Top-Rated High Mast Led Flood Light Brands for Industrial Sites

Industrial facilities face a critical challenge that directly impacts productivity, safety, and operational costs: inadequate lighting in expansive outdoor areas. When your warehouse yard remains dimly lit after sunset, when equipment operators struggle to identify hazards at rail terminals, or when security risks escalate due to shadowy corners in container ports, the consequences extend far beyond inconvenience. Choosing the right High Mast Led Flood Light solution becomes essential for maintaining 24/7 operations while managing energy expenditure effectively. This comprehensive guide reveals top-rated brands and critical selection criteria that industrial decision-makers need to illuminate large-scale facilities with confidence, ensuring worker safety, operational efficiency, and long-term cost savings through proven lighting technology.

Understanding High Mast Led Flood Light Technology for Industrial Applications

Industrial lighting has undergone a revolutionary transformation with LED technology replacing traditional metal halide and high-pressure sodium systems. High Mast Led Flood Light installations now dominate ports, mining sites, airport tarmacs, and manufacturing complexes where lighting poles reach heights between 80 to 150 feet. These advanced systems deliver superior illumination while consuming substantially less energy than conventional alternatives. Modern High Mast Led Flood Light fixtures incorporate sophisticated thermal management systems, precision optics for targeted light distribution, and robust construction engineered specifically for harsh industrial environments where temperature extremes, vibration, moisture, and corrosive atmospheres pose constant challenges to equipment longevity.

Essential Technical Specifications for Industrial High Mast Lighting

When evaluating High Mast Led Flood Light options for industrial sites, understanding technical specifications becomes paramount to making informed decisions. Lumen output represents the total quantity of visible light emitted, with industrial applications typically requiring between 50,000 to 130,000 lumens per fixture depending on mounting height and coverage area requirements. Color temperature, measured in Kelvin, affects visibility and worker alertness, with most industrial facilities preferring 5000K to 6500K for crisp, daylight-quality illumination that enhances safety and productivity. Power consumption ratings between 500W to 1000W deliver optimal efficiency ratios, with modern High Mast Led Flood Light systems achieving 130 lumens per watt or higher through advanced LED chip technology and driver electronics that maximize energy conversion while minimizing heat generation and electrical waste.

