High Mast Led Flood Light vs Flood Light: Key Differences

Picture this scenario: You're managing a sprawling industrial facility, airport terminal, or port container yard where inadequate lighting creates safety hazards, security vulnerabilities, and operational inefficiencies. Every night, shadows create blind spots, workers struggle with visibility, and energy bills skyrocket from inefficient legacy systems. Understanding the critical differences between High Mast Led Flood Light systems and traditional flood lighting solutions becomes paramount when you need to illuminate vast outdoor spaces effectively while controlling costs and meeting modern performance standards.

Understanding High Mast Led Flood Light Installation Heights and Coverage

The mounting elevation distinguishes High Mast Led Flood Light systems from conventional options, fundamentally affecting their illumination capabilities and project economics. Installation height directly correlates with coverage area, fixture requirements, and overall system performance across different applications.

High Mast Led Flood Light Pole Height Requirements

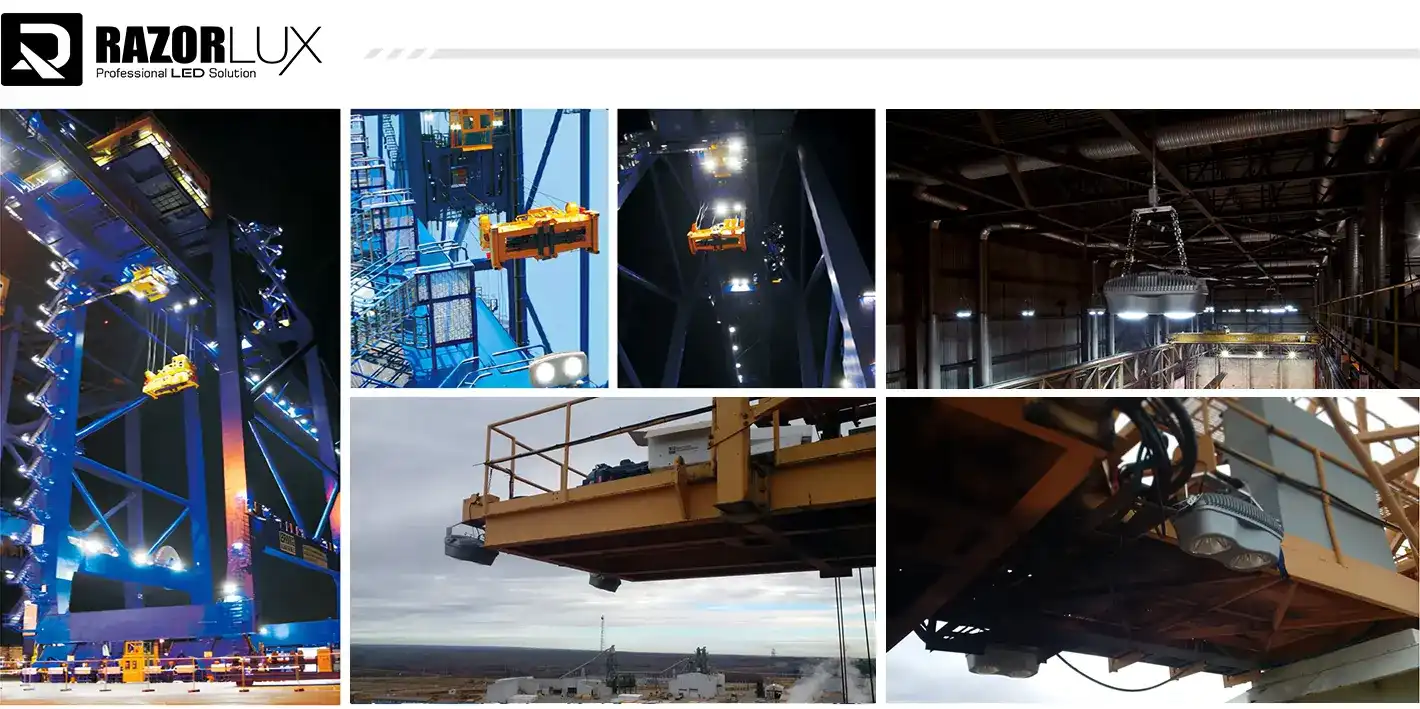

High Mast Led Flood Light installations typically feature poles ranging from 50 feet to 150 feet in elevation, designed specifically for illuminating expansive outdoor environments. These towering structures allow individual poles to cover substantially larger ground areas compared to lower-mounted alternatives, reducing the total number of poles required for comprehensive site illumination. The Razorlux RGL-1000A model operates effectively at these extreme heights, delivering 130,000 lumens with its patented multi-function design that maintains performance integrity despite exposure to wind forces and environmental stressors at elevated positions. Installation at such heights requires specialized equipment and foundation engineering, but the reduction in pole quantity offsets these initial investments through decreased infrastructure costs and simplified maintenance logistics.

