Explosion Proof Flood Lights for High-Risk Work Environments

Every day, workers in refineries, chemical plants, and offshore platforms face invisible dangers that standard lighting simply cannot address safely. When flammable gases, combustible dust, or volatile vapors fill the air, a single spark from conventional lighting can trigger catastrophic explosions, putting lives and operations at risk. Explosion Proof Flood Lights are engineered specifically to eliminate ignition sources in these hazardous atmospheres, providing brilliant illumination while containing any internal sparks or heat within sealed, robust enclosures that meet stringent international safety standards.

Understanding Explosion Proof Flood Lights Technology and Safety Standards

What Makes Explosion Proof Flood Lights Different from Standard Industrial Lighting?

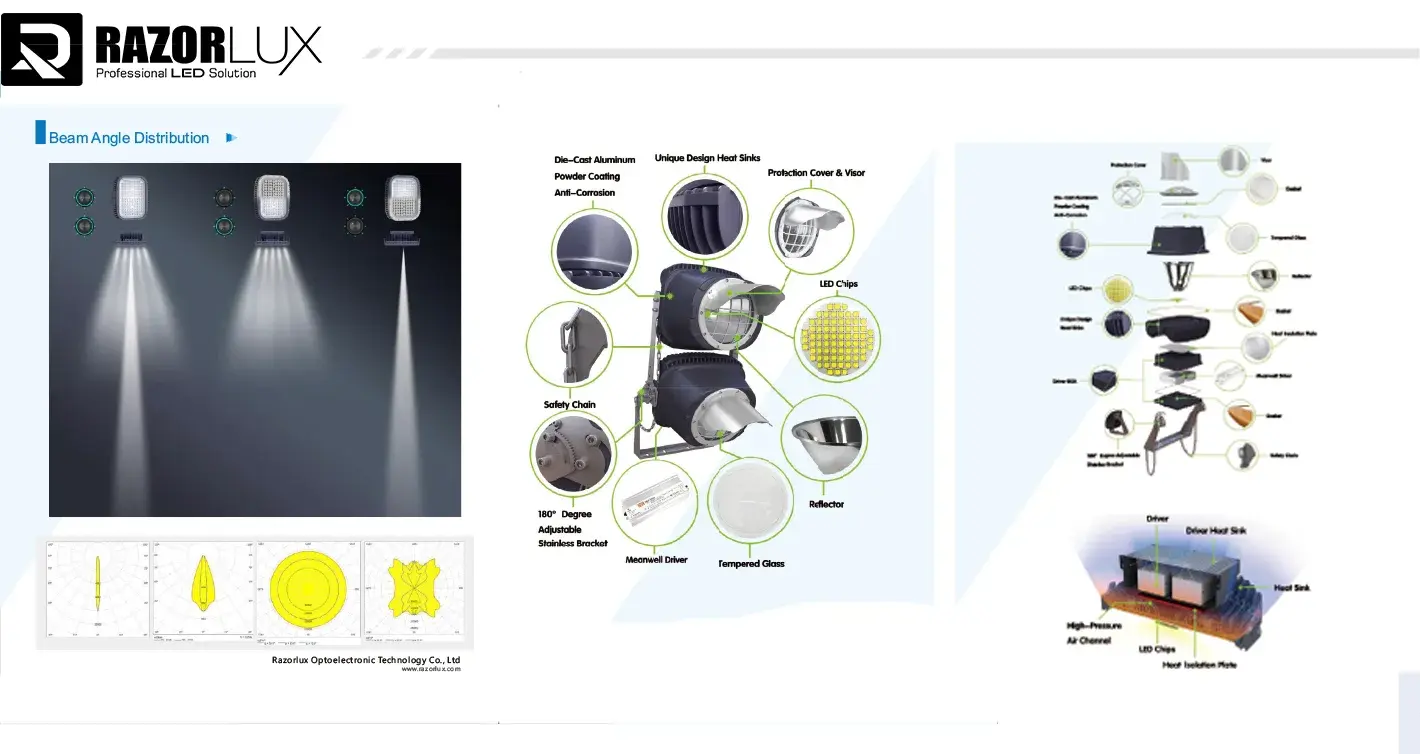

Explosion Proof Flood Lights are fundamentally distinct from conventional industrial lighting in their construction philosophy and operational principles. These specialized luminaires feature hermetically sealed enclosures manufactured from die-cast ADC12 aluminum alloy that can withstand internal explosions without rupturing or allowing flames to escape into the surrounding hazardous atmosphere. The enclosure design incorporates pressure relief pathways and flame-tight joints that cool escaping gases below ignition temperature. Xi'an Razorlux's Explosion Proof Flood Lights utilize patented housing designs with IP68 protection ratings, ensuring complete protection against dust ingress and prolonged water immersion. The tempered glass lens achieves 95% light transmission while resisting shock and vibration, maintaining optical integrity even under severe mechanical stress. Unlike standard lights, every electrical component—from the high-efficacy 700mA LED chips to the MEANWELL HLG series drivers—is contained within explosion-proof barriers that prevent any ignition source from contacting external explosive atmospheres.

Critical Safety Certifications Required for Hazardous Location Lighting Applications

Navigating the complex landscape of safety certifications is essential when selecting Explosion Proof Flood Lights for high-risk environments. International standards bodies have established rigorous testing protocols to ensure luminaires can safely operate in classified hazardous locations. ATEX certification, mandatory for European markets, verifies equipment suitability for explosive atmospheres under directive requirements. IECEx certification provides global recognition through harmonized international standards administered by the International Electrotechnical Commission. North American markets require UL and CUL certifications demonstrating compliance with Class I Division 1 and Division 2 classifications for gas and vapor hazards, as well as Class II classifications