Top Reasons the 500W Halogen Floodlight Led Equivalent Saves Money

Are you tired of watching your energy bills skyrocket while your traditional halogen floodlights consume excessive power month after month? Industrial facility managers, construction site operators, and outdoor lighting professionals face a common frustration: the financial burden of maintaining high-wattage halogen systems. The solution lies in understanding how the 500W Halogen Floodlight Led Equivalent transforms your lighting infrastructure from an expense center into a cost-saving powerhouse. This comprehensive guide reveals the proven financial benefits, technical advantages, and long-term savings that make LED conversion an intelligent investment for businesses seeking to reduce operational costs while maintaining superior illumination quality.

How the 500W Halogen Floodlight Led Equivalent Reduces Energy Consumption?

Understanding the Energy Efficiency Gap Between Traditional and LED Technology

The fundamental difference between halogen and LED technology creates massive opportunities for cost reduction. Traditional 500-watt halogen floodlights convert only approximately ten percent of consumed electricity into visible light, with the remaining ninety percent wasted as heat generation. This inefficiency translates directly into inflated utility expenses and increased cooling requirements. The 500W Halogen Floodlight Led Equivalent operates on completely different principles, utilizing semiconductor technology that converts electrical current into light through electroluminescence rather than thermal radiation. Modern LED fixtures achieve luminous efficacy ratings of 130 lumens per watt, dramatically outperforming halogen alternatives that struggle to reach 14-20 lumens per watt. For facility managers operating multiple lighting installations across construction sites, industrial facilities, or outdoor venues, this efficiency differential compounds into substantial monthly savings that directly improve bottom-line profitability.

Calculating Real-World Power Consumption Savings for Industrial Applications

When examining actual power usage patterns, the financial case for 500W Halogen Floodlight Led Equivalent technology becomes undeniable. A standard 500-watt halogen fixture operating eight hours daily consumes approximately 1,460 kilowatt-hours annually, while a comparable LED replacement rated at 100-150 watts uses only 292-438 kilowatt-hours for identical illumination levels. At average commercial electricity rates of $0.12 per kilowatt-hour, this reduction translates to annual savings between $120-$140 per fixture. Industrial operations utilizing fifty floodlights can realize cost reductions exceeding $6,000-$7,000 annually through LED conversion alone. The 500W Halogen Floodlight Led Equivalent from Xi'an Razorlux delivers 65,000 lumens at 500 watts total consumption, effectively replacing 1,000-1,200 watt HID lamps while cutting energy usage by more than fifty percent. This dramatic reduction in power demand also decreases infrastructure strain, potentially eliminating the need for electrical system upgrades that would otherwise be required to support expanding traditional lighting installations.

