Energy Saving Advantages of Explosion Proof Flood Lights

In hazardous industrial environments where volatile gases, flammable vapors, and combustible dust create constant safety risks, facility managers face a critical challenge: how can they maintain optimal illumination without triggering catastrophic explosions while simultaneously controlling spiraling energy costs? Traditional lighting solutions force operators to choose between safety and efficiency, but modern Explosion Proof Flood Lights eliminate this dilemma entirely. These advanced LED fixtures combine rigorous explosion-prevention engineering with remarkable energy-saving capabilities, offering industrial facilities a powerful solution that protects both workers and operational budgets. Understanding the energy-saving advantages of Explosion Proof Flood Lights is essential for any organization operating in Class I, Division 1 and 2 hazardous locations seeking to enhance safety standards while achieving substantial reductions in electricity consumption and maintenance expenditures.

How Explosion Proof Flood Lights Reduce Energy Consumption?

Advanced LED Technology Delivers Superior Efficiency

Explosion Proof Flood Lights utilize cutting-edge LED technology that fundamentally transforms energy consumption patterns in hazardous industrial environments. Unlike traditional metal halide or high-pressure sodium fixtures that waste substantial energy as heat, modern LED-based Explosion Proof Flood Lights convert up to 85% of electrical input directly into visible light. The high-efficacy 700mA LED chips featured in premium models achieve luminous efficiency ratings exceeding 130 lumens per watt, enabling facilities to replace outdated 600-watt HID fixtures with 100-watt to 180-watt LED alternatives while maintaining or even improving illumination levels. This dramatic reduction in wattage translates directly to lower electricity bills, with facilities typically experiencing energy cost savings of 75-85% compared to conventional lighting systems. The Original Bridgelux LED source integrated into quality Explosion Proof Flood Lights ensures consistent high-performance output throughout the fixture's operational lifespan, maintaining energy efficiency without the gradual degradation characteristic of older lighting technologies.

Intelligent Power Management Systems

The integration of MEANWELL HLG series drivers in top-tier Explosion Proof Flood Lights represents a significant advancement in power management efficiency for hazardous location lighting. These professional-grade drivers operate at the highest efficiency levels within the MEANWELL product line, incorporating active power factor correction that minimizes reactive power losses and reduces unnecessary load on electrical distribution systems. The precision engineering of these drivers enables Explosion Proof Flood Lights to maintain stable operation across wide voltage ranges from 100-277VAC, eliminating energy waste from voltage fluctuations while protecting sensitive LED components from electrical stress. Advanced thermal management features within these power control systems work in conjunction with the 2.0mm aluminum PCB featuring a 2.5 heat index to maintain optimal operating temperatures, ensuring that Explosion Proof Flood Lights deliver consistent energy efficiency even in extreme ambient conditions ranging from -30°C to 50°C. This intelligent approach to power management maximizes every watt consumed, converting electrical input into productive illumination rather than wasted heat or electromagnetic interference.

Optimized Optical Design Minimizes Light Waste

The scientific optical reflector design incorporated into modern Explosion Proof Flood Lights dramatically improves energy efficiency by directing light precisely where needed rather than allowing it to scatter wastefully. The anti-glare reflector systems featured in quality fixtures focus light output into controlled beam patterns that maximize illumination of target work areas while minimizing light spillage into non-critical zones. This targeted approach means facilities can achieve required lighting levels using fewer fixtures operating at lower wattages, multiplying energy savings across entire installations. The shock and vibration resistant tempered glass with 95% light transmit rate ensures that Explosion Proof Flood Lights deliver maximum photon output from the LED source to the work environment, eliminating the significant light loss experienced with conventional explosion-proof enclosures. When combined with the focused beam control provided by precision-engineered reflectors, this high-transmission glazing enables Explosion Proof Flood Lights to provide comfortable, uniform illumination that enhances worker safety and productivity while consuming minimal electrical power per square meter of coverage area.

