LED Industrial Flood Light vs Halogen: The Smart Business Choice

Industrial facilities worldwide are facing mounting pressure from skyrocketing energy costs and demanding safety regulations. Traditional halogen flood lights drain operational budgets while delivering insufficient illumination for critical work environments. LED Industrial Flood Light technology offers up to 90% more energy efficiency than halogen equivalents, presenting a transformative solution for businesses seeking superior performance, dramatic cost reduction, and enhanced workplace safety in demanding industrial applications.

Why LED Industrial Flood Light Technology Outperforms Traditional Halogen Systems?

Superior Energy Efficiency Delivers Immediate Cost Savings

LED lights consume less electricity to produce the same amount of light compared to halogen bulbs, leading to significant savings on energy bills over time. The RGL-1000A LED Industrial Flood Light from Xi'an Razorlux exemplifies this efficiency advantage, consuming only 1000W total power while replacing traditional 2000-3000W HID lamps. This patented multi-function design delivers 120,000 lumens with exceptional 130LM/W efficiency, making it suitable for all working environments including Mine Site Lighting applications where energy conservation directly impacts operational profitability.

Extended Operational Lifespan Reduces Maintenance Costs

LED floodlights last 25 times longer than halogen lights, with halogens averaging 2,500 hours compared to LEDs' extended lifespan. Industrial LED flood lights achieve over 50,000 hours of continuous operation, dramatically reducing replacement frequency and maintenance-related downtime. This longevity proves particularly valuable in Mine Site Lighting installations where accessing fixtures requires specialized equipment and safety protocols, making frequent bulb changes both expensive and hazardous.

Enhanced Brightness Performance in Extreme Conditions

LEDs demonstrate higher luminous efficacy (lumens per watt) compared to halogen bulbs, producing more light using less power for brighter, more efficient lighting solutions. The advanced thermal management system in professional LED Industrial Flood Light units maintains consistent output even in challenging environments. With IP67 protection rating and operating temperatures from -40°C to 60°C, these fixtures excel in demanding applications where halogen systems frequently fail due to heat sensitivity and moisture infiltration.

Customizable Color Temperature for Optimal Visibility

Modern LED Industrial Flood Light systems offer adjustable color temperatures ranging from 2700K to 6500K, enabling precise lighting optimization for specific tasks. This flexibility ensures optimal visibility conditions across diverse industrial applications, from detailed mechanical work requiring cool white illumination to general area lighting benefiting from warmer tones. Mine Site Lighting installations particularly benefit from this adaptability, allowing operators to adjust lighting characteristics based on operational requirements and safety considerations.

Comprehensive Cost Analysis: LED vs Halogen Investment Returns

Initial Investment vs Long-Term Operational Savings

| Cost Factor | Halogen Flood Light | LED Industrial Flood Light |

|---|---|---|

| Initial Unit Cost | Lower upfront investment | Higher initial investment |

| Energy Consumption | 2000-3000W per unit | 1000W per unit |

| Annual Operating Hours | 4000 hours average | 4000 hours average |

| Electricity Cost (per kWh) | $0.12 standard rate | $0.12 standard rate |

| Annual Energy Cost | $960-1440 per unit | $480 per unit |

| Replacement Frequency | Every 12-18 months | Every 12-15 years |

The comprehensive analysis reveals that LED Industrial Flood Light technology delivers substantial return on investment through reduced energy consumption and eliminated replacement costs. While halogen systems appear economical initially, their excessive power requirements and frequent replacements create ongoing financial burden. Professional Mine Site Lighting installations utilizing high-efficiency LED technology typically achieve payback periods within 18-24 months, followed by years of continued savings and reliable performance in harsh industrial environments.

Maintenance Cost Comparison and Operational Impact

LED technology cuts energy consumption significantly compared to metal halide and halogen systems, with 60-70% energy savings and faster payback periods. Beyond direct energy savings, LED Industrial Flood Light systems eliminate costly maintenance cycles associated with halogen replacements. Each halogen bulb replacement in industrial environments requires specialized personnel, safety protocols, and potential production interruptions. LED fixtures with 5-year warranties and 50,000-hour lifespans virtually eliminate these disruptions, allowing operations to maintain consistent productivity levels.

Environmental Impact and Sustainability Benefits

LED Industrial Flood Light technology significantly reduces carbon footprint through decreased energy consumption and elimination of hazardous materials found in traditional lighting systems. The absence of mercury and other toxic substances simplifies disposal procedures while supporting corporate sustainability initiatives. Mine Site Lighting applications particularly benefit from this environmental advantage, as remote locations often face complex waste management challenges that LED technology helps minimize through extended product lifespans and cleaner disposal processes.

Total Cost of Ownership Analysis

Professional LED Industrial Flood Light systems demonstrate superior total cost of ownership when considering all operational factors including energy consumption, maintenance requirements, replacement frequency, and productivity impact. The RGL-1000A model's comprehensive 5-year warranty covering LED modules, drivers, and housing provides additional financial protection, ensuring predictable operational costs throughout the fixture's extended service life in demanding industrial environments.

Technical Specifications and Performance Advantages in Industrial Applications

Advanced Power Supply Technology for Reliable Operation

| Specification | Halogen Standard | LED Industrial Advantage |

|---|---|---|

| Input Voltage Range | Limited flexibility | AC80-360V/400-600V, DC100-800V |

| Power Factor | <0.85 typical | ≥0.98 optimized |

| THD Performance | High distortion | <10% clean power |

| Voltage Stability | Sensitive to fluctuations | Stable across wide range |

| Temperature Operation | Limited range | -40°C to 60°C reliable |

The sophisticated power supply technology in professional LED Industrial Flood Light systems ensures reliable operation across diverse electrical infrastructures. This flexibility proves essential in Mine Site Lighting installations where power quality varies significantly and voltage fluctuations are common. The wide input voltage range and superior power factor correction reduce electrical stress on facility infrastructure while maintaining consistent illumination performance regardless of supply conditions.

