How do LED crane lights comply with safety regulations and standards?

When industrial accidents strike due to inadequate crane lighting, the consequences can be devastating - from worker injuries to costly equipment damage and regulatory violations. The answer lies in understanding how modern LED Crane Light systems comply with stringent safety regulations and international standards, ensuring both operational efficiency and workplace safety in demanding industrial environments.

Essential Safety Standards for Industrial LED Crane Light Systems

International Certification Requirements for LED Crane Light Applications

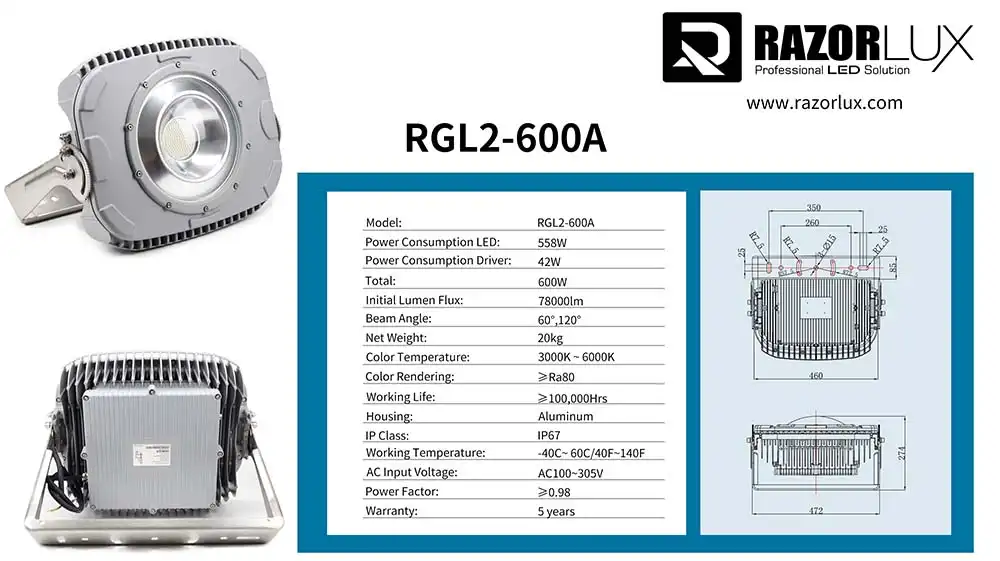

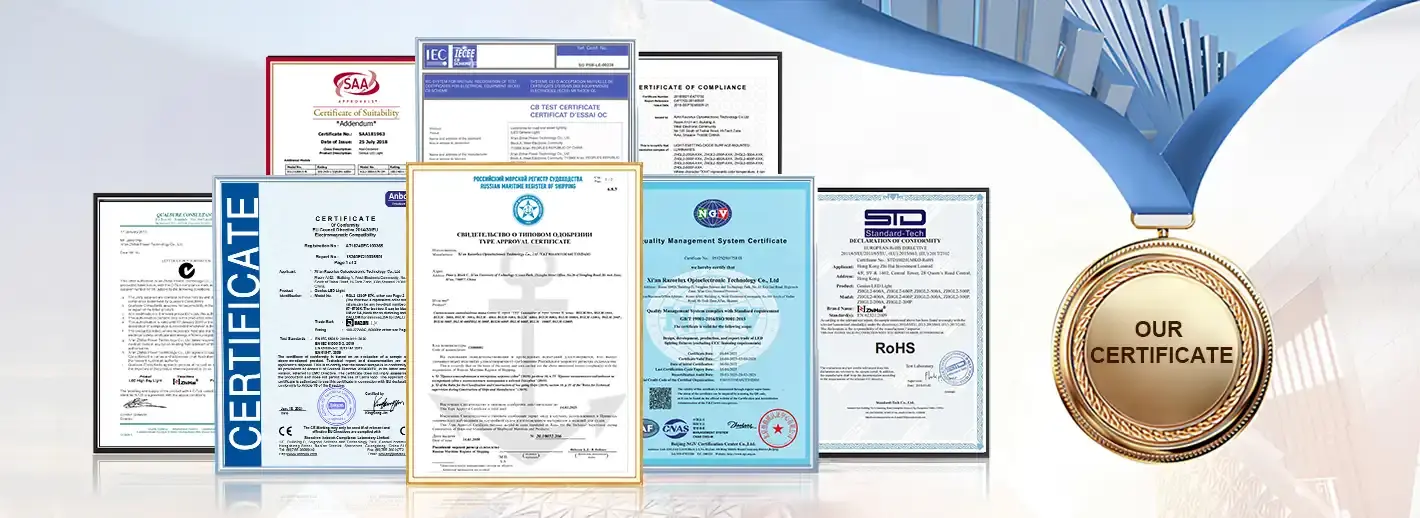

Modern LED Crane Light fixtures must meet multiple international safety standards to ensure reliable operation across global markets. IP67 certified lights are designed for use in all weather conditions both indoors and outdoors, providing the necessary protection against dust ingress and water immersion. The certification process involves rigorous testing of electrical safety, electromagnetic compatibility, and environmental durability. Xi'an Razorlux's LED crane lighting solutions comply with comprehensive standards including UL for North American markets, CE marking for European compliance, SAA for Australian requirements, and RoHS for environmental safety. These certifications ensure that every LED Crane Light Fixture meets the highest safety benchmarks for industrial applications.

OSHA Compliance and Workplace Safety Regulations

OSHA regulations require effective warning signals for crane operations, and safety lights can be added to existing cranes as retrofits to reduce collision risks. The Occupational Safety and Health Administration mandates specific lighting requirements for crane operations to prevent workplace accidents and ensure operator visibility. LED Crane Light systems must provide adequate illumination for safe load handling, proper visibility of crane movements, and clear warning signals for nearby personnel. Compliance with OSHA standards includes maintaining proper light intensity levels, ensuring reliable operation in harsh conditions, and implementing appropriate warning light systems that alert workers to crane operations.

