7 Tips for Installing Baseball Field Lights Efficiently and Safely

Installing Baseball Field Lights can feel overwhelming when you're facing tight deadlines, safety compliance requirements, and budget constraints. Whether you're managing a municipal park upgrade, running a high school athletics program, or overseeing a professional stadium renovation, poor lighting installation can lead to costly delays, safety hazards, and inadequate illumination that affects game quality. This comprehensive guide provides seven proven tips for installing Baseball Field Lights efficiently and safely, helping you avoid common pitfalls while ensuring optimal performance for players, spectators, and broadcast requirements.

Pre-Installation Planning for Baseball Field Lights

Proper planning forms the foundation of any successful Baseball Field Lights installation project. Without thorough preparation, you risk encountering unexpected obstacles that can derail your timeline and inflate costs significantly.

Conducting Comprehensive Site Assessment

Before breaking ground, conduct a detailed site assessment of your baseball facility. This evaluation should examine existing electrical infrastructure, soil conditions for pole foundations, proximity to power sources, and potential obstacles like underground utilities or overhead power lines. Document field dimensions precisely, measuring from home plate to the outfield fence, as this determines whether you need a four-pole, six-pole, or eight-pole layout. Fields measuring two hundred to two hundred fifty feet typically require four poles, while three hundred foot fields need six poles, and four hundred foot fields or broadcast-ready facilities require eight poles for optimal coverage. Professional Baseball Field Lights installations demand accurate measurements to ensure uniform illumination across the entire playing surface, preventing dark spots that compromise player safety and game quality.

Understanding Lighting Standards and Compliance Requirements

Different levels of play require specific illumination standards that directly impact your Baseball Field Lights selection and configuration. Professional baseball stadiums typically need minimum illuminance levels of one hundred fifty foot-candles for infields and one hundred foot-candles for outfields, while high school facilities require fifty foot-candles for infields and thirty foot-candles for outfields. Recreational and youth league fields can operate with thirty foot-candles infield and twenty foot-candles outfield illumination. Beyond brightness levels, uniformity ratios must be maintained, typically two-to-one or better for infields and two-point-five-to-one for outfields, ensuring consistent lighting without harsh transitions or shadowy areas. Your Baseball Field Lights must also comply with local ordinances regarding light trespass, sky glow restrictions, and curfew times to avoid conflicts with neighboring properties and environmental regulations.

Developing Detailed Installation Timeline and Budget

Create a realistic project schedule that accounts for all phases including permit acquisition, equipment procurement, site preparation, electrical work, pole installation, fixture mounting, and system testing. Weather contingencies should be built into your timeline, particularly for outdoor concrete work and electrical connections that cannot proceed during precipitation. Budget comprehensively for all components including LED fixtures, poles, mounting hardware, electrical infrastructure upgrades, labor costs, engineering fees, permits, and a contingency reserve of ten to fifteen percent for unexpected issues. Quality Baseball Field Lights represent a significant investment, but choosing energy-efficient LED technology delivers long-term operational savings through reduced electricity consumption and minimal maintenance requirements over the fixture's fifty-thousand-hour-plus lifespan.

Selecting the Right Baseball Field Lights Equipment

Equipment selection directly impacts installation efficiency, long-term performance, and total cost of ownership. Making informed choices about fixtures, poles, and control systems sets your project up for success.