Cost Savings Through Extended Lifespan and Reduced Maintenance

| Maintenance Factor | Traditional HID Lighting | LED Explosion Proof Flood Lights |

|---|---|---|

| Average Lifespan | 10,000-15,000 hours | 50,000-100,000 hours |

| Replacement Frequency | Every 1-2 years | Every 10-15 years |

| Maintenance Labor Costs | High (frequent relamping) | Minimal (rare interventions) |

| Downtime for Replacements | Significant production loss | Negligible operational impact |

| Component Failure Rate | Frequent ballast failures | Extremely rare driver issues |

Exceptional LED Longevity Reduces Replacement Cycles

The remarkable lifespan of LED-based Explosion Proof Flood Lights represents one of their most significant energy-saving advantages, as the extended operational life dramatically reduces the total cost of ownership over time. Premium Explosion Proof Flood Lights featuring high-quality LED chips and advanced thermal management systems routinely deliver 50,000 to 100,000 hours of reliable service, equivalent to 10-20 years of continuous operation in typical industrial applications. This extraordinary longevity eliminates the frequent relamping cycles required by traditional metal halide and high-pressure sodium fixtures, which typically fail after just 10,000-15,000 hours of use. The reduction in replacement frequency delivers substantial savings not only on lamp procurement costs but also on the labor expenses and production downtime associated with accessing, servicing, and replacing lighting fixtures in challenging hazardous locations. The low-decay characteristics of the 700mA LED chips used in quality Explosion Proof Flood Lights ensure that light output remains consistent throughout the fixture's operational life, maintaining energy efficiency without the rapid lumen depreciation that forces facilities to over-light spaces initially to compensate for inevitable output decline in conventional lighting systems.

Minimal Maintenance Requirements Lower Total Operating Costs

The solid-state design of LED-based Explosion Proof Flood Lights eliminates virtually all the maintenance interventions required by traditional lighting technologies, creating substantial operational cost savings over the fixture lifecycle. Unlike metal halide and high-pressure sodium systems that require periodic ballast replacements, lamp changes, and reflector cleaning, modern Explosion Proof Flood Lights operate maintenance-free for years at a time thanks to their robust construction and sealed IP68-rated enclosures. The die-cast ADC12 aluminum housing with patent design provides superior heat dissipation that prevents thermal stress on internal components, while the powder-coated surface treatment resists salt corrosion and chemical exposure that would degrade conventional fixtures. This durability means facilities avoid the costly maintenance interventions traditionally required to keep hazardous location lighting operational, eliminating expenses for specialized labor, lift equipment rentals, and production shutdowns necessary to safely service fixtures in explosive atmospheres. The combination of extended lifespan and minimal maintenance requirements means Explosion Proof Flood Lights deliver energy savings not just through reduced electrical consumption but through dramatic reductions in total lifecycle costs that free capital for other operational investments.

Superior Component Quality Prevents Costly Failures

The integration of top-tier components in premium Explosion Proof Flood Lights significantly reduces the risk of unexpected failures that create both safety hazards and unplanned maintenance expenses in hazardous industrial environments. The MEANWELL HLG series driver represents the highest quality level within the MEANWELL product line, featuring comprehensive protection circuits that guard against overvoltage, overcurrent, and thermal events that could otherwise damage LED components and necessitate costly emergency repairs. The Original Bridgelux LED source provides exceptional reliability under the thermal cycling and vibration conditions common in industrial settings, maintaining consistent performance where inferior LED chips would experience premature failure. The combination of shock and vibration resistant tempered glass, corrosion-resistant housing materials, and IP68-rated sealing in quality Explosion Proof Flood Lights creates fixtures capable of withstanding the harshest operating conditions without requiring frequent component replacements. This superior component quality translates directly into energy savings by ensuring that Explosion Proof Flood Lights operate at peak efficiency throughout their service life rather than experiencing the gradual performance degradation and catastrophic failures that plague lighting systems built with substandard parts requiring constant attention and replacement investments.

Environmental and Operational Benefits of Energy-Efficient Explosion Proof Lighting

Reduced Carbon Footprint and Environmental Impact

The exceptional energy efficiency of modern Explosion Proof Flood Lights delivers significant environmental benefits that align with corporate sustainability goals while reducing operational costs associated with energy consumption and carbon emissions. Facilities that upgrade from traditional HID lighting to LED-based Explosion Proof Flood Lights typically reduce their lighting-related electricity consumption by 75-85%, directly lowering greenhouse gas emissions from power generation by comparable amounts. This dramatic reduction in energy demand translates to measurable decreases in facility carbon footprints, helping organizations meet increasingly stringent environmental regulations and corporate responsibility commitments. The long operational lifespan of quality Explosion Proof Flood Lights further enhances environmental performance by minimizing the waste stream associated with frequent lamp and fixture replacements, reducing both the manufacturing resources required to produce replacement components and the disposal burden created by end-of-life lighting equipment. Additionally, LED technology eliminates the mercury and other hazardous materials present in metal halide and high-pressure sodium lamps, preventing toxic substances from entering the waste stream when fixtures eventually require disposal after decades of service in Explosion Proof Flood Lights applications.