Maritime and Port Authority Standards

Port cranes need special lights to be safe and work right, especially when it's dark or the weather is bad. Maritime applications require LED Crane Light fixtures to meet additional safety standards specific to marine environments. These include resistance to salt spray corrosion, compliance with International Maritime Organization guidelines, and adherence to port authority lighting specifications. The demanding marine environment necessitates robust construction with IP67 protection, marine-grade anti-corrosion coatings, and reliable performance in extreme weather conditions.

Aviation Safety Lighting Requirements

Any structure exceeding 200 feet above ground level should normally be marked and/or lighted according to FAA regulations. Tower cranes and tall industrial structures equipped with LED crane lighting must comply with Federal Aviation Administration requirements for aircraft warning systems. For cranes with angular booms, lights must be mounted on pivot axis systems to remain level and visible. These regulations ensure that LED Crane Light installations do not create aviation hazards while maintaining operational effectiveness for industrial applications.

Technical Compliance Features and Performance Standards

IP Rating and Environmental Protection Standards

| Protection Level | Standard Requirements | LED Crane Light Applications |

|---|---|---|

| IP65 | Dust tight, water jet protection | General industrial environments |

| IP67 | Dust tight, temporary immersion | Marine and harsh weather conditions |

| IK10 | Maximum impact resistance | Heavy-duty construction sites |

Environmental protection standards define the durability requirements for LED Crane Light systems operating in challenging conditions. The IP rating system evaluates protection against solid particles and liquid ingress, while IK ratings assess impact resistance capabilities. Xi'an Razorlux's LED crane lighting solutions achieve IP67 rating, ensuring complete dust protection and resistance to temporary water immersion up to one meter depth. This level of protection enables reliable operation in shipyards, construction sites, and offshore installations where exposure to harsh environmental conditions is inevitable.