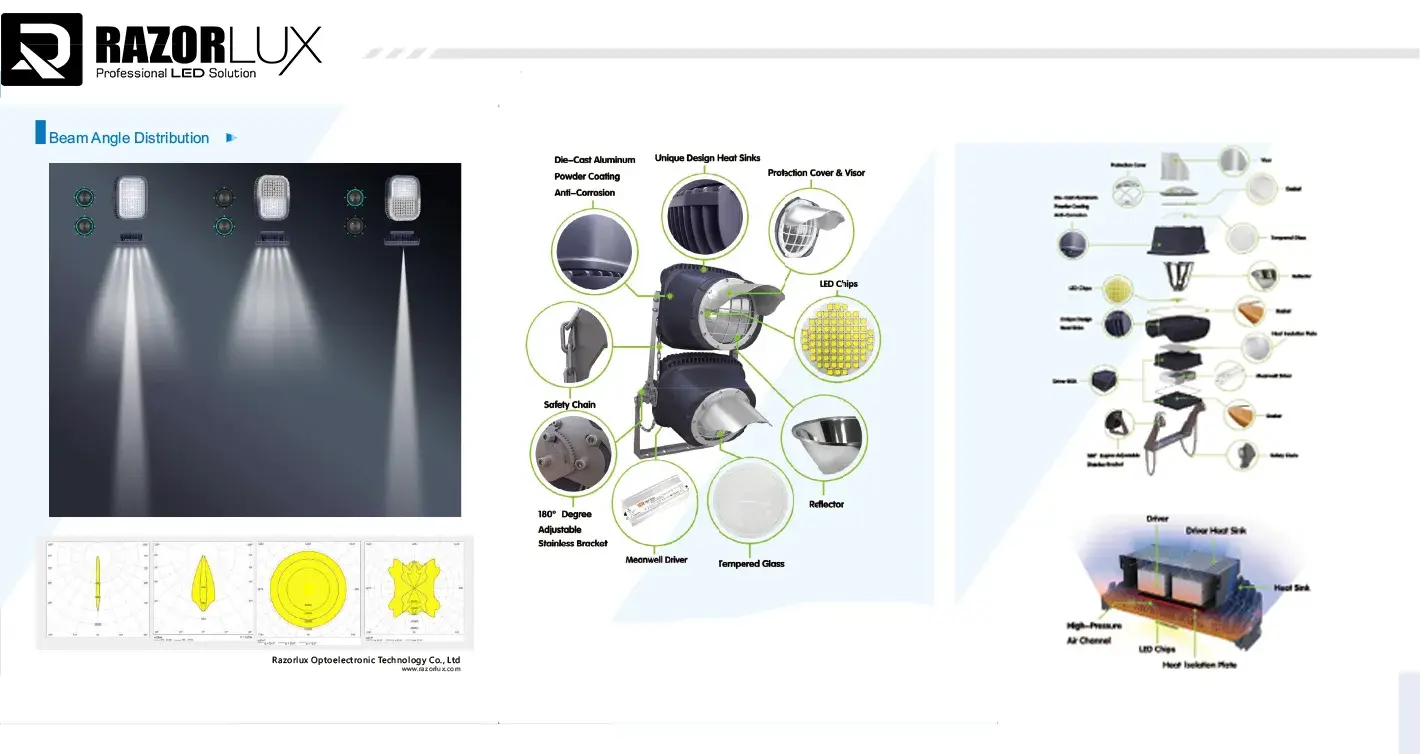

Beam Angle Selection and Light Distribution Patterns

Proper beam angle selection directly impacts the effectiveness of High Mast Led Flood Light installations at industrial sites where specific coverage patterns determine both illumination quality and fixture quantity required. Narrow beam angles ranging from 40° to 60° concentrate light over longer distances, making them ideal for targeting specific work zones or creating perimeter security lighting in applications where focused intensity matters more than widespread coverage. Medium beam angles between 60° to 90° provide balanced distribution suitable for general area lighting across parking lots, loading docks, and equipment storage yards where moderate spread and adequate intensity must coexist. Wide beam angles from 120° to 140° deliver extensive coverage for high-mounted fixtures illuminating vast open spaces such as container terminals and aircraft aprons, though installations may require asymmetric beam distributions like 140°x60° to optimize ground coverage while minimizing wasted light directed skyward or toward adjacent properties.

Durability Standards and Environmental Protection Requirements

Industrial High Mast Led Flood Light fixtures must withstand environmental conditions far exceeding typical commercial lighting challenges, making durability specifications critical selection criteria. IP67 ingress protection rating ensures complete protection against dust infiltration and temporary water immersion, essential for coastal facilities, mining operations, and locations experiencing heavy precipitation or equipment wash-down procedures. Corrosion resistance through marine-grade coatings, stainless steel brackets, and specialized surface treatments protects investments in facilities near saltwater, chemical processing areas, or regions with harsh atmospheric conditions. Impact resistance rated at IK10 provides confidence that High Mast Led Flood Light housings withstand severe mechanical impacts from flying debris, equipment collisions, or vandalism attempts, while thermal management systems incorporating aluminum heat sinks and advanced cooling architectures enable continuous operation across temperature ranges from -40°C to +60°C without performance degradation or premature failure.

Comparing Leading High Mast Led Flood Light Manufacturers

The global marketplace offers numerous High Mast Led Flood Light manufacturers, each presenting unique value propositions regarding technology, reliability, and total cost of ownership. Industry-leading brands have established reputations through decades of innovation, extensive product testing, international certifications, and proven performance across thousands of installations worldwide. Understanding manufacturer strengths, specializations, and market positioning helps industrial buyers match specific facility requirements with appropriate supplier capabilities. The following comparison examines key players who consistently deliver high-performance lighting solutions engineered specifically for demanding industrial environments where failure carries significant operational and safety consequences.

