards to survive harsh environmental conditions. The IP67 rating represents the gold standard for outdoor industrial lighting, providing complete protection against dust infiltration and safeguarding against water immersion up to one meter depth for thirty minutes. This level of protection ensures that waterproof floodlights continue operating reliably even during heavy rainstorms, snow accumulation, or when subjected to high-pressure washdown procedures common in marine and industrial facilities. Meanwhile, IP65-rated fixtures offer excellent protection against water jets from any direction, making them suitable for slightly less extreme applications while maintaining robust weather resistance.

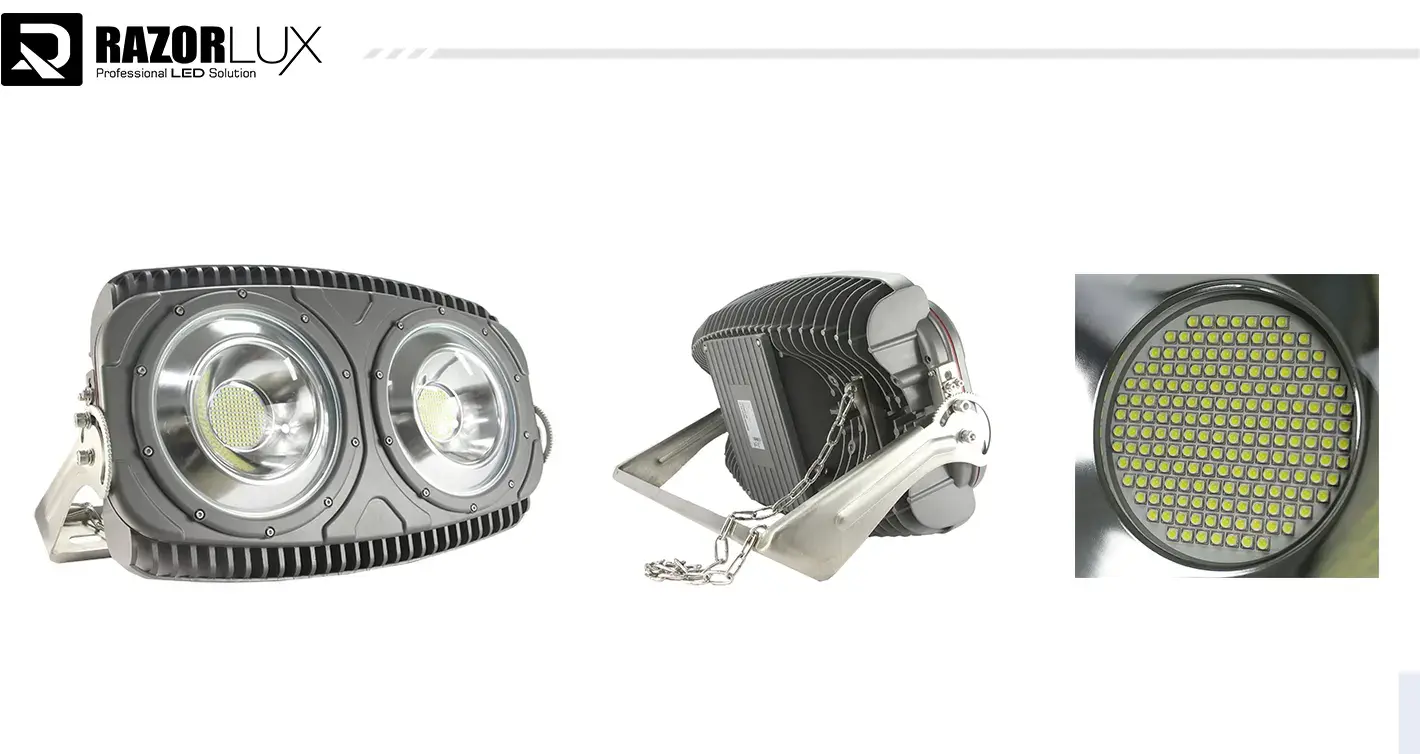

Marine-Grade Corrosion Resistance Technology

Harsh coastal and offshore environments demand exceptional corrosion resistance beyond standard outdoor lighting capabilities. Premium waterproof floodlights feature specialized marine-grade anti-corrosion coatings applied to aluminum housings, creating a protective barrier against salt spray, chemical exposure, and atmospheric moisture. The combination of powder-coated aluminum construction with stainless steel mounting brackets ensures decades of reliable service in the most aggressive environments. This corrosion-resistant design prevents premature degradation that plagues inferior lighting systems, eliminating frequent replacement costs and minimizing maintenance downtime in critical industrial operations.