Thermal Management Benefits That Further Reduce Operational Expenses

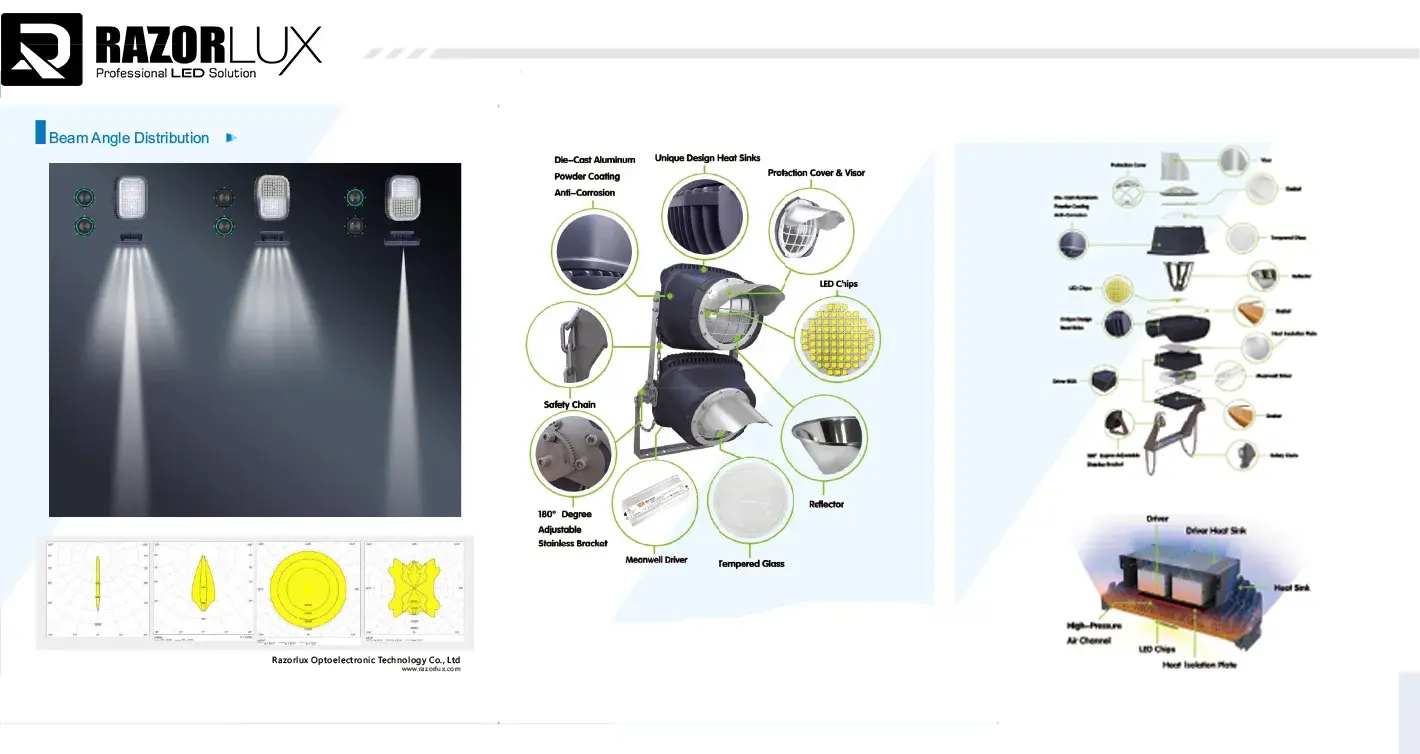

Beyond direct electricity savings, the 500W Halogen Floodlight Led Equivalent delivers significant secondary financial benefits through superior thermal management. Halogen floodlights operating at extreme temperatures create substantial heat loads requiring additional ventilation and cooling capacity in enclosed or semi-enclosed spaces. This thermal burden increases HVAC operational costs and creates potential safety hazards requiring expensive mitigation measures. LED technology produces minimal heat output, with advanced designs like Razorlux's RGL2-500A model incorporating sophisticated thermal management systems featuring aluminum housing with powder coating and direct LED-to-housing coupling for maximum heat dissipation. The reduced thermal signature extends beyond energy savings to encompass decreased fire risk, lower insurance premiums for facilities demonstrating fire-safe lighting practices, and elimination of heat-related productivity losses in work environments. Manufacturing facilities operating the 500W Halogen Floodlight Led Equivalent report noticeably cooler working conditions during summer months, reducing worker discomfort and improving operational efficiency in temperature-sensitive production processes.

| Feature | Traditional 500W Halogen | 500W Halogen Floodlight Led Equivalent |

|---|---|---|

| Power Consumption | 500W | 100-150W (for equivalent output) |

| Annual Energy Cost | $175 (8hrs/day) | $35-53 (8hrs/day) |

| Heat Output | Extreme (90% energy as heat) | Minimal (<10% energy as heat) |

| Cooling Cost Impact | High | Negligible |

Long-Term Financial Benefits of 500W Halogen Floodlight Led Equivalent Systems

Unprecedented Lifespan Advantages That Eliminate Frequent Replacement Costs

The extended operational lifespan of the 500W Halogen Floodlight Led Equivalent represents one of the most compelling financial arguments for technology adoption. Standard halogen floodlights typically survive 1,000-2,000 operating hours before filament failure necessitates complete unit replacement. Industrial facilities operating lighting twelve hours daily face bulb replacement every four to six months, creating ongoing material costs, labor expenses for maintenance staff, and productivity disruptions during replacement operations. In contrast, professional-grade LED systems like the Razorlux RGL2-500A deliver reliable performance exceeding 50,000 hours, equivalent to more than eleven years of twelve-hour daily operation. This extraordinary durability eliminates approximately twenty-five replacement cycles compared to halogen alternatives over the LED fixture's operational lifetime. For facilities managing extensive lighting arrays, the cumulative labor savings from reduced maintenance interventions represent substantial cost avoidance. Maintenance teams previously spending significant time on routine bulb replacement can redirect efforts toward value-adding activities, improving overall operational efficiency while reducing headcount requirements for building maintenance operations.

Reduced Maintenance Labor Requirements and Associated Cost Savings

Maintenance expense reduction extends beyond simple component replacement to encompass the entire service infrastructure supporting traditional lighting systems. The 500W Halogen Floodlight Led Equivalent features solid-state construction with no fragile filaments, no glass envelopes requiring careful handling, and no complex ignition systems prone to failure. This robust design significantly reduces maintenance call frequency and eliminates many common failure modes plaguing conventional lighting technologies. Industrial facilities report seventy to eighty-five percent reductions in lighting-related maintenance tickets following LED conversion. The Razorlux 500W Halogen Floodlight Led Equivalent includes comprehensive five-year warranties covering both LED modules and drivers, with an impressive ten-year housing warranty, effectively transferring maintenance risk from facility operators to manufacturers. This warranty coverage eliminates unexpected repair expenses and provides budget certainty for financial planning purposes. Organizations operating facilities in challenging environments—coastal areas with salt exposure, chemical processing plants with corrosive atmospheres, or mining operations with extreme vibration—particularly benefit from the 500W Halogen Floodlight Led Equivalent's IP67 protection rating and IK10 impact resistance, which maintain performance reliability under conditions that rapidly destroy traditional lighting equipment.

