Top Explosion Proof Flood Lights Brands You Can Trust

In hazardous industrial environments where flammable gases, vapors, or combustible dust are present, a single spark from conventional lighting can trigger catastrophic explosions. This isn't a theoretical risk—it's a daily reality for workers in oil refineries, chemical plants, and offshore platforms. When safety managers face the challenge of illuminating Zone 1 and Zone 2 hazardous areas, they need more than just bright lights—they need certified Explosion Proof Flood Lights that meet stringent international standards while delivering reliable performance year after year. This comprehensive guide reveals the most trusted brands in explosion-proof lighting, helping you make informed decisions that protect both your workforce and your operations.

Understanding Explosion Proof Flood Lights Standards and Certifications

What Makes Explosion Proof Flood Lights Essential for Hazardous Locations?

Explosion Proof Flood Lights are specifically engineered to contain any internal sparks or explosions within their housings, preventing ignition of surrounding hazardous atmospheres. Unlike standard industrial lighting, these fixtures undergo rigorous testing to ensure their enclosures can withstand internal explosions without allowing flames or hot gases to escape. The construction typically features heavy-duty die-cast aluminum housings with precision-machined surfaces that create flame-proof joints, tempered glass lenses capable of withstanding shock and extreme temperature variations, and specialized cable entry systems with certified sealing compounds. Modern Explosion Proof Flood Lights incorporate advanced LED technology, offering superior energy efficiency compared to traditional HID lamps while maintaining the robust safety features required for hazardous area classifications including Class I Division 1 and Division 2 zones.

Critical Certifications You Must Verify Before Purchase

When evaluating Explosion Proof Flood Lights manufacturers, certification compliance is non-negotiable for legal operation and workplace safety. ATEX certification is mandatory for European markets, verifying compliance with directive standards for equipment used in potentially explosive atmospheres. IECEx certification provides international recognition based on IEC standards, facilitating global acceptance across multiple jurisdictions. UL and CUL certifications from Underwriters Laboratories ensure compliance with North American safety standards for hazardous locations. Additional certifications including DLC for energy efficiency, PSE for Japanese markets, SAA and C-TICK for Australian compliance, along with CE marking for European conformity, demonstrate a manufacturer's commitment to meeting diverse international requirements. Products should also carry IP68 ingress protection ratings, confirming complete dust-tightness and protection against continuous submersion, which is essential for outdoor installations and marine environments where Explosion Proof Flood Lights face exposure to harsh weather conditions.

Comparing Explosion Proof Standards Across Different Regions

| Region | Certification | Hazardous Area Classification | Key Requirements |

|---|---|---|---|

| Europe | ATEX | Zone 0, 1, 2 (Gas) / Zone 20, 21, 22 (Dust) | Temperature class, equipment group, ignition protection type |

| International | IECEx | Zone 0, 1, 2 (Gas) / Zone 20, 21, 22 (Dust) | Harmonized with IEC 60079 series standards |

| North America | UL/CUL | Class I Div 1/2, Class II Div 1/2 | NEC Article 500 compliance, temperature codes |

| China | CCC/CQC | Zone 0, 1, 2 | GB 3836 series standards compliance |

Key Features That Define Top-Tier Explosion Proof Flood Lights Brands

Advanced LED Technology and Optical Performance

Leading Explosion Proof Flood Lights manufacturers incorporate high-efficacy LED chips operating at 700mA current with minimal light decay, ensuring consistent illumination throughout the fixture's operational lifespan. Premium brands utilize original Bridgelux LED sources or equivalent tier-one manufacturers, delivering luminous efficacy exceeding industry standards while maintaining excellent color rendering properties essential for inspection tasks and safety monitoring. The optical design employs scientific reflector configurations that focus light precisely where needed, minimizing glare and creating comfortable viewing conditions even during extended work shifts. Anti-glare features combined with shock-resistant tempered glass lenses achieving 95% light transmission ensure maximum light output reaches the work area. Power options typically range from 30W for confined spaces to 180W for large-area illumination, with 80W and 100W models serving as versatile mid-range solutions suitable for most industrial applications requiring Explosion Proof Flood Lights with flexible mounting configurations.