Electrical Safety and Power Quality Standards

LED Crane Light systems must comply with strict electrical safety standards to prevent hazards and ensure reliable operation. Input voltage compatibility ranging from AC80-315Vac to DC80-400Vdc provides flexibility for various power systems while maintaining safety compliance. Power factor requirements exceeding 0.98 ensure efficient energy utilization and reduced electrical system stress. Total harmonic distortion below 10% prevents interference with sensitive equipment and maintains power quality standards. These specifications ensure that LED Crane Light installations meet electrical safety codes and provide stable, efficient operation across diverse industrial applications.

Photometric Performance and Lighting Standards

LED fixtures must undergo rigorous testing according to ANSI C136.31 standard for vibration resistance. Photometric standards define the lighting performance requirements for LED Crane Light systems, including luminous efficacy, color rendering, and beam distribution characteristics. The 130LM/W efficiency rating of modern LED crane lights significantly exceeds traditional lighting technologies while providing superior light quality. Color rendering index (CRI) values above Ra75 ensure accurate color perception for safe operation, while customizable color temperatures from 2700K to 6500K accommodate specific application requirements and regulatory standards.

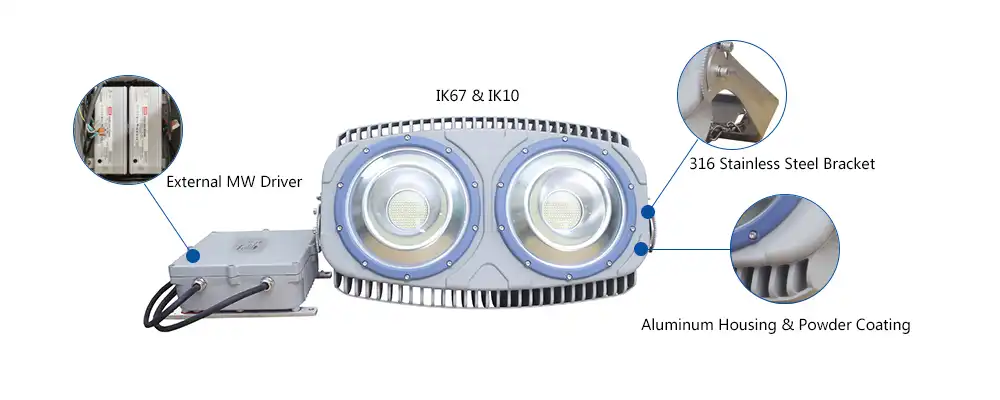

Structural Design and Mechanical Standards

The mechanical design of LED Crane Light fixtures must withstand the demanding conditions of industrial crane operations, including constant vibration, shock loads, and thermal cycling. Stainless steel bracket construction provides corrosion resistance and structural integrity, while aluminum housing with powder coating ensures lightweight durability. Working temperature ranges from -40°C to 60°C accommodate extreme climate conditions, and humidity tolerance up to 95% enables operation in high-moisture environments. These design specifications ensure long-term reliability and compliance with mechanical safety standards.

Quality Assurance and Manufacturing Compliance

ISO 9001 Quality Management Systems

| Quality Control Stage | Testing Requirements | Compliance Standards |

|---|---|---|

| Assembly Line | Worker skill verification | ISO 9001 procedures |

| Finished Products | Final inspection protocols | Quality management standards |

| Photometric Testing | Integrating sphere measurements | IES lighting standards |

| Aging Tests | Performance reliability validation | Long-term durability requirements |

Manufacturing compliance begins with ISO 9001 quality management systems that ensure consistent production standards and continuous improvement processes. Xi'an Razorlux's certified facilities implement comprehensive quality control measures throughout the LED Crane Light production process. Assembly line procedures verify worker competency and adherence to manufacturing specifications, while finished product inspections validate compliance with technical requirements. Photometric testing using integrating spheres ensures accurate light output measurements and compliance with lighting standards.

