3 Critical Checks for Choosing a Weatherproof LED Industrial Flood Light

Picture this: your facility's lighting fails during a critical nighttime operation, leaving workers in darkness and production grinding to a halt. This nightmare scenario becomes reality for businesses that skimp on proper lighting evaluation. When selecting LED Industrial Flood Light solutions for harsh environments, three critical checks determine whether your investment delivers reliable performance or costly disappointment. Understanding these essential verification points ensures your industrial lighting withstands extreme conditions while maintaining optimal illumination for years to come.

Understanding IP Rating Requirements for Industrial Led Flood Lights Outdoor Applications

Evaluating IP65 vs IP67 Protection Standards

The first critical check involves understanding Ingress Protection ratings, particularly the difference between IP65 and IP67 certifications for LED Industrial Flood Light installations. IP65 provides dust-tight protection and guards against water jets from any direction, making it suitable for most outdoor applications. However, IP67 offers superior protection by withstanding temporary immersion in water up to one meter deep for thirty minutes. Industrial facilities near coastal areas, chemical processing plants, or locations with frequent washdown procedures require IP67-rated Industrial Led Flood Lights Outdoor units to prevent moisture infiltration that could compromise electrical components and reduce operational lifespan.

Assessing Corrosion Resistance Features

Marine-grade anti-corrosion coatings become essential when deploying LED Industrial Flood Light systems in challenging environments. Aluminum housing with specialized powder coating treatments provides enhanced protection against saltwater exposure, chemical vapors, and industrial pollutants. Stainless steel brackets and mounting hardware resist oxidation better than standard steel components. The combination of proper materials and protective coatings ensures Industrial Led Flood Lights Outdoor maintain structural integrity and electrical performance despite continuous exposure to corrosive elements that would rapidly degrade inferior lighting solutions.

Analyzing Temperature Tolerance Specifications

Operating temperature ranges directly impact LED Industrial Flood Light reliability in extreme climates. Quality units must function consistently across wide temperature variations, typically from -40°C to 60°C (-40°F to 140°F), without performance degradation. Advanced thermal management systems, including aluminum heat sinks and optimized airflow designs, prevent overheating that reduces LED lifespan and light output. Industrial Led Flood Lights Outdoor with inadequate thermal protection experience premature failure, color shifting, and reduced efficacy in high-temperature environments common in manufacturing facilities, refineries, and outdoor installations.

| Temperature Range | Performance Impact | Recommended Applications |

|---|---|---|

| -40°C to 60°C | Optimal performance | All industrial environments |

| -20°C to 40°C | Good performance | Moderate climate zones |

| 0°C to 30°C | Basic performance | Indoor or sheltered areas |

Verifying Power Efficiency and Lumen Output for LED Industrial Flood Light Performance

Calculating Lumens per Watt Efficiency

The second critical check focuses on evaluating luminous efficacy, measured in lumens per watt, which determines long-term operational costs and environmental impact. Premium LED Industrial Flood Light units achieve 130LM/W or higher efficiency ratings, significantly outperforming traditional HID alternatives that typically deliver 50-80LM/W. This superior efficiency translates to substantial energy savings, reduced carbon footprint, and lower utility expenses over the fixture's operational lifetime. Industrial Led Flood Lights Outdoor with lower efficacy ratings consume excessive electricity while generating unwanted heat that accelerates component degradation and increases cooling requirements.

Determining Optimal Beam Angle Configuration

Beam angle selection directly affects illumination uniformity and coverage area for LED Industrial Flood Light installations. Narrow beam angles (40°-60°) concentrate light for focused applications like loading docks or equipment inspection areas. Medium beam angles (90°-120°) provide balanced coverage for general facility lighting. Wide beam angles (140°+) deliver broad area illumination for large yards or warehouse spaces. Proper beam angle matching to application requirements eliminates dark spots, reduces glare, and minimizes the total number of Industrial Led Flood Lights Outdoor fixtures needed for complete coverage.

Analyzing Power Factor and THD Specifications

Power quality parameters including Power Factor (≥0.98) and Total Harmonic Distortion (THD <10%) indicate LED Industrial Flood Light electrical efficiency and grid compatibility. High power factor reduces reactive power consumption and prevents utility penalties. Low THD minimizes electrical interference with sensitive equipment. Industrial Led Flood Lights Outdoor with poor power quality characteristics create inefficiencies throughout electrical systems and may violate utility company requirements for commercial installations.