for combustible dust environments. Razorlux's Explosion Proof Flood Lights carry comprehensive certifications including ATEX, UL, CUL, DLC, PSE, SAA, C-TICK, CQC, CE, and RoHS, ensuring global regulatory compliance. These certifications validate that the luminaires have undergone exhaustive testing for thermal management, electrical safety, ingress protection, impact resistance, and explosion containment capabilities. The certification process examines every aspect of the lighting fixture, from material selection and gasket integrity to thermal behavior under maximum operating temperatures ranging from negative thirty degrees Celsius to fifty degrees Celsius.

Zone Classification Systems and Appropriate Lighting Selection Criteria

Understanding hazardous area classification systems is fundamental to selecting appropriate Explosion Proof Flood Lights for specific industrial applications. The Zone classification system, prevalent in international markets following IEC standards, divides hazardous locations into Zone 0, Zone 1, and Zone 2 based on the frequency and duration of explosive atmosphere presence. Zone 0 represents areas where explosive atmospheres exist continuously or for extended periods, requiring the highest level of protection. Zone 1 encompasses locations where explosive atmospheres are likely to occur during normal operations, while Zone 2 covers areas where explosive atmospheres are unlikely except under abnormal conditions. Parallel to this system, North American standards employ the Class-Division-Group classification framework. Class I locations contain flammable gases or vapors, Class II addresses combustible dusts, and Class III deals with easily ignitable fibers. Division 1 indicates continuous or frequent hazard presence, while Division 2 suggests occasional or abnormal condition hazards. Group classifications further subdivide based on specific material properties—Group A for acetylene, Group B for hydrogen, Groups C and D for various industrial gases and vapors. Razorlux's Explosion Proof Flood Lights are engineered for Zone 1 and Zone 2 applications, providing versatile solutions across multiple hazardous location requirements with power options spanning 30 watts to 180 watts to accommodate varied illumination needs and installation geometries.

| Classification System | Zone/Class | Hazard Frequency | Razorlux Suitability |

|---|---|---|---|

| IEC Zone System | Zone 1 | Explosive atmosphere likely during normal operations | Fully certified and tested |

| IEC Zone System | Zone 2 | Explosive atmosphere unlikely except abnormal conditions | Optimal for cost-effective safety |

| NEC Class-Division | Class I Division 1 | Continuous or frequent gas/vapor presence | Meets all requirements |

| NEC Class-Division | Class I Division 2 | Occasional gas/vapor under abnormal conditions | Exceeds minimum standards |