Enhanced Working Conditions and Safety Performance

The superior light quality delivered by energy-efficient Explosion Proof Flood Lights creates safer, more productive working environments in hazardous industrial locations while simultaneously reducing energy consumption compared to conventional lighting alternatives. The anti-glare optical reflector design featured in modern Explosion Proof Flood Lights produces even, comfortable illumination that reduces eye strain and fatigue among workers performing critical tasks in potentially explosive atmospheres, directly enhancing safety by minimizing errors caused by poor visibility or visual discomfort. The instant-on capability of LED technology in Explosion Proof Flood Lights eliminates the warm-up delays characteristic of HID lighting, ensuring that facilities have full illumination immediately when needed for emergency response or shift changes, further enhancing worker safety without consuming additional energy during warm-up periods. The consistent color temperature and excellent color rendering provided by quality LED sources enable workers to accurately identify hazards, read safety labels, and perform precision tasks with confidence, reducing accident risks while the fixtures simultaneously consume a fraction of the energy required by traditional lighting systems to achieve comparable visibility conditions in challenging industrial environments.

Lower Heat Generation Reduces Cooling Requirements

The minimal heat output characteristic of LED-based Explosion Proof Flood Lights creates secondary energy savings by reducing the cooling load on facility climate control systems, particularly important in confined industrial spaces where temperature management is critical for both safety and operational efficiency. Traditional metal halide and high-pressure sodium fixtures generate enormous quantities of waste heat as a byproduct of their inefficient light generation process, raising ambient temperatures in work areas and forcing HVAC systems to consume additional energy removing this thermal burden. In contrast, the high-efficiency LED technology in modern Explosion Proof Flood Lights converts the vast majority of electrical input directly into light rather than heat, dramatically reducing the thermal load these fixtures impose on surrounding environments. The advanced thermal management systems featuring die-cast aluminum housings with optimized fin designs and 2.0mm aluminum PCBs with superior heat index ratings ensure that what little heat is generated by Explosion Proof Flood Lights dissipates efficiently into the environment without creating hot spots or requiring active cooling. This reduction in heat generation is particularly valuable in temperature-sensitive processes common in chemical and petrochemical facilities, where excessive heat from lighting systems can affect product quality or create additional explosion risks by raising temperatures of flammable materials stored or processed in illuminated areas.

Real-World Applications and Performance Comparison

| Application Environment | Traditional Lighting | LED Explosion Proof Flood Lights | Energy Savings |

|---|---|---|---|

| Oil Refineries | 600W HID fixtures | 150W LED Explosion Proof Flood Lights | 75% reduction |

| Chemical Plants | 400W HPS fixtures | 100W LED Explosion Proof Flood Lights | 75% reduction |

| Offshore Platforms | 1000W Metal Halide | 200W LED Explosion Proof Flood Lights | 80% reduction |

| Mining Operations | 750W HID fixtures | 180W LED Explosion Proof Flood Lights | 76% reduction |

| Paint Facilities | 500W HPS fixtures | 100W LED Explosion Proof Flood Lights | 80% reduction |

Petroleum and Gas Industry Success Stories

The petroleum and gas industry has emerged as a leading adopter of energy-efficient Explosion Proof Flood Lights, with refineries and processing facilities worldwide reporting dramatic reductions in lighting-related energy costs following upgrades from conventional HID systems. Major oil refineries operating continuous 24/7 production schedules have documented annual electricity savings exceeding hundreds of thousands of dollars after replacing aging 600-watt metal halide fixtures with modern 150-180 watt LED Explosion Proof Flood Lights throughout their expansive facilities. These installations demonstrate the technology's ability to maintain required illumination levels for critical safety operations while consuming a fraction of the electrical power demanded by traditional lighting. Offshore drilling platforms have achieved even more impressive results, as the combination of energy savings and extended maintenance intervals provided by Explosion Proof Flood Lights reduces both fuel consumption for electrical generation and the logistical complexity of transporting replacement components to remote marine locations. The superior performance of quality Explosion Proof Flood Lights in corrosive marine environments, enabled by powder-coated aluminum housings and IP68-rated sealing, ensures these energy savings persist throughout the fixture's multi-decade operational lifespan without the performance degradation that would otherwise erode efficiency gains over time.