| Manufacturer | Core Strengths | Typical Lumen Range | Warranty Period | Primary Applications |

|---|---|---|---|---|

| Xi'an Razorlux | 200+ patents, marine-grade construction, customizable power options | 50,000-130,000 lumens | 5 years comprehensive | Ports, industrial yards, offshore platforms |

| Dialight | 10-year warranty, modular design, surge protection | 30,000-65,000 lumens | 10 years | Airports, container yards, rail facilities |

| Phoenix Lighting | Heritage since 1950s, repairability focus, constant vibration resistance | 40,000-100,000 lumens | 5-7 years | Mining sites, shipyards, marine environments |

| HPWINNER | IoT integration, customizable solutions, low maintenance | 50,000-120,000 lumens | 3-5 years | Highways, sports complexes, parking facilities |

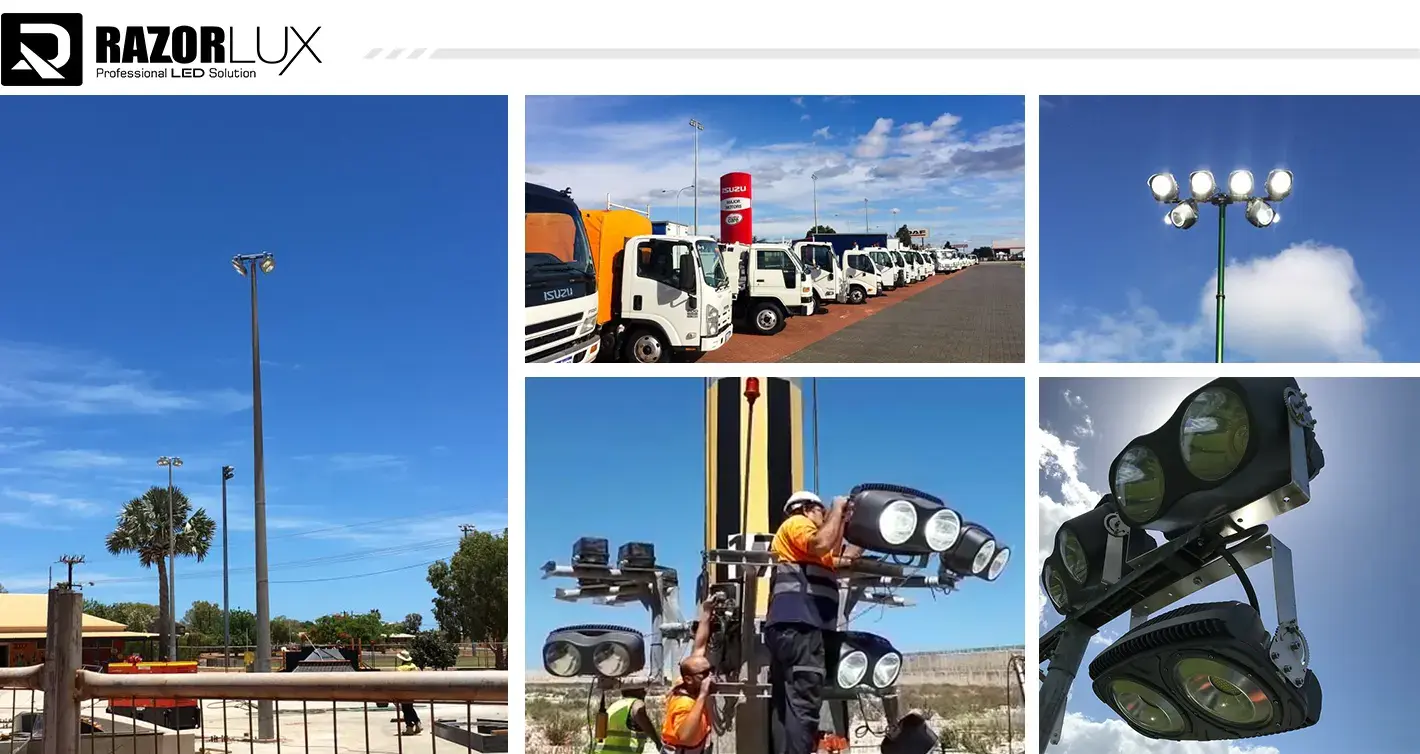

Xi'an Razorlux: Innovation and Versatility for Demanding Environments

Xi'an Razorlux Optoelectronic Technology Co., Ltd. has established itself as a formidable High Mast Led Flood Light manufacturer since its founding in 1998, accumulating over 200 patents covering LED Packaging, power control systems, and structural design innovations that address specific industrial lighting challenges. The company's flagship RGL-1000A model exemplifies their engineering philosophy, delivering 130,000 lumens through a 1000W power consumption configuration that replaces 2000-3000W metal halide systems with dramatic energy savings and maintenance reduction. Razorlux High Mast Led Flood Light fixtures feature patented multi-function designs accommodating extraordinary voltage flexibility from AC 80-305V to DC 100-400V and extended DC ranges up to 800V, enabling deployment across diverse power infrastructure scenarios including renewable energy installations, industrial microgrids, and locations with unstable electrical supplies where conventional lighting systems would fail or require expensive power conditioning equipment.