Key Technical Features of High-Performance Explosion Proof Flood Lights

Advanced LED Technology and Optical Performance in Hazardous Environments

The heart of modern Explosion Proof Flood Lights lies in their advanced LED technology, which delivers superior performance compared to legacy HID lighting solutions while maintaining critical safety parameters. Razorlux integrates original Bridgelux LED sources renowned for exceptional luminous efficacy and extended operational lifespans exceeding fifty thousand hours. These high-efficacy 700mA LED chips feature low decay characteristics, maintaining consistent lumen output throughout their service life without the dramatic depreciation curves associated with metal halide or high-pressure sodium lamps. The LED packages mount on 2.0-millimeter aluminum printed circuit boards featuring a heat index of 2.5, facilitating optimal thermal transfer from junction to heat sink. Scientific optical reflector design enhances light distribution, creating focused, even illumination patterns that minimize glare and maximize visual comfort for personnel working in challenging conditions. The anti-glare engineering prevents harsh shadows and reduces eye strain during extended work periods, critical for maintaining safety awareness in hazardous environments. Unlike traditional explosion-proof lighting using HID sources operating at temperatures exceeding one thousand degrees Celsius, LED-based Explosion Proof Flood Lights generate significantly less heat while producing equivalent or superior luminous output. This fundamental thermal advantage enhances safety margins, reduces cooling requirements, and extends component longevity in sealed enclosure environments where heat dissipation presents ongoing challenges for maintaining explosion-proof integrity.

Thermal Management Systems and Heat Dissipation Engineering Excellence

Effective thermal management represents the most critical engineering challenge in Explosion Proof Flood Lights design, directly impacting safety, performance, and longevity. LED junction temperature must remain below manufacturer-specified maximums to prevent accelerated lumen depreciation, color shift, and premature failure. Razorlux's patented die-cast ADC12 aluminum housing design optimizes heat dissipation through strategically engineered fin arrays that maximize surface area exposure to ambient air currents. The housing material selection balances thermal conductivity requirements with mechanical strength demands imposed by explosion-proof certification testing protocols. Advanced computational fluid dynamics modeling informs fin geometry, spacing, and orientation to enhance convective heat transfer coefficients under varied installation orientations. The 2.0-millimeter aluminum PCB with 2.5 heat index specification creates a low thermal resistance pathway between LED junctions and the housing heat sink, minimizing temperature gradients that could compromise performance. Powder-coated surface treatment not only provides corrosion resistance but also enhances thermal emissivity, improving radiative heat dissipation particularly important in enclosed or poorly ventilated hazardous locations. The thermal management system maintains LED operating temperatures well within safe parameters across the entire specified ambient temperature range from negative thirty degrees to positive fifty degrees Celsius. This robust thermal engineering ensures Explosion Proof Flood Lights deliver consistent performance whether installed in arctic offshore platforms or tropical petrochemical facilities, maintaining safety margins and reliability under diverse environmental stressors.

Power Management and Driver Technology for Reliable Hazardous Location Operation

Superior power management systems distinguish professional-grade Explosion Proof Flood Lights from inferior alternatives, directly affecting reliability, safety, and operational costs. Razorlux exclusively specifies MEANWELL HLG series drivers, representing the highest performance tier in MEANWELL's extensive product portfolio. These constant-current LED drivers incorporate advanced power factor correction circuitry achieving power factors exceeding 0.95, minimizing reactive power consumption and reducing electrical distribution system loading. Wide input voltage ranges accommodate global electrical standards and tolerate voltage fluctuations common in industrial power distribution networks, maintaining stable LED current regulation despite supply variations. Built-in surge protection guards against transient overvoltages resulting from lightning strikes, inductive load switching, or utility system disturbances—critical protection for equipment installed in exposed outdoor hazardous locations. The HLG series drivers feature aluminum housing construction with convection cooling fins, allowing fanless operation that eliminates mechanical failure modes while maintaining appropriate junction temperatures within explosion-proof enclosures. Dimming compatibility through 0-10V analog control or DALI digital protocols enables intelligent lighting management, allowing facilities to optimize illumination levels based on operational requirements, occupancy patterns, or emergency conditions while reducing energy consumption during periods of reduced activity. The driver's robust construction and comprehensive protection features ensure multi-year reliable operation in demanding industrial environments where maintenance access may be restricted by hazardous area protocols or remote installation locations, reducing total cost of ownership for facility operators.