Comprehensive Testing and Validation Procedures

LED Crane Light systems undergo extensive testing protocols to verify compliance with safety regulations and performance standards. Aging tests simulate long-term operation under accelerated conditions, validating the 50,000-hour working life expectancy and identifying potential reliability issues. Vibration testing according to ANSI standards ensures structural integrity under operational stresses. Environmental testing validates IP67 protection levels and confirms performance across specified temperature and humidity ranges. These comprehensive validation procedures guarantee that every LED Crane Light meets or exceeds regulatory requirements.

Certification Documentation and Traceability

Complete certification documentation provides traceability and regulatory compliance verification for LED Crane Light installations. Technical drawings, product specifications, and installation guides support engineering and project planning requirements while ensuring compliance with local codes and standards. Warranty coverage including 5-year LED module protection and 10-year housing warranty demonstrates manufacturer confidence in product reliability and regulatory compliance. This comprehensive documentation package enables customers to verify compliance with applicable safety standards and regulatory requirements.

Supply Chain Quality Management

Quality management extends throughout the supply chain to ensure component reliability and regulatory compliance. Meanwell power supplies provide certified electrical safety and performance reliability, while high-grade aluminum housing materials meet structural standards. Component sourcing follows strict quality criteria to ensure consistency and compliance with international standards. This comprehensive approach to supply chain management guarantees that every LED Crane Light component contributes to overall system safety and regulatory compliance.

Conclusion

LED Crane Light compliance with safety regulations requires comprehensive adherence to international standards, rigorous testing protocols, and quality manufacturing processes that ensure reliable performance in demanding industrial environments.

Ready to upgrade your crane lighting with fully compliant LED solutions? As a leading China LED Crane Light factory and China LED Crane Light supplier, Xi'an Razorlux offers professional consultation for your specific requirements. Our China LED Crane Light manufacturer expertise ensures competitive LED Crane Light prices with certified quality. Browse our LED Crane Light for sale options or contact our team at sam@razorlux.com for customized lighting solutions that meet your exact compliance needs and operational requirements.

References

1. "Overhead and Gantry Cranes Safety Standards," American Society of Mechanical Engineers, ASME B30.2-2005

2. "Roadway and Area Lighting Equipment - Vibration Testing," American National Standards Institute, ANSI C136.31-2010

3. "General Requirements for Electric Lighting Equipment," Underwriters Laboratories, UL 1598-2008

4. "Occupational Safety and Health Standards for Construction - Cranes and Derricks," Occupational Safety and Health Administration, 29 CFR 1926 Subpart CC

VIEW MORELed Outdoor Arena Lights

VIEW MORELed Outdoor Arena Lights VIEW MORE1000 Watt Led Stadium Light

VIEW MORE1000 Watt Led Stadium Light VIEW MORE100 Watt Ufo Led Lights

VIEW MORE100 Watt Ufo Led Lights VIEW MOREEnergy Saving Dimmable LED Flood Light With Stainless Steel Bracket

VIEW MOREEnergy Saving Dimmable LED Flood Light With Stainless Steel Bracket VIEW MOREAluminum IK10 Led Stadium Lights 500W 60000lm Led Sports Ground Floodlights

VIEW MOREAluminum IK10 Led Stadium Lights 500W 60000lm Led Sports Ground Floodlights VIEW MORE5700K Outdoor Garden Led Light Ip67 100000lm Flood Lights For Volleyball Court

VIEW MORE5700K Outdoor Garden Led Light Ip67 100000lm Flood Lights For Volleyball Court VIEW MOREHigh Mast Sports Arena Lighting 130lm/W 600 Watt Outdoor Stadium Lighting

VIEW MOREHigh Mast Sports Arena Lighting 130lm/W 600 Watt Outdoor Stadium Lighting VIEW MORELuminaire Led Flood Light

VIEW MORELuminaire Led Flood Light

_1750326878398.png)