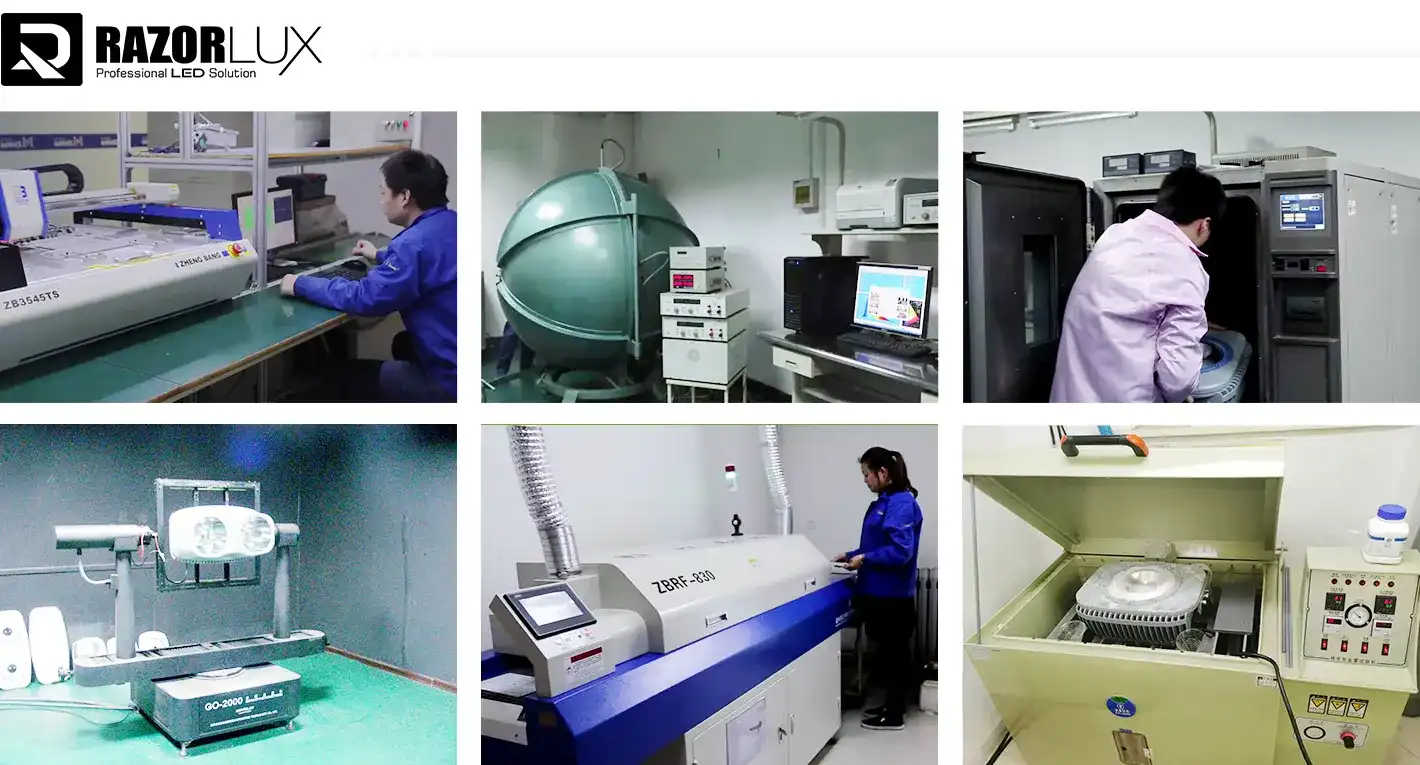

Technical Excellence and Certification Standards

The Razorlux approach to High Mast Led Flood Light manufacturing emphasizes comprehensive testing protocols and international certification compliance that validates performance claims through independent third-party verification. Their products maintain UL, CE, RoHS, SAA, C-Tick, DLC, CB certifications alongside ISO 9001:2015 quality management system certification, demonstrating commitment to manufacturing excellence and regulatory compliance across global markets. Marine-grade anti-corrosion coatings applied to aluminum housings and stainless steel mounting brackets ensure longevity in the harshest coastal and industrial environments where salt spray, chemical exposure, and atmospheric pollutants accelerate equipment degradation. Advanced thermal management through precision-engineered aluminum heat sinks maintains LED junction temperatures within optimal operating ranges, preserving the stated 50,000+ hour operational lifespan while sustaining rated lumen output throughout the fixture's service life, a critical consideration for High Mast Led Flood Light installations where replacement requires expensive crane operations and production disruptions.

Customization Capabilities and Global Service Network

Industrial facilities often require High Mast Led Flood Light solutions tailored to unique operational requirements, electrical infrastructure constraints, or specific photometric performance objectives that standard catalog products cannot adequately address. Razorlux maintains flexible manufacturing capabilities enabling customization across multiple parameters including wattage configurations from 500W to 1500W, color temperature selections from warm 2700K to cool 6500K, housing material variations, mounting hardware adaptations, and intelligent control system integration supporting 0-10V dimming, DALI protocols, and emergency backup power functions that maintain illumination for two hours during utility failures. Their comprehensive service framework encompasses pre-sales technical consultation assisting specification development, custom sampling and prototyping for performance validation before bulk ordering, detailed technical documentation supporting engineering and installation planning, OEM/ODM partnership programs for branded lighting solutions, and responsive after-sales support backed by strategically positioned subsidiaries in the USA and Hong Kong that facilitate rapid response to customer needs across major global markets.

Evaluating Cost-Effectiveness and Return on Investment