| Power Option | Luminous Output | Application Suitability | Energy Efficiency |

|---|---|---|---|

| 30W | Suitable for localized task lighting | Small equipment areas, valve stations | Maximum efficiency for minimal lighting needs |

| 80W | Medium area coverage | Walkways, loading zones, small work areas | Optimal balance of output and consumption |

| 100W | Substantial illumination for active work zones | Production areas, maintenance platforms | High output with excellent efficacy |

| 180W | Maximum area coverage capability | Large tank farms, expansive facilities | Replaces 400W HID with 60% energy reduction |

Industrial Applications and Installation Best Practices for Explosion Proof Lighting

Oil and Gas Sector Requirements and Deployment Strategies

The oil and gas industry represents the primary application sector for Explosion Proof Flood Lights due to the pervasive presence of flammable hydrocarbons throughout exploration, production, refining, and distribution operations. Offshore platforms operate in particularly challenging environments where explosive gas atmospheres combine with corrosive saltwater spray, high winds, and extreme weather conditions demanding the most robust explosion-proof lighting solutions. Razorlux's marine-grade anti-corrosion coating specifically addresses these severe environmental challenges, protecting aluminum housings and hardware from accelerated deterioration that compromises explosion-proof integrity. Refineries present diverse hazardous zones requiring varied Explosion Proof Flood Lights configurations—process units contain continuous Class I Division 1 areas near distillation columns and cracking units, while loading racks and tank farms typically classify as Division 2 locations. Strategic lighting placement must accommodate operational workflows, providing adequate illumination for routine operations, maintenance activities, and emergency response scenarios without creating glare or dark zones that compromise safety situational awareness. Drilling operations, whether onshore or offshore, demand portable and permanently installed Explosion Proof Flood Lights capable of illuminating rig floors, derricks, and auxiliary equipment during round-the-clock operations. Pipeline infrastructure, including pumping stations and valve stations distributed across remote terrain, requires reliable lighting solutions with emergency battery backup capabilities ensuring continued illumination during power interruptions. Installation considerations must address hazardous area classification boundaries, electrical distribution constraints, mounting structure availability, and maintenance accessibility while maintaining compliance with increasingly stringent environmental lighting regulations limiting light pollution and protecting nocturnal wildlife habitats.

Chemical Processing Facilities and Pharmaceutical Manufacturing Safety Lighting

Chemical processing and pharmaceutical manufacturing facilities handle diverse hazardous materials creating complex explosion-proof lighting requirements spanning multiple classification zones. Chemical plants processing volatile organic compounds, reactive intermediates, and flammable solvents require comprehensive Explosion Proof Flood Lights coverage in reactor buildings, distillation areas, storage facilities, and loading zones. The lighting system must accommodate varied ceiling heights, equipment congestion, and architectural constraints while providing uniform illumination supporting quality control, process monitoring, and safety inspections. Pharmaceutical manufacturing cleanroom environments present unique challenges where explosion-proof lighting must satisfy both hazardous location requirements and stringent contamination control protocols. Razorlux's sealed IP68 construction prevents particle generation or harboring, supporting compliance with Good Manufacturing Practice regulations while providing explosion protection in areas handling flammable solvents used for extraction, crystallization, and formulation processes. Paint and coating operations, whether standalone facilities or integrated manufacturing lines, create volatile organic compound atmospheres requiring Class I Division 1 Explosion Proof Flood Lights in spray booths, mixing rooms, and drying ovens. The lighting system must tolerate overspray buildup while maintaining explosion-proof integrity and providing color-rendering capabilities supporting quality verification of finished surfaces. Installation planning must coordinate with ventilation system design, ensuring adequate illumination without creating airflow disruptions that compromise vapor removal effectiveness. Maintenance protocols must establish regular inspection schedules verifying gasket integrity, lens cleanliness, and mounting security, with all maintenance activities following proper hot work permit procedures when performed in classified hazardous locations to prevent inadvertent ignition sources during lamp replacement or fixture servicing operations.