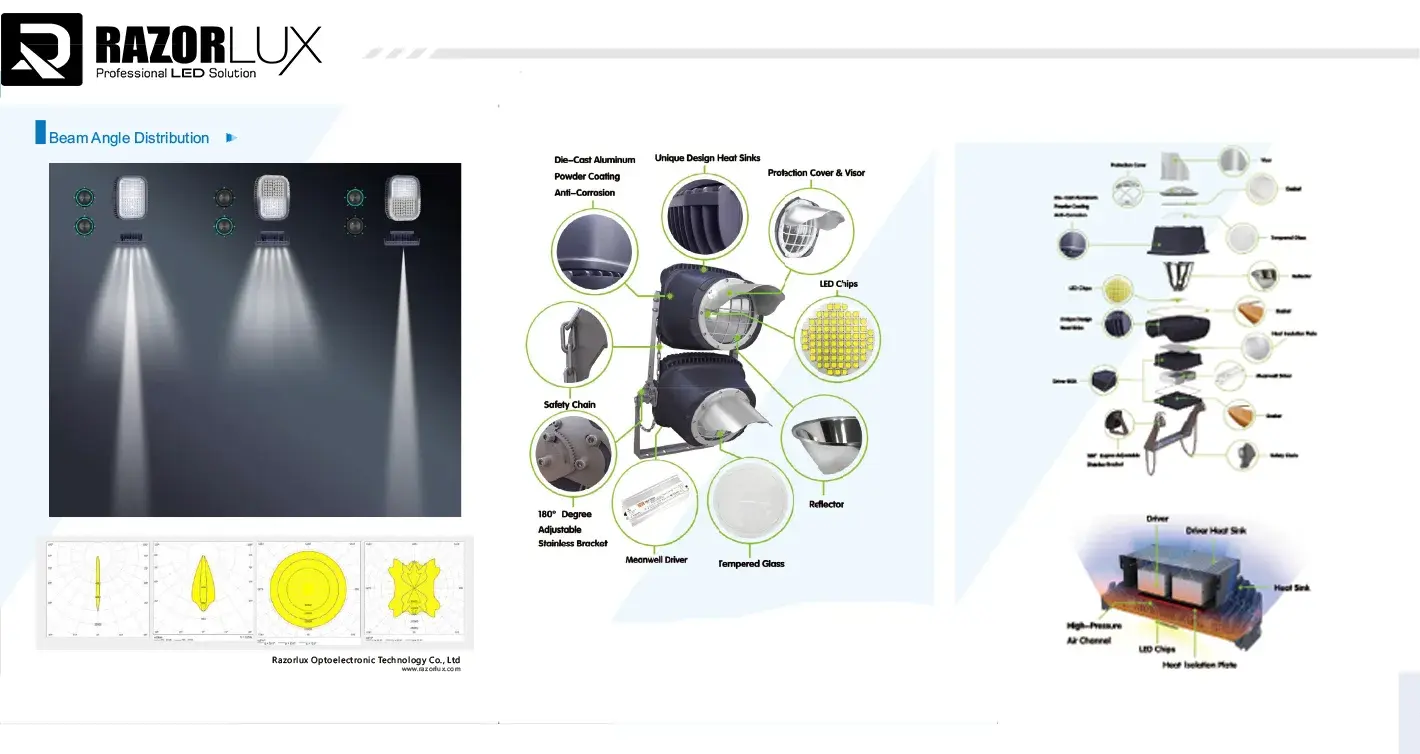

Choosing High-Performance LED Fixtures

Modern Baseball Field Lights utilize LED technology that delivers superior performance compared to traditional metal halide systems. When selecting fixtures, prioritize models offering high lumen output, appropriate beam angles for your pole layout, excellent color rendering index above seventy-five for accurate ball tracking, and robust construction rated IP65 or IP67 for weather resistance. The Razorlux RGL-120P model exemplifies professional-grade Baseball Field Lights with one hundred twenty watts power consumption delivering thirteen thousand two hundred lumens, replacin two hundred fifty to three hundred watt metal halide lamps while drastically reducing energy costs. This fixture features twenty-degree beam angle for precise light distribution, color temperature range from two thousand to six thousand Kelvin allowing customization for optimal visibility, and aluminum housing with powder coating ensuring durability in demanding outdoor environments. Advanced thermal management systems extend LED lifespan beyond fifty thousand hours, while Meanwell power supplies provide reliable performance with power factor exceeding zero-point-ninety-eight and total harmonic distortion below ten percent.