Wide Operating Temperature Range Capability

Extreme temperature fluctuations challenge conventional lighting equipment, but industrial waterproof floodlights engineered for harsh conditions operate reliably from -40°C to 60°C (-40°F to 140°F). This exceptional temperature tolerance enables consistent performance across diverse climates, from Arctic installations to desert industrial facilities. Advanced thermal management systems dissipate heat effectively even during continuous operation in high ambient temperatures, while cold-weather performance features ensure instant illumination and stable light output when temperatures plummet. The wide operating range makes these waterproof floodlights ideal for year-round outdoor deployment without seasonal concerns about equipment failure.

Technical Specifications and Performance Comparison

| Specification | Premium Industrial Model | Standard Outdoor Model | Traditional HID Equivalent |

|---|---|---|---|

| Rated Power | 1000W LED | 1000W LED | 2200-2500W HID |

| Luminous Efficacy | 130 lm/W | 90-100 lm/W | 50-70 lm/W |

| Total Light Output | 120,000 lumens | 90,000-100,000 lumens | 110,000-140,000 lumens |

| Color Temperature Range | 2700K-6500K | 3000K-5000K | 3200K-4200K |

| IP Protection Rating | IP67/IP65 | IP65/IP54 | IP54 or lower |

| Operating Lifespan | ≥50,000 hours | 30,000-40,000 hours | 10,000-20,000 hours |

| Input Voltage Range | AC 80-315V | AC 100-277V | Requires specific voltage |

| Power Factor | ≥0.98 | ≥0.90 | 0.85-0.95 |

| Color Rendering Index | Ra≥75 (Ra≥90 optional) | Ra≥70 | Ra 65-75 |

| Impact Resistance | IK10 | IK08 | IK06 |

| Warranty Coverage | 5 years comprehensive | 2-3 years limited | 1-2 years |

High-Efficiency LED Technology Benefits

Modern waterproof floodlight technology delivers 130 lumens per watt, dramatically outperforming traditional metal halide and high-pressure sodium fixtures while consuming significantly less energy. A 1000W LED floodlight effectively replaces 2200-2500W HID lamps, delivering comparable or superior illumination with 50-60% energy savings. This efficiency translates directly into reduced operational costs, lower cooling requirements, and decreased carbon footprint for environmentally conscious facilities. The superior efficacy of LED waterproof floodlights makes them particularly valuable for large-scale installations like shipyards, container terminals, and offshore platforms where hundreds of fixtures operate continuously.

Customizable Beam Angle Options

Precise light distribution optimizes visibility for specific applications, and professional waterproof floodlights offer multiple beam angle configurations including 15°, 20°, and 30° options. Narrow 15° beams provide long-throw illumination ideal for perimeter security and tall structure lighting, focusing intense light over greater distances. Medium 20° beams balance throw distance with coverage area, making them versatile for general industrial applications. Wide 30° beams deliver broader coverage patterns suitable for loading docks, yard areas, and workspaces requiring even illumination across larger surfaces. This beam angle flexibility enables lighting designers to specify optimal configurations for each location's unique requirements.

Superior Color Rendering Performance

Color rendering capability significantly impacts safety and work quality in industrial environments, making CRI (Color Rendering Index) a critical specification for waterproof floodlights. Standard models with Ra≥75 provide adequate color discrimination for most industrial tasks, while premium options offering Ra≥80 or Ra≥90 enable accurate color perception crucial for inspection work, quality control, and maintenance tasks. Higher CRI values allow workers to identify color-coded equipment, recognize warning signs clearly, and perform detailed visual work safely even during nighttime operations. The availability of customizable color rendering ensures waterproof floodlights meet specific operational requirements across diverse industrial applications.