High Mast Led Flood Light procurement decisions must extend beyond initial purchase price to encompass total cost of ownership calculations factoring energy consumption, maintenance requirements, expected lifespan, and operational disruption costs associated with fixture replacement or repair activities. Comprehensive financial analysis reveals that premium High Mast Led Flood Light systems with higher upfront investment frequently deliver superior long-term value through reduced energy bills, extended replacement intervals, and minimized maintenance labor costs that collectively offset initial price premiums within relatively short payback periods. Industrial facilities operating continuous lighting schedules experience the most dramatic savings, with typical installations achieving return on investment within two to four years while simultaneously improving illumination quality, workplace safety, and environmental sustainability metrics that increasingly influence corporate reporting requirements and stakeholder expectations in modern industrial operations.

| Cost Factor | Traditional Metal Halide | Standard LED | Premium High Mast Led Flood Light |

|---|---|---|---|

| Initial fixture cost | $800-1,200 | $1,500-2,000 | $2,500-3,500 |

| Annual energy cost (per fixture) | $1,400-1,800 | $600-800 | $400-550 |

| Expected lifespan | 10,000-15,000 hours | 30,000-40,000 hours | 50,000-70,000 hours |

| Maintenance frequency | Every 2 years | Every 4-5 years | Every 7-10 years |

| 10-year total cost | $16,000-20,000 | $9,000-11,000 | $7,500-9,000 |

Energy Savings and Environmental Impact Reduction

Modern High Mast Led Flood Light technology delivers remarkable energy efficiency improvements compared to legacy lighting systems, with leading products achieving luminous efficacy ratings of 130 lumens per watt or higher through optimized LED chip selection, advanced driver electronics, and precision optical systems that direct maximum light toward target surfaces rather than wasting output through atmospheric dispersion or poor beam control. Industrial facilities replacing 2000W metal halide systems with equivalent 1000W High Mast Led Flood Light fixtures immediately reduce electrical consumption by 50% while maintaining or improving illumination levels, translating to substantial utility cost reductions that compound over years of continuous operation. Beyond direct financial benefits, reduced energy consumption decreases carbon emissions, supports corporate sustainability initiatives, and may qualify facilities for utility rebate programs, green building certifications, or preferential financing terms increasingly available for energy-efficient infrastructure investments that align with governmental climate action objectives and societal expectations regarding responsible industrial operations.