| Specification | Value | Benefit |

|---|---|---|

| Power Consumption | 120W | Reduces energy costs by 50-60% vs traditional HID |

| Lumen Output | 13,200 lm | Provides bright, uniform illumination |

| Beam Angle | 20° | Enables precise light control and targeting |

| Color Temperature | 2000-6000K | Customizable for optimal visibility conditions |

| IP Rating | IP67 | Withstands harsh weather and outdoor conditions |

| Lifespan | ≥50,000 hours | Minimizes maintenance and replacement costs |

| Warranty | 5 years (LED & Driver) | Ensures long-term reliability and protection |

Determining Optimal Pole Configuration and Height

Pole placement strategy significantly influences lighting uniformity and glare control for Baseball Field Lights installations. Strategic positioning behind home plate angling toward the outfield, along baselines extending into the outfield, and around the outfield perimeter facing inward creates overlapping light patterns that eliminate shadows and provide consistent illumination. Pole heights must be sufficient to illuminate the entire field without creating distracting glare that impairs player visibility, typically ranging from sixty to eighty feet for high school fields and eighty to one hundred fifty feet for professional stadiums. Avoid placing poles within glare zones where fixtures shine directly at pitchers, batters, or fielders tracking fly balls. The eight-pole layout represents the gold standard for professional Baseball Field Lights systems, providing coverage from multiple angles that ensures the ball remains visible regardless of its trajectory, while also meeting requirements for high-definition broadcast with minimal fixture visibility in camera frames.

Implementing Smart Control Systems

Modern Baseball Field Lights benefit from intelligent control systems that enhance operational flexibility and energy efficiency. Zero-to-ten-volt and DALI dimming capabilities allow you to adjust illumination levels for different activities, providing full brightness for competitive games while dimming to fifty or seventy-five percent for practices or community events, generating substantial energy savings. Programmable timers automate lighting schedules, ensuring lights activate before sunset games and deactivate at designated times to comply with local curfew ordinances. Wireless control options enable facility managers to operate lighting remotely via smartphone applications, providing convenient on-off control and emergency override capabilities. Some advanced Baseball Field Lights systems incorporate emergency backup power that maintains operation for two hours during power outages, ensuring player safety and allowing games to continue during temporary electrical disruptions, a feature that proves invaluable for tournament schedules and televised events.

Safety Protocols and Installation Best Practices

Safety must remain the top priority throughout every phase of your Baseball Field Lights installation. Proper protocols protect workers, ensure code compliance, and prevent costly accidents or injuries.

Implementing Comprehensive Safety Procedures

Before commencing installation work, develop detailed safety protocols covering all aspects of the project. Conduct mandatory safety briefings for all personnel, ensuring everyone understands their responsibilities, potential hazards, and emergency procedures. Require appropriate personal protective equipment including hard hats, safety glasses, high-visibility vests, steel-toed boots, and fall protection harnesses for workers operating at heights during Baseball Field Lights fixture mounting. Establish clear work zones with barrier fencing and warning signage to prevent unauthorized access during construction activities. Implement lockout-tagout procedures for all electrical work, verifying power sources are de-energized and properly tagged before technicians begin wiring tasks. Weather monitoring becomes critical for outdoor installations, with work suspended during lightning storms, high winds above twenty-five miles per hour that create unsafe conditions for crane operations, or precipitation that compromises electrical safety. Maintain first aid kits, fire extinguishers, and emergency contact information readily accessible throughout the work site.

| Safety Equipment | Application | Standard |

|---|---|---|

| Hard Hats | Protects from falling objects during pole erection | ANSI Z89.1 |

| Fall Protection | Required for work above 6 feet during fixture installation | OSHA 1926.501 |

| Insulated Tools | Prevents electrical shock during wiring work | ASTM F1505 |

| Arc Flash PPE | Protects during energized electrical work | NFPA 70E |

| Traffic Control | Manages vehicle and pedestrian access to work zones | MUTCD Standards |