Applications and Industry-Specific Requirements

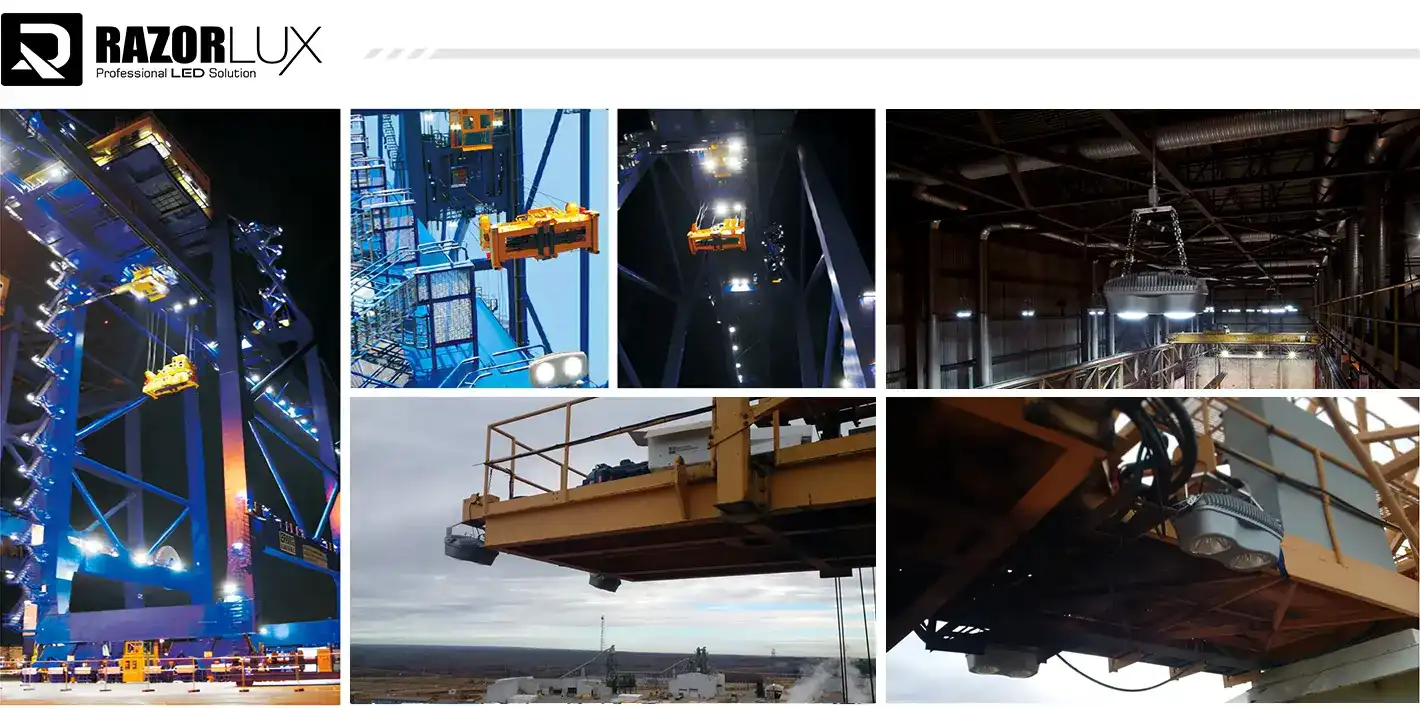

Maritime and Offshore Installation Demands

Maritime environments present the most challenging conditions for lighting equipment, requiring waterproof floodlights specifically engineered to withstand constant salt spray exposure, high humidity, and violent weather. Shipyards depend on reliable illumination for round-the-clock vessel construction and maintenance activities, where lighting failures can halt critical operations. Offshore oil and gas platforms require lighting systems that maintain functionality through hurricanes, extreme temperature variations, and corrosive atmospheres while meeting stringent safety regulations. Container ports and terminals need robust waterproof floodlights capable of illuminating vast cargo handling areas continuously, ensuring safe operations regardless of weather conditions affecting visibility.

Heavy Industrial and Mining Operations

Steel mills, foundries, and heavy manufacturing facilities operate in environments with extreme temperatures, airborne particulates, and mechanical vibrations that quickly destroy inadequate lighting systems. Industrial-grade waterproof floodlights must endure these punishing conditions while providing consistent illumination for safety-critical operations. Mining operations, both surface and near-surface facilities, require lighting that functions reliably in dusty, humid, and often corrosive atmospheres where equipment failure poses serious safety risks. The combination of IP67 protection, IK10 impact resistance, and robust aluminum construction ensures waterproof floodlights survive the mechanical stresses and environmental challenges inherent in heavy industrial applications.

Infrastructure and Coastal Facility Applications

| Application Type | Key Lighting Requirements | Recommended Configuration |

|---|---|---|

| Bridge and Overpass | High-visibility, minimal maintenance, weather-resistant | 1000W, 30° beam, 5000-5700K, IP67 |

| Coastal Processing Plants | Corrosion resistance, high humidity tolerance, continuous operation | 1000W, 20° beam, 4000-5000K, IP67 |

| Port Terminals | Wide area coverage, high output, durability | 1000W, 30° beam, 5000-6500K, IP65/IP67 |

| Dry Docks | Precise illumination, adjustable angles, impact resistance | 1000W, 15-20° beam, 4000-5700K, IP67 |

| Construction Sites | Temporary installation flexibility, extreme weather capability | 1000W, 20-30° beam, 5000-6500K, IP65 |

| Railway Yards | Long-distance throw, consistent color, all-weather reliability | 1000W, 15° beam, 4000-5000K, IP67 |

| Petrochemical Facilities | Explosion-proof options, chemical resistance, safety compliance | 1000W, varies, 4000-5000K, IP67 ATEX |

| Military Installations | Security lighting, tactical flexibility, rugged construction | 1000W, 15-20° beam, varies, IP67 |

Specialized Environmental Certifications

Different industries and regions mandate specific certifications ensuring waterproof floodlights meet safety, performance, and environmental standards. RMRS (Russian Maritime Register of Shipping) certification qualifies lighting for marine vessel and offshore platform installations. UL and DLC listings verify North American safety and energy efficiency standards, while CE marking confirms European regulatory compliance. RoHS certification ensures environmental responsibility by restricting hazardous substances in manufacturing. SAA and C-Tick approvals enable Australian and New Zealand market access. These comprehensive certifications demonstrate that premium waterproof floodlights undergo rigorous third-party testing and meet international quality benchmarks essential for global project specifications.