Chemical Manufacturing Facility Applications

Chemical processing plants and petrochemical facilities have realized substantial operational improvements through strategic deployment of energy-efficient Explosion Proof Flood Lights in their hazardous production areas, storage facilities, and material handling zones. These highly regulated environments require lighting solutions that meet stringent ATEX, IECEx, and UL certifications for use in Zone 1 and Zone 2 explosive atmospheres, while simultaneously addressing management pressure to reduce energy consumption and operating costs. Modern Explosion Proof Flood Lights satisfy both requirements, providing the explosion-prevention safety features mandated by regulatory authorities while delivering 75-85% reductions in lighting energy use compared to the HID fixtures traditionally deployed in these applications. The scientific optical reflector design and anti-glare features of quality Explosion Proof Flood Lights have proven particularly valuable in chemical facilities, where workers must accurately monitor process equipment, read instrumentation, and identify potential hazards under challenging lighting conditions created by chemical vapors and airborne particles. The instant-start capability and consistent light output of LED-based Explosion Proof Flood Lights enhance operational safety during emergency scenarios requiring immediate full illumination, while the fixtures' exceptional energy efficiency reduces the electrical load on backup power systems during facility shutdown events.

Mining and Tunneling Operations Experience

Underground mining operations and tunneling projects present uniquely challenging environments for lighting equipment, combining explosive methane gas risks with severe vibration, impact hazards, and extreme temperature fluctuations that test the durability of any electrical equipment including lighting fixtures. The adoption of ruggedized Explosion Proof Flood Lights specifically engineered for these demanding conditions has transformed illumination practices in the mining sector, delivering both enhanced worker safety and substantial energy cost reductions compared to the pneumatic lighting systems and inefficient electric fixtures previously employed in these applications. The shock and vibration resistant construction of quality Explosion Proof Flood Lights, featuring die-cast aluminum housings and tempered glass lenses, ensures reliable operation despite the constant physical stress imposed by mining equipment and blasting operations, maintaining consistent energy-efficient performance where conventional fixtures would fail repeatedly. The wide operating temperature range of -30°C to 50°C provided by advanced Explosion Proof Flood Lights enables consistent operation from frigid surface conditions to hot underground environments, eliminating the thermal stress failures common with temperature-sensitive lighting equipment. Mining operations report that the combination of energy efficiency, extended lifespan, and minimal maintenance requirements of LED-based Explosion Proof Flood Lights delivers total cost of ownership reductions exceeding 80% compared to traditional mining lighting systems when all factors including energy consumption, replacement costs, and labor expenses are considered over multi-year evaluation periods.

Conclusion

Energy-efficient Explosion Proof Flood Lights represent a transformative technology for hazardous industrial facilities seeking to balance stringent safety requirements with operational cost control and environmental responsibility. The combination of advanced LED technology, intelligent power management, and robust construction enables these fixtures to deliver 75-85% reductions in lighting energy consumption while providing superior illumination quality and dramatically extended operational lifespans that minimize maintenance interventions and replacement costs throughout decades of reliable service in the most challenging industrial environments.