Mining Operations and Grain Handling Facility Lighting Solutions

Mining and agricultural processing facilities face Class II combustible dust hazards requiring specialized Explosion Proof Flood Lights engineered for dust-ignition-proof performance. Underground mining operations present particularly severe challenges combining combustible coal dust or metal dust atmospheres with corrosive moisture, mechanical vibration from equipment operation, and confined spaces limiting heat dissipation. Surface mining facilities, including crushing plants, conveyor systems, and stockpile areas, generate substantial dust concentrations requiring comprehensive lighting coverage for safe twenty-four-hour operations. Razorlux's shock and vibration-resistant construction withstands the severe mechanical stresses inherent in mining environments, maintaining explosion-proof integrity despite constant vibration from heavy machinery and occasional impact from falling material. Grain elevators and flour mills contain combustible organic dust creating Class II Division 1 and Division 2 hazardous locations throughout storage bins, conveying systems, and milling equipment. Historical catastrophic dust explosions in grain handling facilities emphasize the critical importance of properly certified Explosion Proof Flood Lights eliminating ignition sources. The lighting system must provide adequate illumination for inspection activities, supporting early detection of hot spots, bearing failures, or material accumulations that could trigger dust fires or explosions. Agricultural processing facilities handling powdered materials face similar combustible dust challenges requiring comprehensive explosion-proof lighting strategies. Installation considerations must address dust accumulation on fixture surfaces, ensuring adequate cooling despite insulating dust layers while maintaining appropriate illumination levels as lens surfaces become obscured. Regular cleaning protocols maintain optical performance and thermal management effectiveness, with cleaning intervals determined by dust generation rates and deposition characteristics specific to each facility's operations and materials handling systems.

Conclusion

Explosion Proof Flood Lights represent essential safety infrastructure for high-risk industrial environments where lighting failure or ignition could trigger catastrophic consequences. Xi'an Razorlux Optoelectronic Technology Co., Ltd. delivers comprehensive solutions combining advanced LED technology, rigorous safety certifications, and robust construction engineered specifically for the most demanding hazardous location applications globally.

Ready to enhance safety and operational efficiency in your hazardous work environment? As a leading China Explosion Proof Flood Lights manufacturer, China Explosion Proof Flood Lights supplier, and China Explosion Proof Flood Lights factory, Xi'an Razorlux offers competitive Explosion Proof Flood Lights wholesale pricing and flexible Explosion Proof Flood Lights for sale options. Contact our technical team today for customized lighting solutions, detailed product specifications, and Explosion Proof Flood Lights price quotations tailored to your specific project requirements. Our experts provide comprehensive pre-sales consultation, custom sampling, technical documentation, and responsive after-sales support backed by 3-year or 5-year warranty coverage. With over 200 patents, mature R&D capabilities, GMP-certified manufacturing, complete international certifications, and fast global delivery via air, rail, and sea freight, Razorlux stands ready to illuminate your hazardous locations safely and efficiently. Reach out to sam@razorlux.com for immediate assistance—bookmark this resource for future reference as you plan your next explosion-proof lighting upgrade or expansion project.

References

1. National Fire Protection Association (NFPA). "NFPA 70: National Electrical Code - Hazardous Locations Classification and Protection Methods." NFPA Standards Council, 2023 Edition.

2. International Electrotechnical Commission (IEC). "IEC 60079 Series: Explosive Atmospheres - Equipment Requirements and Testing Protocols for Hazardous Area Applications." IEC Technical Committee 31, 2022.

3. Underwriters Laboratories (UL). "UL 844 Standard for Safety: Electric Lighting Fixtures for Use in Hazardous Locations - Testing and Certification Requirements." UL LLC Safety Standards Division, 2024.

4. Health and Safety Executive (HSE). "Dangerous Substances and Explosive Atmospheres Regulations - ATEX Equipment Selection and Installation Guidance for Industrial Facilities." HSE Books Publication Series, 2023.

_1750326878398.png)