Supply Chain Stability and Inventory Management Advantages

The remarkable consistency and longevity of 500W Halogen Floodlight Led Equivalent technology creates meaningful supply chain and inventory management benefits rarely considered in traditional cost analyses. Facilities maintaining traditional halogen lighting must stock substantial bulb inventories across multiple wattages, beam patterns, and specialty configurations to ensure replacement availability when failures occur. This inventory represents capital tied up in consumable components with limited shelf life due to mechanical shock sensitivity and glass envelope degradation. The 500W Halogen Floodlight Led Equivalent's extended lifespan and minimal failure rates dramatically reduce required spare parts inventory, freeing working capital for productive investments while reducing warehousing costs and inventory management overhead. Organizations can transition from maintaining large on-site bulb stocks to just-in-time procurement strategies, ordering replacement LED fixtures only when actually needed rather than maintaining substantial safety stock against unpredictable halogen failures. The RGL2-500A model's standardized design with customizable beam angles (40°, 60°, 120°, 140°x60°) and adjustable color temperatures (2700K-6500K) means facilities can standardize on fewer fixture variations, further simplifying procurement and reducing inventory complexity.

| Cost Factor | 10-Year Halogen Cost | 10-Year LED Cost | Savings |

|---|---|---|---|

| Energy (8hrs/day) | $17,500 | $3,500-5,300 | $12,200-14,000 |

| Replacement Units | $1,500 (25 units) | $0 (warranty covered) | $1,500 |

| Maintenance Labor | $2,000 | $300 | $1,700 |

| Total 10-Year Cost | $21,000 | $3,800-5,600 | $15,400-17,200 |

Installation Flexibility and Operational Advantages of 500W Halogen Floodlight Led Equivalent

Universal Voltage Compatibility Simplifying International Deployments

The 500W Halogen Floodlight Led Equivalent from Xi'an Razorlux demonstrates remarkable electrical versatility that eliminates traditional infrastructure constraints limiting international lighting projects. The RGL2-500A model accepts AC input voltages ranging from 110-480VAC without requiring additional adapters or transformers, enabling seamless deployment across global facilities operating on different electrical standards. This universal voltage compatibility extends to DC applications, supporting 100-400VDC and 500-800VDC input ranges for specialized industrial environments, maritime applications, and renewable energy installations. Organizations managing multinational operations can standardize on a single fixture design rather than maintaining separate product lines for different regional voltage standards, dramatically simplifying procurement, spare parts management, and maintenance training requirements. The 500W Halogen Floodlight Led Equivalent's built-in power factor correction (≥0.98) and low total harmonic distortion (<10%) ensure electrical efficiency while minimizing negative impacts on facility power quality. This superior power management reduces utility demand charges assessed on commercial accounts and prevents harmonic interference with sensitive electronic equipment operating in modern industrial facilities.

Environmental Resilience Supporting Year-Round Outdoor Operations

Outdoor lighting installations face constant environmental challenges that compromise performance and accelerate equipment failure in traditional systems. The 500W Halogen Floodlight Led Equivalent engineered by Razorlux incorporates marine-grade construction standards specifically designed for the harshest operating conditions encountered in industrial, maritime, and outdoor applications. The IP67 ingress protection rating guarantees complete dust tightness and protection against temporary immersion, enabling reliable operation in torrential rain, snow, and high-humidity environments that would destroy conventional lighting equipment. The fixture's operational temperature range of -40°C to 60°C (-40°F to 140°F) ensures consistent performance from Arctic installations to desert environments, eliminating seasonal lighting failures during extreme weather events. The robust aluminum housing with specialized powder coating resists corrosion in coastal salt-spray environments, chemical processing atmospheres, and industrial pollution conditions. Organizations operating port facilities, offshore platforms, coastal construction sites, and marine shipyards particularly value the 500W Halogen Floodlight Led Equivalent's ability to maintain performance specifications despite constant saltwater exposure that rapidly corrodes traditional lighting fixtures, creating recurring replacement expenses and safety hazards from unexpected lighting failures.