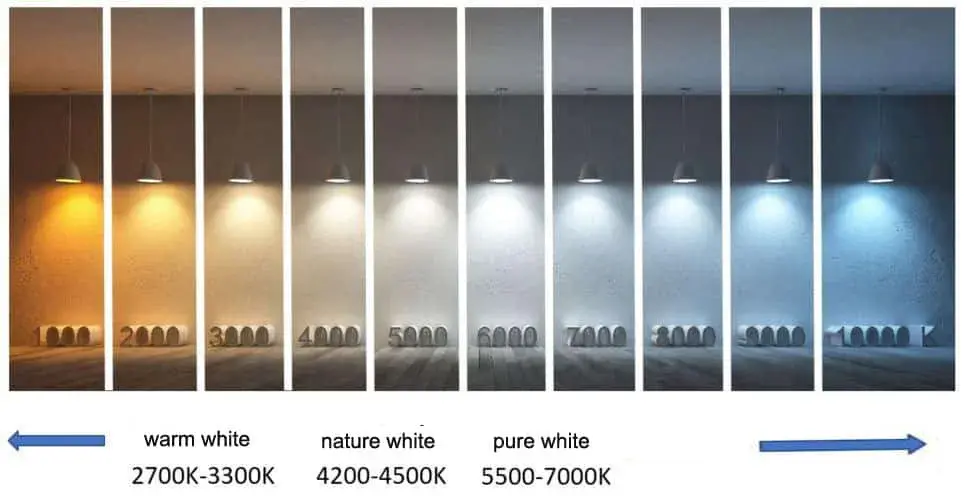

Evaluating Color Rendering and Temperature Options

Color rendering capabilities (CRI ≥75) and adjustable color temperatures (2700K-6500K) enhance workplace safety and productivity. Higher CRI values improve color discrimination for quality control tasks, while appropriate color temperature selection reduces eye strain and maintains circadian rhythm alignment for night shift workers. LED Industrial Flood Light systems offering customizable color parameters provide flexibility for diverse industrial applications and changing operational requirements.

| Power Specification | Standard Value | Premium Value | Industrial Benefit |

|---|---|---|---|

| Efficacy (LM/W) | 100-120 | 130+ | Maximum energy savings |

| Power Factor | 0.9+ | 0.98+ | Reduced utility costs |

| THD | <15% | <10% | Improved power quality |

| CRI | Ra>70 | Ra>75 | Enhanced visibility |

Ensuring Longevity Through Quality Components and Warranty Coverage

Evaluating LED Module and Driver Quality

The third critical check examines component quality, starting with LED modules and power supply systems that determine LED Industrial Flood Light reliability and maintenance requirements. Premium manufacturers utilize top-tier LED chips with proven track records and robust power supplies from established brands like Meanwell. Quality drivers incorporate advanced thermal protection, surge suppression, and dimming compatibility features. Industrial Led Flood Lights Outdoor equipped with inferior components experience frequent failures, requiring costly replacements and creating operational disruptions that exceed initial purchase price savings from cheaper alternatives.

Assessing Warranty Terms and Coverage

Comprehensive warranty protection reflects manufacturer confidence in LED Industrial Flood Light quality and provides financial protection against premature failures. Standard warranties typically cover LED modules for 5 years and drivers for 3-5 years, while premium manufacturers offer extended coverage up to 10 years for housing components. Warranty terms should specify coverage for gradual light output degradation (L70 maintenance), not just complete failure. Industrial Led Flood Lights Outdoor backed by extensive warranties reduce long-term ownership costs and provide predictable maintenance budgets for facility managers.