Ensuring Proper Electrical Installation

Electrical work for Baseball Field Lights demands strict adherence to National Electrical Code requirements and local jurisdiction amendments. Engage licensed electricians with experience in sports lighting installations, as they understand the unique demands of high-wattage outdoor systems operating in variable weather conditions. Size conductors appropriately for the total connected load plus twenty-five percent capacity for future expansion, preventing voltage drop that reduces fixture performance and potentially damages sensitive LED drivers. Install ground-fault circuit interrupter protection where required by code, typically for receptacles and circuits in damp or wet locations. Weatherproof all junction boxes, conduit connections, and fixture wiring terminations using appropriate sealing methods rated for outdoor exposure to moisture, temperature extremes, and ultraviolet radiation. Implement proper grounding and bonding throughout the system, connecting all metallic poles, fixtures, and electrical enclosures to the facility's grounding electrode system, creating a safe path for fault current and protecting against lightning-induced surges that could damage Baseball Field Lights equipment or create shock hazards.

Coordinating Professional Installation Teams

Successful Baseball Field Lights installation requires coordination among multiple specialty contractors including electrical contractors, pole installation crews, concrete foundation specialists, and lighting engineers. Establish clear communication protocols with regular progress meetings to address issues promptly and maintain schedule adherence. Define scope boundaries between trades to prevent gaps in responsibility or duplicated efforts that waste resources. Schedule work sequences logically, allowing adequate curing time for concrete foundations before pole erection, completing all pole installation before beginning electrical rough-in, and conducting fixture aiming only after all fixtures are securely mounted and connected. Professional project management ensures Baseball Field Lights installation proceeds efficiently with minimal conflicts, change orders, or delays. Quality contractors bring specialized equipment like hydraulic cranes for pole erection, telescopic lifts for fixture installation at heights, and photometric testing instruments to verify illumination levels meet design specifications before final acceptance.

Testing, Commissioning, and Maintenance Planning

Proper testing and ongoing maintenance ensure your Baseball Field Lights deliver reliable performance throughout their operational lifespan. These final steps validate installation quality and establish procedures for long-term system care.

Conducting Comprehensive System Testing

Upon completion of physical installation, conduct thorough testing before accepting the Baseball Field Lights system. Verify all fixtures illuminate properly with no dead lamps, flickering, or abnormal color variations indicating driver issues or loose connections. Measure actual illumination levels using calibrated light meters at multiple field locations, comparing results against design specifications to confirm infield and outfield illuminance meets requirements with acceptable uniformity ratios. Test all control functions including manual on-off operation, dimming responses across the full range, timer programming accuracy, and emergency backup power activation if installed. Inspect all electrical connections for proper torque, secure mounting, and appropriate environmental sealing. Document any deficiencies requiring correction before final acceptance, holding contractors responsible for addressing punch list items within agreed timeframes. Professional commissioning includes photometric testing with integrating sphere equipment that precisely characterizes each fixture's lumen output, beam pattern, color temperature, and color rendering index, ensuring Baseball Field Lights meet manufacturer specifications and warranty conditions.

Establishing Preventive Maintenance Programs

Despite LED technology's reputation for minimal maintenance requirements, establishing a proactive service program maximizes Baseball Field Lights lifespan and prevents unexpected failures during critical events. Schedule annual inspections examining fixture cleanliness, mounting security, lens clarity, and housing condition. Clean lenses and reflectors as needed to maintain optimal light output, as dirt accumulation can reduce effective illumination by ten to fifteen percent over time. Inspect all electrical connections for corrosion, overheating evidence, or looseness that could lead to failures. Test ground-fault protection devices and surge suppression equipment to verify continued functionality. Monitor fixture performance over time, tracking any lamps exhibiting reduced output, color shift, or premature failure that might indicate driver problems or environmental stress. Maintain detailed service records documenting all inspections, repairs, and component replacements, providing valuable data for warranty claims and helping predict future maintenance needs. Razorlux Baseball Field Lights include comprehensive five-year warranties covering LED modules and drivers, with ten-year housing warranties, backed by responsive technical support helping resolve issues quickly and maintaining optimal field illumination.