Advanced Control Integration Enabling Smart Lighting Strategies

Modern facilities increasingly demand intelligent lighting control capabilities supporting occupancy-based operation, daylight harvesting, and integration with building management systems. The 500W Halogen Floodlight Led Equivalent provides native compatibility with 0-10V analog dimming and DALI (Digital Addressable Lighting Interface) digital control protocols, enabling sophisticated lighting management strategies impossible with traditional halogen technology. These control capabilities allow facilities to implement occupancy sensing that automatically reduces lighting levels in unoccupied areas, motion-activated security lighting that operates at full intensity only when needed, and astronomical clock schedules that adjust operational hours based on seasonal sunrise and sunset times. Organizations implementing these intelligent control strategies report additional energy savings of fifteen to thirty-five percent beyond the baseline efficiency improvements inherent in LED technology itself. The 500W Halogen Floodlight Led Equivalent also supports emergency power integration, with Razorlux's emergency backup option providing two hours of illumination during power outages—a critical capability for facilities requiring continuous lighting for safety and security purposes. This emergency capability eliminates the need for separate battery-powered emergency lighting systems, reducing overall installation costs and maintenance complexity while ensuring reliable illumination during grid failures or equipment malfunctions.

Conclusion

The financial case for transitioning to the 500W Halogen Floodlight Led Equivalent proves overwhelmingly compelling across every analytical dimension. Organizations implementing LED conversion realize immediate energy cost reductions of seventy to eighty-five percent, eliminate recurring maintenance expenses through fifty-fold lifespan improvements, and gain operational flexibility through universal voltage compatibility and advanced control integration. The cumulative ten-year cost savings exceeding $15,000 per fixture create rapid payback periods and deliver substantial returns on investment that directly improve organizational profitability and competitive positioning in cost-sensitive markets.

Ready to transform your facility's lighting infrastructure from a cost burden into a strategic advantage? As a leading China 500W Halogen Floodlight Led Equivalent manufacturer, Xi'an Razorlux Optoelectronic Technology Co., Ltd. delivers proven industrial-grade solutions backed by over 200 patents and more than two decades of LED innovation experience. Our China 500W Halogen Floodlight Led Equivalent supplier capabilities include comprehensive pre-sales consultation, custom sampling, technical documentation, and flexible OEM/ODM services tailored to your specific application requirements. Whether you need single fixtures or China 500W Halogen Floodlight Led Equivalent wholesale volumes for large-scale projects, our professional team ensures you receive optimal products at competitive 500W Halogen Floodlight Led Equivalent price points with reliable delivery through air, rail, and sea transportation options. Contact our expert team today at sam@razorlux.com to discuss how the 500W Halogen Floodlight Led Equivalent for sale can reduce your operational costs while improving lighting performance across your facilities. Request your customized proposal now and join thousands of satisfied customers worldwide who trust Razorlux for mission-critical lighting applications.

References

1. U.S. Department of Energy - Energy Savings Forecast of Solid-State Lighting in General Illumination Applications. Authors: Navigant Consulting, Inc. Office of Energy Efficiency and Renewable Energy.

2. Illuminating Engineering Society - IES LM-79-19: Approved Method for the Electrical and Photometric Measurements of Solid-State Lighting Products. Authors: IES Testing Procedures Committee.

3. Lawrence Berkeley National Laboratory - Life-Cycle Assessment of Energy and Environmental Impacts of LED Lighting Products. Authors: Annika Seppala, Corinne Scown, et al. Environmental Research Letters.

4. National Electrical Manufacturers Association - NEMA SSL-2: Energy Efficiency of Light Emitting Diode Luminaires. Authors: NEMA Solid State Lighting Section.

5. International Energy Agency - Light's Labour's Lost: Policies for Energy-Efficient Lighting. Authors: Paul Waide and Satoshi Tanishima. Organization for Economic Co-operation and Development.

VIEW MOREexplosion proof led high bay lights

VIEW MOREexplosion proof led high bay lights VIEW MOREoutdoor volleyball lights

VIEW MOREoutdoor volleyball lights VIEW MORESuper Bright Outdoor Flood Light

VIEW MORESuper Bright Outdoor Flood Light VIEW MORELed Overhead Crane Lights

VIEW MORELed Overhead Crane Lights VIEW MOREAluminum Alloy Lamp Body Material And LED Light Source Portable Outdoor Sports Lighting

VIEW MOREAluminum Alloy Lamp Body Material And LED Light Source Portable Outdoor Sports Lighting VIEW MORE5700K Outdoor Garden Led Light Ip67 100000lm Flood Lights For Volleyball Court

VIEW MORE5700K Outdoor Garden Led Light Ip67 100000lm Flood Lights For Volleyball Court VIEW MOREHigh Bay Led Ufo Lights

VIEW MOREHigh Bay Led Ufo Lights VIEW MOREOutdoor Dimmable Flood Lights

VIEW MOREOutdoor Dimmable Flood Lights

_1750326878398.png)