Robust Construction and Thermal Management Systems

Superior Explosion Proof Flood Lights feature die-cast ADC12 aluminum housings with patented designs optimizing both structural integrity and heat dissipation characteristics. The housing construction must achieve IP68 ratings, providing complete protection against dust ingress and continuous water immersion, which is critical for outdoor installations and marine environments. Advanced thermal management incorporates 2.0mm aluminum PCBs with heat index ratings of 2.5, efficiently conducting heat away from LED junctions to maintain optimal operating temperatures even in ambient conditions ranging from -30°C to 50°C. Powder-coated surface treatments provide exceptional resistance to salt spray corrosion and chemical exposure while preventing dust accumulation that could compromise heat dissipation or optical performance. The integration of MEANWELL HLG series drivers represents the highest tier of power supply reliability, offering precise current regulation, wide input voltage ranges, and built-in protection features including over-temperature, over-voltage, over-current, and short-circuit safeguards that extend overall system longevity.

Comparative Analysis of Power Options and Applications

| Power Rating | Lumens Output | Typical Coverage Area | Ideal Applications | Mounting Height |

|---|---|---|---|---|

| 30W | 4,200-4,500 lm | 15-25 m² | Confined spaces, small zones, pathway lighting | 3-5 meters |

| 80W | 11,200-12,000 lm | 40-60 m² | Medium production areas, loading docks | 6-10 meters |

| 100W | 14,000-15,000 lm | 60-80 m² | General industrial lighting, warehouses | 8-12 meters |

| 180W | 25,200-27,000 lm | 100-150 m² | Large manufacturing facilities, offshore platforms | 12-18 meters |

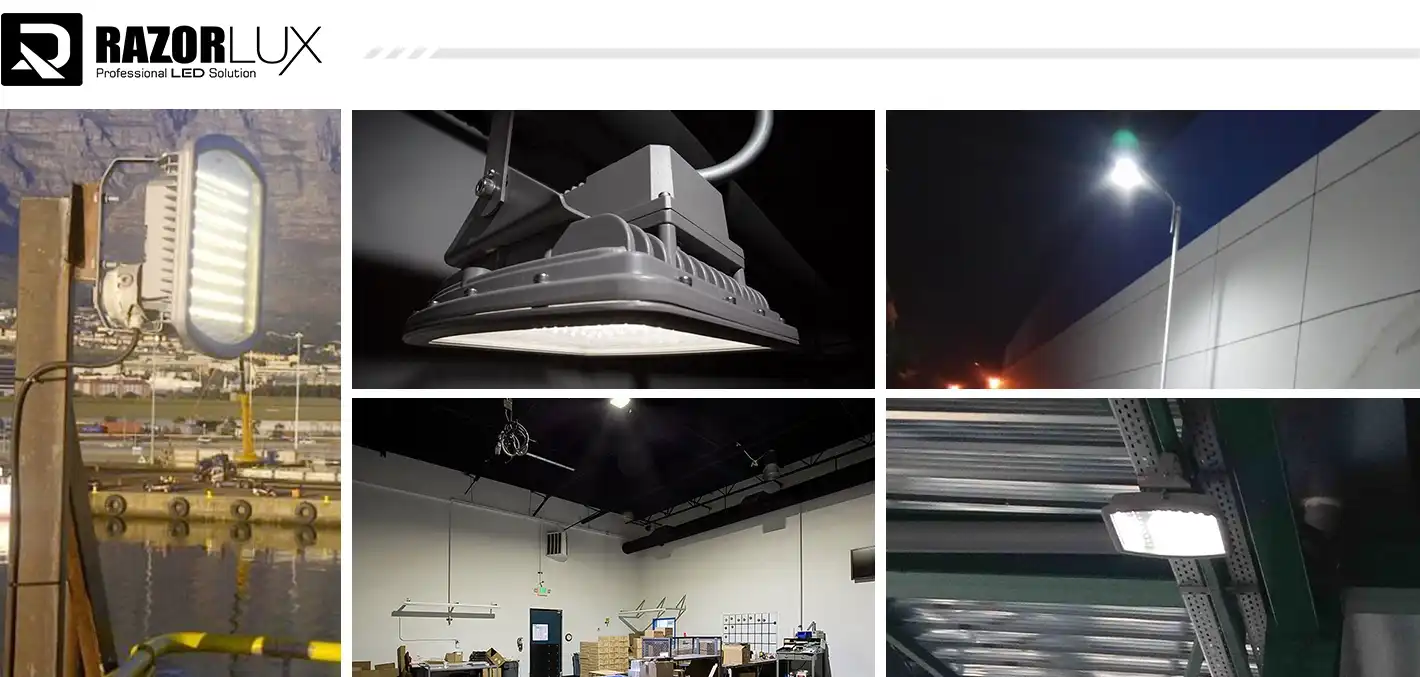

Why Xi'an Razorlux Stands Among Top Explosion Proof Flood Lights Manufacturers?