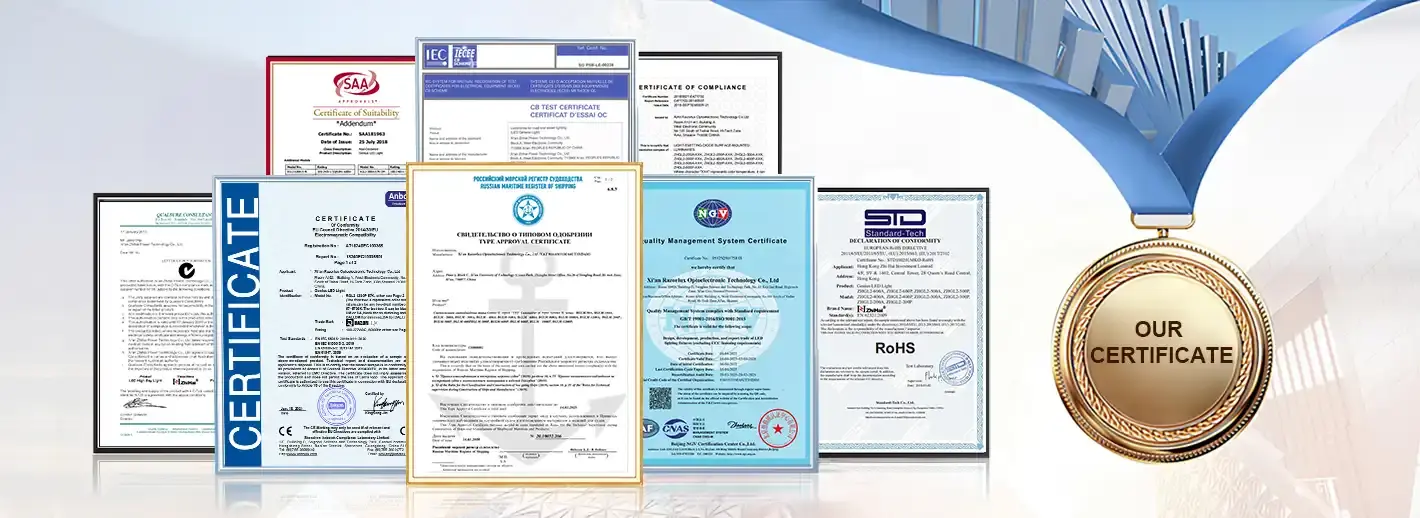

Analyzing Certification and Compliance Standards

International certifications validate LED Industrial Flood Light safety, performance, and compatibility with regional electrical codes. Essential certifications include UL (North America), CE (Europe), RoHS (environmental compliance), and SAA (Australia/New Zealand). Specialized maritime certifications become critical for port facilities and offshore installations. Industrial Led Flood Lights Outdoor lacking proper certifications may fail inspection requirements, create liability issues, and face installation restrictions that limit deployment options.

Reviewing Manufacturer Support Services

Post-installation support capabilities significantly impact LED Industrial Flood Light lifecycle value through technical assistance, replacement parts availability, and upgrade pathways. Established manufacturers maintain global service networks, provide detailed technical documentation, and offer customization services for unique applications. Industrial Led Flood Lights Outdoor from manufacturers with limited support infrastructure create long-term risks when technical issues arise or facility requirements change.

Conclusion

Selecting the right LED Industrial Flood Light requires careful evaluation of IP ratings, power efficiency, and component quality. These three critical checks ensure your investment delivers reliable performance in demanding industrial environments while minimizing operational costs and maintenance requirements.

Ready to illuminate your facility with premium LED Industrial Flood Light solutions? Xi'an Razorlux Optoelectronic Technology Co., Ltd., a leading China LED Industrial Flood Light factory, offers cutting-edge Industrial Led Flood Lights Outdoor with IP67 protection, 130LM/W efficiency, and 5-year warranties. As a trusted China LED Industrial Flood Light supplier and China LED Industrial Flood Light manufacturer, Razorlux provides comprehensive lighting solutions with competitive LED Industrial Flood Light price points and China LED Industrial Flood Light wholesale options. Our mature R&D team, GMP factory, and complete certifications ensure LED Industrial Flood Light for sale meets the highest quality standards. contact us at sam@razorlux.com for professional consultation and customized solutions that withstand your harshest operating conditions.

References

1. "LED Lighting System Design and Installation Guidelines" - International Association of Lighting Designers, Technical Committee on Industrial Applications

2. "Weatherproof Electrical Equipment Standards and Testing Procedures" - Institute of Electrical and Electronics Engineers, Working Group on Industrial Lighting

3. "Energy Efficiency in Industrial Lighting Systems" - American National Standards Institute, Committee on Commercial and Industrial Lighting

4. "Corrosion Protection for Outdoor Electrical Equipment" - National Association of Corrosion Engineers, Industrial Equipment Division

VIEW MORE120W Warm White Led Floodlight

VIEW MORE120W Warm White Led Floodlight_1748337998981.webp) VIEW MOREExplosion Proof Led Fixtures

VIEW MOREExplosion Proof Led Fixtures VIEW MOREDLC Led Stadium Lights 120lm/W 6000K Football Stadium Floodlights Fixtures

VIEW MOREDLC Led Stadium Lights 120lm/W 6000K Football Stadium Floodlights Fixtures VIEW MORERound 120w Led Industrial Flood Light 14400lm Anti Glare Led Flood Light

VIEW MORERound 120w Led Industrial Flood Light 14400lm Anti Glare Led Flood Light VIEW MORELed Sport Court Lights

VIEW MORELed Sport Court Lights VIEW MOREHigh Mast Luminaire

VIEW MOREHigh Mast Luminaire VIEW MOREBest Led Stadium Lights

VIEW MOREBest Led Stadium Lights VIEW MOREBarn Security Light

VIEW MOREBarn Security Light

_1750326878398.png)