Planning for System Upgrades and Expansion

Design your Baseball Field Lights installation with future flexibility in mind. Specify electrical infrastructure with adequate capacity for potential fixture additions or upgrades to higher-output models as technology advances. Consider installing conduit stubouts and junction boxes at strategic locations to facilitate future expansion without extensive electrical work. Document your complete system including fixture locations, aiming points, electrical circuit assignments, and control programming to simplify future modifications or troubleshooting. As LED technology continues improving with higher efficacy and enhanced features, your facility may benefit from upgrading fixtures while retaining existing poles and electrical infrastructure, providing performance improvements at a fraction of full system replacement costs. Modern Baseball Field Lights from manufacturers like Razorlux feature modular designs allowing component-level servicing, where failed drivers or LED modules can be replaced individually rather than discarding entire fixtures, reducing long-term ownership costs and environmental impact through reduced waste. Strategic planning during initial installation creates pathways for cost-effective upgrades that keep your baseball facility's lighting at the forefront of technology and performance.

Conclusion

Installing Baseball Field Lights efficiently and safely requires meticulous planning, quality equipment selection, strict safety protocols, and ongoing maintenance commitment. By following these seven comprehensive tips, you can navigate the complexities of sports lighting installation while delivering a system that enhances player performance, ensures spectator satisfaction, and provides reliable service for decades. Modern LED technology from manufacturers like Xi'an Razorlux Optoelectronic Technology Co., Ltd. offers superior illumination quality, dramatic energy savings, and minimal maintenance requirements compared to traditional lighting systems.

Ready to illuminate your baseball facility with professional-grade lighting? As a leading China Baseball Field Lights manufacturer and China Baseball Field Lights supplier, Xi'an Razorlux Optoelectronic Technology Co., Ltd. delivers comprehensive solutions backed by over two decades of expertise and two hundred-plus patents. Our China Baseball Field Lights factory produces premium fixtures meeting international standards including UL, CE, RoHS, and DLC certifications. We offer competitive Baseball Field Lights wholesale pricing with flexible customization options including OEM and ODM services tailored to your specific requirements. Explore our complete range of Baseball Field Lights for sale featuring advanced specifications, industry-leading warranties, and exceptional Baseball Field Lights price value. Our mature R&D team, GMP-certified manufacturing facility, extensive inventory, and professional sales support ensure fast delivery and responsive service. Contact our lighting specialists today at sam@razorlux.com to discuss your project requirements, request technical documentation, or obtain a detailed quotation. Bookmark this guide for future reference as you plan your baseball field lighting transformation.

References

1. Illuminating Engineering Society (IES). "Recommended Practice for Sports and Recreational Area Lighting." IES RP-6-15. New York: Illuminating Engineering Society of North America.

2. American Sports Builders Association. "Lighting Systems for Athletic Fields: Design and Installation Guidelines." ASBA Technical Manual Series. Atlanta: American Sports Builders Association.

3. National Fire Protection Association. "NFPA 70: National Electrical Code." Article 680 - Swimming Pools, Spas, Hot Tubs, and Similar Installations; Article 410 - Luminaires and Lighting Accessories. Quincy: NFPA.

4. U.S. Department of Energy. "LED Lighting for Sports and Athletic Facilities." Solid-State Lighting Program Report. Washington: Office of Energy Efficiency & Renewable Energy.

VIEW MOREcricket stadium lighting

VIEW MOREcricket stadium lighting VIEW MOREled arena flood lights

VIEW MOREled arena flood lights VIEW MOREoutdoor badminton court lighting

VIEW MOREoutdoor badminton court lighting VIEW MORE120 Volt Led Outdoor Flood Lights

VIEW MORE120 Volt Led Outdoor Flood Lights VIEW MORE1500 Watt Stadium Lights

VIEW MORE1500 Watt Stadium Lights VIEW MORERoHS High Bay Led Lighting Industry Shop 150 Watt High Luminous

VIEW MORERoHS High Bay Led Lighting Industry Shop 150 Watt High Luminous VIEW MORESports Field Led Flood Lights

VIEW MORESports Field Led Flood Lights VIEW MOREAttractive Flood Lights

VIEW MOREAttractive Flood Lights

_1750326878398.png)