Two Decades of Innovation in Hazardous Area Lighting

Xi'an Razorlux Optoelectronic Technology Co., Ltd., formerly known as Xi'an Zhihai Power Technology Co., Ltd., has established itself as a premier China Explosion Proof Flood Lights manufacturer since its founding in 1998. With over 200 patents covering LED Packaging technologies, power control systems, and innovative structural designs, Razorlux demonstrates sustained commitment to advancing explosion-proof lighting solutions. The company maintains a mature research and development team with extensive expertise in hazardous area lighting engineering, supported by GMP-certified manufacturing facilities that ensure consistent quality control throughout production processes. As a trusted China Explosion Proof Flood Lights supplier, Razorlux operates subsidiaries in the United States and Hong Kong, with distribution networks spanning Europe, North America, Southeast Asia, and emerging markets worldwide, providing localized support and rapid response to customer requirements regardless of project location or scale.

Comprehensive Product Range Meeting Diverse Industrial Needs

Razorlux's Explosion Proof Flood Lights portfolio addresses the full spectrum of hazardous area illumination requirements across multiple industries. Their fixtures are engineered for oil refineries and gas processing plants where hydrocarbon vapors create Class I Division 1 environments, chemical and petrochemical facilities handling volatile substances, offshore platforms and marine environments requiring corrosion-resistant construction, mining operations and tunneling projects with dust explosion risks, pharmaceutical manufacturing areas maintaining clean room standards, paint spray booths and solvent storage facilities, grain elevators and flour mills with combustible dust hazards, and aircraft hangars requiring both explosion protection and high-quality task lighting. Each application benefits from customizable features including adjustable mounting brackets, various beam angle options from spot to flood configurations, emergency backup power systems providing two hours of operation during power failures, and dimming capabilities compatible with 0-10V and DALI control systems for energy optimization and integration with building management systems.

Quality Assurance and Manufacturing Excellence

As a leading China Explosion Proof Flood Lights factory, Razorlux implements ISO 9001:2015 certified quality management systems ensuring every product meets stringent performance and safety standards. The manufacturing process includes comprehensive assembly line procedures with skilled technicians following documented work instructions, complete photometric testing using integrating spheres to verify luminous output and distribution patterns, extended aging tests subjecting finished Explosion Proof Flood Lights to elevated temperatures and continuous operation cycles that simulate years of field use, and 100% final inspection before packaging. This rigorous approach to quality control, combined with continuous improvement processes and regular internal audits, has earned Razorlux recognition as a reliable China Explosion Proof Flood Lights wholesale supplier capable of handling both small custom orders and large-scale industrial projects. The company maintains substantial inventory levels of popular configurations, enabling rapid fulfillment of urgent requirements while offering flexible customization for specialized applications.

Conclusion

Selecting the right Explosion Proof Flood Lights brand requires careful evaluation of certifications, technical specifications, manufacturing quality, and long-term support capabilities. Xi'an Razorlux Optoelectronic Technology Co., Ltd. exemplifies the characteristics that define trustworthy manufacturers in this critical safety equipment category, combining decades of engineering expertise with comprehensive global certifications and proven field performance across demanding industrial applications worldwide.

Ready to upgrade your hazardous area lighting with certified Explosion Proof Flood Lights? Whether you're seeking competitive China Explosion Proof Flood Lights prices, evaluating China Explosion Proof Flood Lights for sale options, or need custom specifications from an experienced China Explosion Proof Flood Lights manufacturer, Razorlux's professional sales team is ready to assist. With 3-year and 5-year warranty options, emergency power backup capabilities, robust construction using top-tier components like Bridgelux LEDs and MEANWELL drivers, complete marine lighting certifications, large inventory availability, and fast global delivery including express shipping within 3-7 days, Razorlux delivers comprehensive solutions backed by 20+ years of LED lighting expertise. Contact our team today at sam@razorlux.com to discuss your project requirements, request technical documentation, or arrange sample testing—bookmark this resource for future reference as you plan your hazardous area lighting upgrades.

References

1. "Hazardous Area Classification and Control of Ignition Sources" - International Electrotechnical Commission (IEC), Technical Committee 31

2. "Electrical Apparatus for Explosive Gas Atmospheres: General Requirements" - Underwriters Laboratories Standards Department, UL 1203 Standard

3. "Equipment for Use in the Presence of Combustible Dust: General Requirements" - National Fire Protection Association (NFPA), NFPA 499 Guide

4. "Selection and Application of LED Lighting Systems for Hazardous Locations" - Illuminating Engineering Society (IES), Technical Memorandum TM-30

_1750326878398.png)