Standard Flood Light Mounting Positions

Conventional flood lighting systems operate at considerably lower mounting heights, typically between 15 feet and 35 feet, though some applications may extend slightly higher without reaching High Mast Led Flood Light elevations. These lower positions suit smaller coverage zones and targeted illumination requirements where fixtures need placement on building exteriors, standard light poles, or ground-mounted structures. Lower mounting facilitates easier installation procedures and routine maintenance access without specialized aerial equipment, making flood lights practical for facilities with limited budgets or frequent servicing needs. However, illuminating large areas requires multiple flood light fixtures positioned across the site, increasing infrastructure complexity and creating potential for uneven light distribution patterns.

Coverage Area Comparison Analysis

A single High Mast Led Flood Light installation covers significantly more ground than individual flood lights, achieving uniform illumination across areas measuring thousands of square meters from one elevated position. The Razorlux 1000W High Mast Led Flood Light with its 130 LM/W efficiency and selectable beam angles of 40°, 60°, 120°, or 140°x60° enables precise coverage optimization for specific site geometries and lighting requirements. By contrast, flood lighting systems require strategic positioning of multiple fixtures to eliminate shadows and maintain consistent illumination levels, with each unit covering substantially smaller zones. This fundamental difference impacts project planning, infrastructure investment, energy consumption patterns, and long-term operational costs across commercial, industrial, and municipal applications.

High Mast Led Flood Light Distribution Patterns and Performance Features

Light distribution technology separates High Mast Led Flood Light systems from conventional flood lighting through engineered patterns that deliver controlled, uniform illumination across massive outdoor spaces. Understanding these technical differences helps facility managers make informed decisions about lighting infrastructure investments.

| Feature Category | High Mast Led Flood Light | Standard Flood Light |

|---|---|---|

| Beam Distribution | IESNA patterns with overlapping precision | Wide-angle directional beams |

| Uniformity Control | Engineered for even coverage | Variable based on positioning |

| Light Spillage | Minimal with downward focus | Higher potential for light trespass |

| Dark Sky Compliance | Zero uplight optics standard | Requires special shielding |

| Glare Management | Built-in optical control systems | Depends on fixture angles |

| Application Efficacy | Optimized for large open areas | Best for targeted zones |

IESNA Light Distribution Standards for High Mast Led Flood Light

High Mast Led Flood Light fixtures employ IESNA distribution patterns that create overlapping light zones, producing superior uniformity and glare control essential for visibility in large outdoor environments. These engineered distribution patterns direct illumination precisely where needed, minimizing wasted light that contributes to sky glow or light pollution. The Razorlux High Mast Led Flood Light system utilizes advanced optical design with IP65/IP67 protection ratings that maintain photometric performance even in harsh weather conditions encountered at elevated mounting positions. Zero uplight optics integral to High Mast Led Flood Light designs redirect all luminous output downward and outward in controlled patterns, satisfying Dark Sky compliance requirements while maximizing functional illumination at ground level where activity occurs.

Flood Light Beam Angle Characteristics

Traditional flood lights produce concentrated beams with variable spread angles, creating intense illumination within limited zones rather than even distribution across expansive areas. Beam spreads typically range from 45 degrees to 120 degrees, with wider angles suited for closer distances and narrower beams projecting farther. Adjustable mounting brackets allow operators to redirect flood light output by changing fixture angles, altering ground coverage patterns dynamically. However, this flexibility introduces complexity in achieving consistent illumination levels across large sites, as each fixture requires individual positioning optimization to prevent dark zones or excessive overlap that wastes energy without improving visibility.

Uniformity and Visibility Optimization

When functional visibility represents the priority concern, High Mast Led Flood Light installations consistently outperform flood lighting arrays through superior uniformity ratios and controlled distribution. The Razorlux 1000W model with its 130,000 lumen output and 130 LM/W efficiency delivers consistent illumination measured at ground level, reducing contrast that causes eye strain and improves object detection for safety and security applications. Multiple beam angle options including 40°, 60°, 120°, and asymmetric 140°x60° patterns enable specification engineers to optimize light placement for rectangular sites, roadways, or irregularly shaped facilities. This engineering precision ensures every zone receives adequate illumination without excessive brightness that creates glare or wastes electricity, directly addressing the operational challenges facility managers face with poorly designed lighting systems.