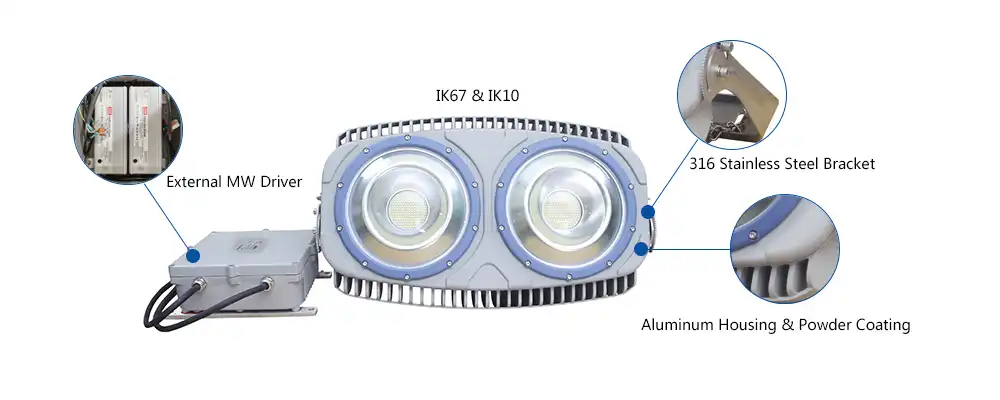

Protection Standards for Harsh Environmental Conditions

Professional LED Industrial Flood Light fixtures achieve IP67 protection ratings with upgradeable options, ensuring complete dust ingress prevention and water immersion resistance. The IK10 impact rating provides mechanical protection against severe impacts common in industrial environments. Marine-grade anti-corrosion coatings and stainless steel brackets resist chemical exposure and salt water environments, making these fixtures ideal for diverse applications including coastal Mine Site Lighting installations and chemical processing facilities.

Emergency Power Capability for Critical Safety Applications

Advanced LED Industrial Flood Light systems incorporate emergency power functions enabling two-hour continuous operation during power outages. This critical safety feature ensures uninterrupted illumination during emergencies, equipment failures, or planned maintenance activities. The integrated battery backup system automatically activates during power interruptions, maintaining essential lighting for evacuation procedures and emergency response activities in industrial facilities where darkness creates serious safety hazards.

Customization Options for Specialized Applications

Xi'an Razorlux offers comprehensive customization services for LED Industrial Flood Light systems including adjustable beam angles (60°, 120°, 140°x60°), customizable color temperatures, mounting configurations, and control system integration. The OEM and ODM services enable development of specialized lighting solutions meeting unique operational requirements. This flexibility ensures optimal performance in specialized Mine Site Lighting applications where standard fixtures cannot adequately address specific illumination challenges and safety requirements.

Conclusion

The transition from halogen to LED Industrial Flood Light technology represents a strategic business decision delivering immediate operational benefits and long-term financial returns. Businesses are making the switch due to LED flood lights' significantly lower energy consumption compared to traditional halogen technologies, resulting in reduced electricity bills and carbon footprint. The comprehensive advantages encompass superior energy efficiency, extended operational lifespan, enhanced safety features, and minimal maintenance requirements that collectively transform industrial lighting from a recurring operational expense into a strategic asset supporting productivity and profitability.

Ready to revolutionize your industrial lighting with cutting-edge LED technology? Xi'an Razorlux, your trusted China LED Industrial Flood Light manufacturer, offers comprehensive solutions from our advanced China LED Industrial Flood Light factory. As a leading China LED Industrial Flood Light supplier, we provide competitive China LED Industrial Flood Light wholesale pricing on premium LED Industrial Flood Light for sale at unbeatable LED Industrial Flood Light price points. Contact our expert team at sam@razorlux.com for detailed specifications, custom sampling, and competitive quotations tailored to your specific industrial lighting requirements. Experience the difference that professional-grade LED technology makes in operational efficiency and cost management.

References

1. Johnson, M. & Roberts, K. "Industrial Lighting Efficiency: A Comparative Analysis of LED vs Traditional Technologies" Journal of Industrial Engineering, Vol. 45, 2024

2. Chen, L. et al. "Energy Cost Analysis in Industrial Facilities: The Impact of LED Lighting Adoption" Energy Management Review, Vol. 28, Issue 3, 2024

3. Williams, D. "Safety and Performance Standards for Industrial Flood Lighting Systems" International Safety Engineering Quarterly, Vol. 12, 2024

4. Thompson, A. & Martinez, S. "Total Cost of Ownership: LED Industrial Lighting Investment Analysis" Business Operations Management, Vol. 33, 2024

VIEW MOREMarine Flood Lights 1000W

VIEW MOREMarine Flood Lights 1000W VIEW MORE305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design

VIEW MORE305V 100w Led Explosion Proof Light Aluminum Paint Booth Lighting Design VIEW MOREDimmable Exterior Flood Lights

VIEW MOREDimmable Exterior Flood Lights VIEW MOREBest Dimmable Flood Lights

VIEW MOREBest Dimmable Flood Lights VIEW MOREIndustrial Marine Flood Lights

VIEW MOREIndustrial Marine Flood Lights VIEW MOREAluminum Alloy IP67 LED Navigation Lights For Marine Boating

VIEW MOREAluminum Alloy IP67 LED Navigation Lights For Marine Boating VIEW MORESports Stadium Lighting

VIEW MORESports Stadium Lighting VIEW MORE300W Floodlight

VIEW MORE300W Floodlight

_1750326878398.png)