Manufacturing Quality and Reliability Standards

Premium Component Selection Criteria

The reliability of waterproof floodlights in harsh environments depends fundamentally on component quality, with premium manufacturers exclusively specifying industrial-grade parts from recognized suppliers. High-efficiency LED chips from manufacturers like Samsung deliver consistent light output, superior color stability, and extended operational lifespans exceeding 50,000 hours. Mean Well power supplies provide stable current regulation across wide input voltage ranges (AC 80-315V), protecting sensitive LED components from power fluctuations common in industrial environments. Aluminum housings undergo precision CNC machining followed by powder coating processes that create durable, corrosion-resistant finishes. This commitment to premium components ensures waterproof floodlights maintain performance specifications throughout their operational life rather than degrading rapidly like budget alternatives.

Comprehensive Quality Control Processes

ISO 9001 certified manufacturing processes establish systematic quality management throughout waterproof floodlight production, from raw material inspection through final testing. Design Failure Mode and Effects Analysis (DFMEA) methodologies identify potential reliability issues before production begins, enabling proactive design improvements that enhance long-term durability. Every completed fixture undergoes 100% functional testing including photometric measurement using integrating spheres, electrical safety verification, and aging tests that simulate extended operation. This rigorous quality control approach eliminates defective units before shipment, ensuring customers receive waterproof floodlights that meet published specifications and perform reliably in demanding field conditions.

Extended Warranty Coverage Programs

Manufacturer confidence in waterproof floodlight quality manifests through comprehensive warranty programs covering components for extended periods. Premium manufacturers offer five-year warranties on LED modules and power drivers, demonstrating confidence in component longevity and manufacturing quality. Housing warranties extending to ten years reflect the durability of marine-grade aluminum construction and advanced corrosion-resistant coatings. These extensive warranty periods provide financial protection for capital equipment investments while confirming manufacturer commitment to product quality. The availability of responsive technical support throughout the warranty period ensures any issues receive prompt resolution, minimizing operational disruptions and maintaining lighting system performance.

Conclusion

Selecting top-rated waterproof floodlights for harsh weather conditions requires careful evaluation of IP ratings, corrosion resistance, temperature tolerance, and certified component quality. Industrial applications demand lighting solutions that deliver reliable performance through storms, extreme temperatures, and corrosive environments where conventional fixtures fail rapidly. The investment in premium waterproof floodlights with IP67 protection, marine-grade construction, and comprehensive warranties provides long-term value through reduced maintenance costs, energy savings, and operational reliability.

Ready to upgrade your facility with industrial-grade waterproof floodlights engineered for the harshest conditions? As a leading China waterproof floodlight manufacturer and China waterproof floodlight supplier, Xi'an Razorlux Optoelectronic Technology Co., Ltd. delivers proven lighting solutions backed by over 20 years of LED technology expertise and global certifications. Our China waterproof floodlight factory produces customizable fixtures with competitive waterproof floodlight prices, offering both waterproof floodlight wholesale programs and individual units for sale. Contact our technical team at sam@razorlux.com for application-specific recommendations, detailed specifications, and sample evaluation units. Save this resource for future reference when planning your next lighting upgrade project.

References

1. Illuminating Engineering Society. "Recommended Practice for Outdoor Environmental Lighting." IES RP-33-14. Illuminating Engineering Society of North America, 2014.

2. International Electrotechnical Commission. "Degrees of Protection Provided by Enclosures (IP Code)." IEC Standard 60529. International Electrotechnical Commission, 2020.

3. U.S. Department of Energy. "LED Lighting Systems for Harsh Industrial Environments: Performance and Reliability." Solid-State Lighting Program Report. DOE Energy Efficiency and Renewable Energy Office, 2022.

4. Maritime and Coastguard Agency. "Code of Practice for Electrical and Electronic Equipment on Ships." MCA Guidance Note MGN 564. United Kingdom Maritime and Coastguard Agency, 2021.

5. American Society for Testing and Materials. "Standard Practice for Classification of Outdoor-Indoor Environmental Conditions for Exterior Lighting." ASTM G154-16. ASTM International, 2021.

_1750326878398.png)