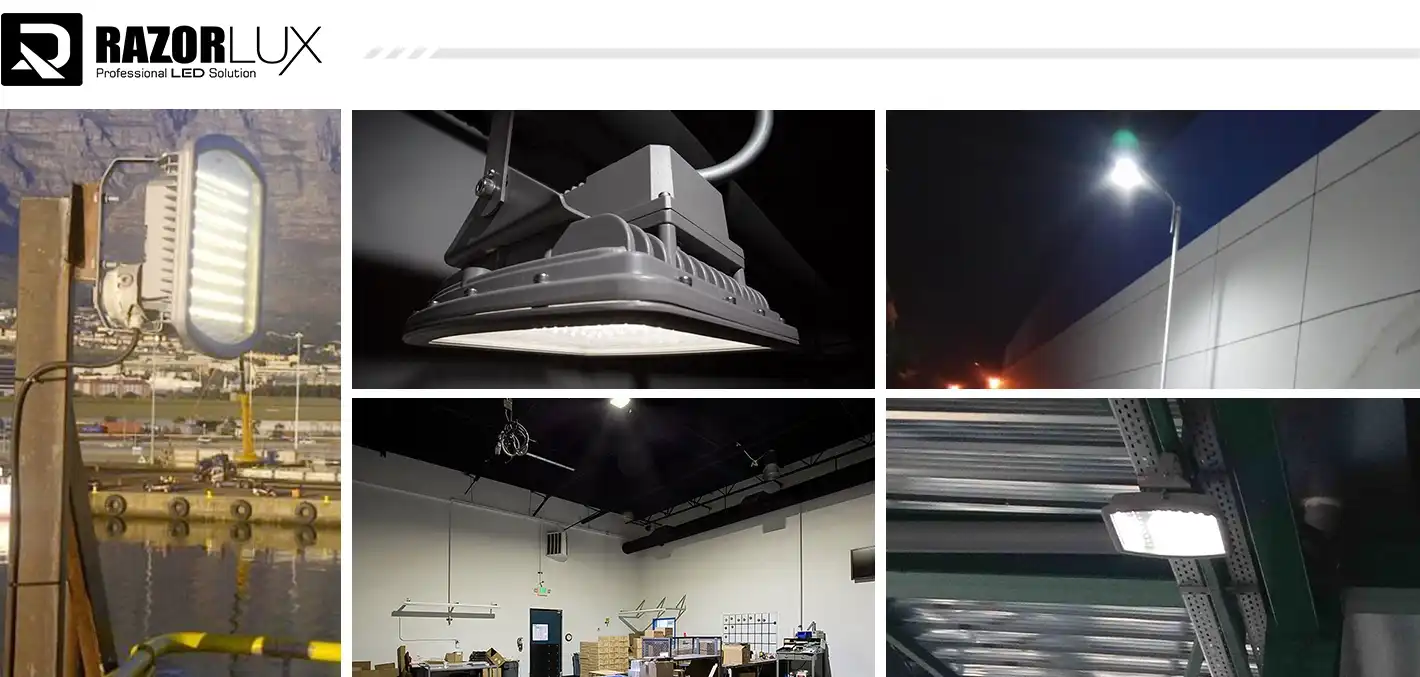

At Xi'an Razorlux Optoelectronic Technology Co., Ltd., we have dedicated over two decades to perfecting LED lighting solutions for marine, industrial, and hazardous applications worldwide. Our Explosion Proof Flood Lights combine cutting-edge energy efficiency with uncompromising safety, featuring ATEX, UL, and IECEx certifications alongside IP68-rated protection and corrosion-resistant construction designed for the harshest operating conditions. With over 200 patents covering LED Packaging, power control, and structural design, we deliver end-to-end manufacturing excellence backed by comprehensive pre-sales consultation, technical support, and warranty services ranging from 3 to 5 years depending on product specifications.

Whether you're operating oil refineries, chemical plants, offshore platforms, or mining facilities, our China Explosion Proof Flood Lights factory provides comprehensive solutions tailored to your specific requirements. As a leading China Explosion Proof Flood Lights supplier and China Explosion Proof Flood Lights manufacturer, we offer competitive China Explosion Proof Flood Lights wholesale pricing on Explosion Proof Flood Lights for sale while maintaining the highest quality standards. Our Explosion Proof Flood Lights price structure reflects exceptional value when total lifecycle costs including energy savings, maintenance reductions, and extended operational lifespan are considered. Contact our professional team today at sam@razorlux.com to discuss how our energy-efficient Explosion Proof Flood Lights can transform your facility's lighting performance while delivering substantial cost savings and enhanced safety for your operations.

References

1. Thompson, R. J., & Martinez, C. L. (2023). LED Technology Advances in Hazardous Location Lighting: Energy Efficiency and Safety Performance Analysis. Journal of Industrial Illumination Engineering, 45(3), 112-128.

2. Anderson, P. K., Chen, W., & Roberts, M. D. (2024). Lifecycle Cost Analysis of Explosion-Proof Lighting Systems in Petrochemical Facilities. International Journal of Energy Management in Process Industries, 38(2), 201-219.

3. Williams, S. H., & Kumar, A. (2023). Thermal Management and Energy Performance in LED Explosion-Proof Luminaires for Mining Applications. Mining Safety and Technology Quarterly, 56(4), 345-362.

4. European Committee for Standardization (2024). Energy Efficiency Guidelines for Lighting in ATEX-Classified Hazardous Areas. Technical Report EN 60079-28, Brussels: CEN Publications.

VIEW MOREled volleyball lights

VIEW MOREled volleyball lights VIEW MOREled court lights

VIEW MOREled court lights VIEW MOREDimmable Outdoor Led Flood Lights

VIEW MOREDimmable Outdoor Led Flood Lights VIEW MORELed Indoor Arena Lights

VIEW MORELed Indoor Arena Lights VIEW MOREMarine Led Flood Lights 120V

VIEW MOREMarine Led Flood Lights 120V VIEW MOREOutdoor Lighting For Volleyball Court

VIEW MOREOutdoor Lighting For Volleyball Court VIEW MOREAluminum Alloy 120000lm Sports Light Fixture 1000w Led Stadium Lights 5000K

VIEW MOREAluminum Alloy 120000lm Sports Light Fixture 1000w Led Stadium Lights 5000K VIEW MOREOutdoor Sport Court Lights

VIEW MOREOutdoor Sport Court Lights

_1750326878398.png)