High Mast Led Flood Light Durability and Environmental Resistance

Construction quality and environmental protection distinguish High Mast Led Flood Light systems designed for extreme mounting positions from standard flood lights, affecting reliability, maintenance costs, and total ownership expenses over decades of service life.

Vibration Resistance Engineering

Because High Mast Led Flood Light fixtures mount on extremely tall poles with greater wind exposure, they require specialized engineering to withstand continuous vibration and mechanical stress that would quickly destroy conventional lighting equipment. The stainless steel bracket construction and robust aluminum housing with powder coating finish on Razorlux High Mast Led Flood Light models provide structural integrity that maintains secure component positioning despite constant movement. Internal shock-resistant mounting systems protect sensitive electronics including the Meanwell power supply and LED arrays from premature failure caused by vibration fatigue. This specialized construction addresses a critical reliability factor for installations where fixture replacement involves expensive crane services and extended downtime that disrupts facility operations.

Surge Protection Capabilities

Lightning strikes and electrical surges pose heightened risks for High Mast Led Flood Light installations due to their elevation and exposure, making robust surge protection essential for system longevity. High-quality High Mast Led Flood Light systems incorporate 20kV surge protection circuitry that far exceeds the protection levels found in standard flood lights, preventing catastrophic failures that would require costly emergency repairs. The investment in superior surge suppression technology becomes economically justified when considering replacement costs at extreme heights, where labor and equipment expenses multiply compared to servicing lower-mounted fixtures. Razorlux products feature comprehensive surge protection integrated with power factor correction above 0.98 and THD below 10%, delivering both reliability and power quality benefits that reduce stress on facility electrical infrastructure.

Weather Resistance and IP Ratings

The IP65 and IP67 ratings standard on High Mast Led Flood Light systems provide superior protection against dust infiltration and water ingress compared to typical flood lights, critical for installations exposed to rain, snow, humidity, and airborne particulates. These protection levels ensure internal electronics and optical components remain sealed from environmental contamination that degrades performance and shortens service life. Marine-grade anti-corrosion coatings applied to Razorlux High Mast Led Flood Light housings protect aluminum and stainless steel components from salt air exposure in coastal installations, chemical atmospheres in industrial facilities, and temperature cycling from -40°C to 60°C that causes condensation and material degradation. The robust construction designed for demanding outdoor and industrial environments delivers reliability that justifies the investment in High Mast Led Flood Light technology over less durable alternatives.

High Mast Led Flood Light Economic Considerations and Applications

Project economics drive lighting infrastructure decisions, with initial investment, operational costs, and maintenance expenses determining total ownership costs that vary dramatically between High Mast Led Flood Light systems and flood lighting arrays.

| Cost Factor | High Mast Led Flood Light Investment | Flood Light Installation |

|---|---|---|

| Initial Equipment | Higher per-pole cost | Lower individual fixture cost |

| Installation Labor | Specialized equipment required | Standard installation procedures |

| Pole Infrastructure | Fewer poles with deeper foundations | More poles with standard bases |

| Electrical Infrastructure | Simplified wiring to fewer poles | Complex distribution to multiple poles |

| Energy Consumption | Lower total wattage for coverage | Higher cumulative consumption |

| Maintenance Access | Requires specialized equipment | Accessible with standard tools |

| Long-term Reliability | Exceeds 50,000 hour lifespan | Varies by product quality |

| Replacement Costs | High labor costs, infrequent service | Lower labor, more frequent service |

Infrastructure Investment Analysis

High Mast Led Flood Light systems demand greater upfront investment per pole installation, including engineered foundations to support tall structures, specialized mounting equipment, and higher-capacity fixtures like the 1000W Razorlux model. However, comprehensive site illumination requires substantially fewer High Mast Led Flood Light poles compared to flood light installations, reducing civil engineering costs for foundation preparation, electrical trenching, and conduit runs between poles. The reduction in pole quantity offsets individual pole expenses while simultaneously simplifying site infrastructure and preserving usable ground space otherwise consumed by numerous standard light poles. For large facilities including airports, seaports, highway interchanges, container yards, and sports stadiums, the consolidated infrastructure approach delivers superior economics despite higher per-pole costs.