Maintenance Cost Reduction and Operational Continuity

The extended operational lifespan of premium High Mast Led Flood Light systems dramatically reduces maintenance activities, associated labor costs, and production disruptions inherent in industrial lighting replacement operations. Traditional metal halide fixtures requiring replacement every 10,000-15,000 hours necessitate crane rentals, specialized technicians, and carefully coordinated production schedule adjustments that collectively impose substantial indirect costs beyond the fixture purchase price itself. High Mast Led Flood Light products rated for 50,000+ hours of operation extend replacement intervals by 3-5 times, reducing maintenance frequency from every 2 years to every 7-10 years in facilities operating lighting systems approximately 12 hours daily. This maintenance reduction eliminates multiple crane mobilizations, minimizes disruption to critical operations, and reallocates maintenance resources to other facility needs while simultaneously reducing inventory carrying costs for replacement fixtures and spare parts that must be maintained for rapid response to unexpected failures.

Warranty Coverage and Long-Term Investment Protection

Comprehensive warranty programs distinguish premium High Mast Led Flood Light manufacturers from budget alternatives, providing financial protection against premature failures while demonstrating manufacturer confidence in product quality and durability. Industry-leading warranties covering 5 to 10 years typically include LED modules, driver electronics, and housing components, ensuring that investment protection extends across all critical system elements rather than limiting coverage to specific components while excluding others prone to failure. Extended warranty periods particularly benefit high-mounting applications where replacement requires expensive equipment mobilization and operational disruption, as comprehensive coverage eliminates unexpected costs during the warranty period while providing leverage for negotiating favorable manufacturer support if issues emerge. When evaluating High Mast Led Flood Light options, warranty terms deserve careful consideration alongside technical specifications and purchase price, as generous coverage reflects manufacturer quality commitment while providing tangible financial value that reduces total cost of ownership and improves project return on investment calculations that justify capital expenditure approvals.

Conclusion

Selecting appropriate High Mast Led Flood Light solutions for industrial sites requires comprehensive evaluation of technical specifications, manufacturer capabilities, total cost of ownership factors, and long-term performance reliability that collectively determine project success. Premium manufacturers like Xi'an Razorlux deliver proven technology combining superior illumination, exceptional durability, remarkable energy efficiency, and comprehensive support services that address the unique challenges facing modern industrial facilities. Investment in quality High Mast Led Flood Light systems pays dividends through reduced energy consumption, minimized maintenance requirements, enhanced workplace safety, and improved operational efficiency that justifies initial expenditure through measurable long-term returns.

As a leading China High Mast Led Flood Light factory, China High Mast Led Flood Light supplier, and trusted China High Mast Led Flood Light manufacturer offering competitive High Mast Led Flood Light wholesale pricing, Xi'an Razorlux provides exceptional High Mast Led Flood Light for sale at transparent High Mast Led Flood Light price points backed by comprehensive warranties and responsive technical support. Contact our experienced team at sam@razorlux.com to discuss your specific lighting requirements, request customized specifications, or schedule facility assessments that identify optimal solutions for your industrial site. Bookmark this resource for future reference whenever lighting decisions arise—your pathway to superior industrial illumination begins with informed brand selection and expert partnership.

References

1. Illuminating Engineering Society. "Recommended Practice for High Mast Lighting." IES RP-8, Committee on Roadway Lighting.

2. Department of Energy, Office of Energy Efficiency and Renewable Energy. "LED Lighting for Industrial Applications: Performance and Economic Analysis." Federal Energy Management Program.

3. International Association of Lighting Designers. "Best Practices for Large-Area Industrial Lighting Design." IALD Technical Publication Series.

4. American National Standards Institute. "Performance Standards for LED Floodlighting Systems in Industrial Environments." ANSI C82.77-2016.

5. International Electrotechnical Commission. "Photometric and Colorimetric Properties of LED Luminaires for General Lighting." IEC 62722 Standard Series.

_1750326878398.png)