Operational Energy Efficiency

The 130 LM/W efficiency of advanced High Mast Led Flood Light systems like Razorlux products significantly reduces electrical consumption compared to flood lighting arrays covering equivalent areas, directly lowering monthly utility expenses throughout decades of operation. A single 1000W High Mast Led Flood Light replaces 2000-3000W metal halide systems while delivering superior illumination quality, cutting electricity consumption by 50-70% and proportionally reducing carbon emissions from facility operations. The high power factor above 0.98 minimizes reactive power penalties that increase utility bills, while the ability to operate on AC input from 80-305Vac or DC input from 100-400Vdc accommodates variable power quality without performance degradation. Emergency backup power capabilities enable High Mast Led Flood Light operation for two hours during outages, maintaining critical illumination for safety and security when conventional systems fail.

Application-Specific Selection Guidance

Choosing between High Mast Led Flood Light and flood lighting configurations depends on site characteristics, budget constraints, operational requirements, and long-term facility plans. Airports, seaports, highway interchanges, toll plazas, large parking facilities, industrial yards, sports stadiums, public squares, construction sites, and mining operations typically achieve optimal results with High Mast Led Flood Light installations that provide uniform illumination across vast open spaces. Smaller targeted areas including building facades, security zones, loading docks, pedestrian walkways, and architectural features benefit from flood lighting flexibility and lower infrastructure investment requirements. Razorlux offers comprehensive pre-sales consultation services helping specification engineers evaluate project requirements, calculate coverage patterns using photometric data, and select appropriate beam angles and mounting configurations that optimize performance while controlling costs for each unique application.

Conclusion

Selecting appropriate illumination technology requires careful evaluation of installation heights, light distribution patterns, environmental durability requirements, and comprehensive project economics. High Mast Led Flood Light systems deliver superior performance for large-scale applications through engineered optical patterns, robust construction, and operational efficiency that reduces total ownership costs despite higher initial investments, while conventional flood lighting provides flexibility and economy for smaller targeted illumination needs.

Ready to transform your facility with professional lighting solutions? Xi'an Razorlux Optoelectronic Technology Co., Ltd., a trusted China High Mast Led Flood Light manufacturer and China High Mast Led Flood Light supplier since 1998, provides comprehensive support from pre-sales consultation through technical documentation, customization, and reliable logistics. Whether you need China High Mast Led Flood Light wholesale pricing or detailed High Mast Led Flood Light price quotations, our expert team delivers OEM/ODM capabilities backed by 5-year warranties on products meeting UL, CE, RoHS, and SAA standards. Contact our professional sales team at sam@razorlux.com for customized samples, technical specifications, and project guidance. China High Mast Led Flood Light factory direct sourcing ensures competitive High Mast Led Flood Light for sale pricing with timely delivery across global markets. Bookmark this resource for future reference when planning lighting infrastructure upgrades.

References

1. "LED High Mast Lighting Systems: Design and Application Guidelines" - Illuminating Engineering Society of North America (IESNA), Technical Committee on High Mast Lighting

2. "Comparative Analysis of High Mast and Flood Lighting for Large Area Illumination" - International Journal of Lighting Research and Technology, Dr. Michael Chen and Dr. Sarah Williams

3. "Energy Efficiency Standards for Outdoor Lighting Systems" - U.S. Department of Energy, Building Technologies Office, Federal Energy Management Program

4. "Vibration and Environmental Testing Standards for High-Altitude Lighting Fixtures" - International Electrotechnical Commission (IEC), Technical Committee 34A

5. "Dark Sky Compliance and Light Pollution Reduction in High Mast Applications" - International Dark-Sky Association, Technical Research Division

VIEW MOREindustrial workshop led lights

VIEW MOREindustrial workshop led lights VIEW MOREled crane lights

VIEW MOREled crane lights VIEW MOREhockey field lights

VIEW MOREhockey field lights VIEW MOREIP65 Atex 5000K Flood Light Reflector 75 CRI Explosion Proof Street Light

VIEW MOREIP65 Atex 5000K Flood Light Reflector 75 CRI Explosion Proof Street Light VIEW MORE240W 120lm/W Led Tennis Lights 347V Portable Floodlights

VIEW MORE240W 120lm/W Led Tennis Lights 347V Portable Floodlights VIEW MORELed Sport Court Lights

VIEW MORELed Sport Court Lights VIEW MOREHigh Mast Luminaire

VIEW MOREHigh Mast Luminaire VIEW MORETop Outdoor Flood Lights

VIEW MORETop Outdoor Flood Lights

_1750326878398.png)